Temperature drift trimming circuit for second-order curvature compensation reference source

A technology of trimming circuit and curvature compensation, applied in the field of compensation circuit, can solve the problems of high cost and difficult temperature drift adjustment, and achieve the effect of simplifying the trimming method, avoiding application limitations, and reducing the difficulty of layout design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

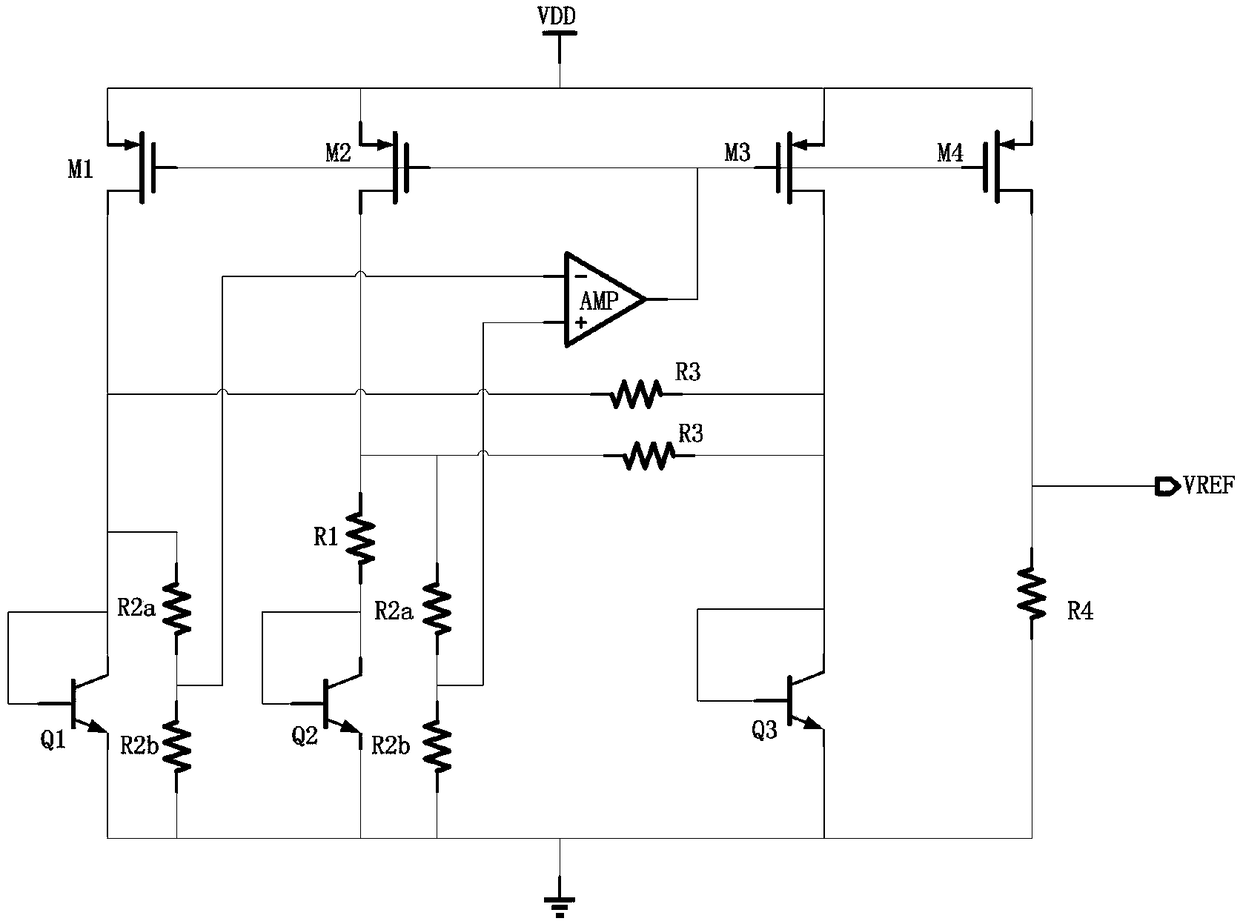

[0025] The structure of the existing second-order curvature compensation reference source is as follows: figure 1 As shown, it includes four PMOS transistors M1, M2, M3 and M4, three transistors Q1, Q2 and Q3, a resistor R1, two resistors R2a, two resistors R2b, two resistors R3 and an amplifier AMP.

[0026] Specifically, the gates of the four PMOS transistors are interconnected, and the sources are all connected to the power supply VDD. The collector of the transistor Q1 is connected to the drain of the PMOS transistor M1, the collector of the transistor Q2 is connected to the drain of the PMOS transistor M2, and the collector of the transistor Q3 is connected to the drain of the PMOS transistor M3; the three transistors Q1, Q2 The collectors of Q3 and Q3 are connected to their own bases; the emitters of the three transistors Q1, Q2 and Q3 are all grounded. One pair of resistors R2a and R2b are connected in series to the collector and emitter of the transistor Q1, respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com