An Intuitive Evaluation Method of Fatigue Life of Materials After Laser Shot Peening Treatment

A technology of laser peening and fatigue life, which is applied in the mechanical field to achieve the effect of improving evaluation efficiency, intuitive scheme, and easy judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

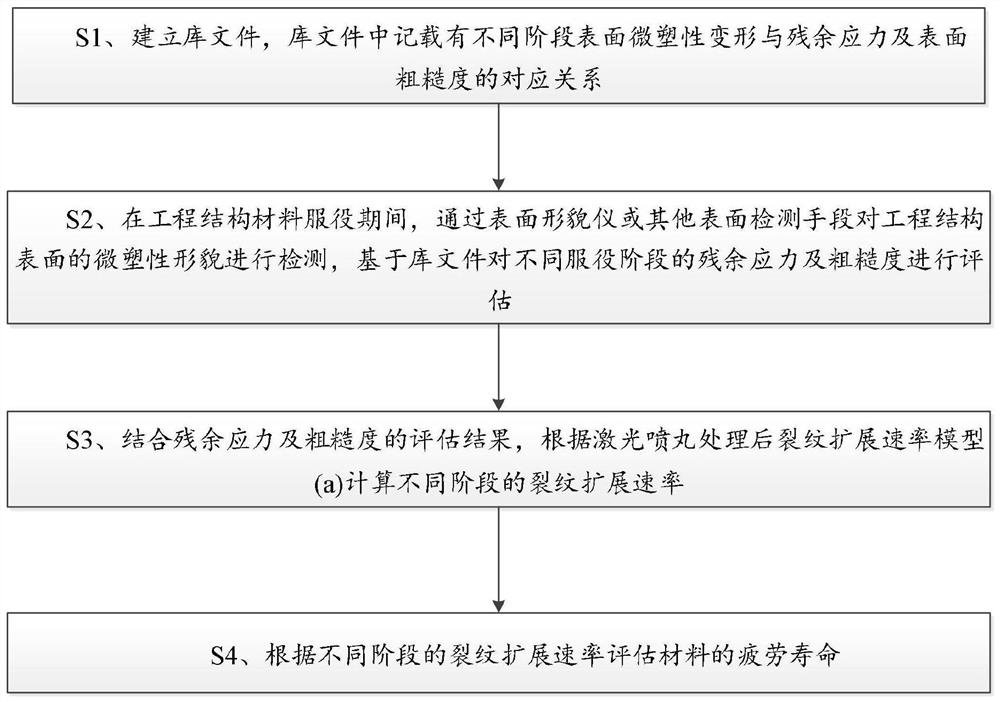

[0024] In this embodiment, an intuitive evaluation method for fatigue life of engineering materials during service based on laser peening surface microplastic deformation mainly includes the following steps, such as figure 1 Shown:

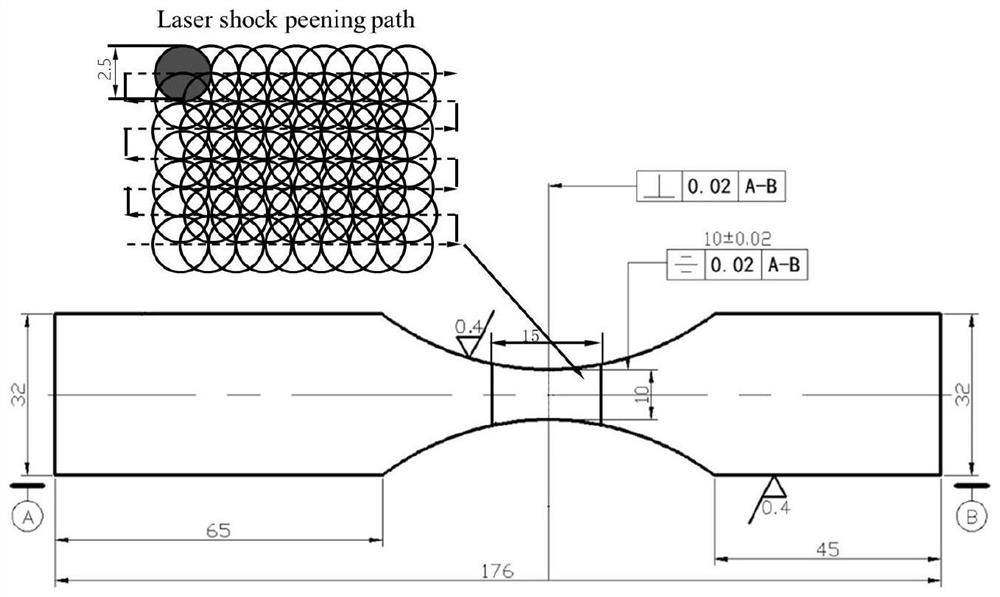

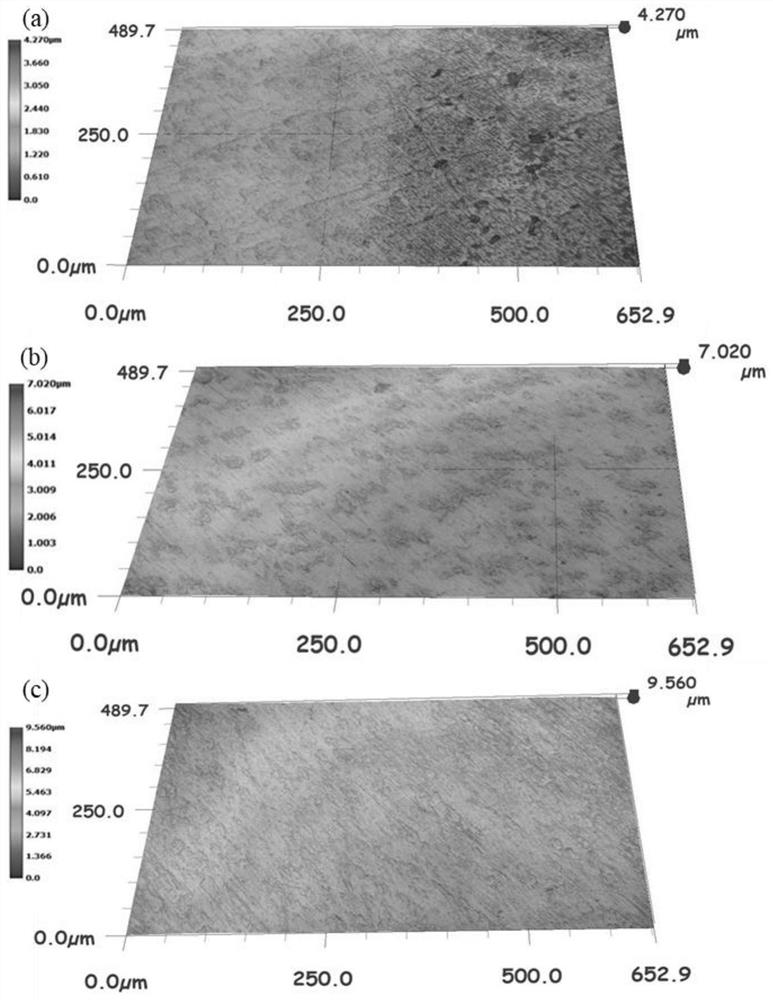

[0025] 1. Establish a library file. The target material used in this embodiment is TC4 titanium alloy, and the sample is processed. The specific size of the sample is as follows: figure 2 As shown, its basic parameters: elastic modulus E=112.5GPa, elastic wave velocity c0=5.09km / s, TC4 titanium alloy density ρ0=4.5×10 3 kg / m 3 , the dynamic yield strength σ of the alloy material Y =1.34GPa, laser shot peening is performed on the sample after processing, and the laser power density used is 3.02GW / cm 2 , the pulse width i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com