Electrolytic aluminum anode device

An electrolytic aluminum anode and steel claw technology, applied in the field of aluminum electrolysis, can solve problems such as low product quality, large power loss, and complex structure, and achieve the effects of improving safety, saving power, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

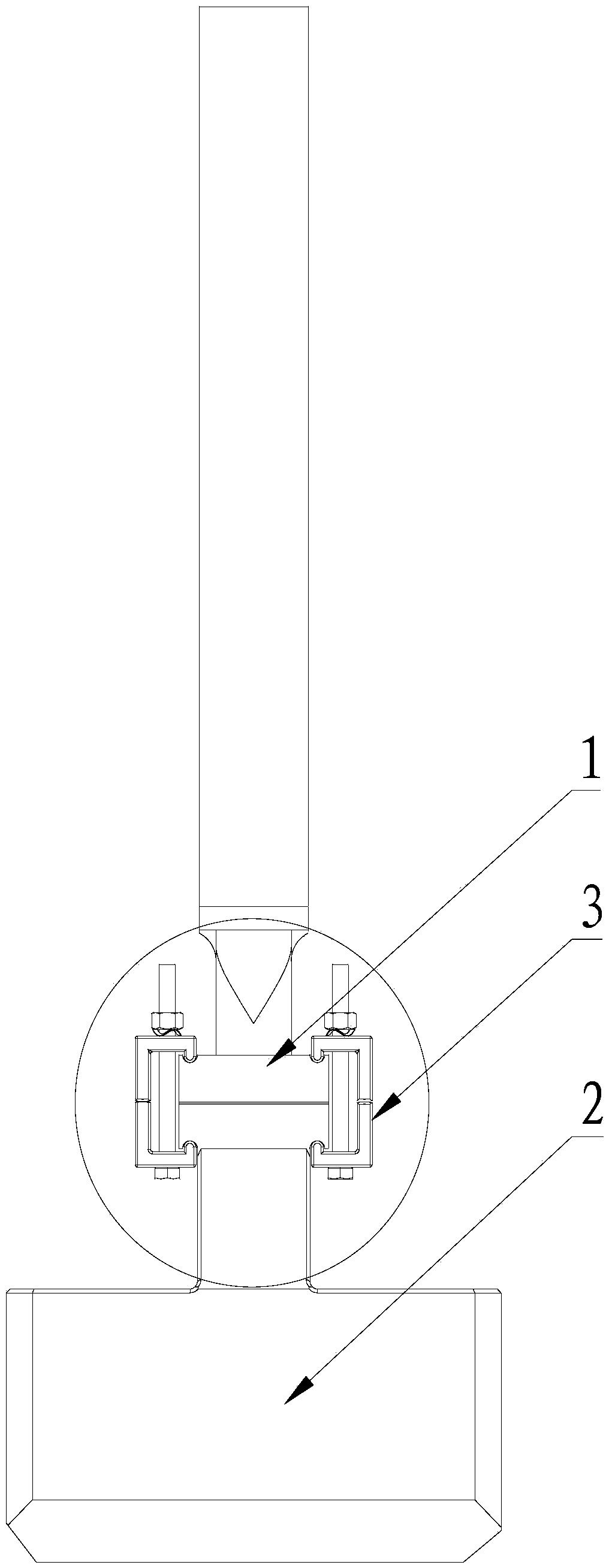

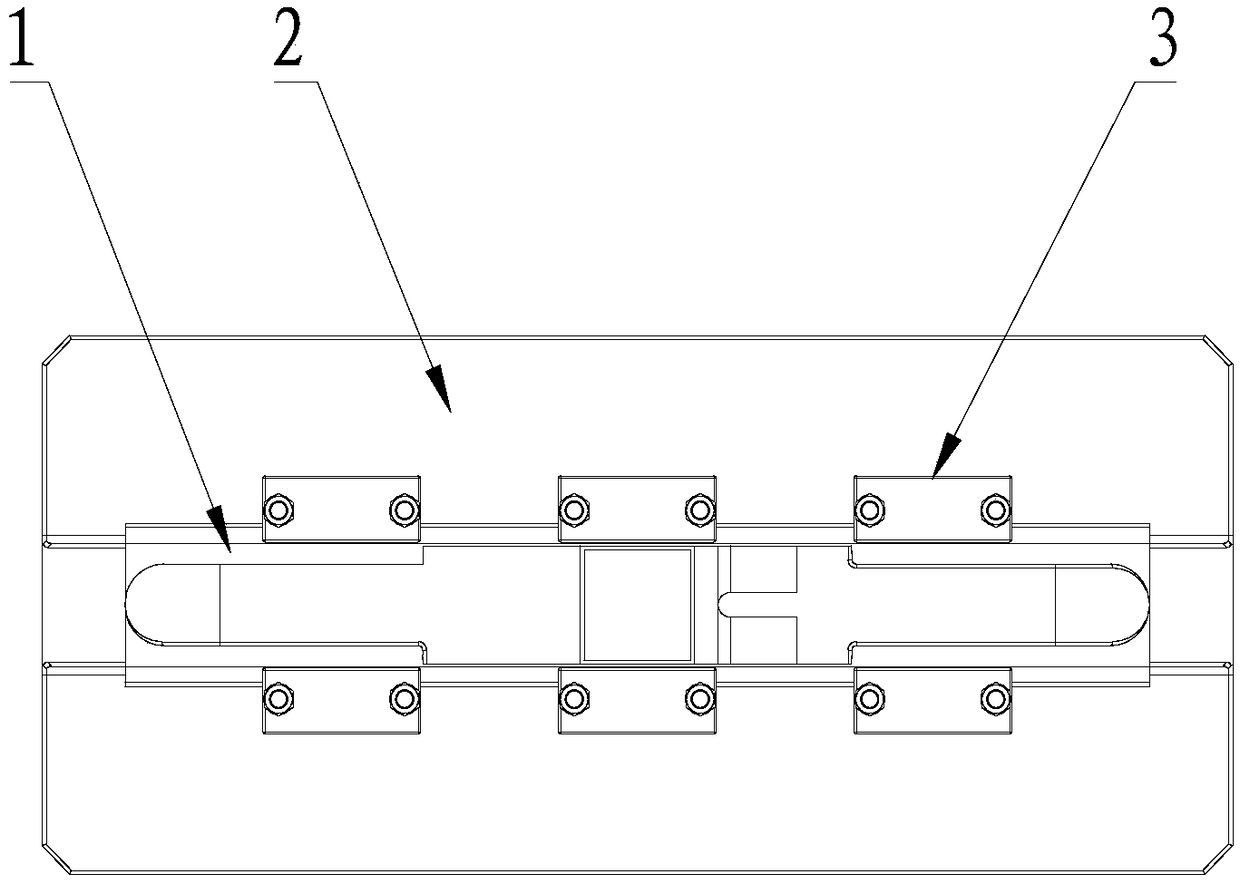

[0017] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0018] The most critical idea of the present invention is that the steel claw and the carbon block are fixedly connected by carbon snaps instead of the traditional welding connection between