Corn drying device adopting biomass formed fuel hot blast furnace

A molding fuel and drying device technology, which is applied in grain drying, drying gas arrangement, drying solid materials, etc., can solve the problems of corn quality decline, different drying energy, unfavorable water evaporation, etc., so as to alleviate the waste of resources and improve drying efficiency , Improve the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

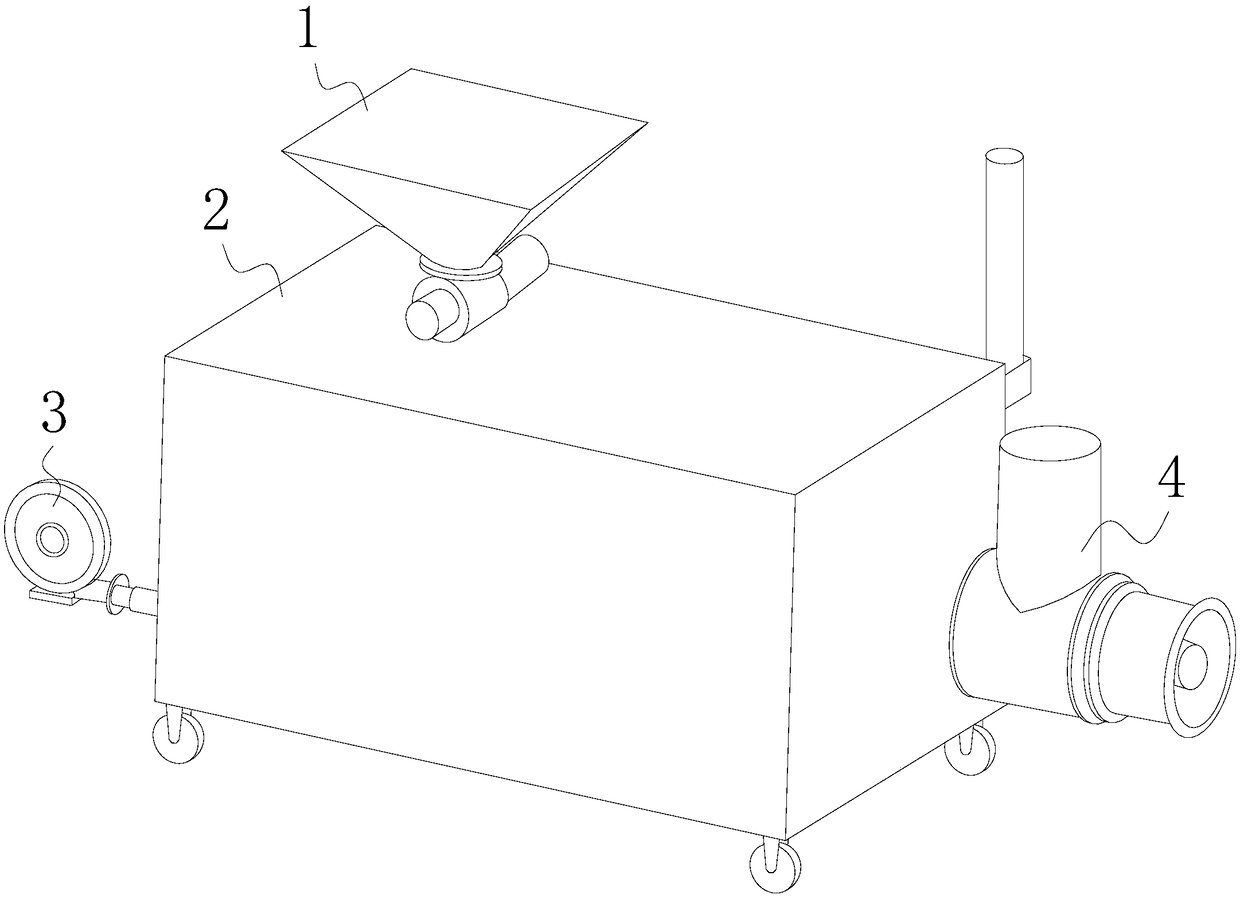

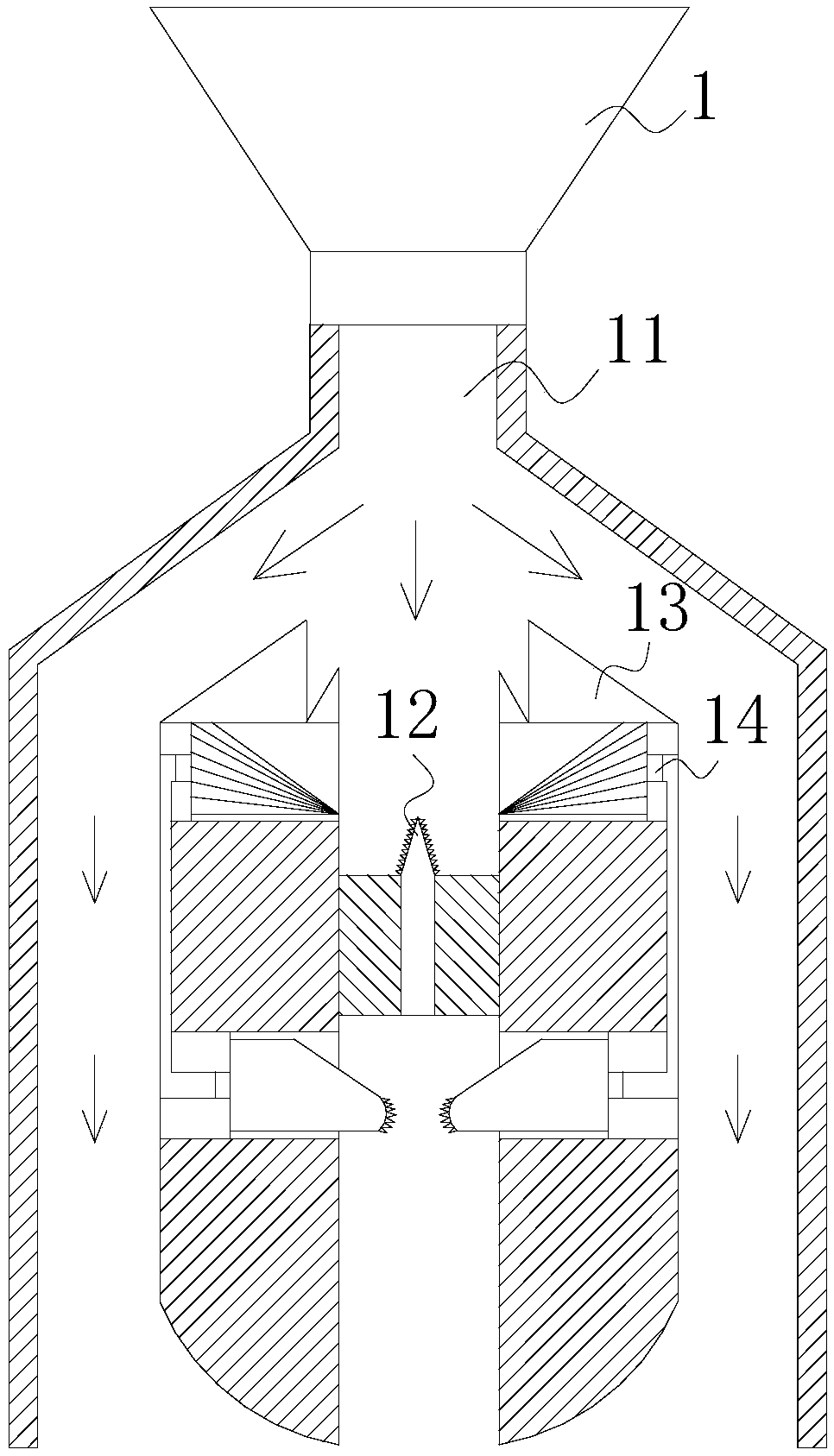

[0027] Such as figure 1 , figure 2 , Figure 5 As shown, the present invention provides a kind of biomass briquette fuel hot stove corn drying device, its structure comprises feed hopper 1, drying box 2, induced draft fan 3, suction fan 4, and the upper port of described drying box 2 is equipped with feed The hopper 1 is provided with an induced draft fan 3 on one side of the drying box 2 and an exhaust fan 4 on the other side. , a scraper cone 13, and a negative pressure cutting mechanism 14. The feeding chamber 11 is divided into an inverted V-shaped structure through a cutting system composed of a partition plate 12, a scraper cone 13, and a negative pressure cutting mechanism 14. In the partition plate 12 The scraper cone 13 and the negative pressure cut-off mechanism 14 are matched with the two sides of the two sides respectively, and the scraper cone 13 directly faces the feed channel of the feed chamber 11 .

