Automatic production device for cakes

An automatic production and cake technology, applied in application, baking, dough cutting machinery, etc., can solve the problems of single cake ingredients and flavors, falling on the tray, inconvenient feeding of paper trays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

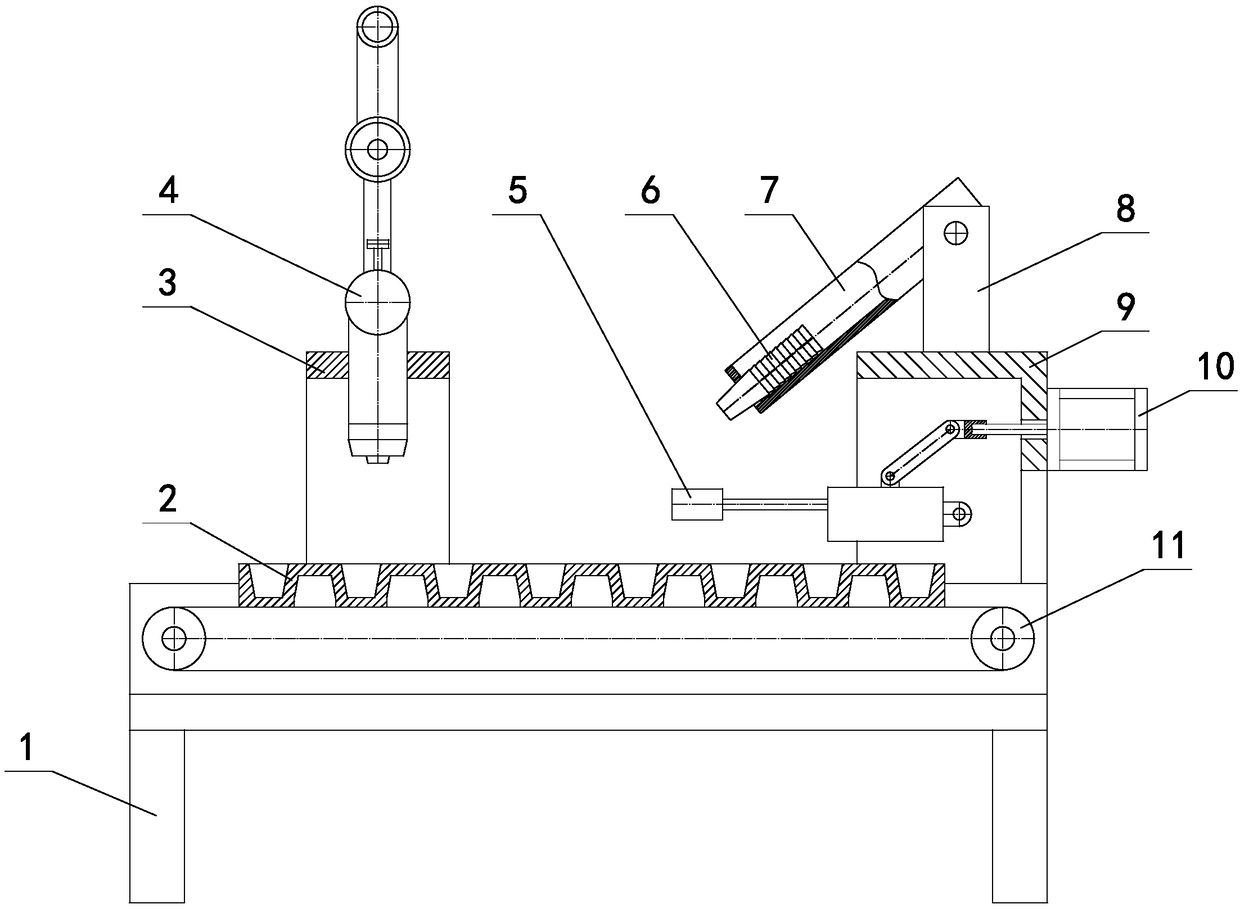

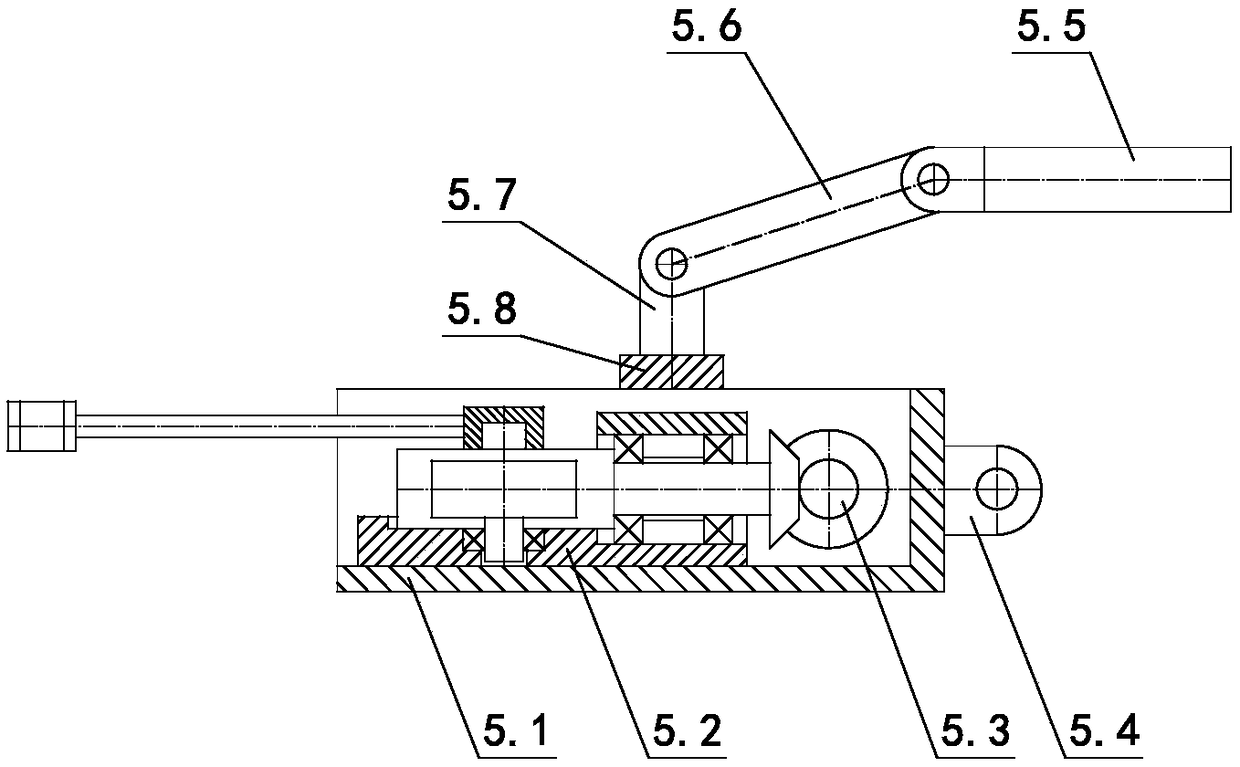

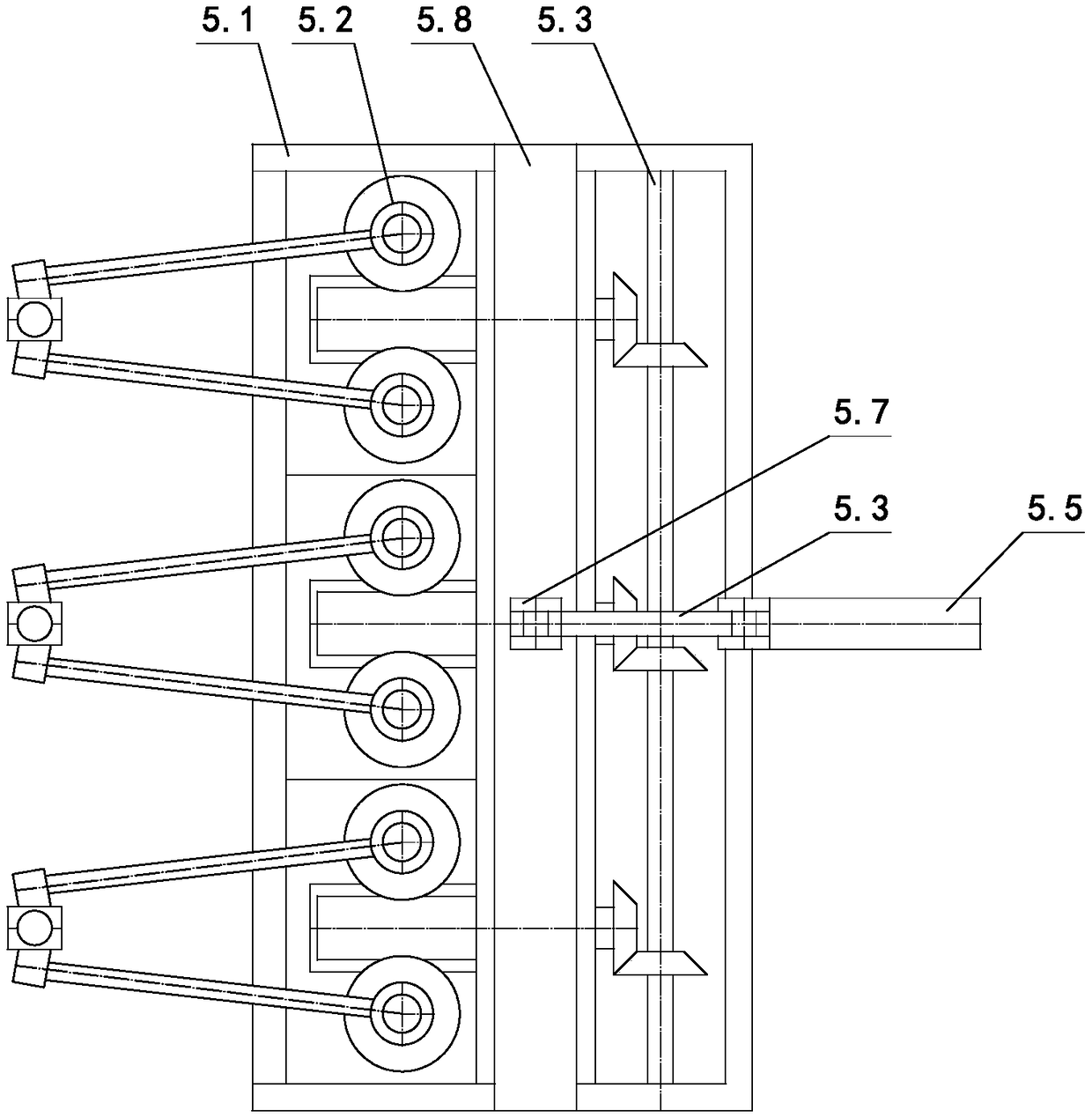

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, the described automatic production device for cakes includes a vertically arranged workbench 1, a conveyer belt 11 is horizontally arranged on the workbench 1, and a tray 2 is horizontally arranged on the conveyer belt 11. A first support 9 is arranged vertically, and a mounting plate 8 is vertically arranged on the first support 9, and a paper bracket 7 is installed on the mounting plate 8, and a paper bracket 6 is placed in the paper bracket 7, and the paper bracket 6 The bottom protrudes from the lower end of the paper bracket 7, and a paper bracket grabbing mechanism 5 is horizontally arranged below the first bracket 9. The paper tray grabbing mechanism 5 includes a horizontally arranged installation box 5.1, and a horizontally installed box 5.1 is installed in the installation box 5.1. Several automatic clamping mechanisms 5.2 arranged side by side, the automatic clamping mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com