Installation device and installation method of large size liner

A mounting device and large-scale technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of unsatisfactory assembly process, inaccurate alignment, slow manual installation speed, etc., to prevent heat dissipation and avoid interference , Installation efficiency and high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the present invention will be described in detail in conjunction with embodiments. It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict. For the convenience of description, if the words "up", "down", "left", and "right" appear in the following, they only indicate that they are consistent with the upper, lower, left, and right directions of the drawings themselves, and do not limit the structure.

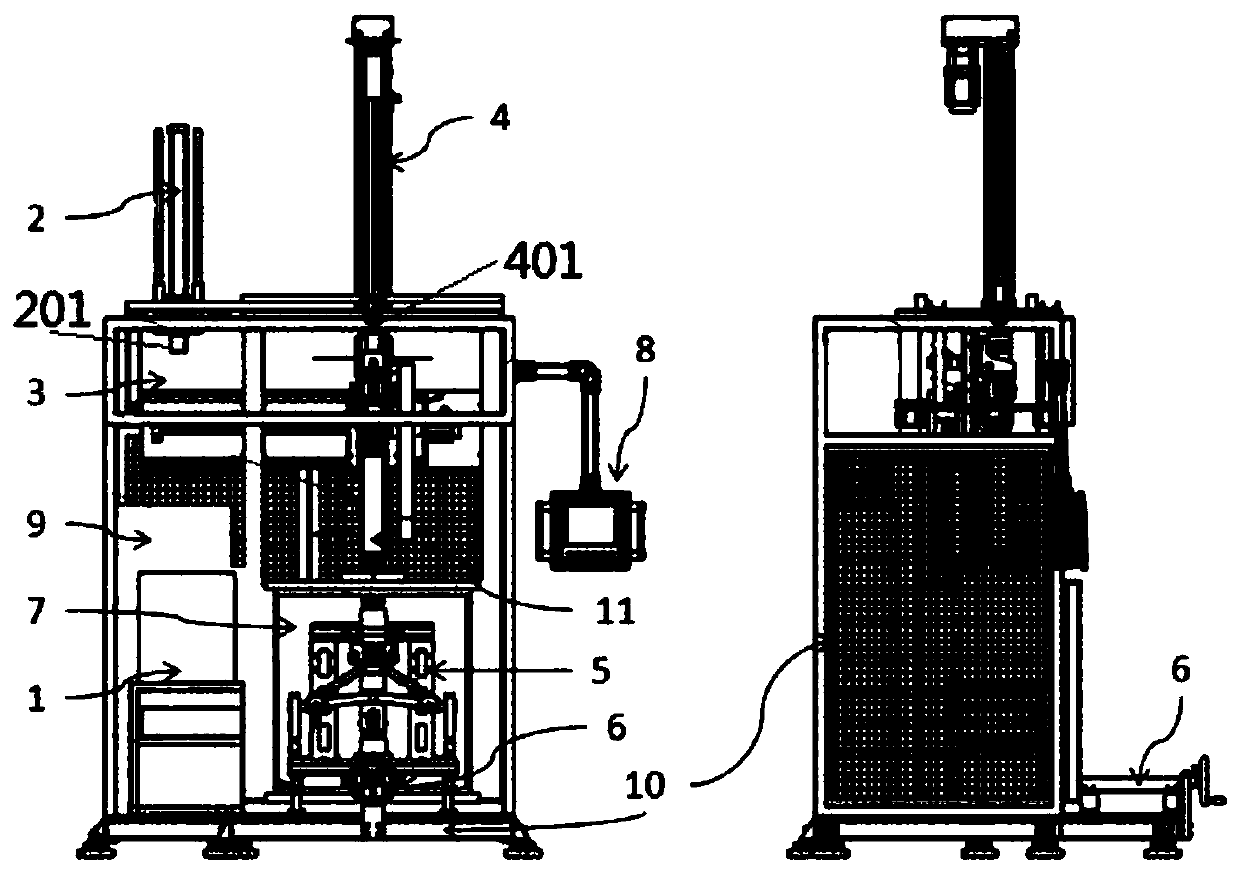

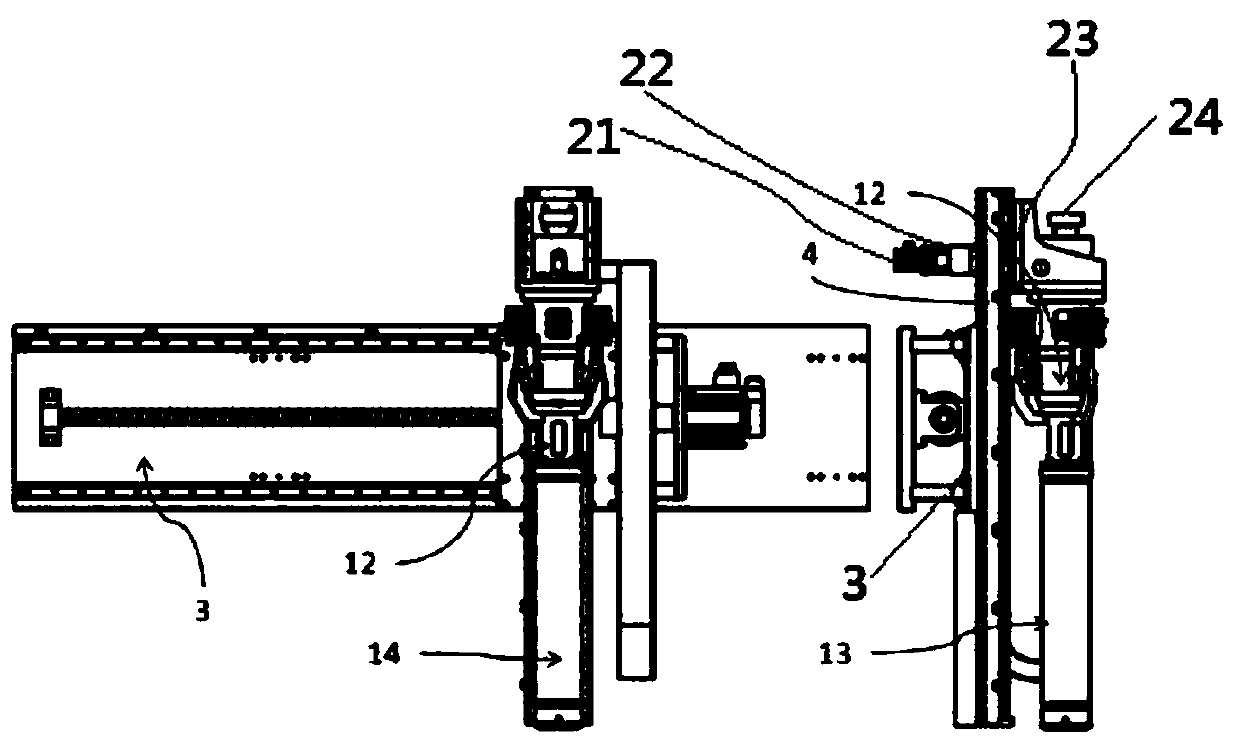

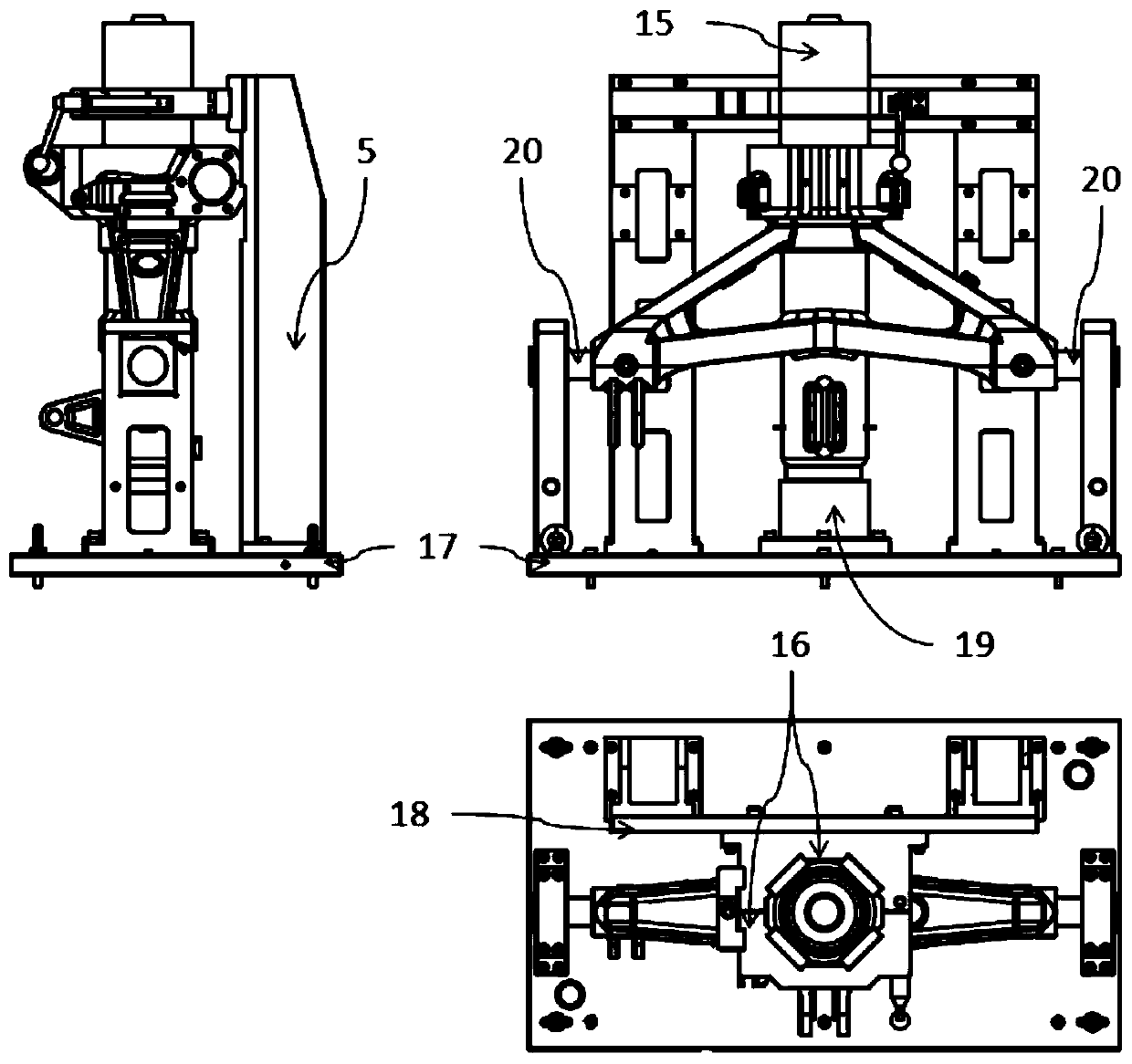

[0043] Such as figure 1 Shown is a schematic structural diagram of a large-size liner installation device of the present invention. It consists of a pressure vessel, a first Z-direction linear module (lift cylinder), an X-direction linear module (servo mechanism), and a second Z-direction linear module ( Pressure servo mechanism), positioning fixture, Y-direction transfer mechanism, heating container, liner positioning mechanism, operation panel, electric control c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com