Ceramic thin plate-glass composite board hidden frame mounting system

A technology of ceramic thin plates and composite plates, which is applied to building components, walls, buildings, etc., can solve the problems of poor facade effect, uneven finish surface of facade wall panels, and inconvenient disassembly. Adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

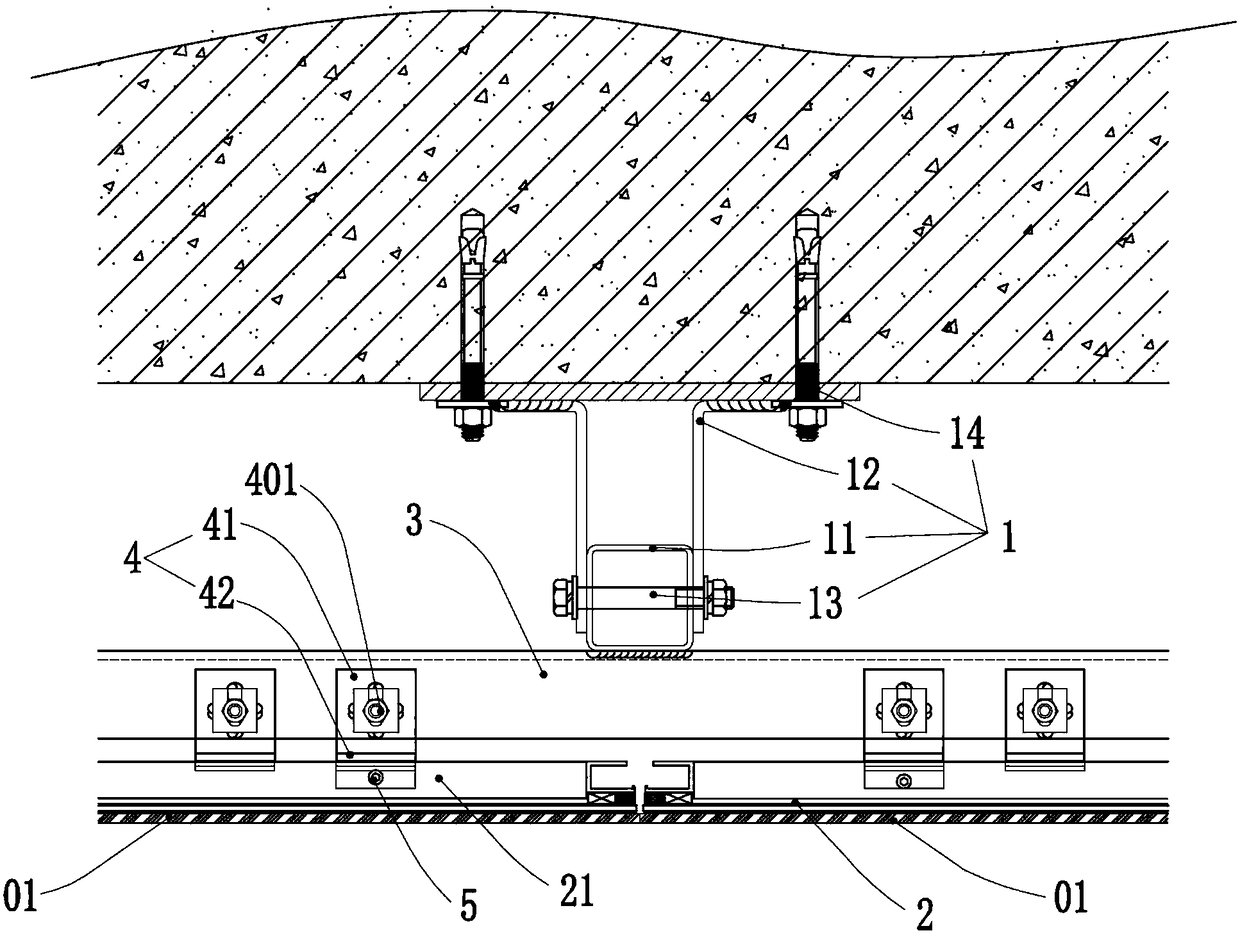

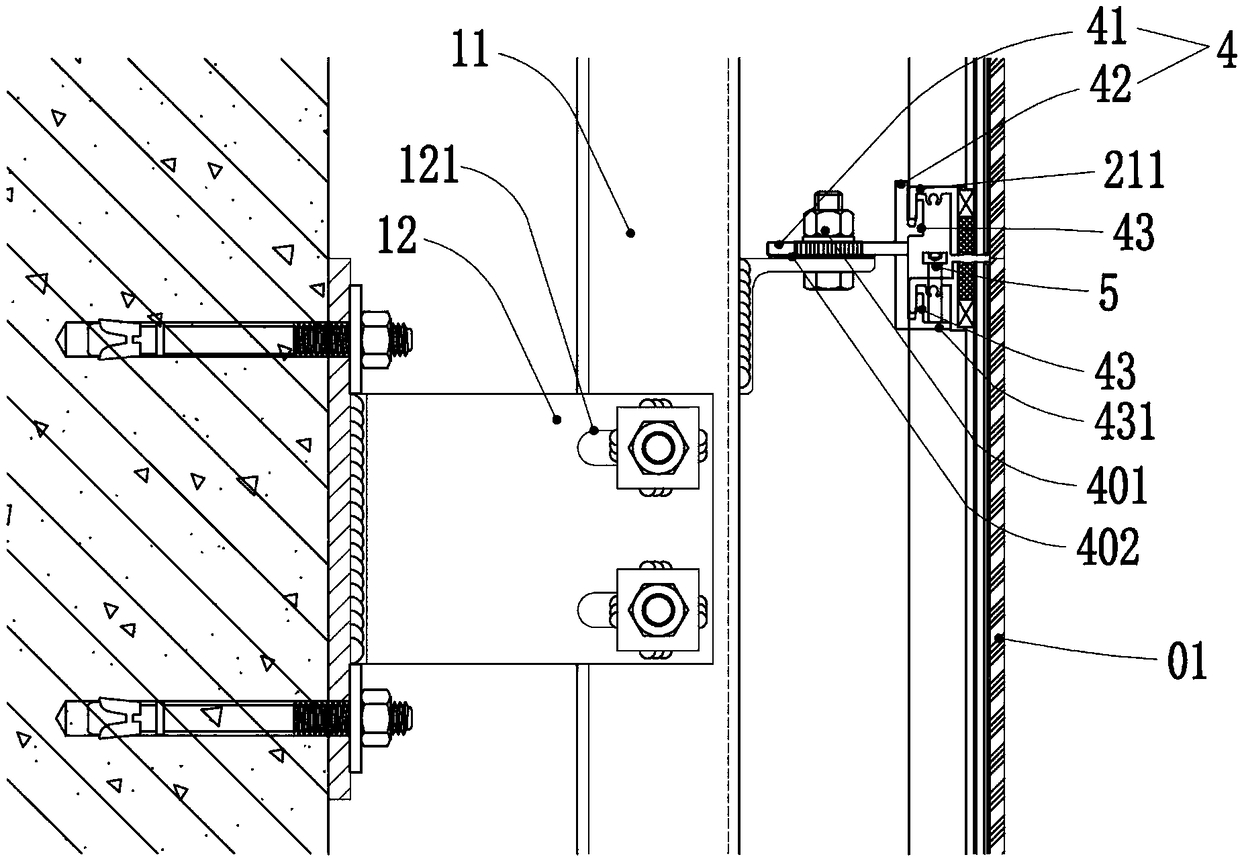

[0028] Such as figure 1 or figure 2 As shown, a ceramic sheet-glass composite panel hidden frame installation system includes a wall fixing assembly 1 and a back frame assembly 2 installed on the wall fixing assembly 1, and the back frame assembly 2 is glued with a ceramic sheet- The glass composite panel 01 also includes beams 3 and pendants 4;

[0029] The beam 3 is installed laterally on the column 11 of the wall fixing assembly 1;

[0030] The hanger 4 is a transverse T-shaped structure, its horizontal surface 41 is installed on the upper end surface of the beam 3 through a bolt assembly 401, and its outward vertical surface 42 is provided with an upwardly facing hook 43, and the hook 43 is set There are two, and the two hooks 43 are arranged up and down;

[0031] The back frame 21 of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com