Glass cutting device facilitating fragment collection

A glass and convenient technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of fragments, accidental injuries of operators, and high labor costs, so as to facilitate collection, avoid fragments from hurting people, and cut glass Size-controllable and accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

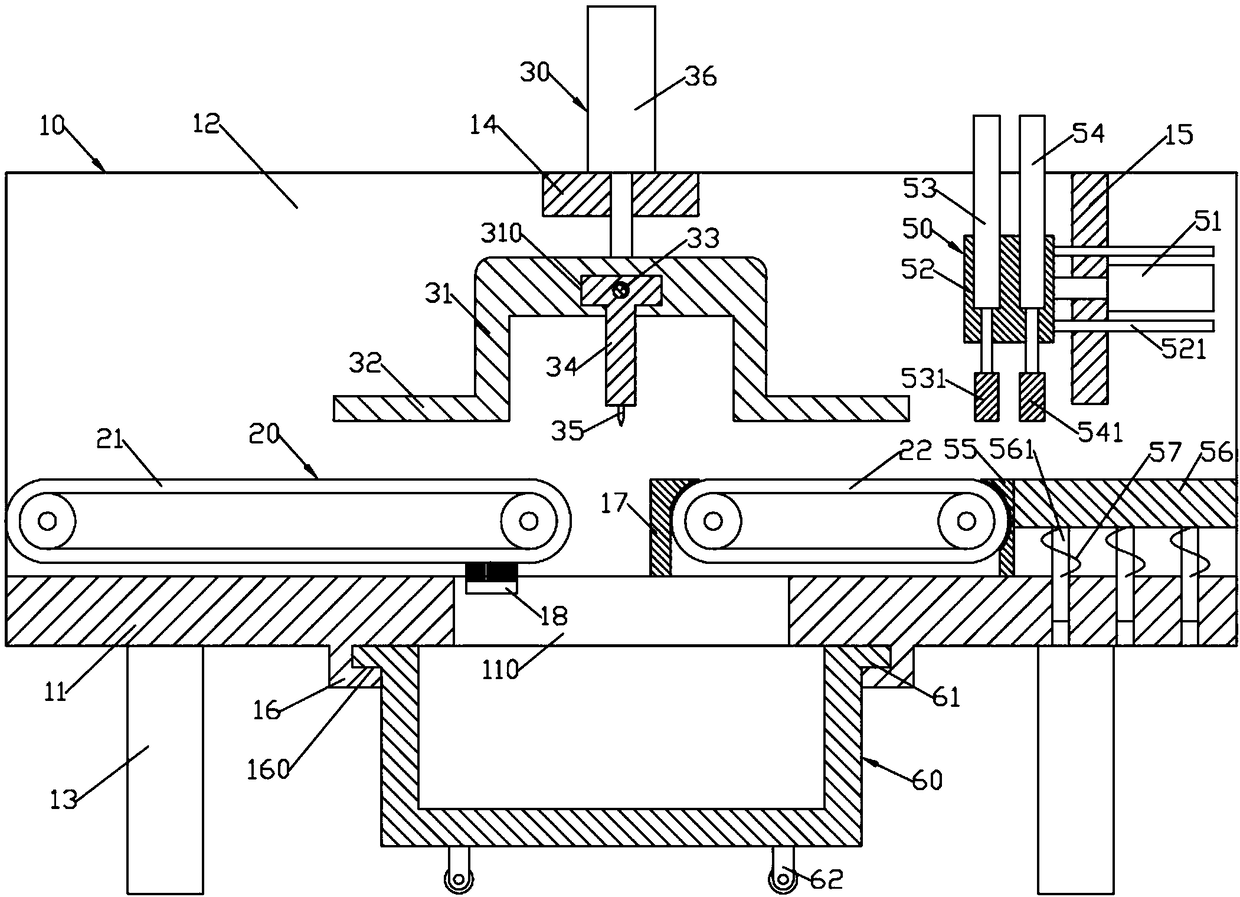

[0017] like figure 1 As shown, a glass cutting device that is convenient for fragment collection includes a support 10, a glass conveying device 20, a scribing device 30, a breaking device 50 and a collecting trolley 60; the support 10 includes a horizontal support plate 11; the horizontal support plate 11 A vertical support plate 12 is formed on the front, rear and two ends of the upper end, and a number of support feet 13 are evenly formed on the lower end surface; an upper support plate 14 is formed between the upper ends of the opposite end faces of a pair of vertical support plates 12, and an upper support plate 14 is formed on the upper right part. A right support plate 15 is formed between them; the glass conveying device 20 includes a left synchronous conveyor belt 21 and a right synchronous conveyor belt 22 distributed left and right; the left synchronous conveyor belt 21 and the right synchronous conveyor belt 22 are arranged between the lower ends of a pair of vertic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap