Etching method of indium tin oxide thin film of capacitive touch panel and its gap part

A technology of touch panel and indium tin oxide, which is applied in the direction of circuits, electrical components, electrical digital data processing, etc., can solve the problems of poor product display effect and low production efficiency, achieve uniform display effect, increase production efficiency, and reduce laser The effect of etching lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

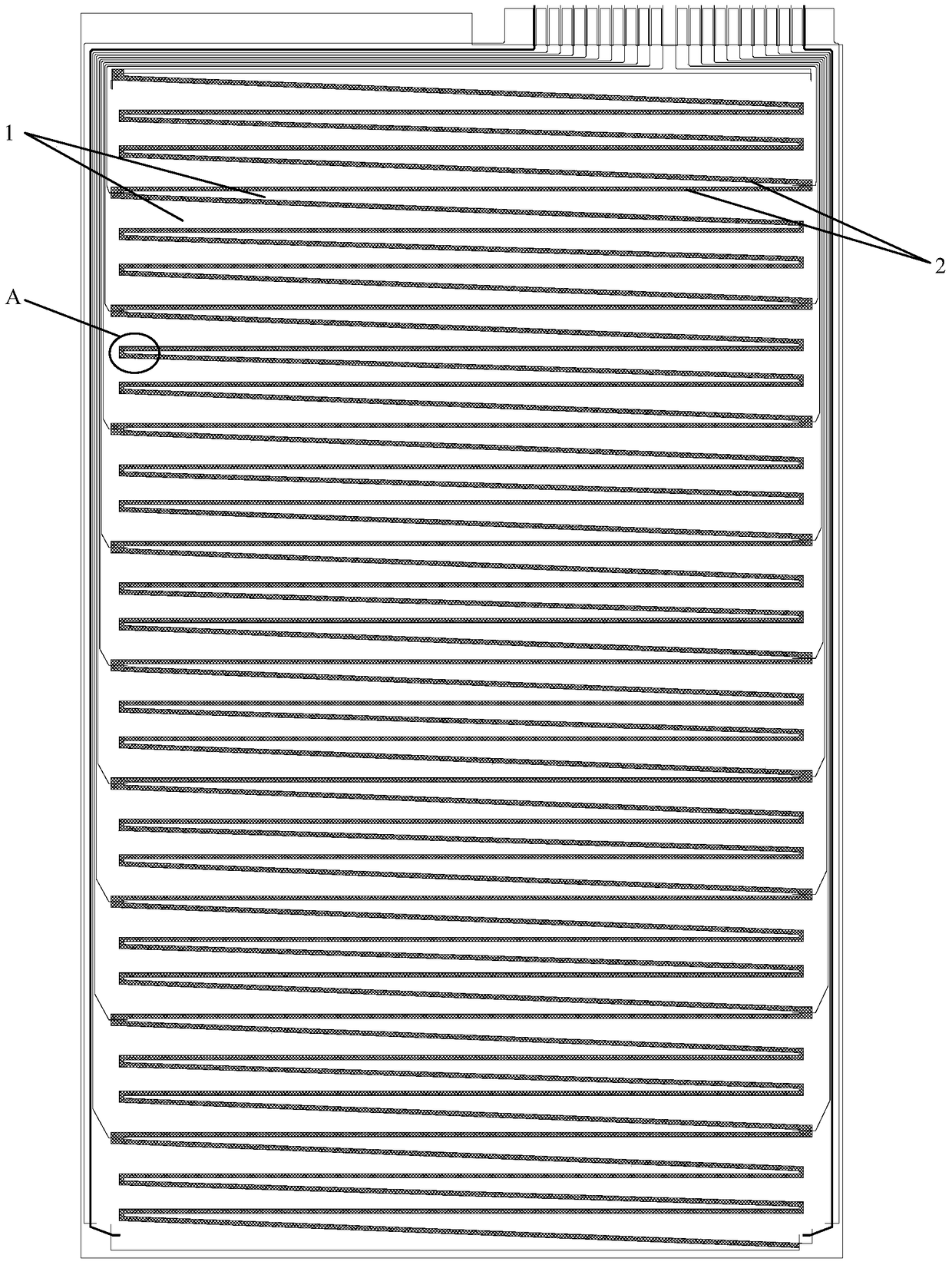

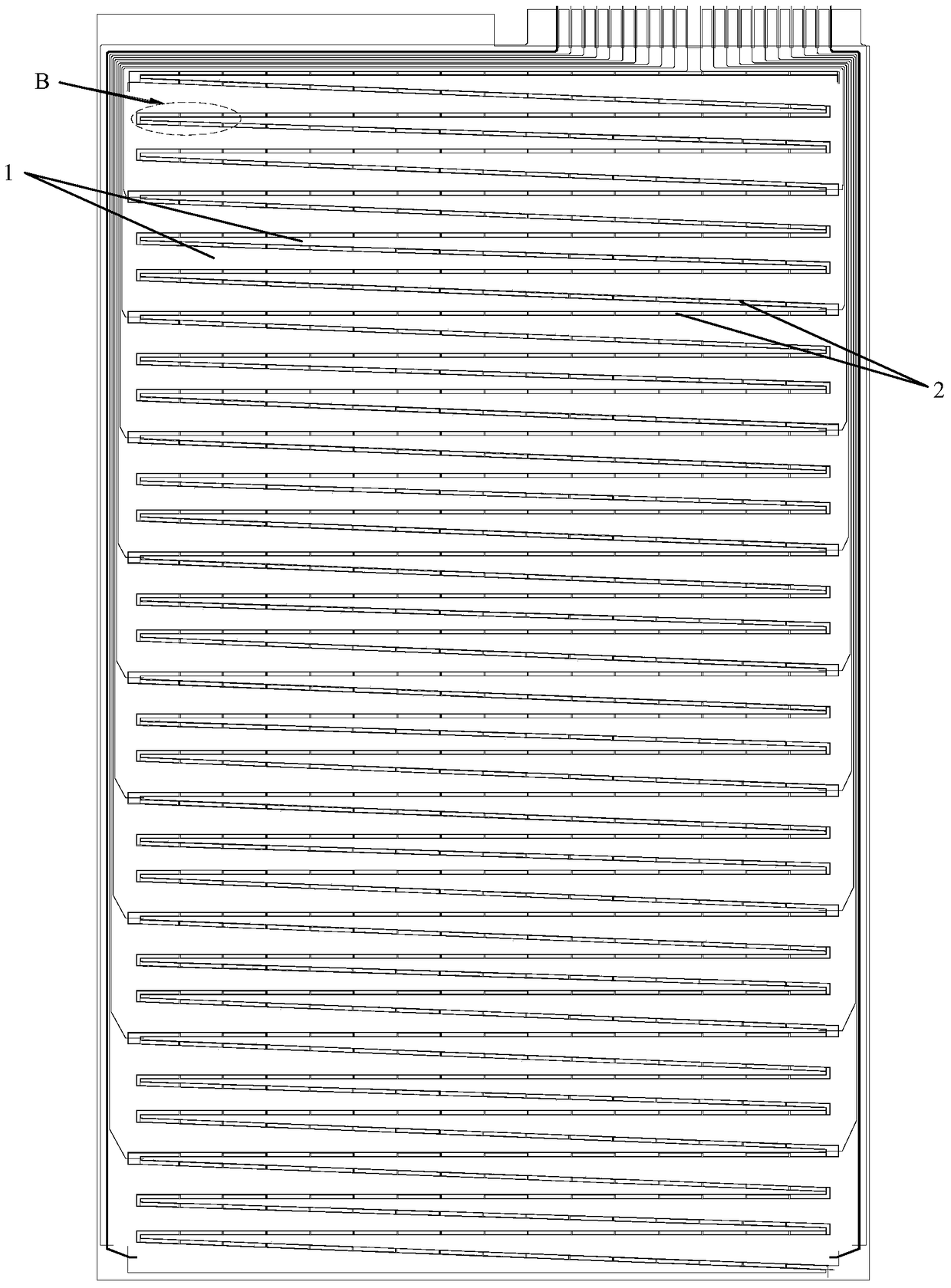

[0030] Such as Figure 3-5 As shown, it is a preferred embodiment of the etching method of the indium tin oxide film in the gap part of the capacitive touch panel of the present invention.

[0031] The insulating transparent substrate of the capacitive touch panel is provided with an indium tin oxide film (ITO), which includes a display area 1 and a gap area 2, such as image 3 As shown, the display area 1 and the gap area 2 are distributed alternately, and the range of the width of the gap area 2 is generally [0.2mm, 0.3mm] limited by the requirements of the control chip. In this embodiment, The width of the gap region 2 is preferably 0.3 mm.

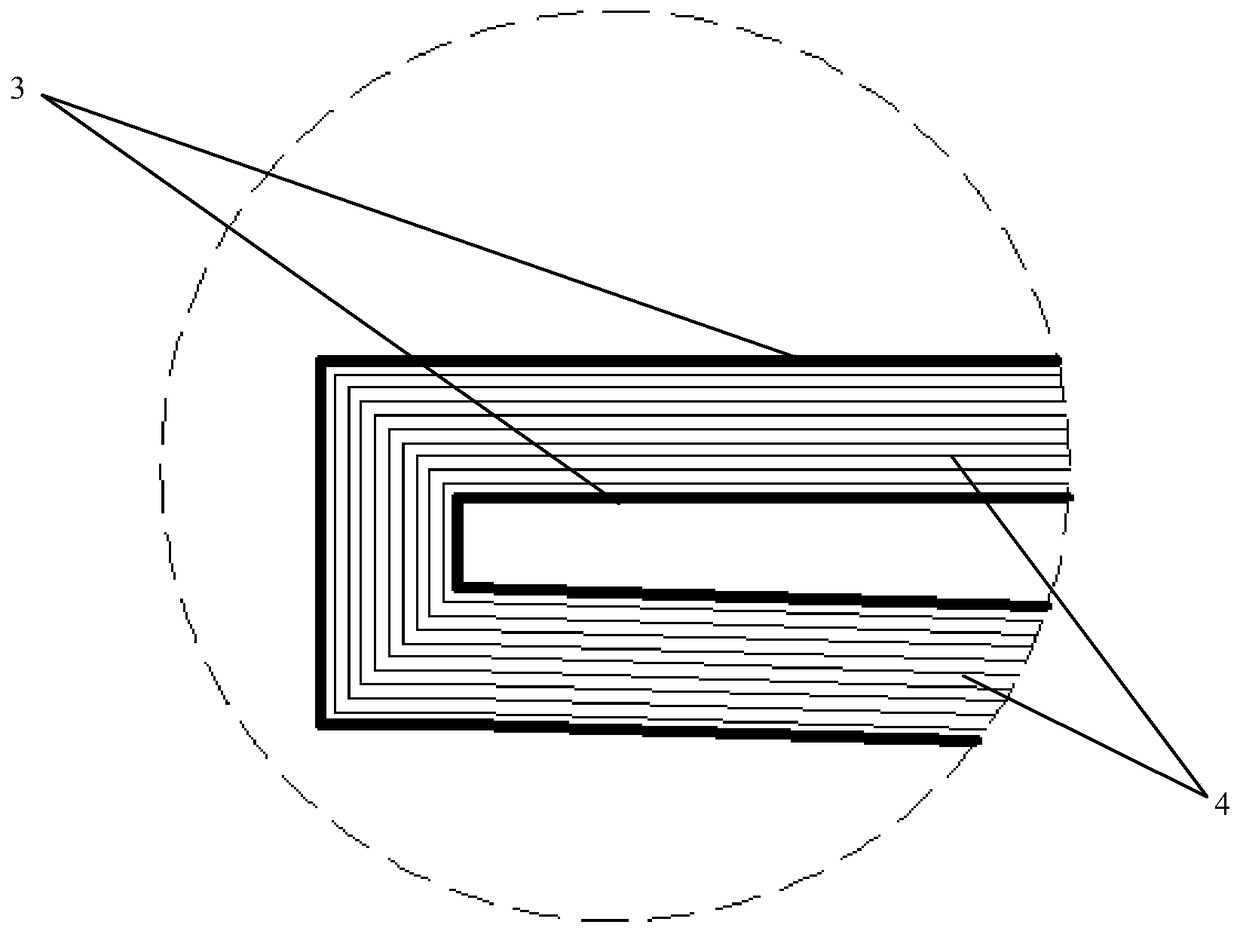

[0032] When etching the ITO of the gap region 2, the ITO of the gap portion 2 is divided into several ITO segments 5 by laser etching lines, as Figure 4 As shown, each of the ITO segments 5 is independent and not connected to each other, that is, there is an interval 6 between adjacent ITO segments 5, and the length of the interval ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com