Method for measuring partial discharge of joint with insulation defect

A technology of partial discharge and measurement method, which is applied in the direction of testing dielectric strength, etc., can solve the problems of decision-making uncertainty in cable equipment maintenance and replacement, and can not give the type of insulation defect of partial discharge discharge, etc., so as to improve the reliability of power supply , the effect of preventing sudden failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific examples.

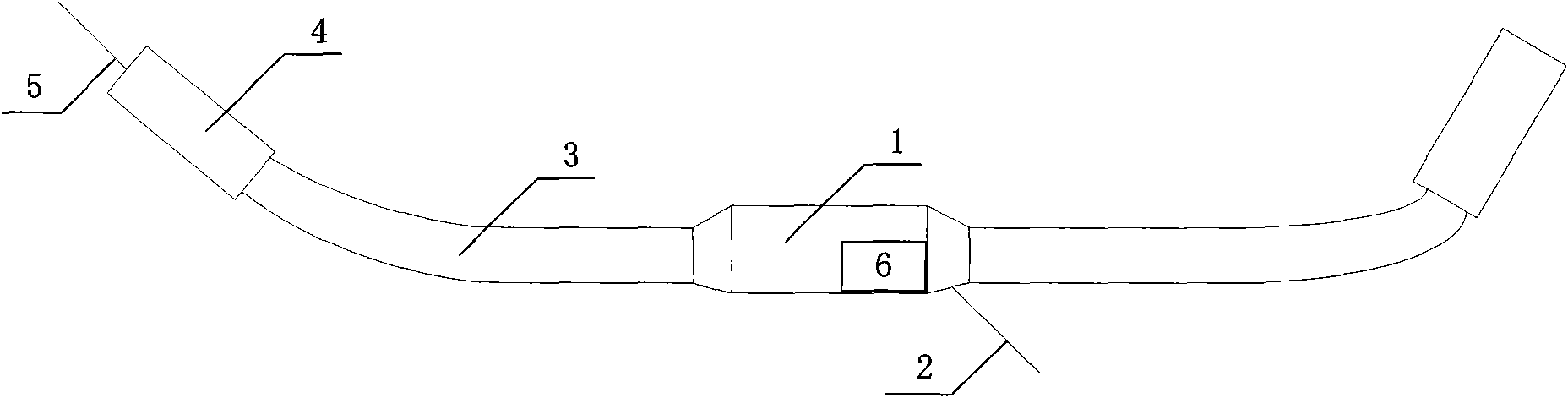

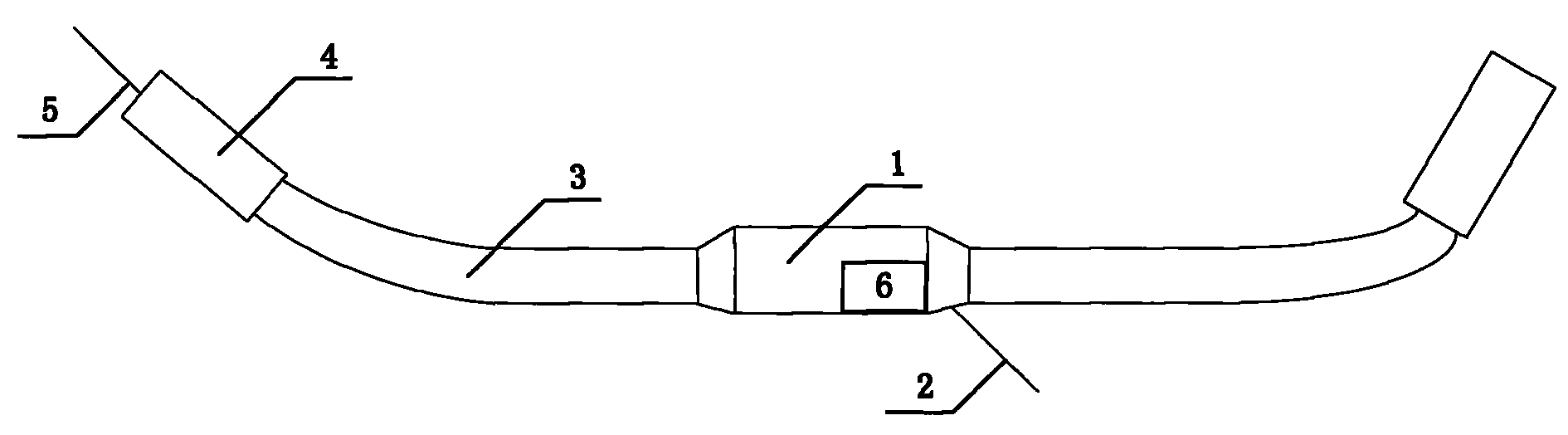

[0016] Such as figure 1 As shown, a partial discharge measurement method for an insulation defect joint, the method hardware includes a joint 1 with an insulation defect, a signal lead line 2, a water pipe 3, a water terminal device 4, a power frequency high voltage interface 5, and a signal sensor 6, including the following Steps to realize: 1) Connect the two ends of the joint 1 with insulation defect to the water pipe 3, and set the water terminal equipment 4 at the end of the water pipe 3; 2) Set the signal lead-out line 2 on the joint 1 with the insulation defect; 3) In the Power frequency high voltage is applied to the water terminal equipment 4 on both sides, and the signal sensor 6 collects the partial discharge signal; 4) The partial discharge signal is output through the signal lead-out line 2 . The signal sensor 6 is installed in the middle joint of the joint 1 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com