Film slitting device and film slitting method

A film device and cutter technology, applied in metal processing, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problem of wafer groove film covering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The detailed features and advantages of the present invention are described in detail below in the implementation manner, and its content is enough to make any person skilled in the art understand the technical content of the present invention and implement it accordingly, and according to the content disclosed in this specification, the scope of protection of the claims and With the accompanying drawings, any person skilled in the art can easily understand the related objects and advantages of the present invention. The following examples further illustrate the concept of the present invention in detail, but do not limit the scope of the present invention in any way.

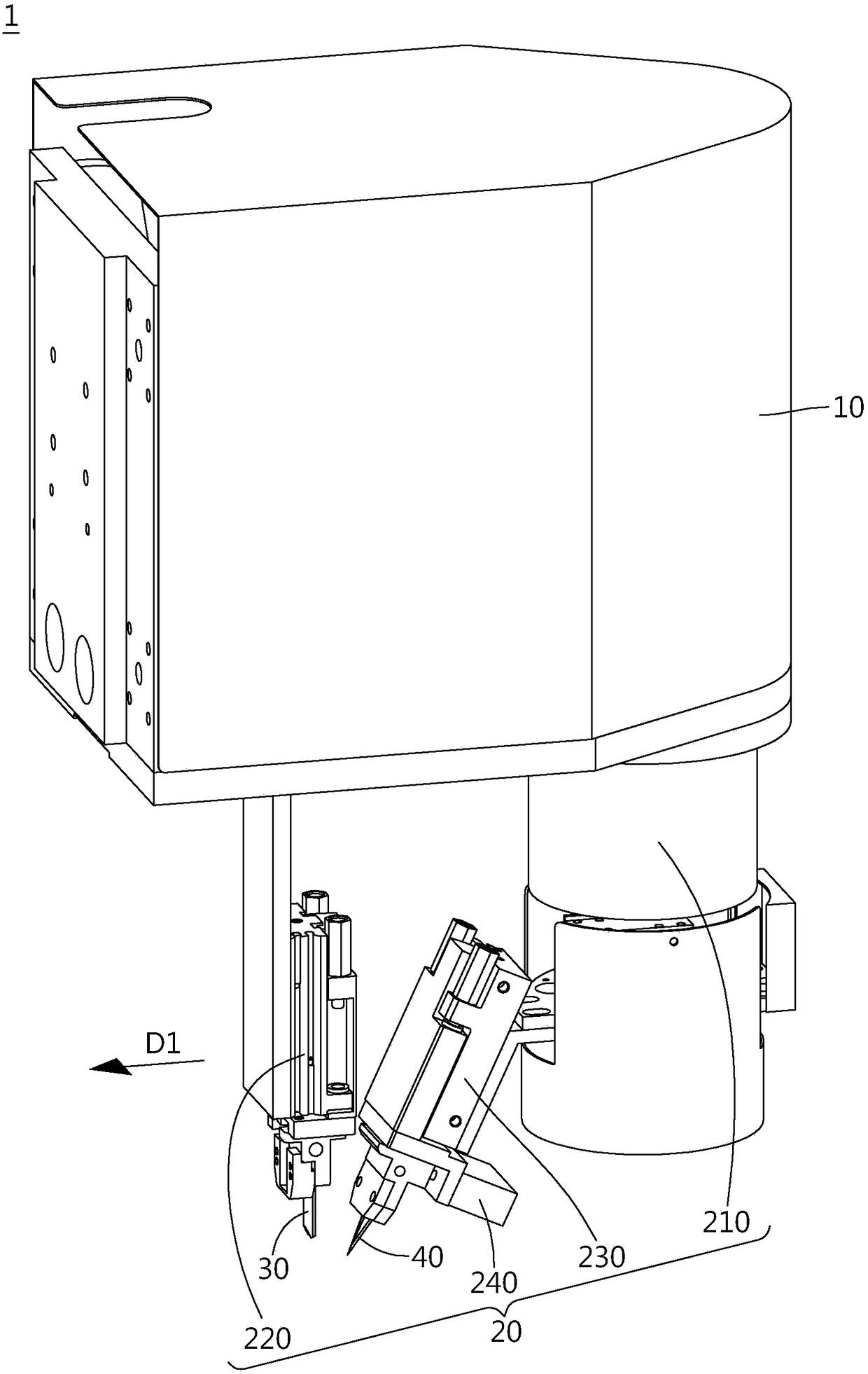

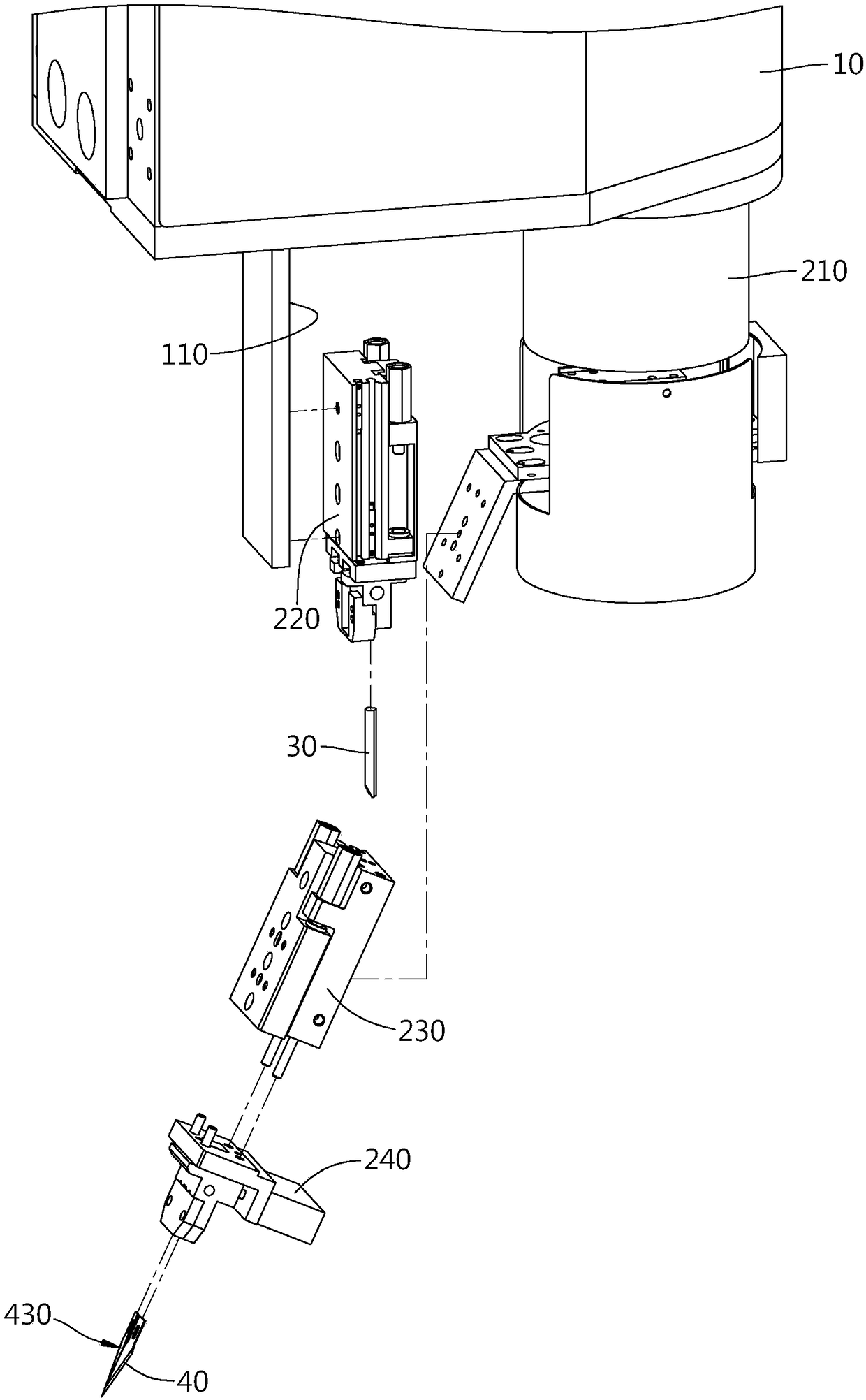

[0060] Please also refer to Figure 1 to Figure 2 . figure 1 It is a three-dimensional schematic diagram of a film cutting device according to an embodiment of the present invention. figure 2 for figure 1 An exploded schematic of the film-slitting device. In this embodiment, the film cutting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com