Air compressor fault remote processing method and system based on internet of things

A technology of remote processing and air compressors, which is applied in the direction of mechanical equipment, machines/engines, liquid variable capacity machinery, etc., which can solve the problems of user loss, inability to understand the operation status of air compressors anytime and anywhere, and maintenance failures. , to achieve the effect of preventing sudden failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

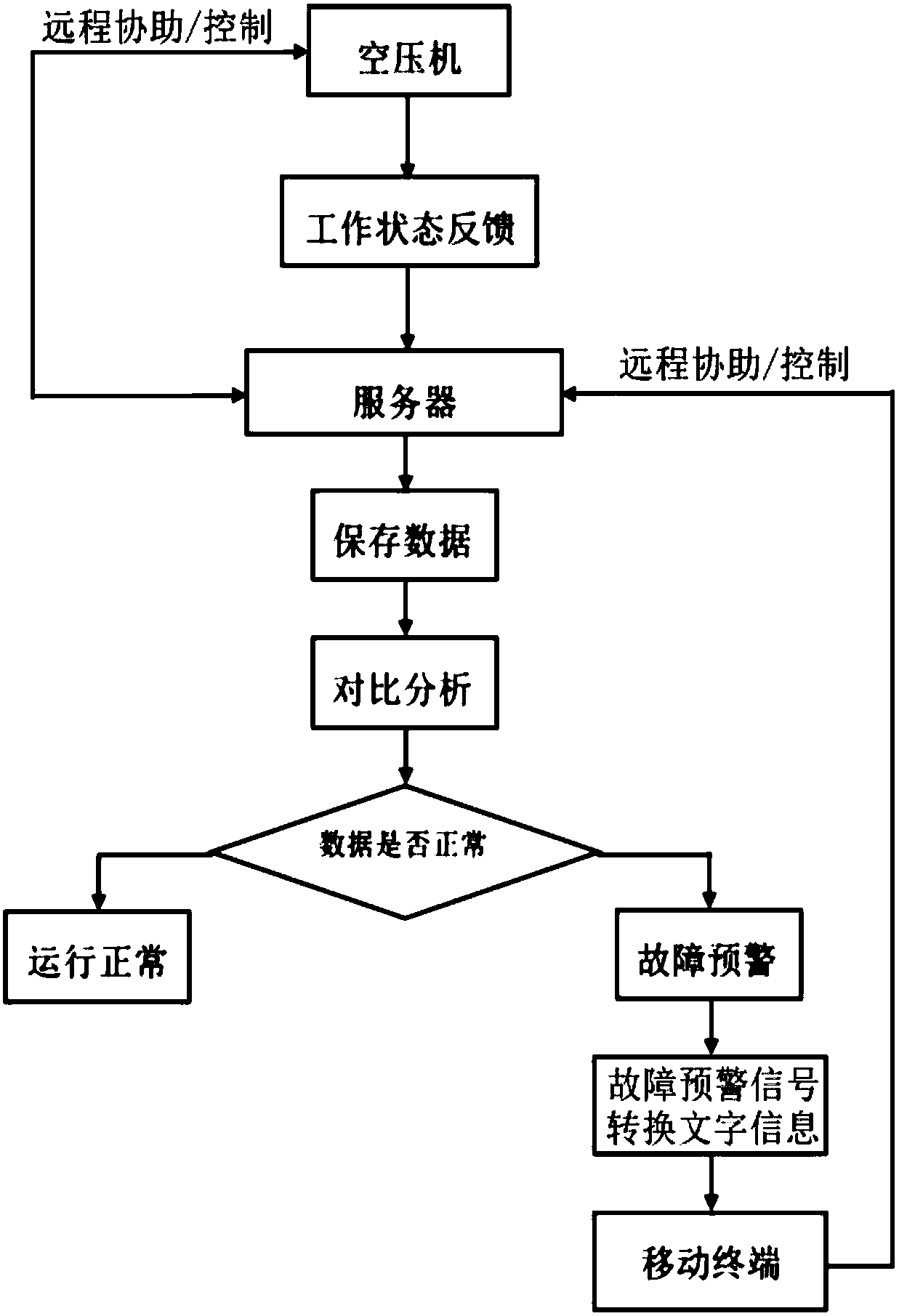

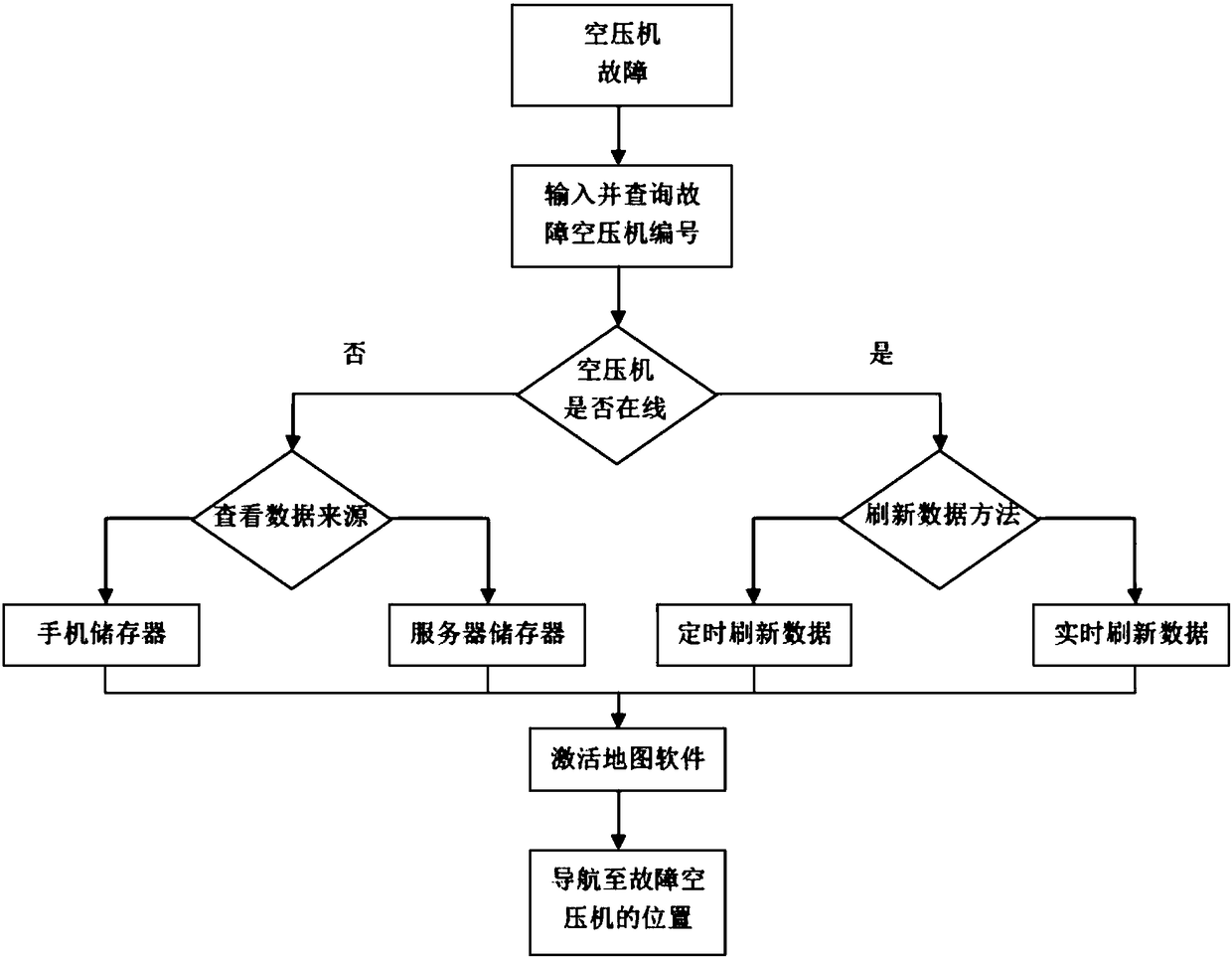

[0034] Such as Figure 1-2 As shown, a remote processing method for air compressor faults based on the Internet of Things includes the following steps:

[0035] A. The air compressor feeds back the working status to the server;

[0036] B. The server saves the data fed back by the air compressor and compares it with the preset safety value in the server;

[0037] C. If the comparison result of the server exceeds the preset safety value, a failure warning signal is generated. The failure warning signal is a pre-designed alarm code, and the alarm code is used for storage records; after that, the alarm code is converted from the server to the text alarm information corresponding to the code;

[0038] D. If the server comparison result exceeds the preset safety value, a text alarm message will be sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com