the steel claw and the carbon block, which reduces the resistance, increases the strength of the connection structure, and saves energy at the same time. electricity.

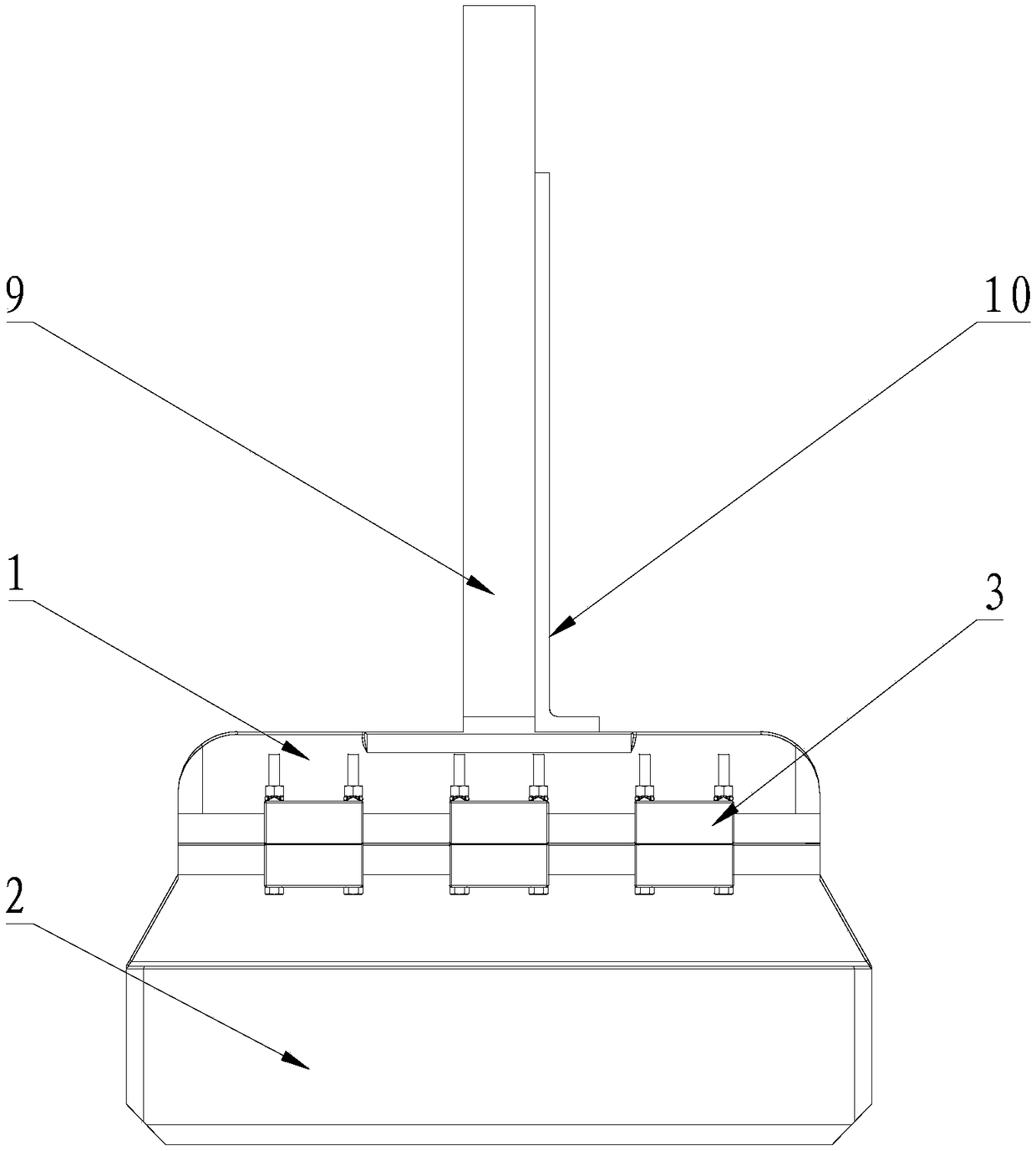

[0019] Please refer to Figure 1 to Figure 9 , an electrolytic aluminum anode device, comprising a steel claw, a carbon block, and a carbon buckle whose two ends are respectively clamped and connected to the steel claw and the carbon block, and the carbon buckle is electrically connected to the steel claw and the carbon block respectively.

[0020] It can be seen from the above description that the benefic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com