Scale detecting method and liquid heating device

A technology of heating equipment and detection method, applied in the field of liquid heating, can solve problems such as untimely cleaning of scaling, achieve the effects of improving reliability and safety, solving untimely cleaning of scaling, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

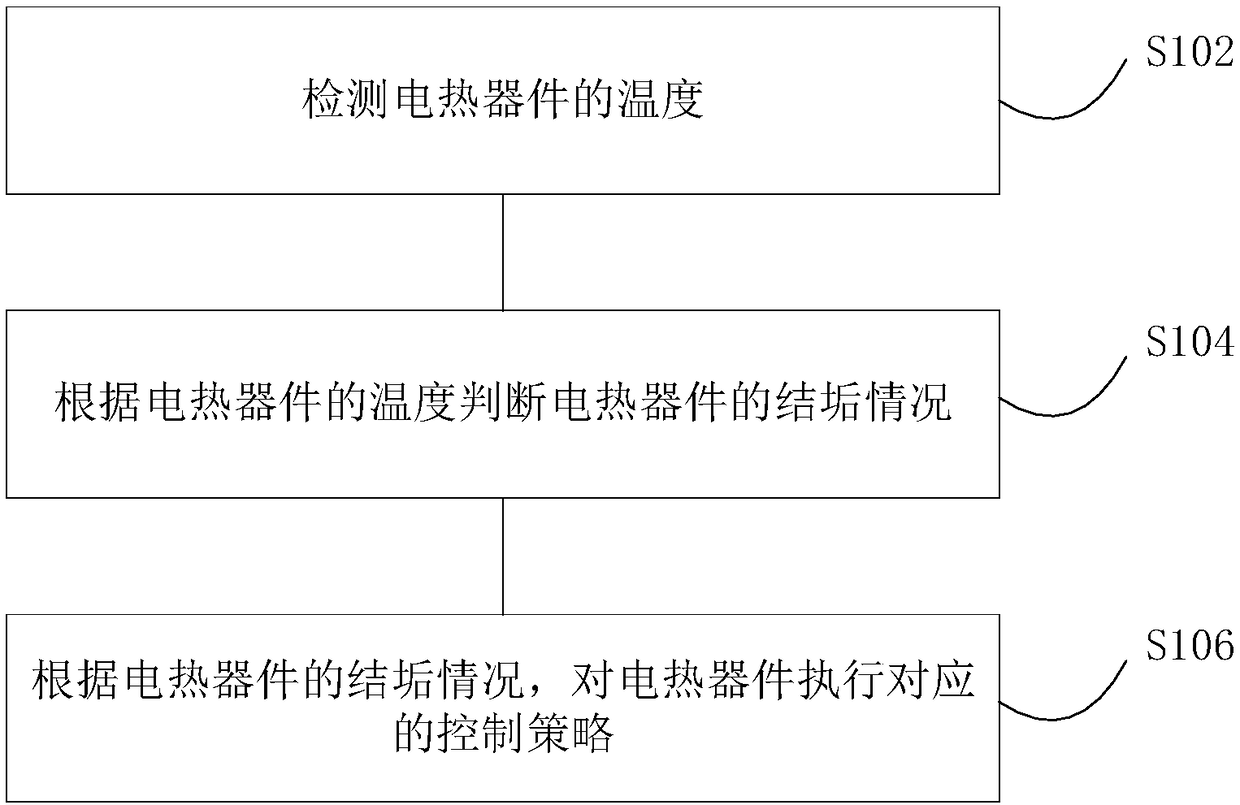

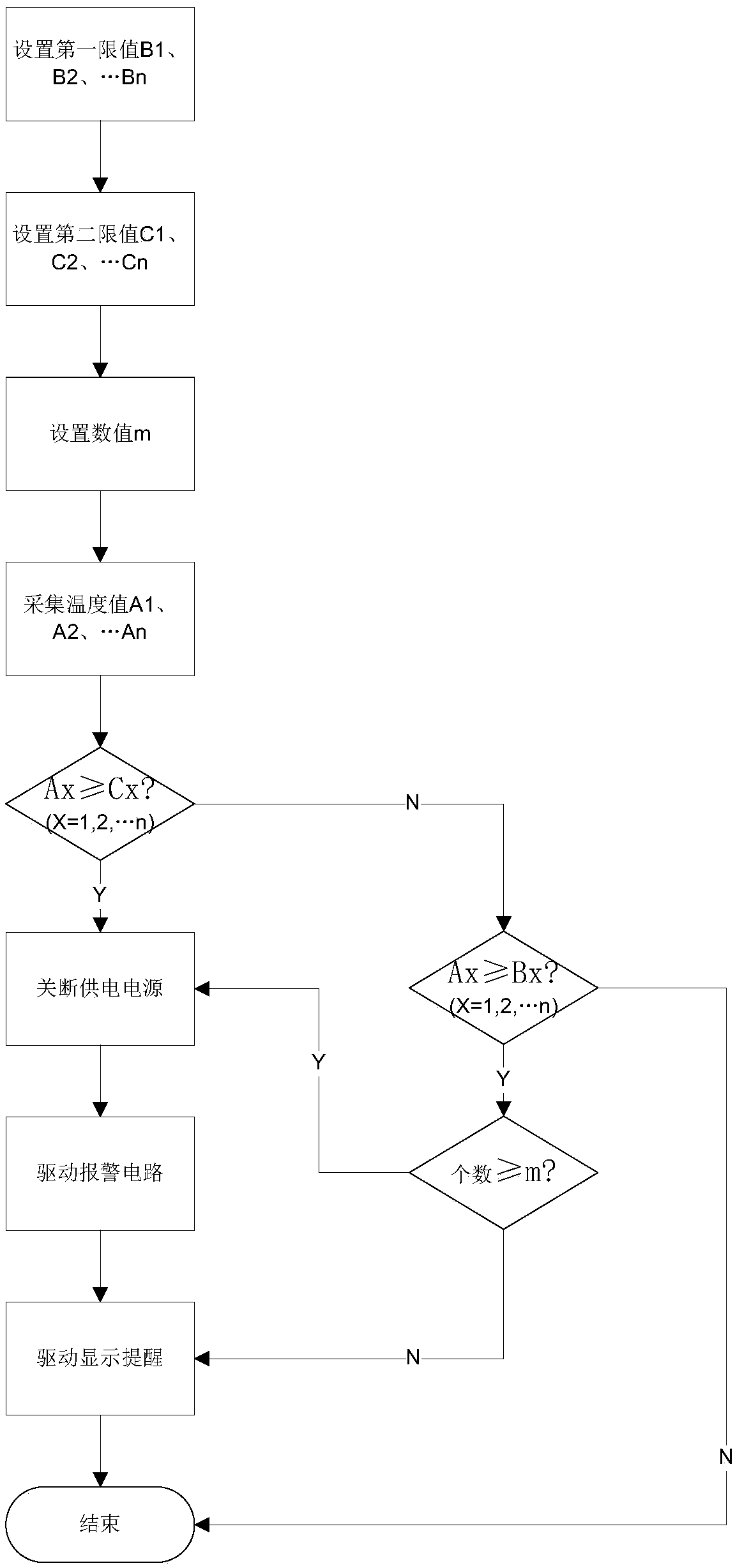

[0032] In the preferred embodiment 1 of the present invention, a scale detection method is provided, which can be directly applied to various liquid heating equipment, and can also be applied to other devices with some functions of liquid heating equipment. When it is specifically implemented, it can be It is realized by installing software, APP on the liquid heating equipment or other devices, or writing corresponding programs of the liquid heating equipment or other device controllers. Specifically, figure 1 An alternative flowchart showing the method, such as figure 1 As shown, the method includes the following steps S102-S106:

[0033] S102: Detect the temperature of the electrothermal device;

[0034] S104: judging the fouling condition of the electric heating device according to the temperature of the electric heating device;

[0035] S106: Execute a corresponding control strategy for the electrothermal device according to the fouling condition of the electrothermal d...

Embodiment 2

[0059] Based on the scale detection method provided in the above-mentioned embodiment 1, a liquid heating device is also provided in the preferred embodiment 2 of the present invention, specifically, Figure 4 shows an optional block diagram of the device, as Figure 4 As shown, the device includes:

[0060] Electric heaters for heating liquids;

[0061] The temperature acquisition module is used to detect the temperature of the electrothermal device;

[0062] The main control module is connected with the temperature acquisition module and the electric heating device, and is used for judging the scaling situation of the electric heating device according to the temperature of the electric heating device, and executing a corresponding control strategy for the electric heating device according to the scaling situation of the electric heating device.

[0063] In the above embodiment, according to the heating characteristics of the electric heating device itself and its temperatu...

Embodiment 3

[0070] Based on the scale detection method provided in the above-mentioned embodiment 1, a computer device is also provided in preferred embodiment 3 of the present invention, including a memory, a processor, and a computer program stored in the memory and operable on the processor, When the processor executes the program, the above scale detection method is realized.

[0071]In the above embodiment, according to the heating characteristics of the electric heating device itself and its temperature change trend, it is judged whether scale is generated on the surface of the electric heating device. . After determining the scaling situation of the electric heating device, according to the scaling situation of the electric heating device, implement the corresponding control strategy for the electric heating device, so as to avoid the potential safety hazard caused by the electric heating device working in an abnormal state, and effectively solve the problem of liquid heating. Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com