Disc ridger

A technology of ridging machine and disc, which is applied in the direction of agricultural machinery and implements, shovels, plows, etc. It can solve the problem of polluted soil, single function, ditches width and ridging height cannot be adjusted according to different crops. problems, to achieve the effect of long service life, stable structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

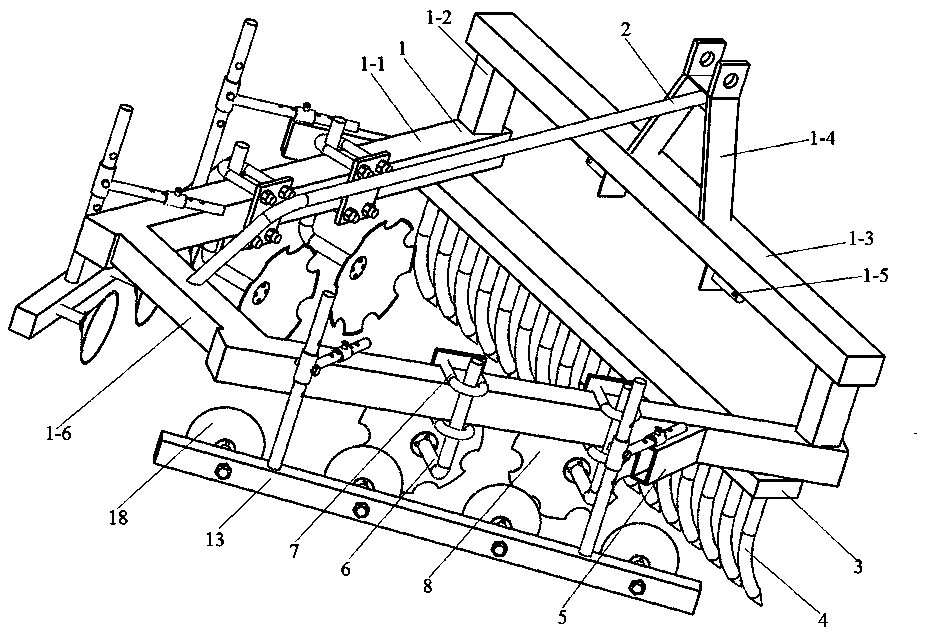

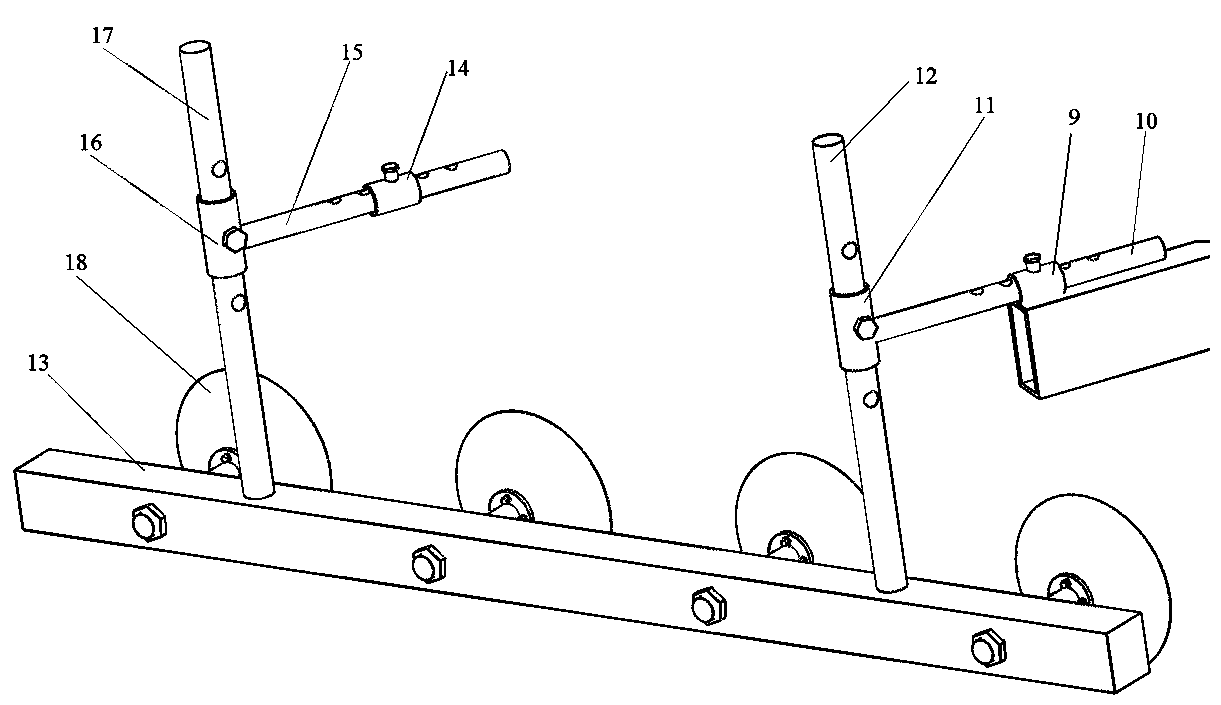

[0014] Such as figure 1 and figure 2 As shown in the schematic diagram of the structure, a disc ridging machine includes a frame 1, and the frame 1 includes sloping plates 1-1 on both sides, and the sloping plates 1-1 on both sides are in the shape of an inverted "eight" outward. Open, the front part of the upper surface of the inclined plates 1-1 on both sides is provided with a column 1-2, the upper end of the column 1-2 is provided with a front beam 1-3, and the middle part of the upper surface of the front beam 1-3 is provided with a suspension arm 1 -4, a pair of fixed shafts 1-5 are arranged in the middle of the lower surface of the front crossbeam 1-3, a through hole is arranged on one side of the fixed shaft, and a rear crossbeam 1-6 is arranged between the rear parts of the inclined plates 1-1 on both sides. A reinforcing bar 2 is arranged between the suspension arm 1-4 and the rear cross beam 1-6, the rear part of the reinforcing bar 2 is an arc structure, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com