Finite Element Simulation Method for Determining the Complete Rule of Solder Joint Damage Accumulation in Irregular Thermal Profile

A simulation method and finite element technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of high cost and long experiment period, and achieve the effect of accurate results, long compensation period and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment

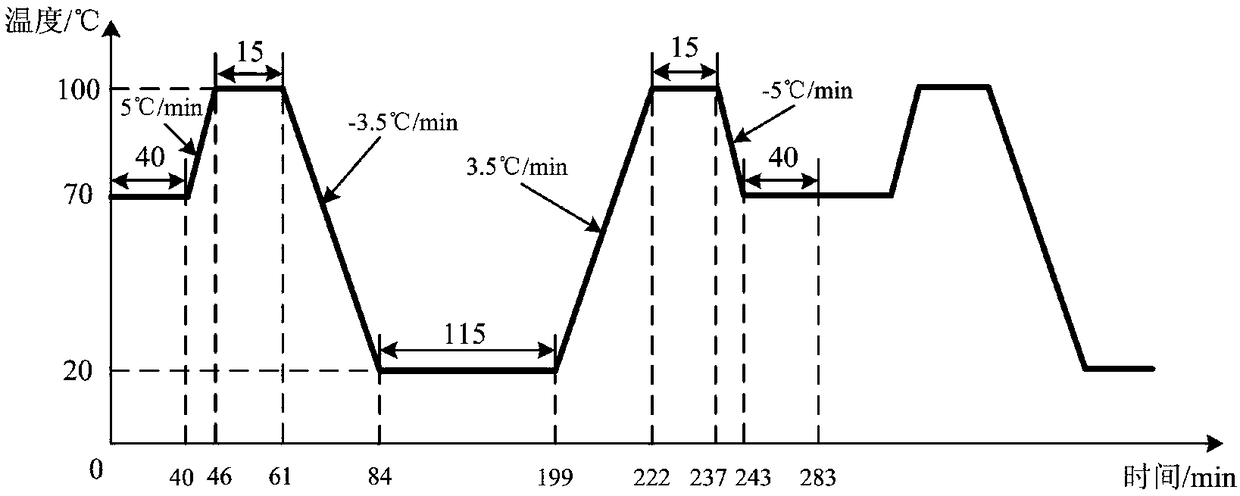

[0121] Taking an aircraft inertial navigation system that performs missions in summer as an example, the finite element simulation method of the damage accumulation law under the irregular temperature cycle profile of the solder joints of BGA packaged devices in its electronic equipment is illustrated. The specific steps of the method are as follows:

[0122] S1. Pre-processing of finite element simulation:

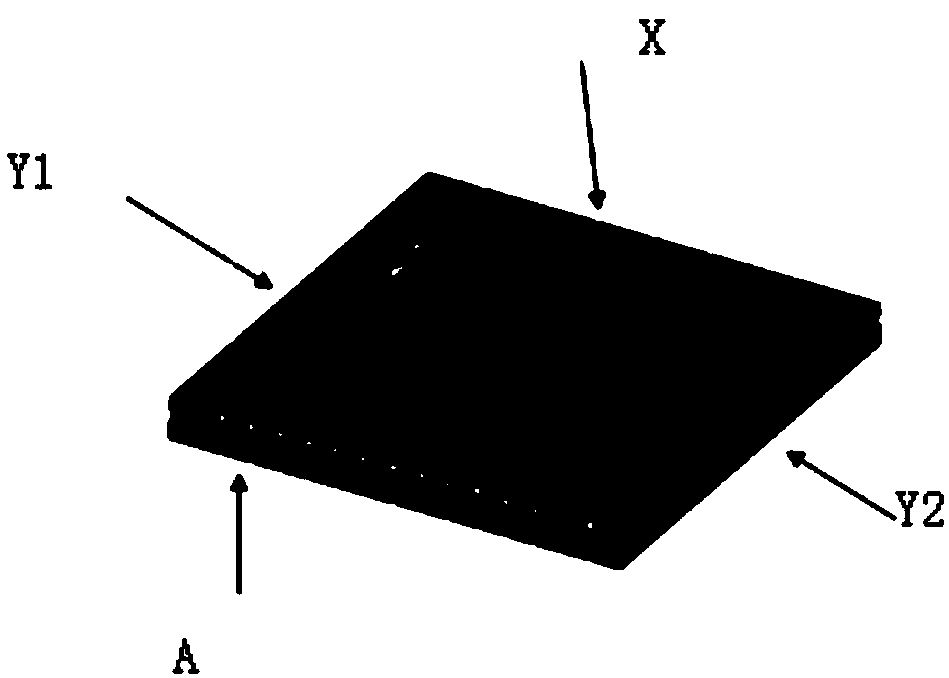

[0123] S11. Determine the components and package form of the finite element three-dimensional structural model, and determine the mesh division method of the model. The finite element model of the chip is packaged in the form of 16mm×16mm BGA, and the chip size is 25mm×25mm. The finite element three-dimensional structure model includes five parts: solder joints, chips, substrates, plastic packaging layers, and PCB layers. The chip information is input into ANSYS software, and Sweeping technology is used to generate octahedral units for solder joints, and hexahedral units...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com