Sand injection device of sand shooting machine for casting

A technology of sand shooting machine and sand materials, which is applied to the parts of molding machines, molding machines, casting and molding equipment, etc. It can solve the problems of uneven feeding, easy blockage of feeding pipes, and sand materials being brought out, so as to improve smoothness The effect of improving the cutting efficiency and increasing the fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

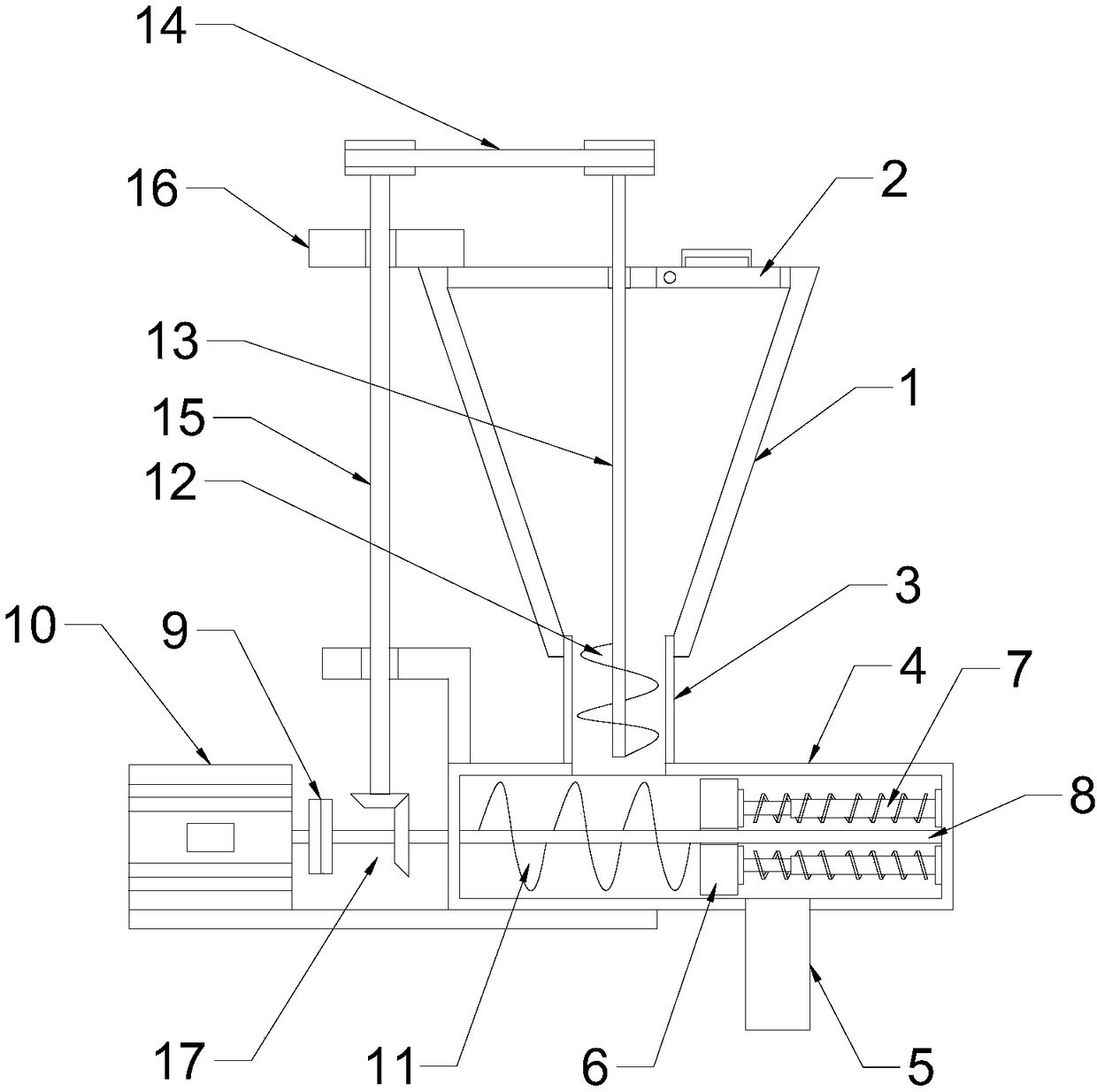

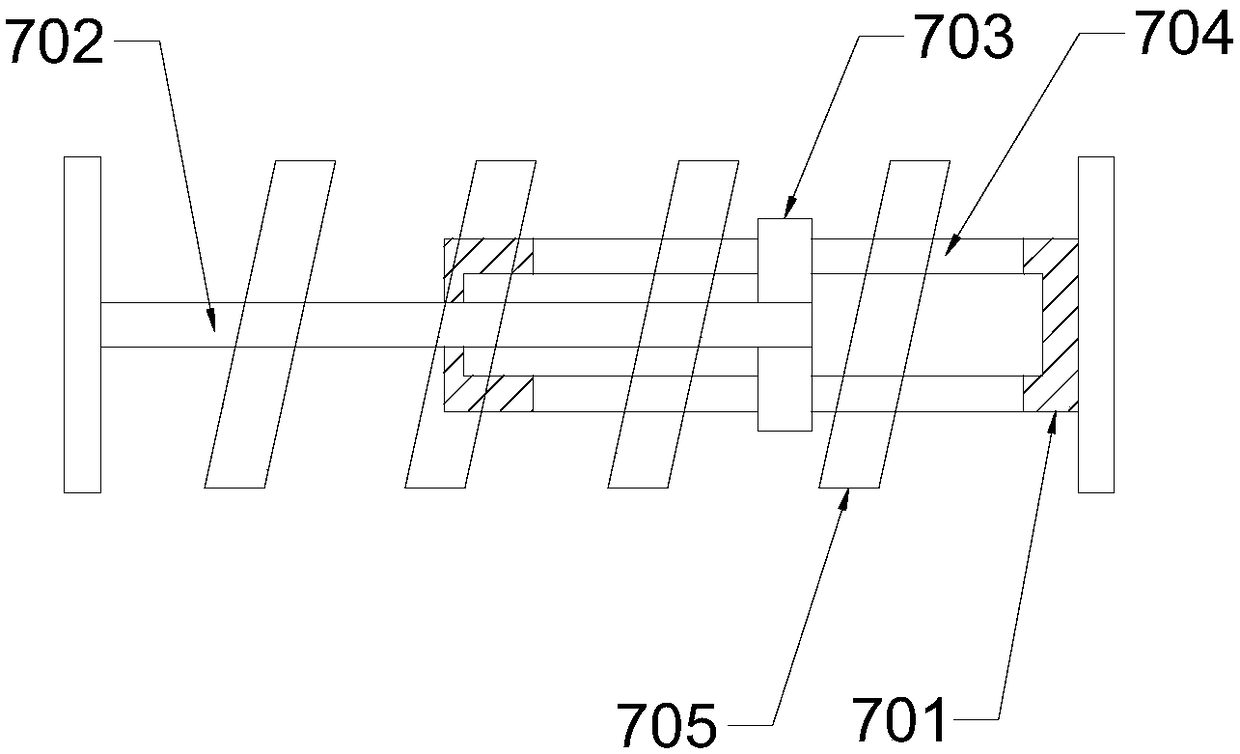

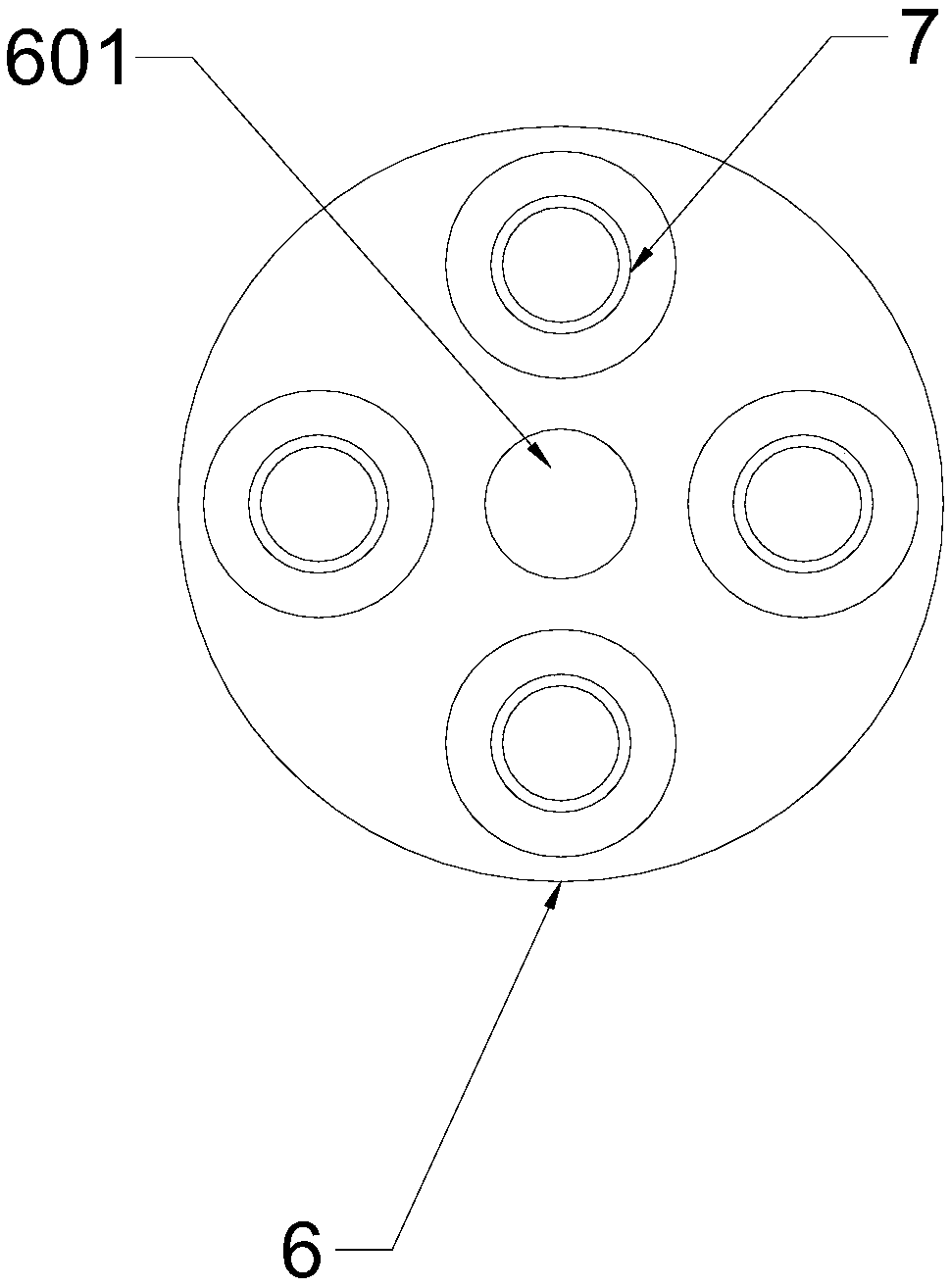

[0023] see Figure 1~2 , in an embodiment of the present invention, a sand injection device for a sand shooting machine for casting, comprising a sand storage bucket 1 for storing sand; the upper end of the sand storage bucket 1 is hinged with an upper cover plate 2 with a handle, and the upper The cover plate 2 is used to inject sand into the sand storage bucket 1; the sand storage bucket 1 is connected to the horizontal pipe 4 through the vertical pipe 3, and the horizontal pipe 4 is nested with a sliding block 6, which is a vertical The disc-shaped slide block that is set, the slide block 6 is slidably connected with the inner wall of the horizontal pipe 4; The inner sleeve rod 702 nested in the outer and inner sleeve 7 and slidingly connected with the outer sleeve 7, the end of the inner sleeve rod 702 is fixedly connected with a nested slider 703 by means of screw fixing, and the outer sleeve 701 is provided with a horizontally arranged The sliding slot 704 is a strip-sh...

Embodiment 2

[0027] see Figure 4 , the difference between this embodiment and Embodiment 1 is that: the central shaft 13 is fixedly connected with a third helical blade 19, and above the third helical blade 19 is fixedly connected with a pulverizer, and the central shaft 13 drives the third helical blade 19 and the pulverizer 18 rotations, crushing and turning the sand material compacted in the sand storage bucket 1, improving the fluidity of the sand material, and improving the feeding efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com