Spray arm and washing machine adopting same

A spray arm and spray hole technology, which is applied in the field of cleaning machines, can solve problems such as flushing, achieve enhanced cleaning effects, good washing effects, and improved cleaning rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

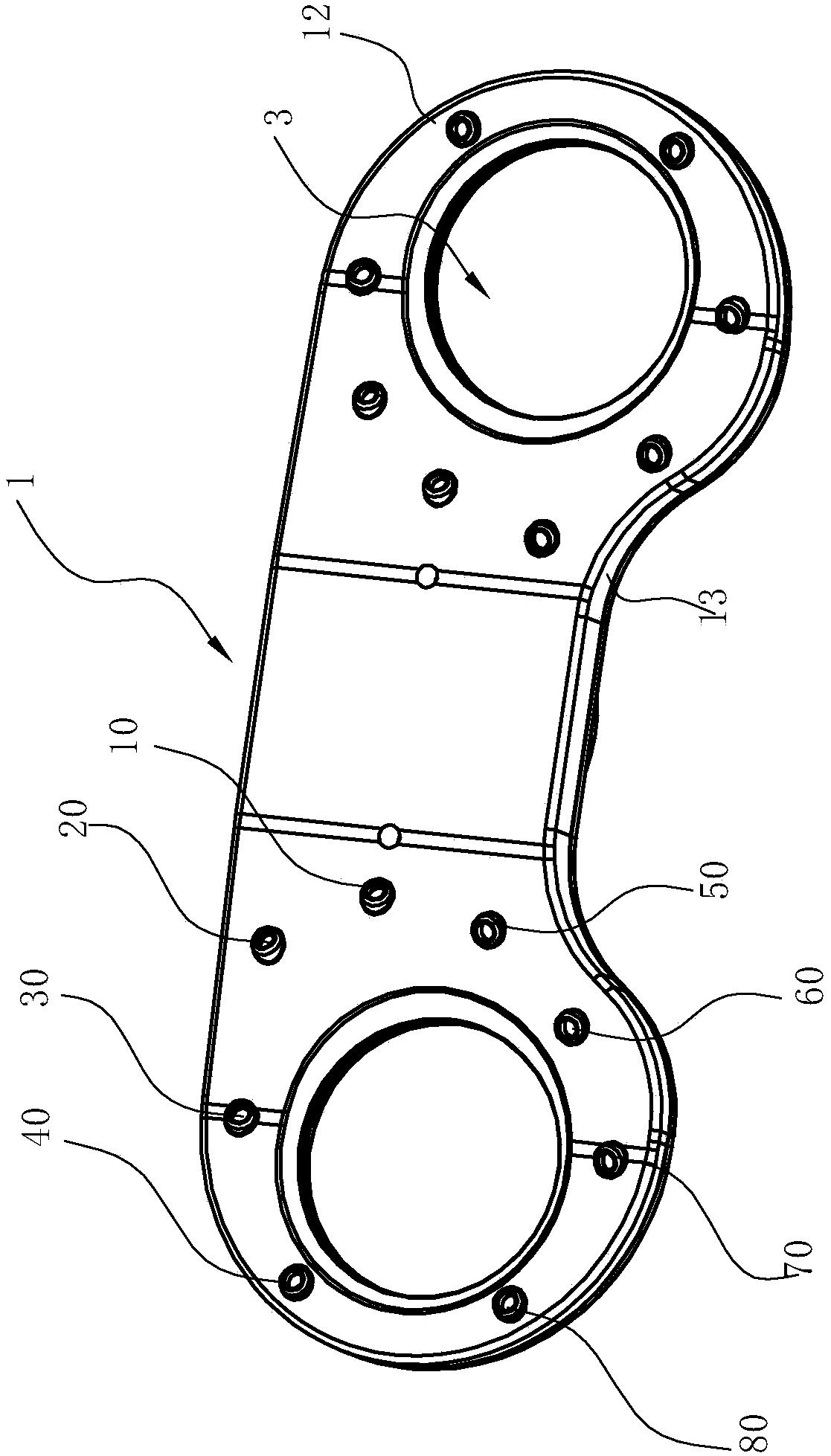

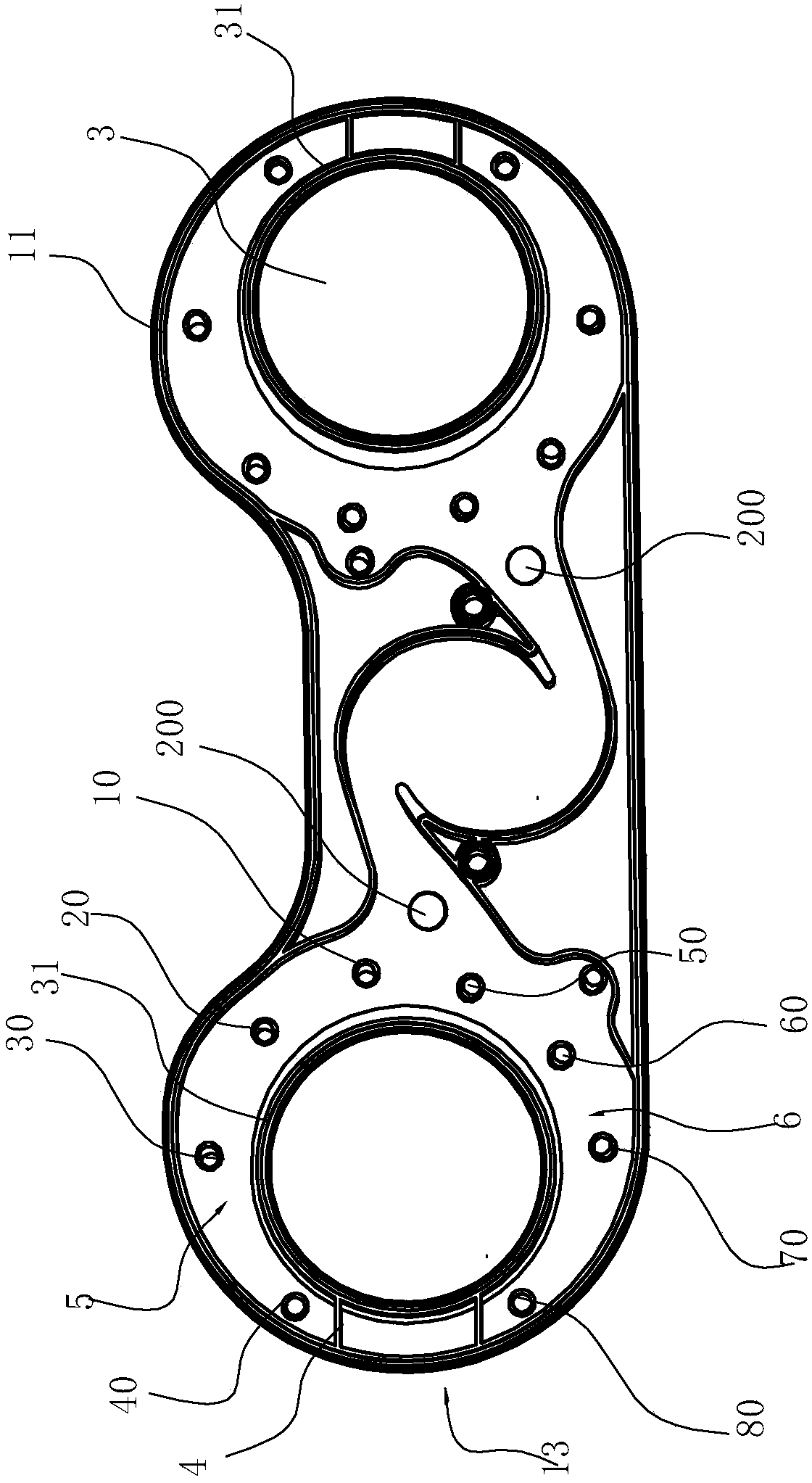

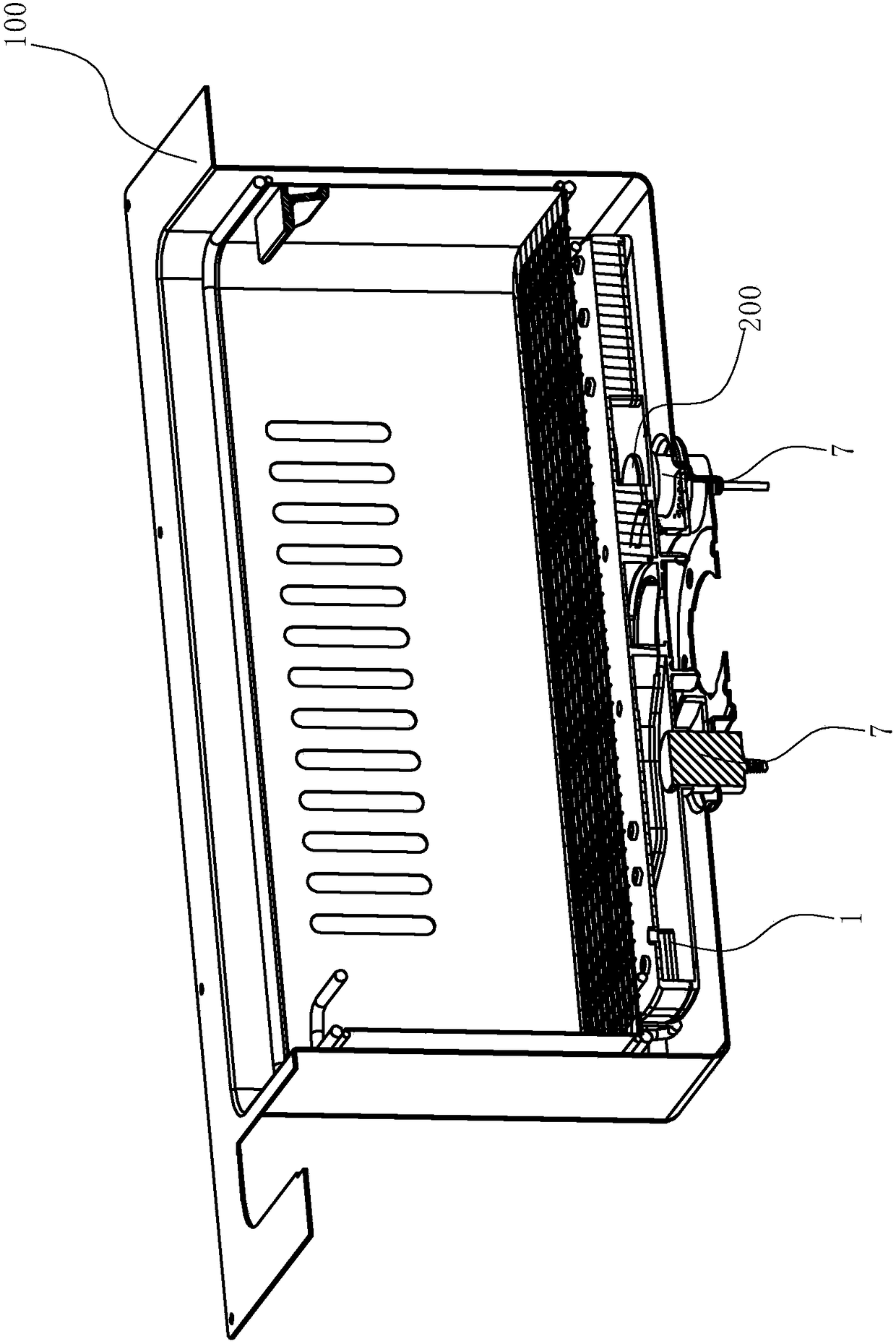

[0024] see Figure 1 ~ Figure 3 , the cleaning machine of the present invention is designed to be particularly suitable for the sink type cleaning machine with a long and narrow water tank, especially for the cleaning of fruits and vegetables, but in fact it can also be applied to ordinary sink type cleaning machines, as well as European type cleaning machines with front doors and Drawer washing machine.

[0025] The following takes the fruit and vegetable cleaning machine as an example to expand the description:

[0026] The fruit and vegetable washing machine includes a water tank body 100, a water pump and a spray arm. Wash the fruits and vegetables to be cleaned. In the present invention, preferably, the sink body 100 is made into a long and narrow shape, so that it can not only better adapt to the space of the user's kitchen (cooperate with other sinks), but also save water compared to square sinks.

[0027] The water pump is arranged in the middle of the bottom of the...

Embodiment 2

[0033] The structure is basically similar to that of Example 1, the difference is that the flow channel is a radial flow channel, such as Figure 4 As shown, it is divided into three sub-channels as the third sub-channel 103, the fourth sub-channel 104 and the fifth sub-channel 105, and at least three spray holes are arranged on the wall corresponding to each sub-channel to control The spray pressure of each bundle of sub-runners is consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com