Staple gun

A nail gun and nail needle technology, applied in the field of nail guns, can solve problems such as failure to fire successfully, excessive elastic force, failure to complete the work purpose, etc., and achieve the effect of avoiding the situation of stuck nails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples only illustrate possible embodiments of the present invention, which are not intended to limit the protection scope of the present invention, and are stated in advance.

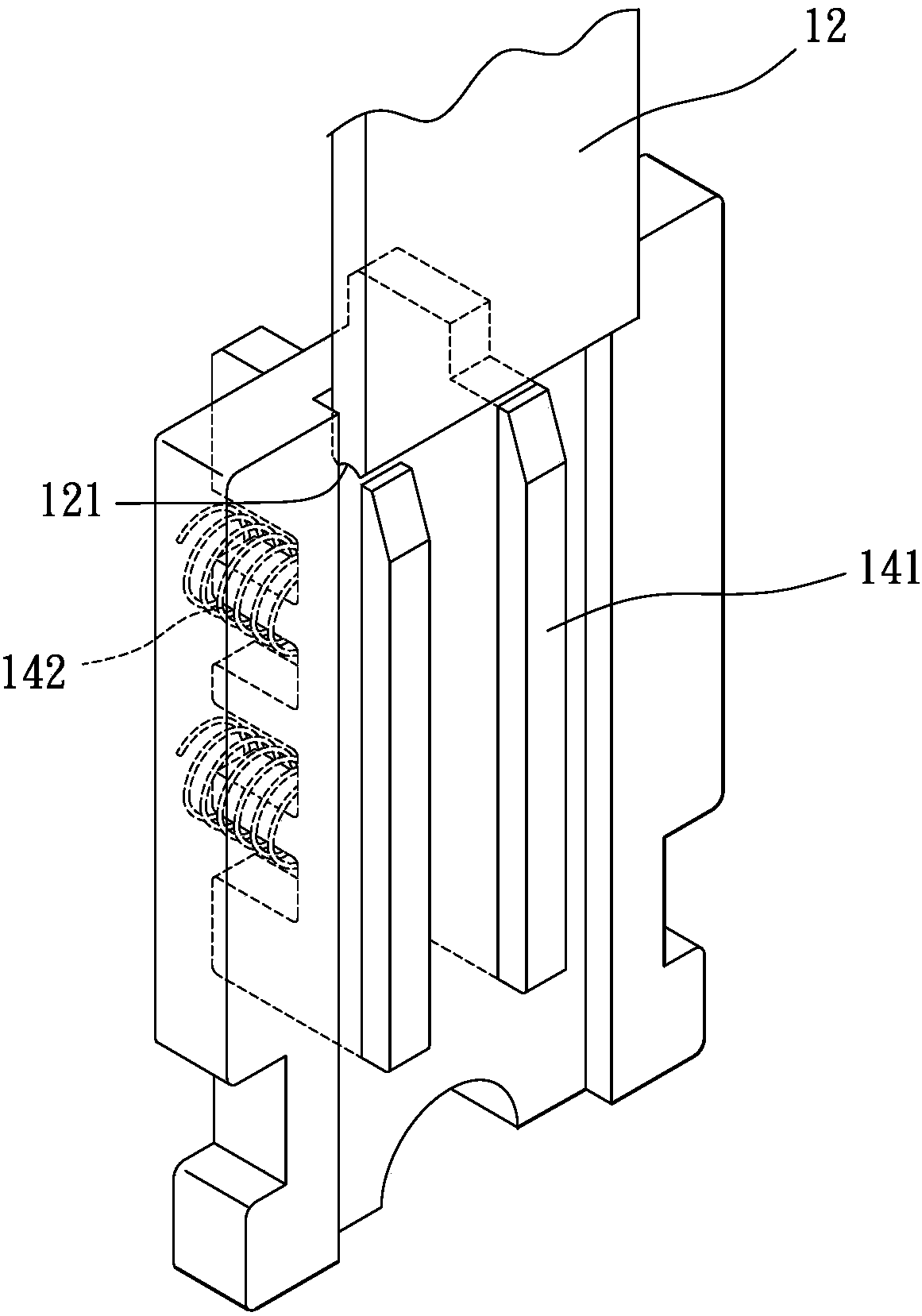

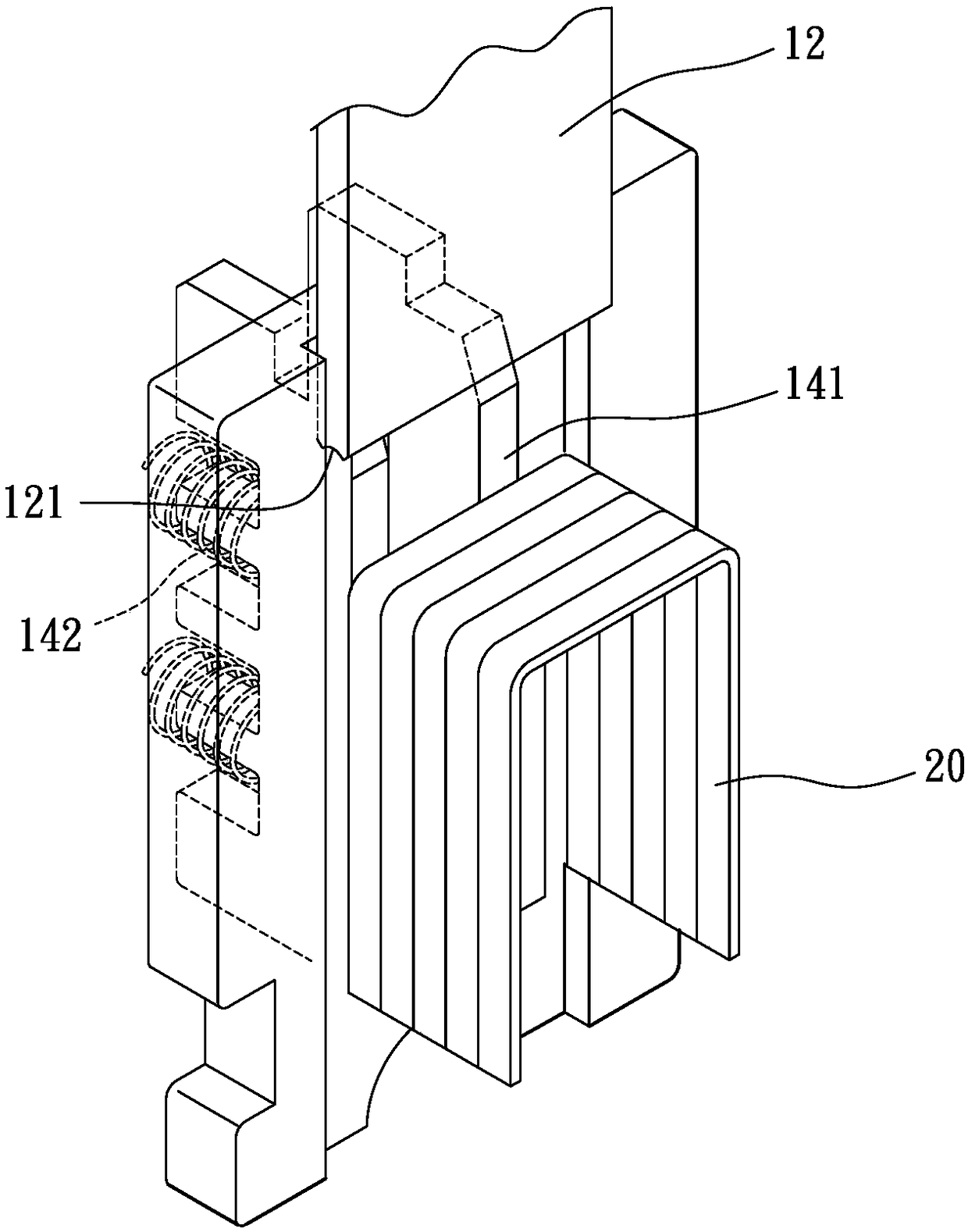

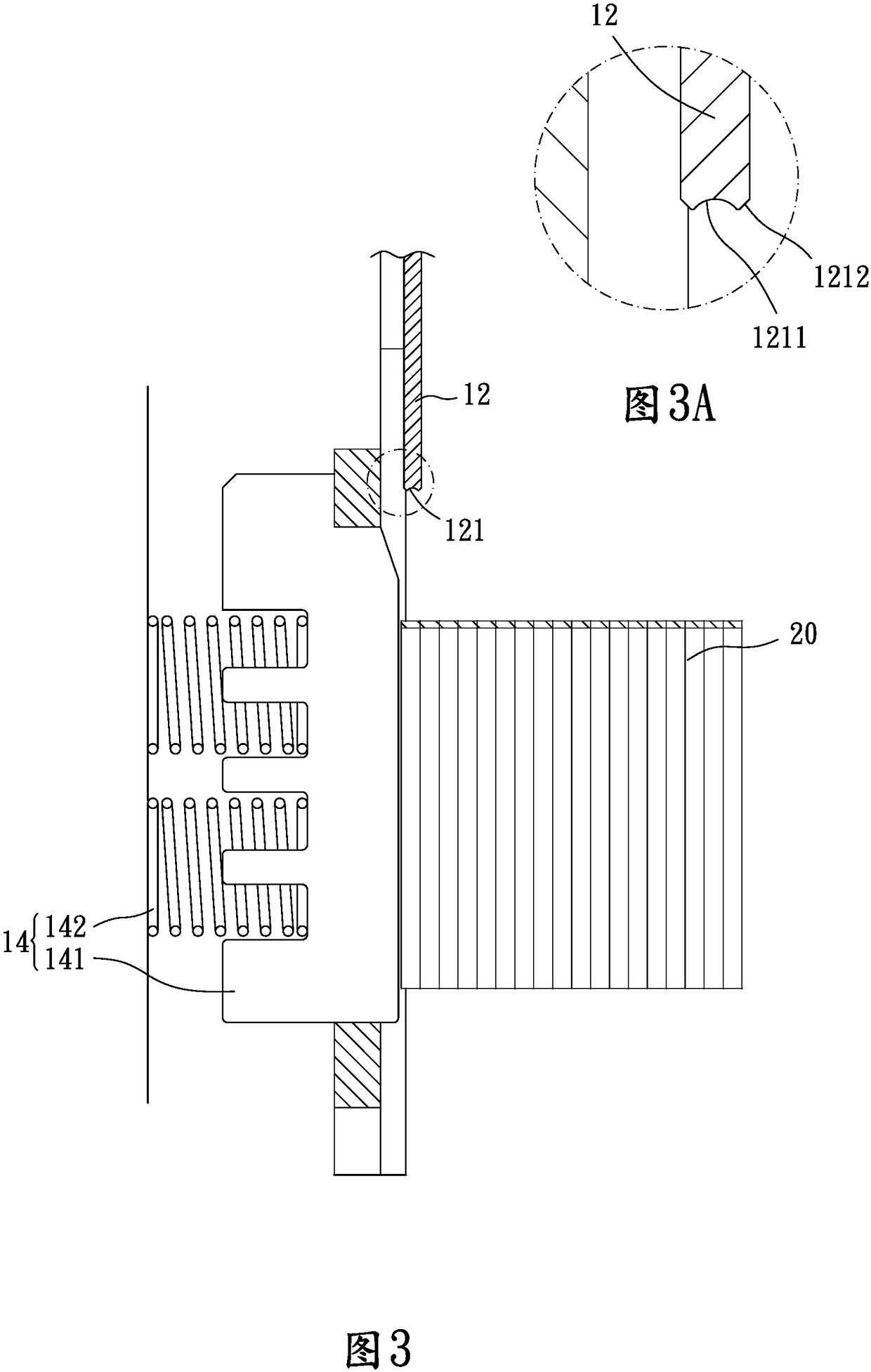

[0030] Please refer to Figure 1 to Figure 5 , The present invention provides a nail gun, comprising a body 10, a nail magazine 11, a striking plate 12, 12a, 12b and a driving part.

[0031] The main body 10 encloses an accommodating space and has an opening below its front end. The accommodating space communicates with the opening. The line connecting the front end and the rear end of the main body 10 defines a length direction; The needle 20 is accommodated; the striker 12, 12a, 12b is arranged on the front end of the body 10 and can slide vertically above the opening; the driving part is arranged on the body 10 and connected with the striker 12, 12a, 12b to drive the striker 12 , 12a, 12b move down to fire the nail needle 20. In this embodiment, the driving part includes a pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap