A kind of preparation method of dam ceramic substrate for ultraviolet LED encapsulation

A technology of LED packaging and ceramic substrates, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that the dams cannot be firmly bonded to the ceramic substrates, and are prone to short circuits, so as to facilitate automated operations, improve product yields, and improve production The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention discloses a method for preparing a dam ceramic substrate for ultraviolet LED packaging, which includes the following steps:

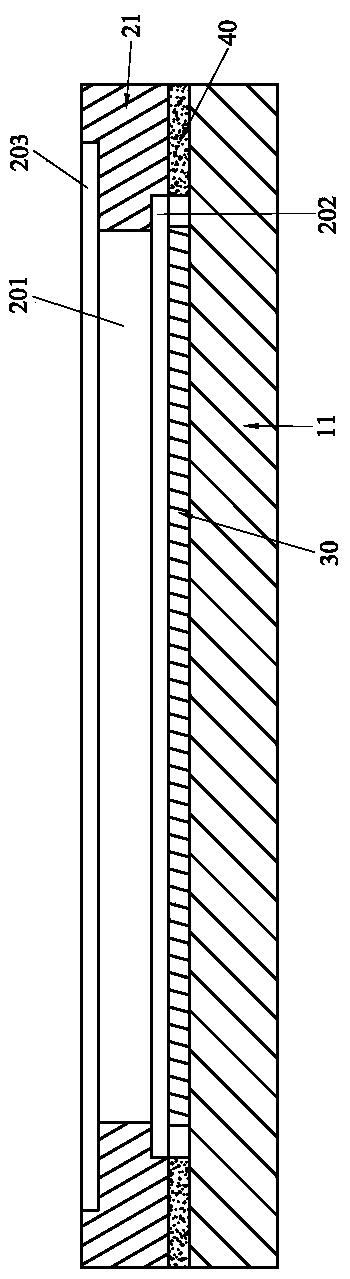

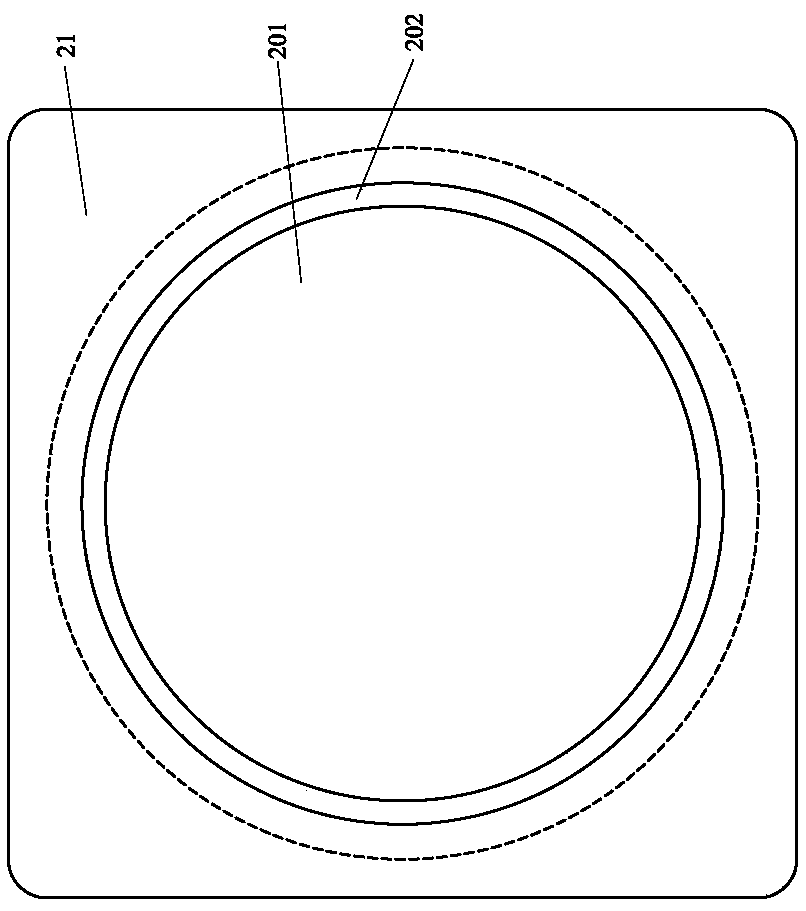

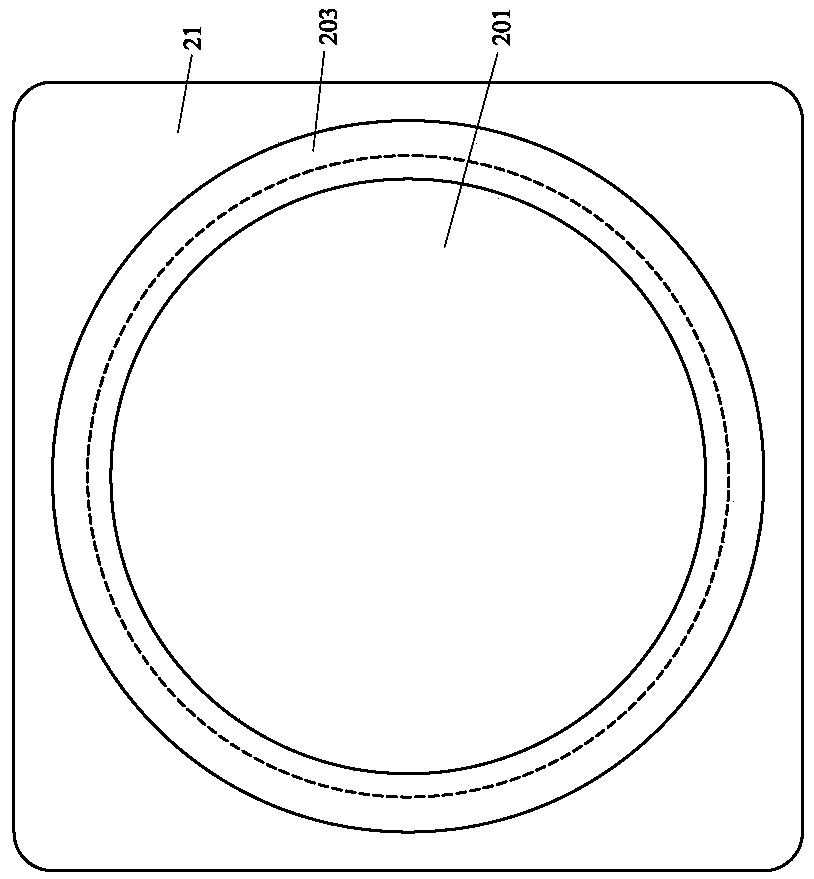

[0028] (1) Make the ceramic substrate and the dam substrate: make a plurality of independent circuits 30 on the surface of the ceramic substrate 10, the independent circuits 30 can be formed by various methods such as electroplating, etching or printing, and each independent circuit 30 is separated from each other; A plurality of through holes 201 are defined on the dam substrate 20 , and the inner diameter of the bottom of each through hole 201 is larger than the maximum width of the independent circuit 30 . The dam substrate 20 is made of metal or ceramic, and in this embodiment, the dam substrate 20 is made of aluminum, which has a better heat dissipation effect. And, a first annular groove 202 is formed on the periphery of the lower end of the through hole 201, and the inner diameter of the first annular groove 202 is greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com