An assembly method of a detachable synchronous locking mechanism placed inside a door leaf

A locking mechanism and assembly method technology, applied in building locks, door/window accessories, building structures, etc., can solve the problems of low transmission efficiency, large transmission torque loss, inconvenient operation, etc., and achieve high transmission efficiency, flexible mechanism, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

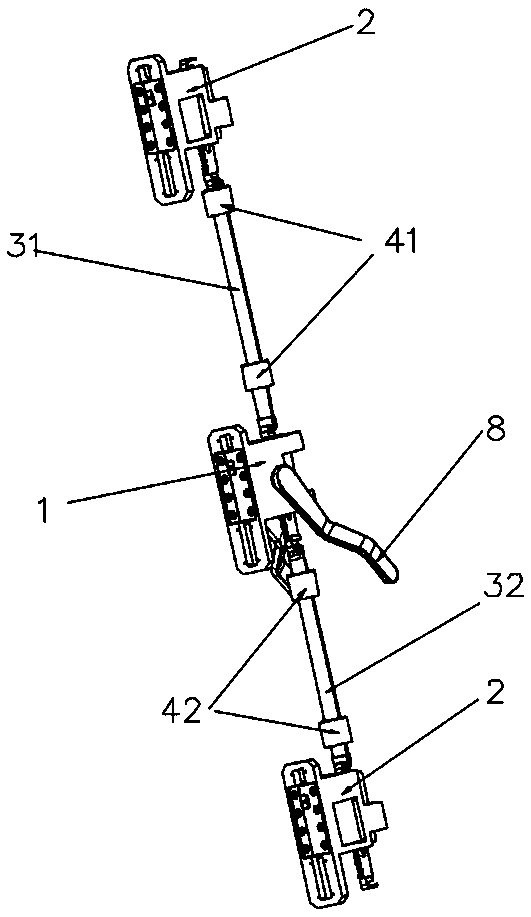

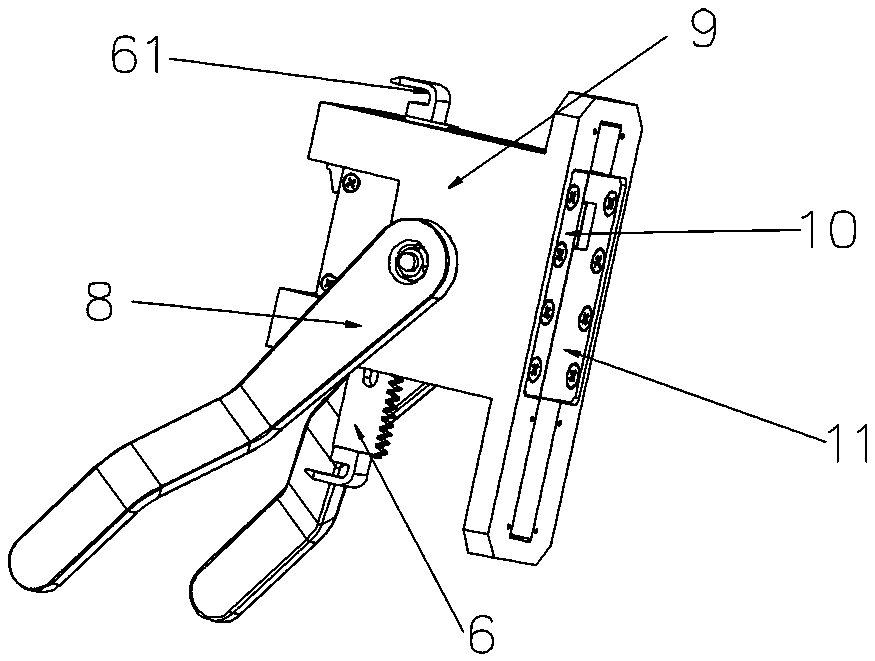

[0039] In the first embodiment, the upper and lower ends of the first rack 6 are provided with hooks 61 for connecting with the hook holes at both ends of the connecting rod.

Embodiment 2

[0040] In the second embodiment, no hook 61 is provided on the upper end of the first rack 6 in the auxiliary lock 2 located at the upper end and the lower end of the first rack 6 in the auxiliary lock 2 located at the lower end.

Embodiment 3

[0041] In the third embodiment, the upper end of the first rack 6 in the auxiliary lock 2 at the upper end and the lower end of the first rack 6 in the auxiliary lock 2 at the lower end are not provided with a hook 61, and a locking head 71 is added for locking Door leaves and upper and lower door frames.

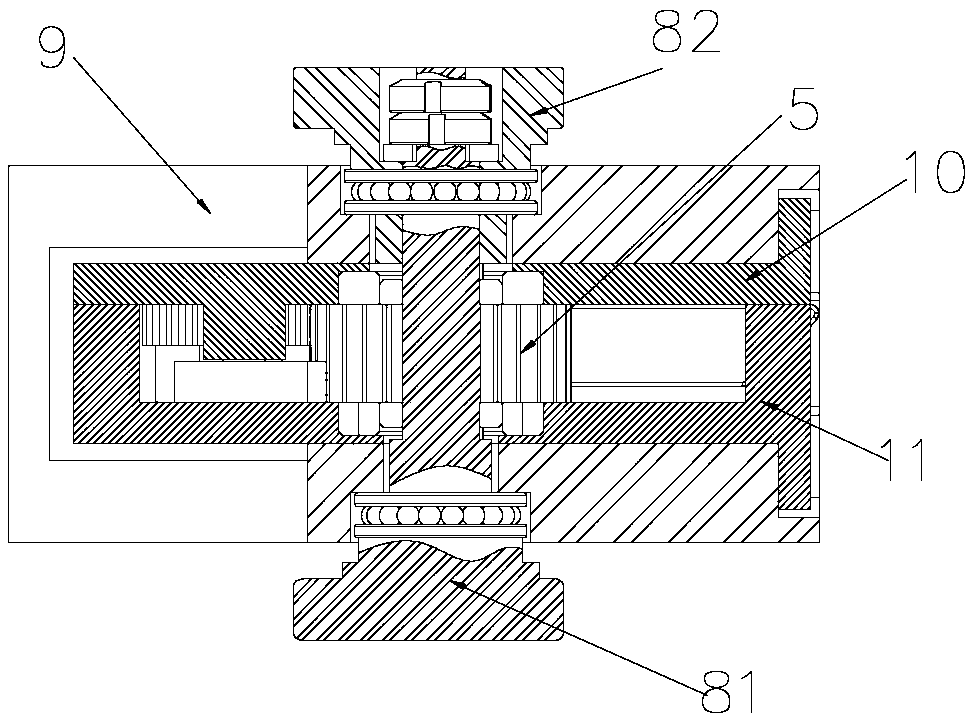

[0042] The main lock 1 is also provided with a handle 8 as an input power, and the handle 8 is fixedly connected with the gear 5 . The handle 8 is used as the input power to drive the gear 5 to rotate, and transmit the torque to the first rack 6 and the second rack 7, and realize the locking assembly through the characteristics of high-precision meshing and high transmission efficiency ratio of the rack and pinion The linkage between and the locking and opening of the door leaf.

[0043] Such as Figure 7 , 8 , 9, further, the main lock 1 and the auxiliary lock 2 also include a fixed seat 9, an upper cover 10 and a lower cover 11, and the upper cover 10 and the lower cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com