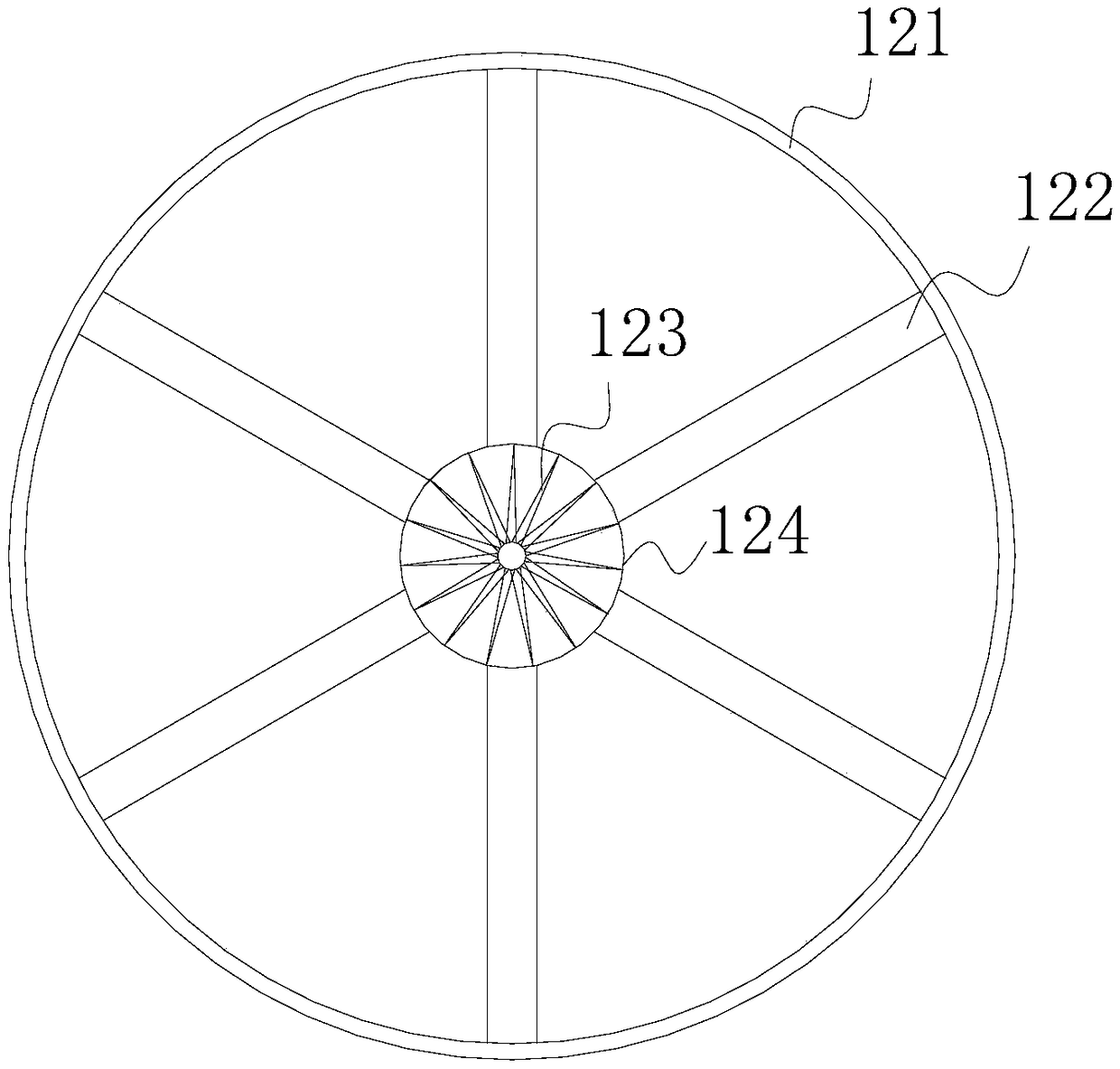

[0028] Such as image 3 As shown, the split disc 12 inc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap