Patents

Literature

33results about How to "For automatic clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

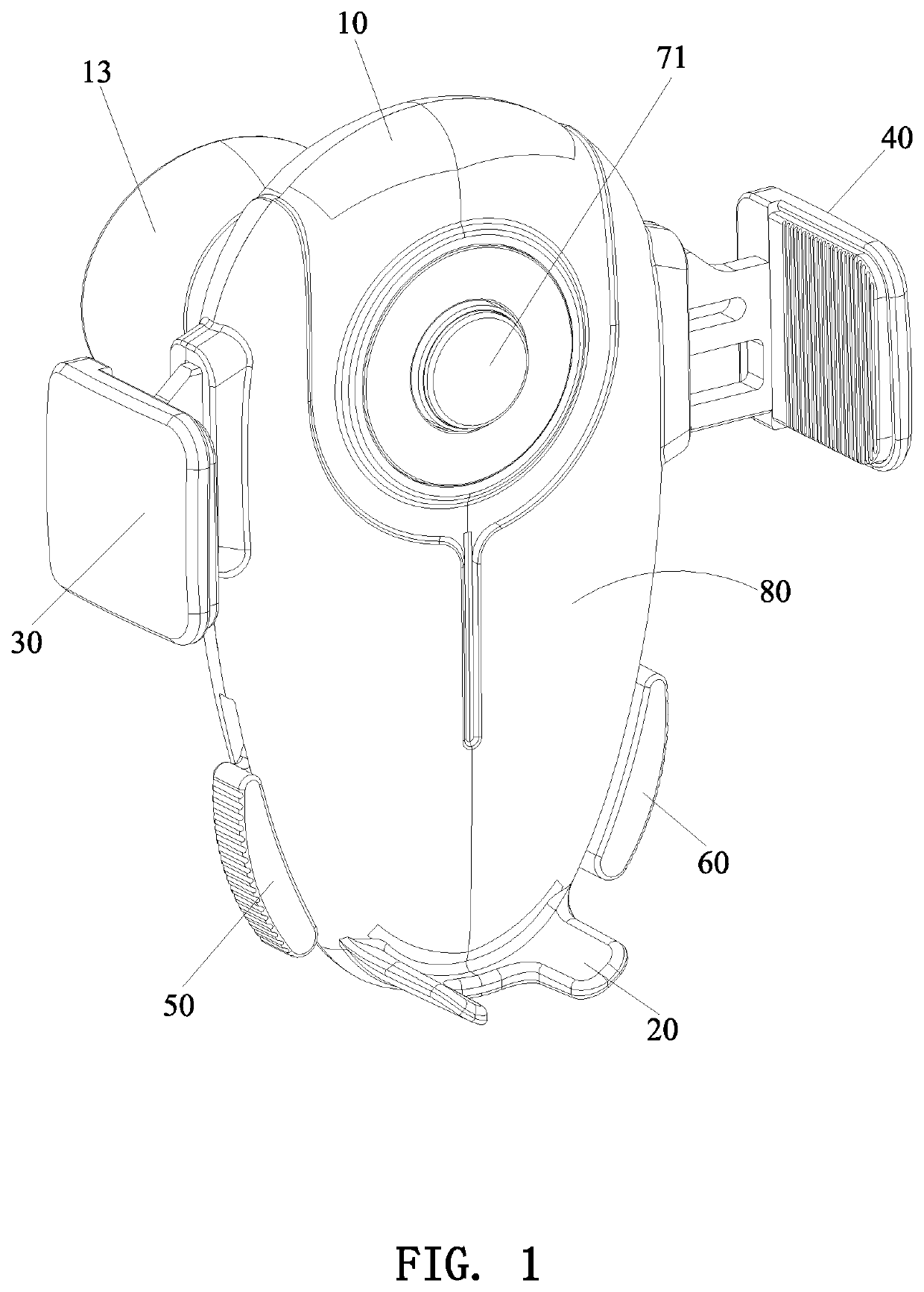

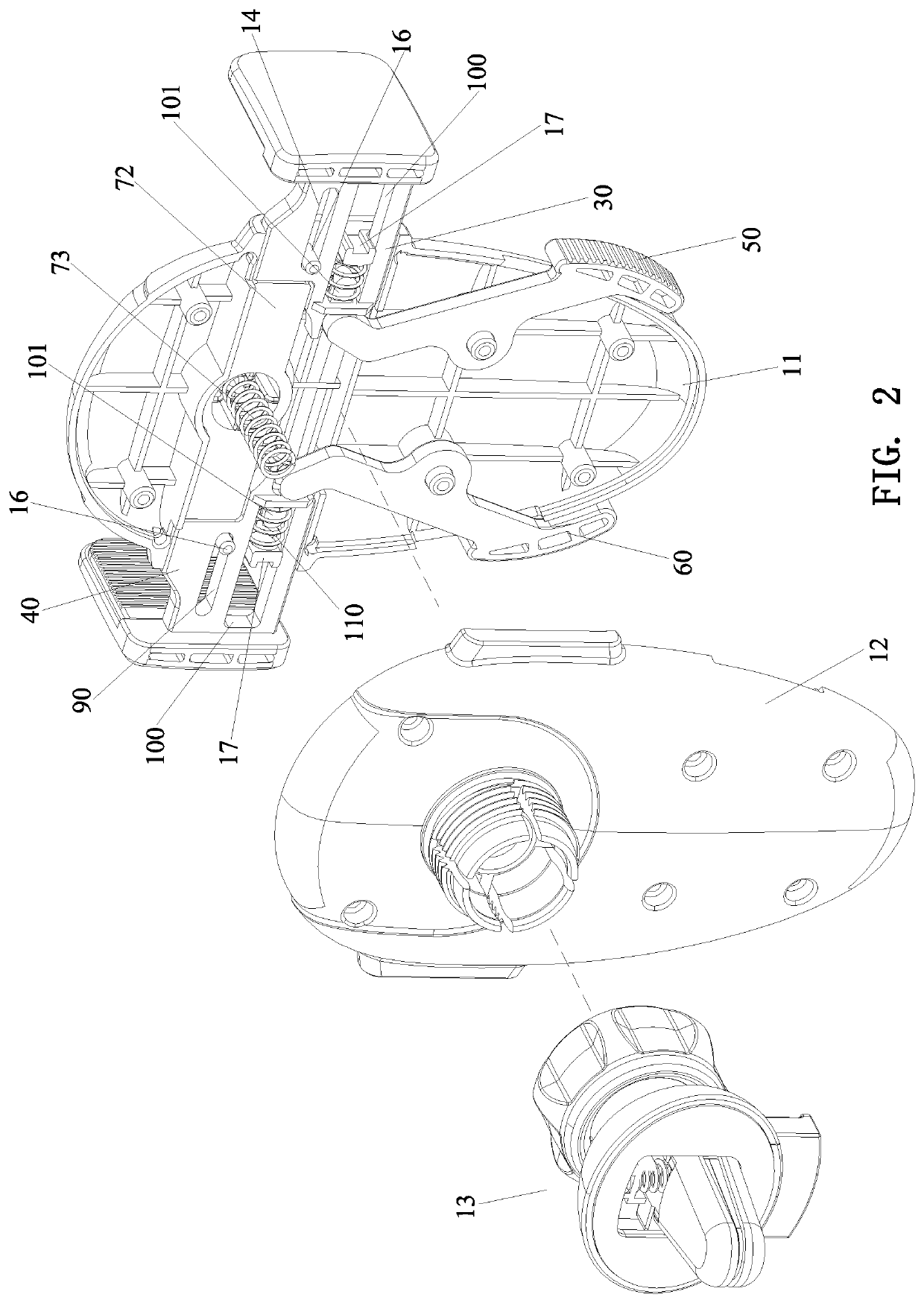

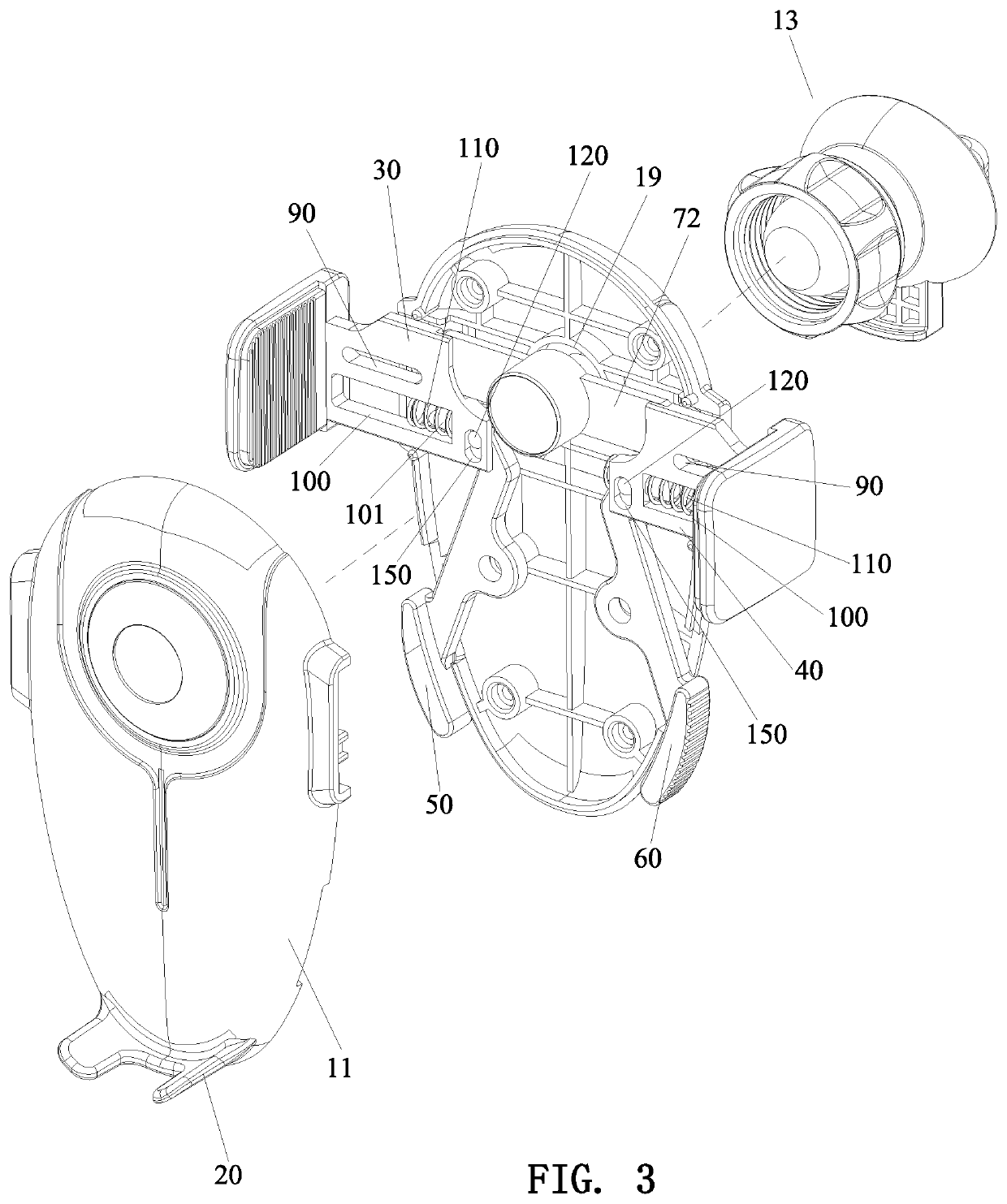

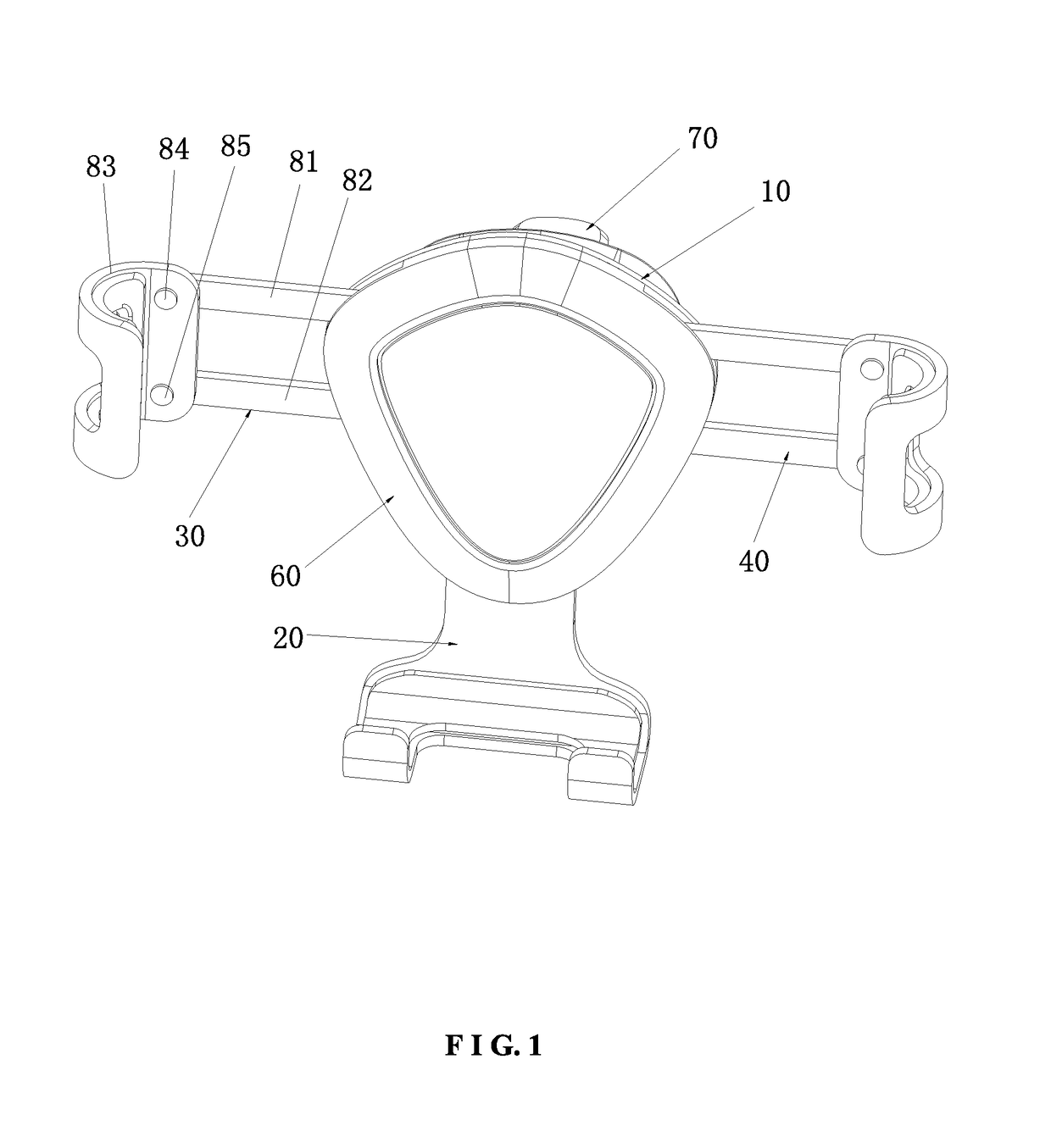

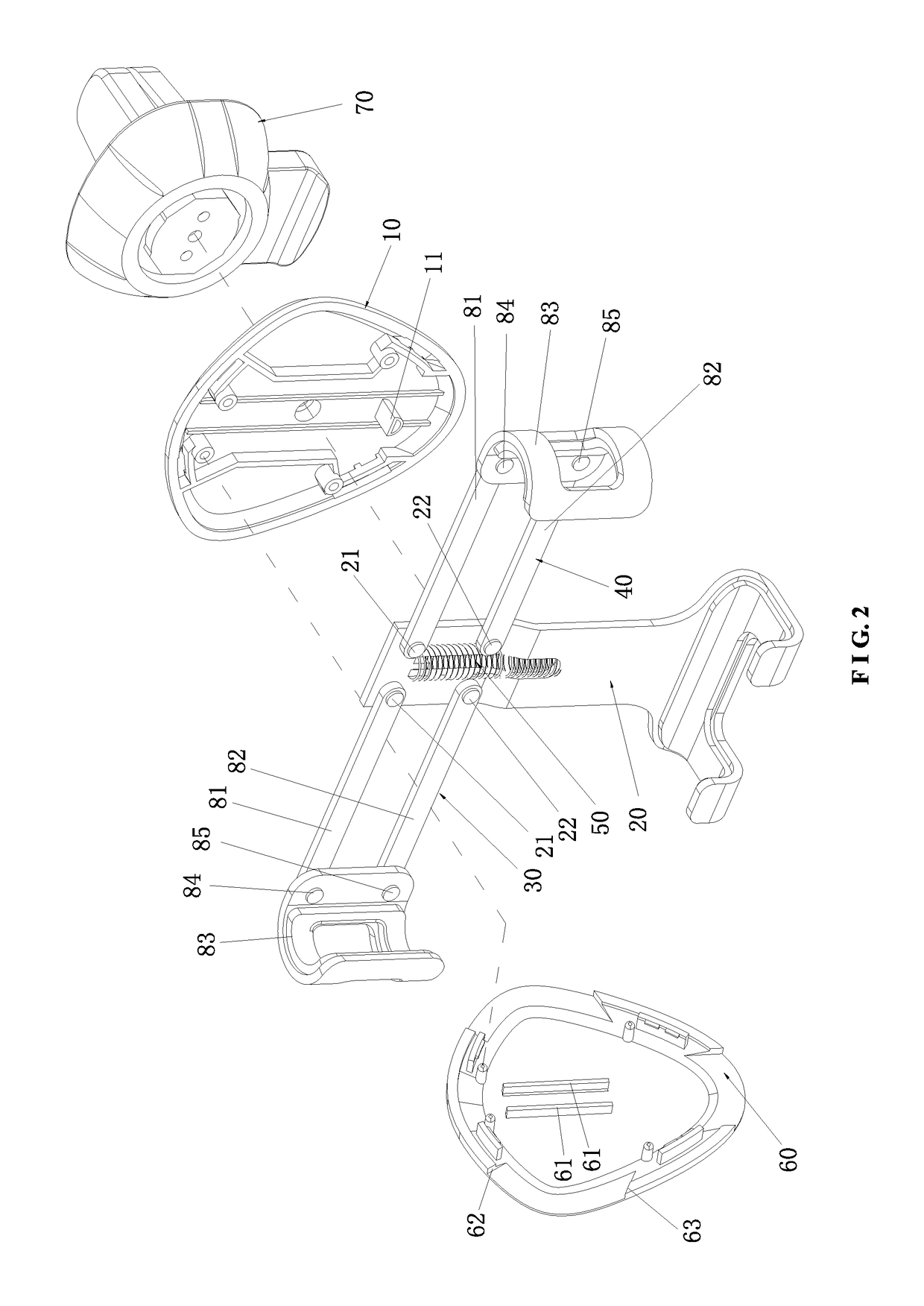

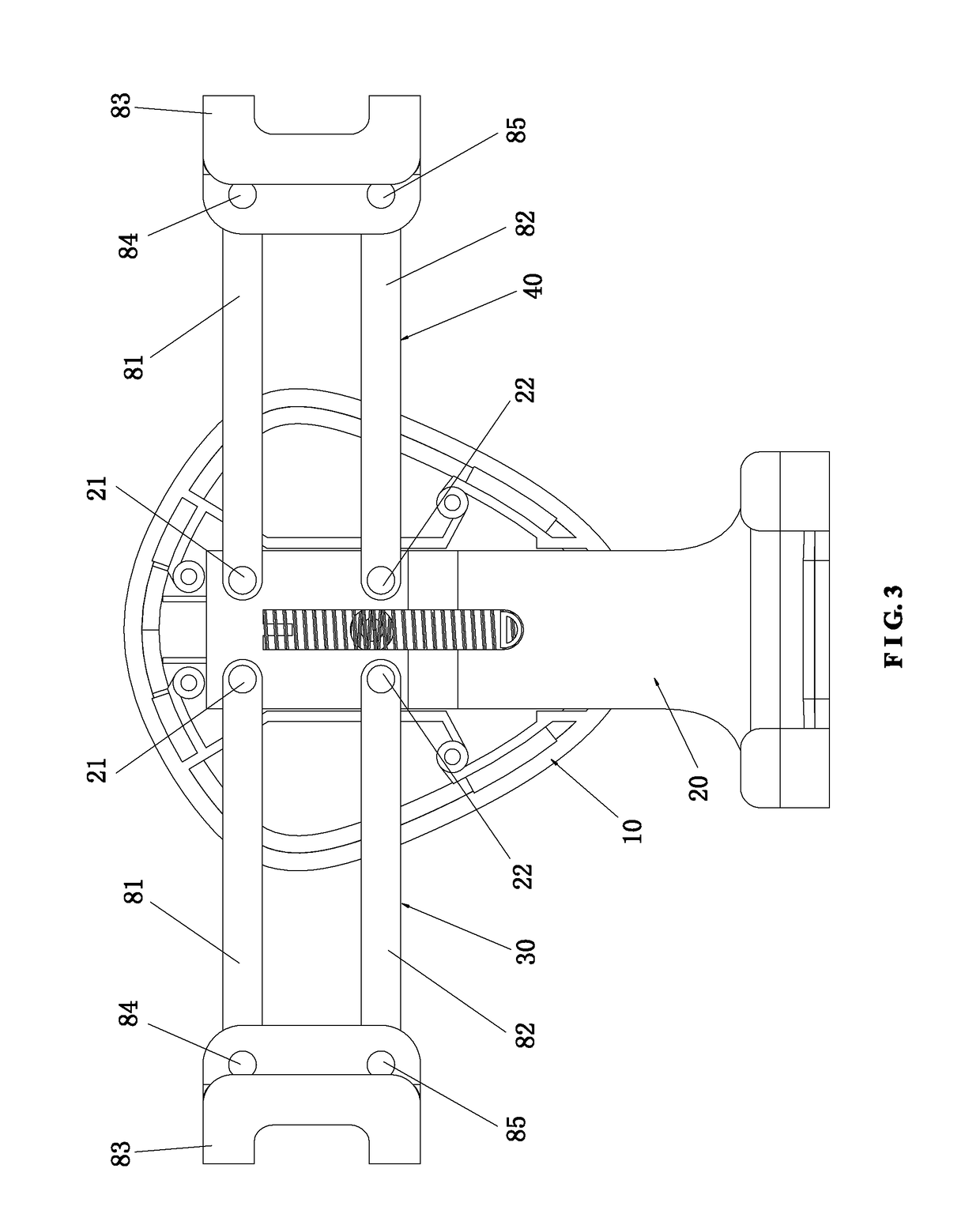

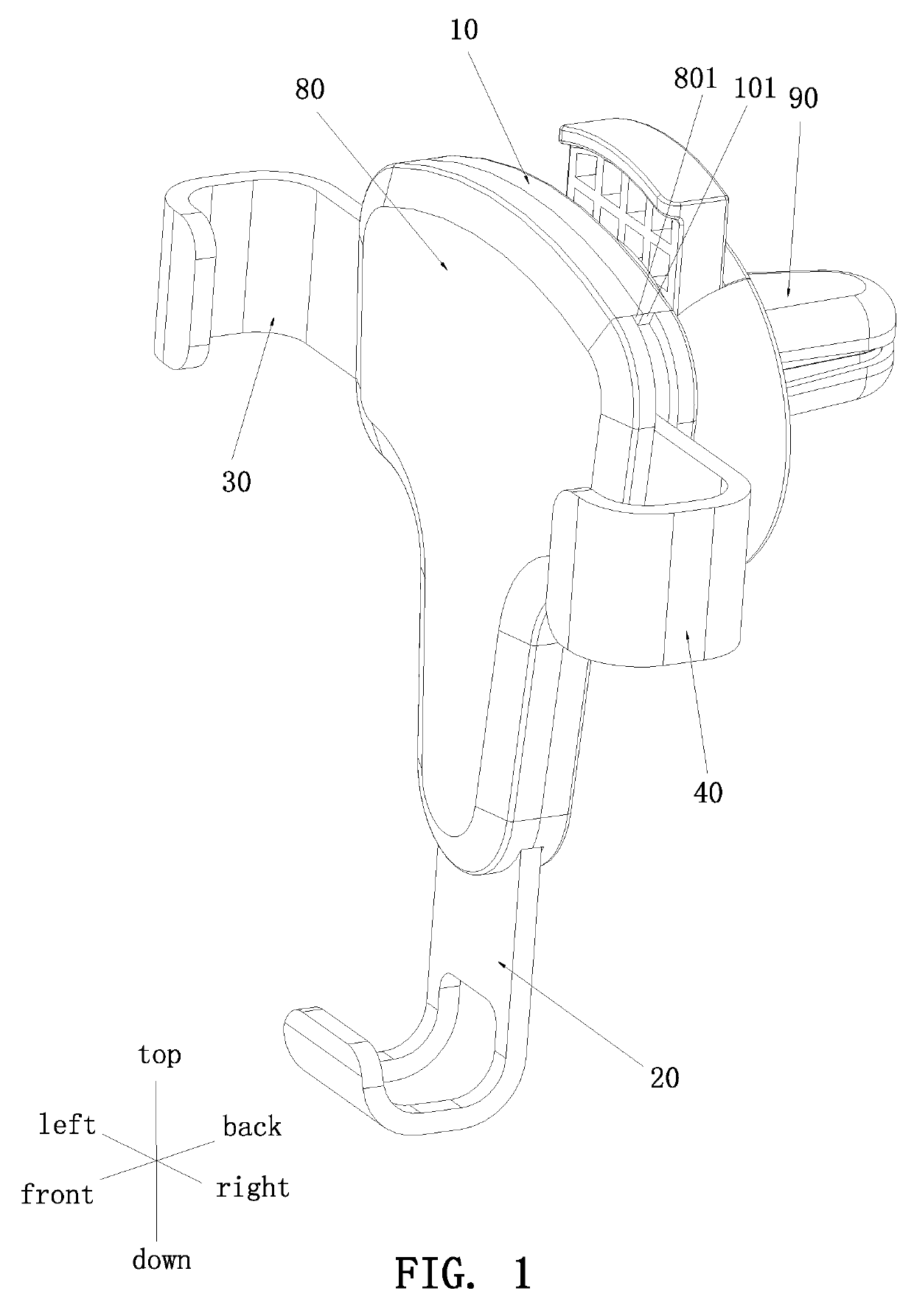

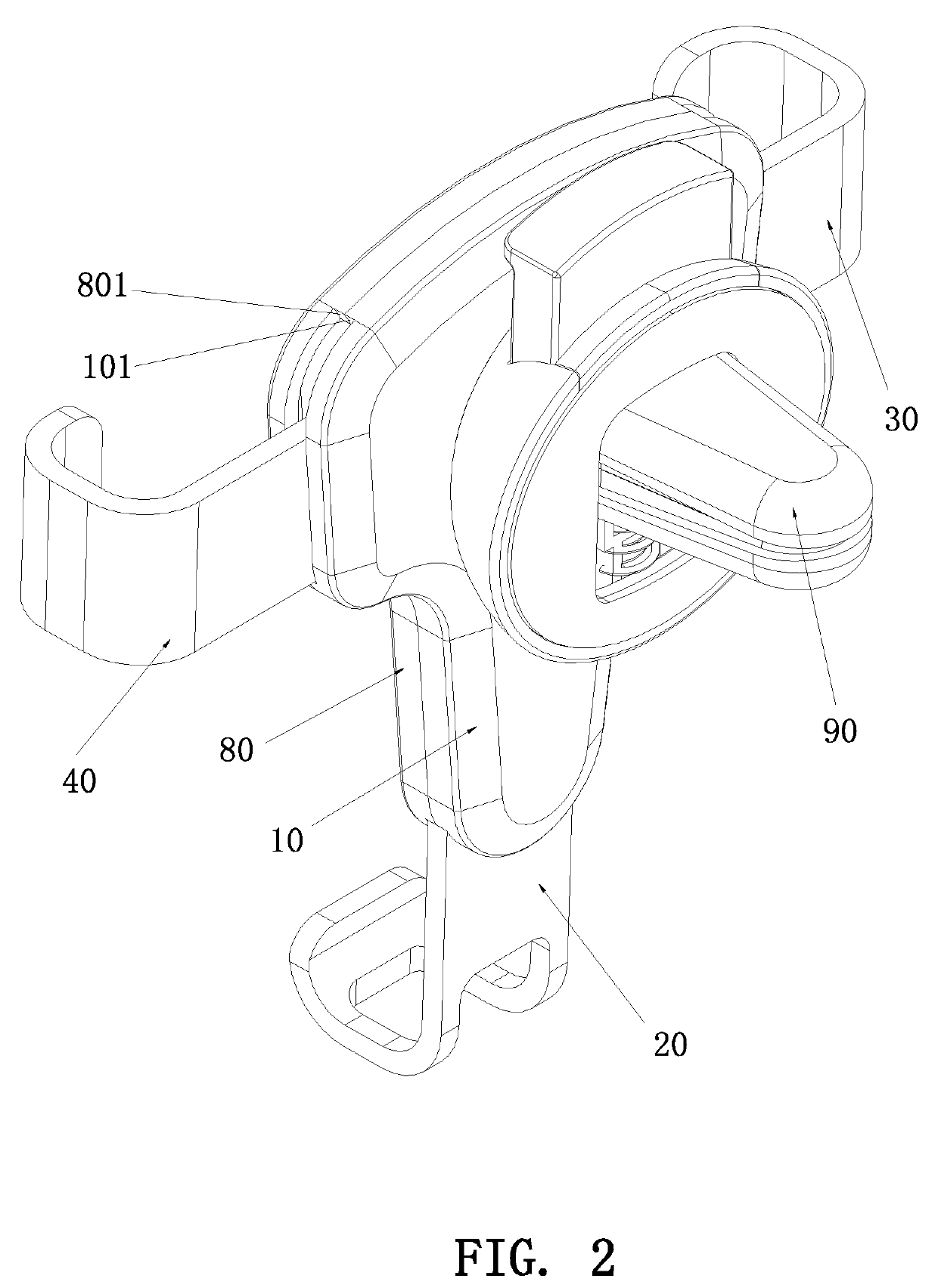

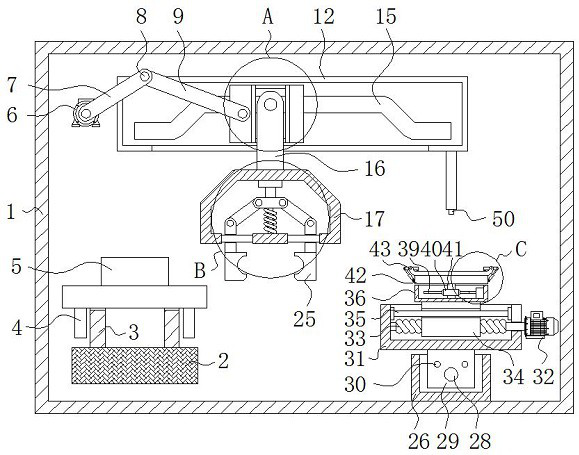

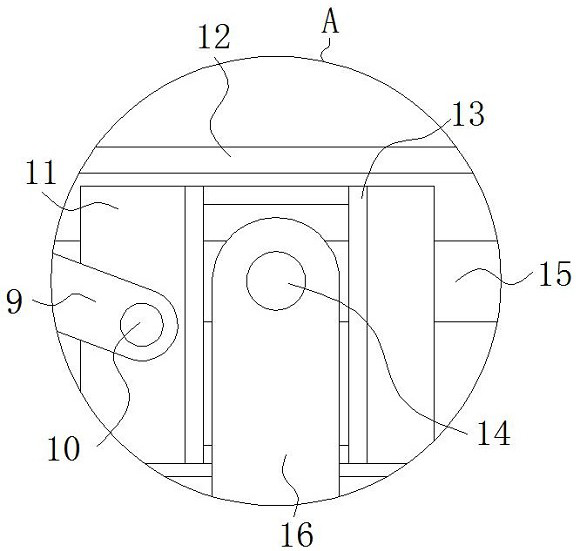

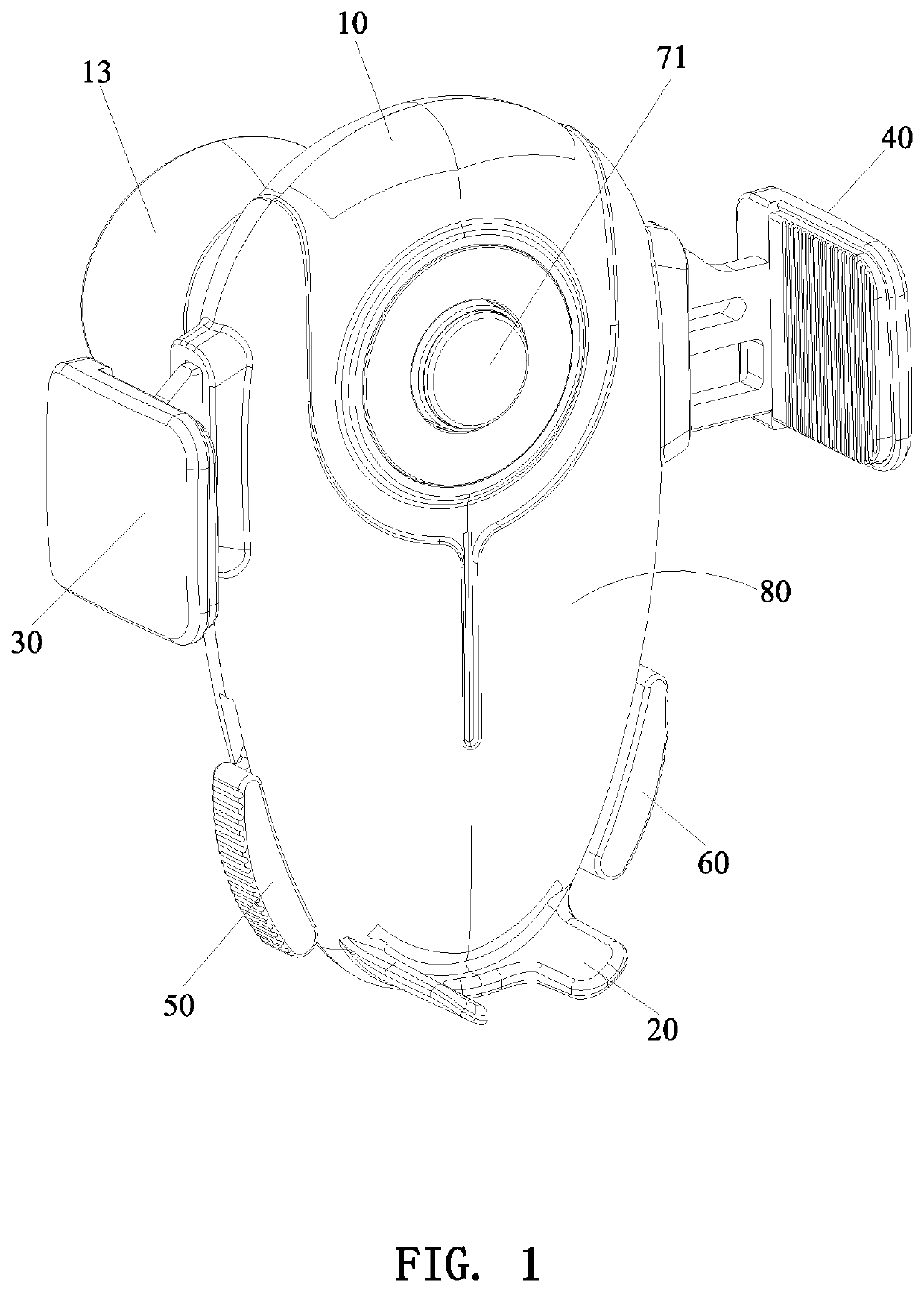

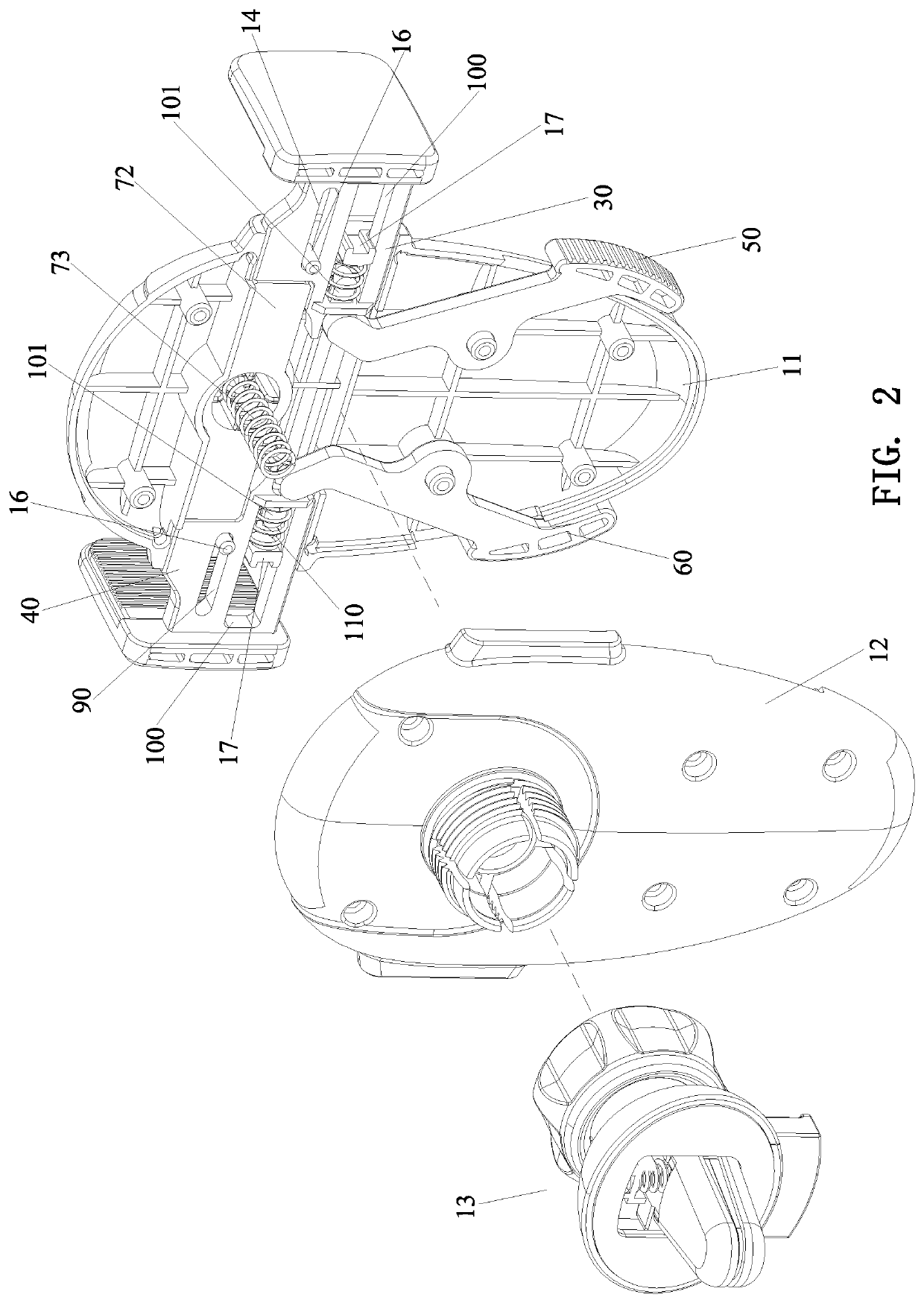

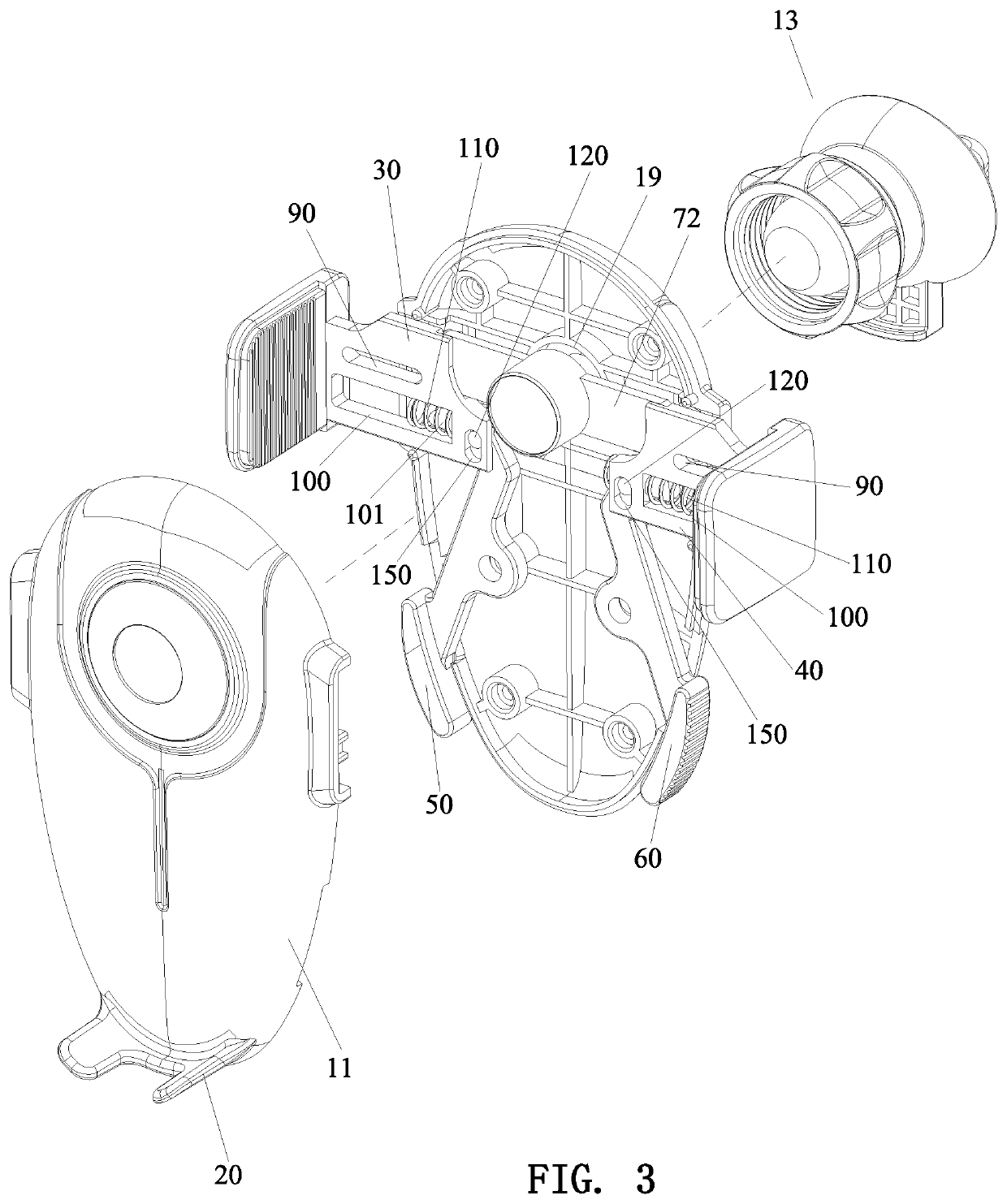

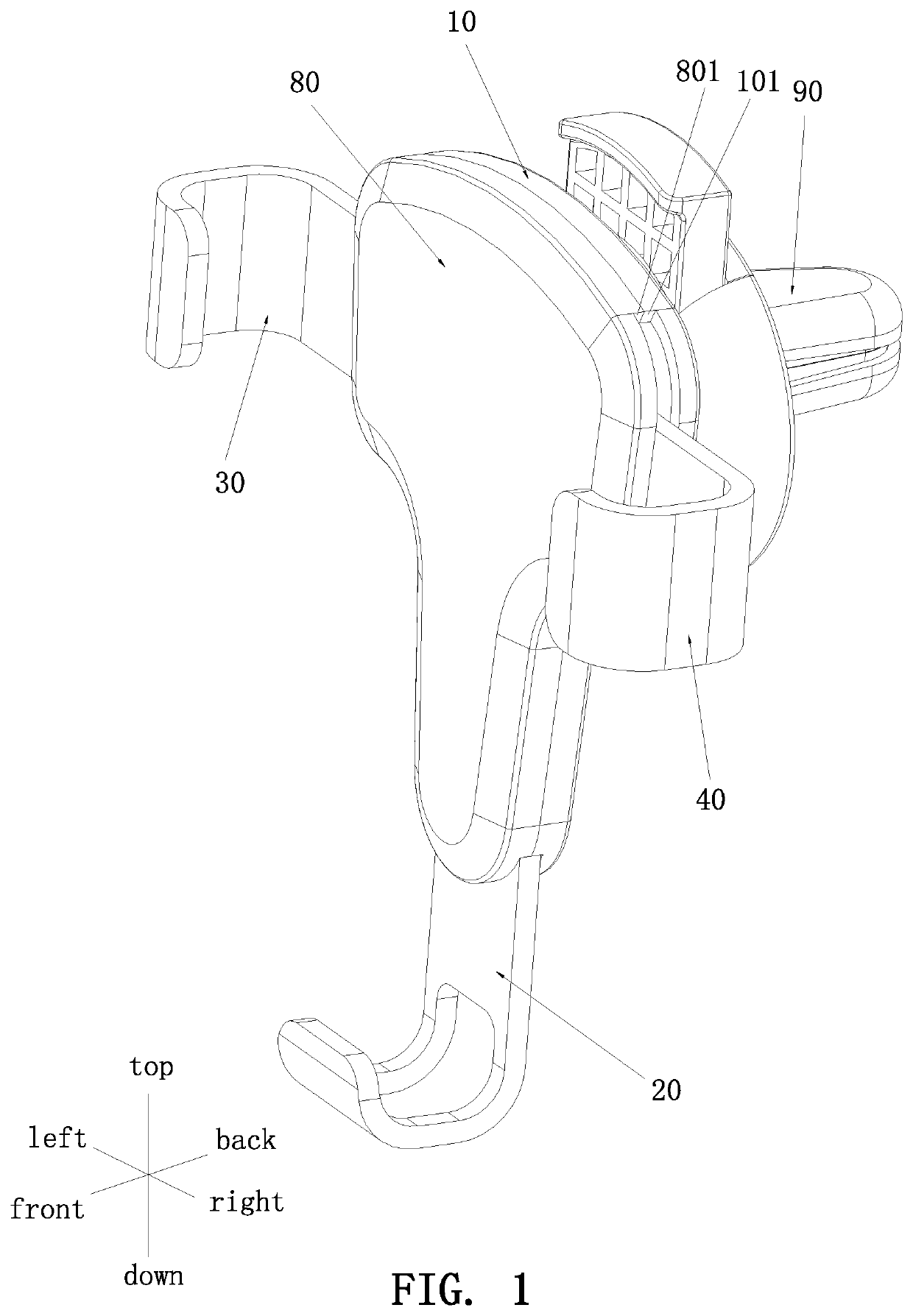

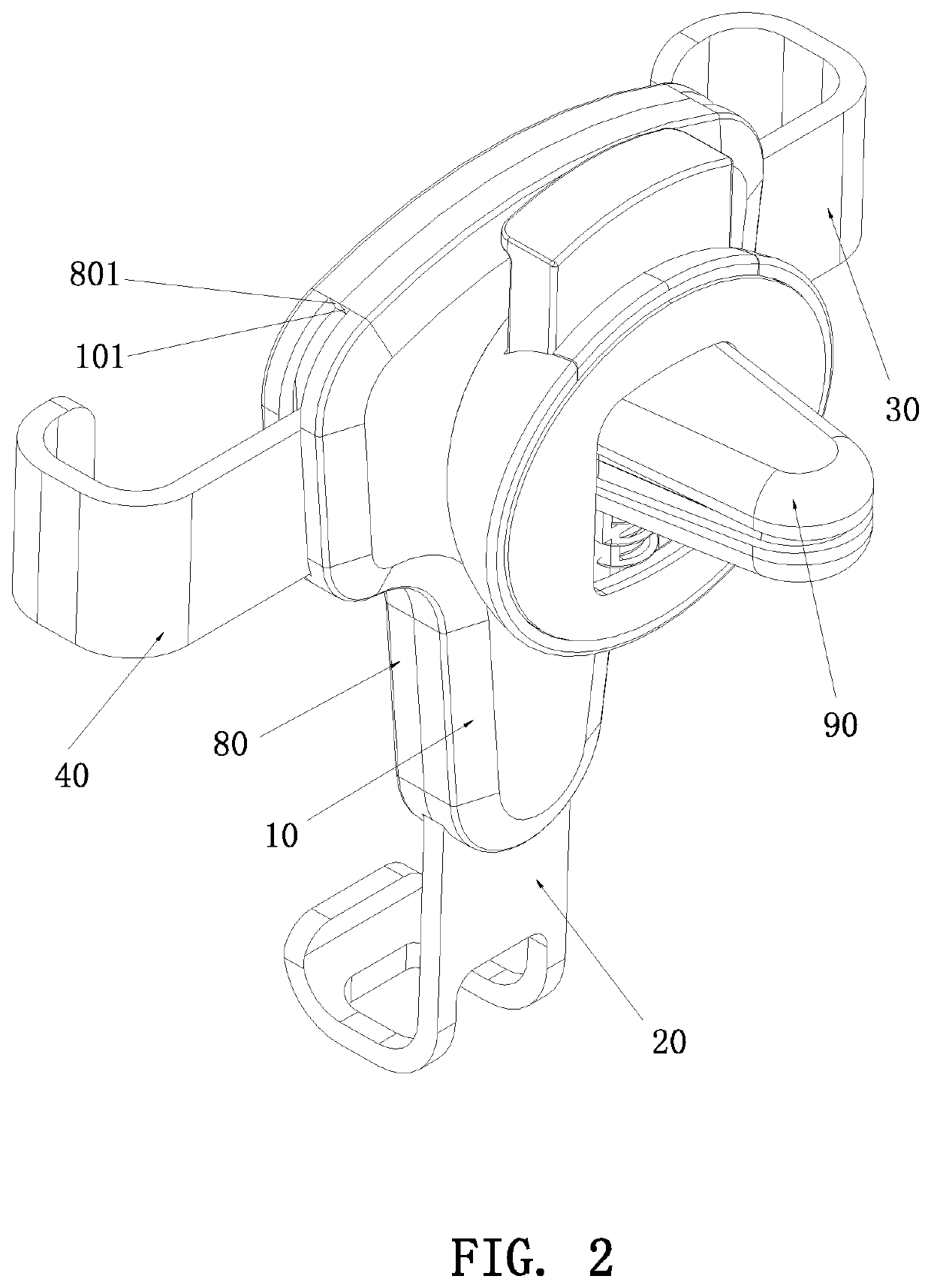

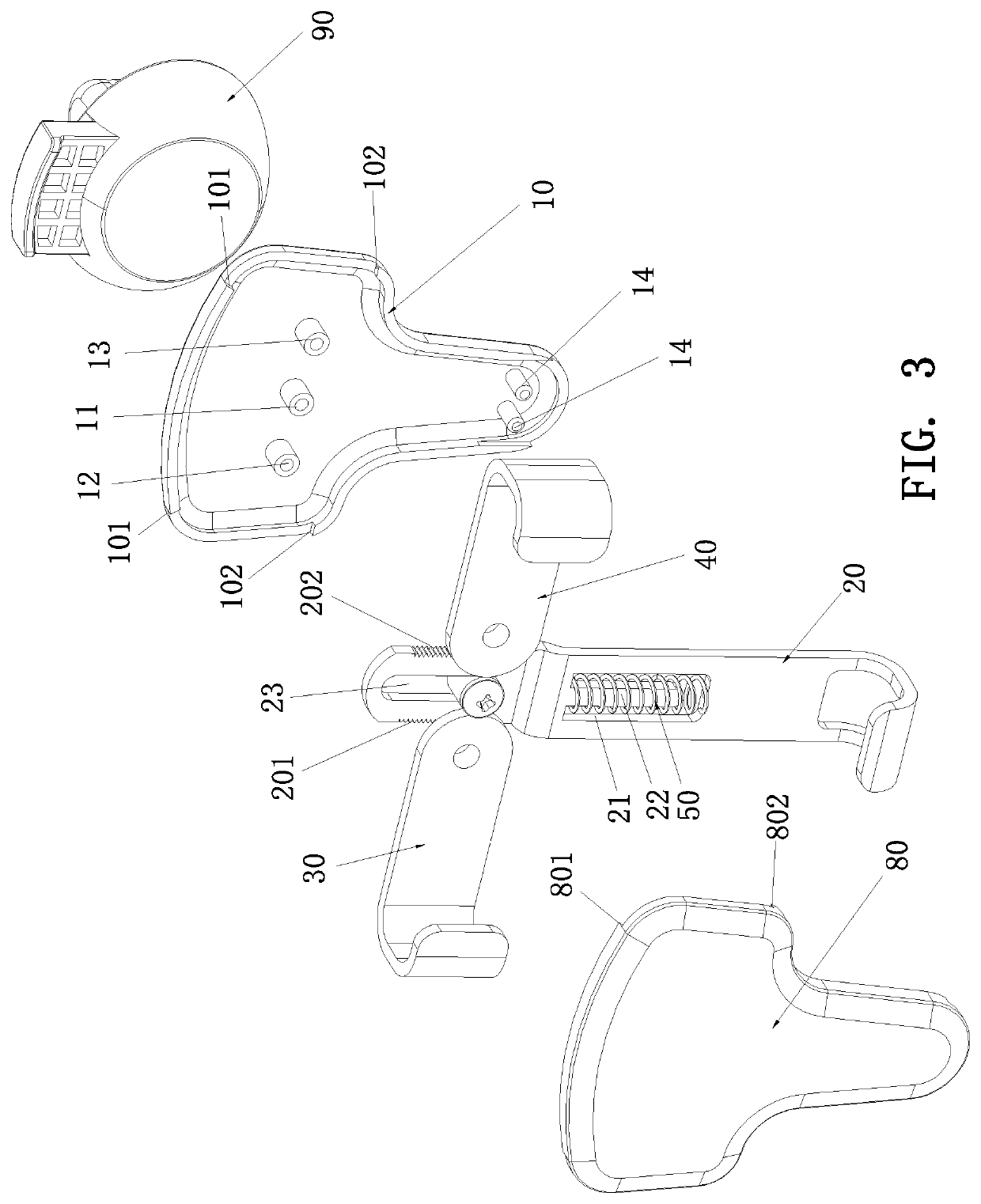

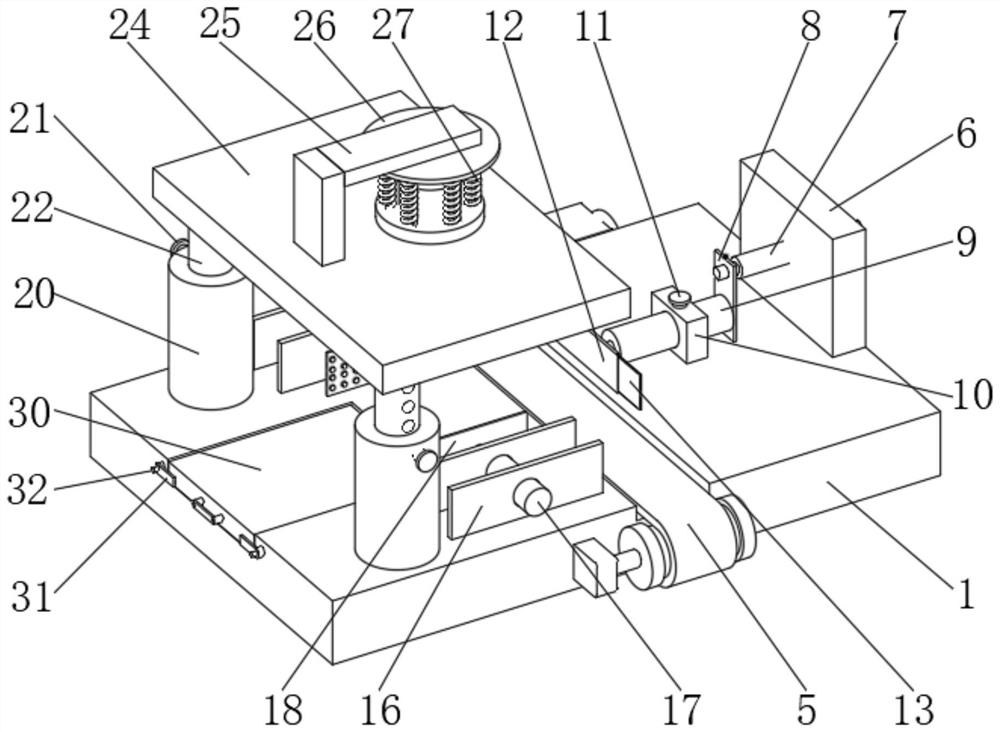

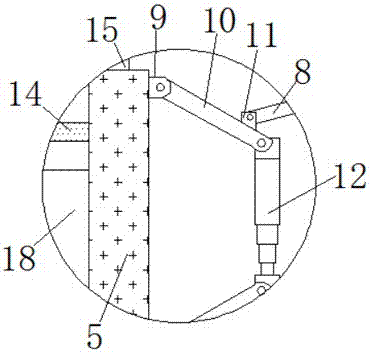

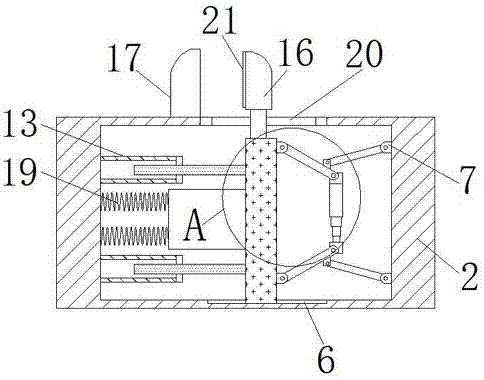

Automatic clamping holder for mobile device

ActiveUS20200191178A1Operation is quick and flexibleGood effectCasings/cabinets/drawers detailsFriction grip releasable fasteningsPinch gripEngineering

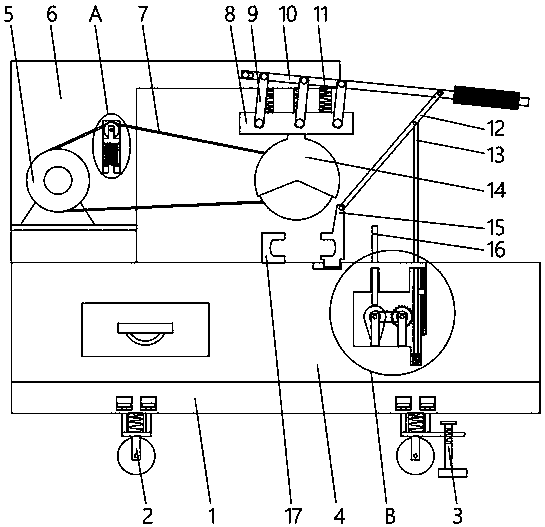

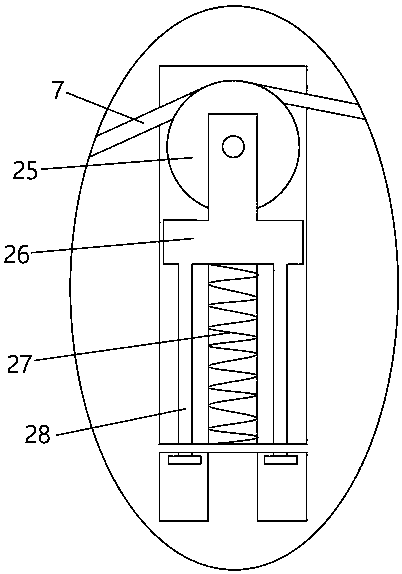

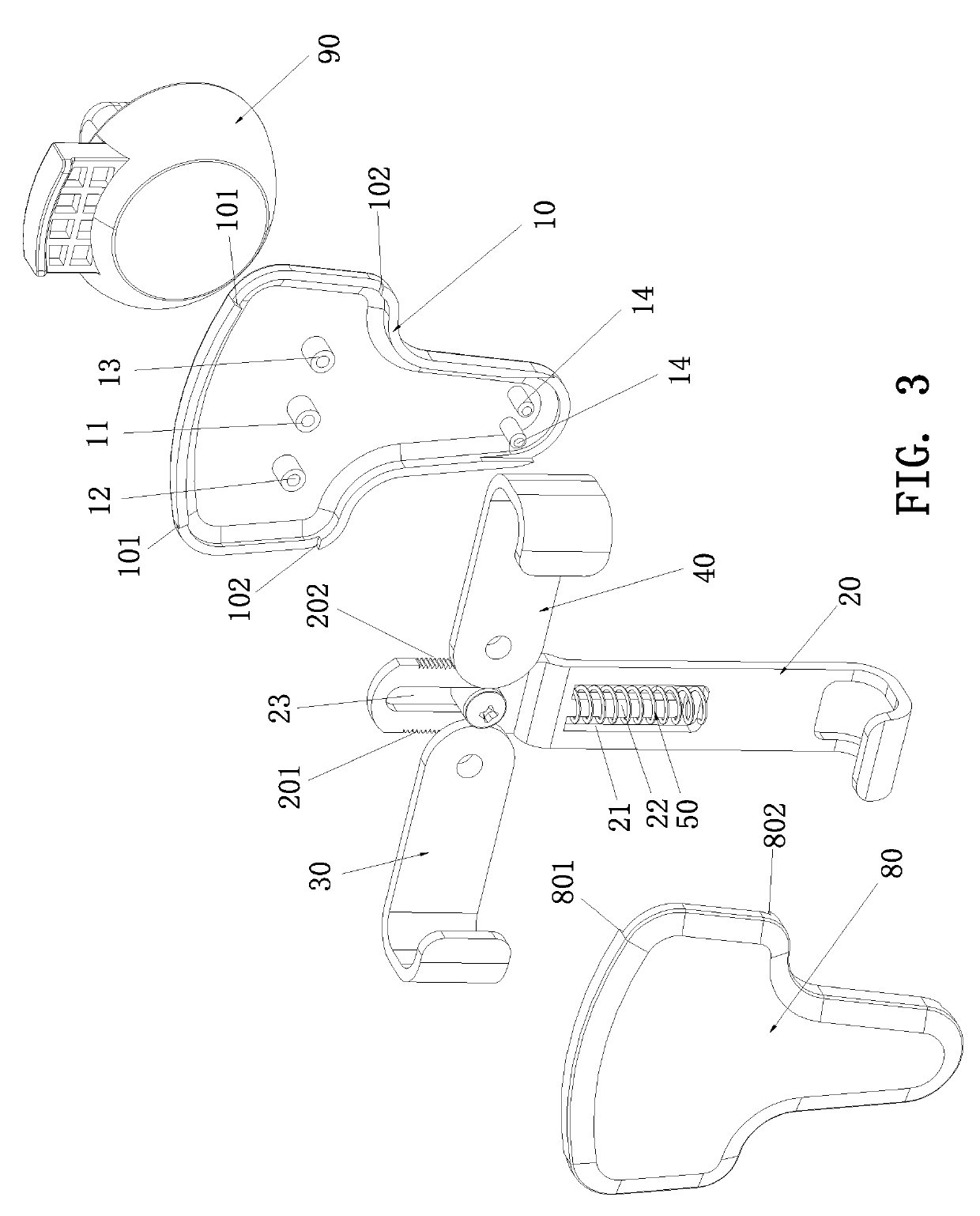

An automatic clamping holder for a mobile device includes a base, a bottom support arm, left and right clamping arms, left and right pressing arms, and a trigger mechanism. The base is provided with left and right slide grooves. A first elastic member is disposed in each of the left and right slide grooves. The holder is provided with the trigger mechanism and the left and right pressing arms for controlling the opening and closing of the holder. The mobile device can be placed in or taken out from the holder more quickly and flexibly, thereby providing convenience for the user.

Owner:SHENZHEN ANNAIJIA ELECTRONICS CO LTD

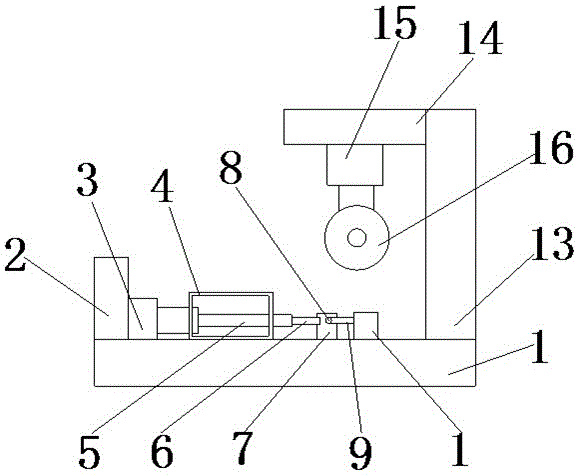

Plastic pipe cutter with clamping function

InactiveCN105818205AWith clamping functionGood clamping functionMetal working apparatusEngineeringExtrusion

The invention discloses a plastic pipe cutting machine with clamping function, which comprises a base, the upper surface of the base is fixedly connected with a block, one side of the block is fixedly connected with a first electric telescopic rod, and the first One end of an electric telescopic rod penetrates the connection block and is fixedly connected with one end of the push-pull rod, and the other end of the push-pull rod passes through the connection block and is fixedly connected with one side of the extrusion block, and the upper surface of the base is fixedly connected with a first Fixed block. The plastic pipe cutting machine with clamping function, through the setting of the first electric telescopic rod and the push-pull rod, the cutting object can be better automatically clamped, which solves the effect of manually holding the cutting object to fix it, and avoids the need for hand-holding. The cutting deviation when the cutting material is cut, through the setting of the extrusion block and the extrusion rod, the cutting material can be clamped more effectively, thus solving the situation of manually fixing the cutting material and avoiding the accidental injury to the worker caused by manual fixed cutting .

Owner:CHANGZHOU WUJIN GOLDEN SUNSHINE ELECTRONICS

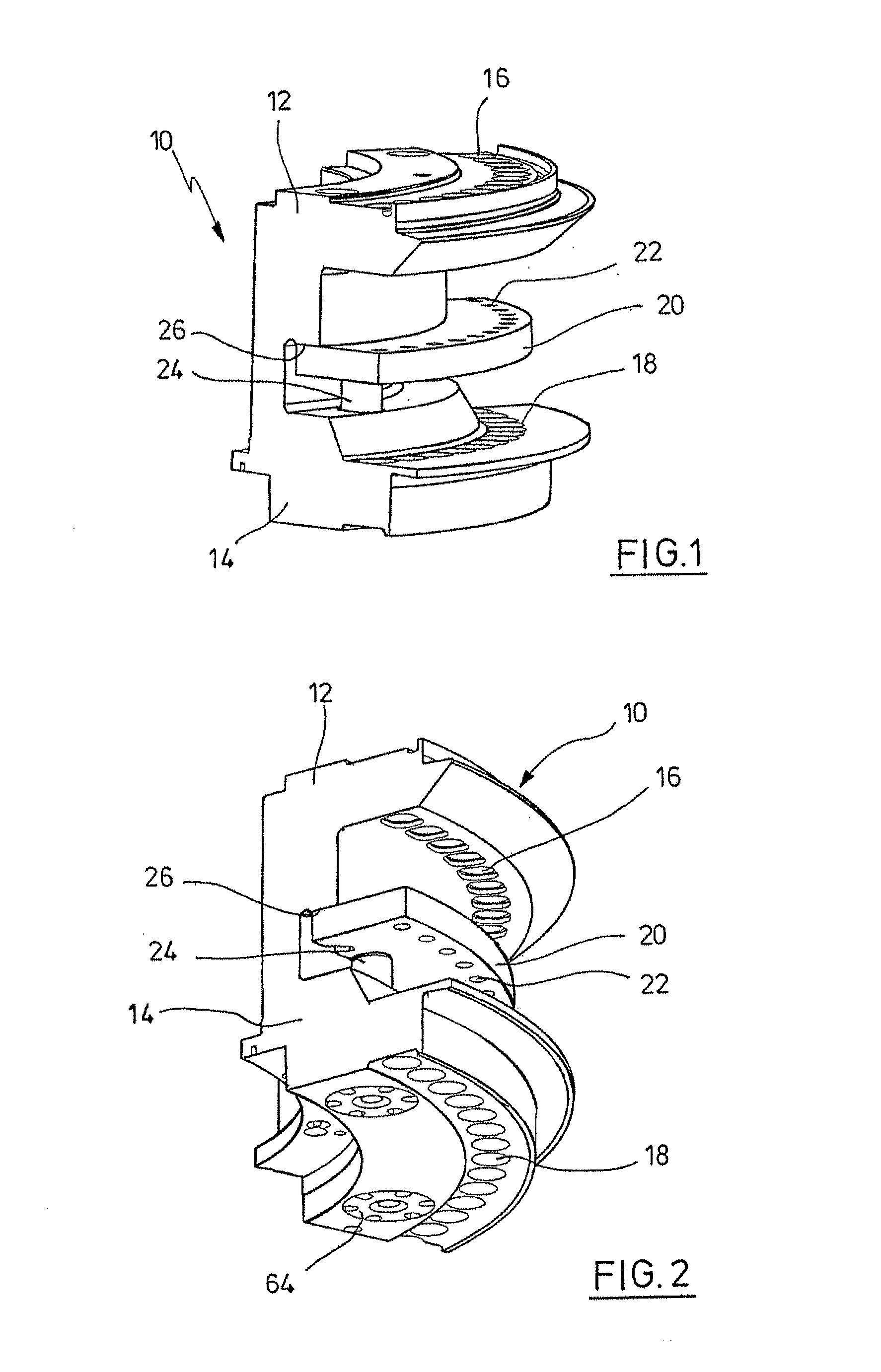

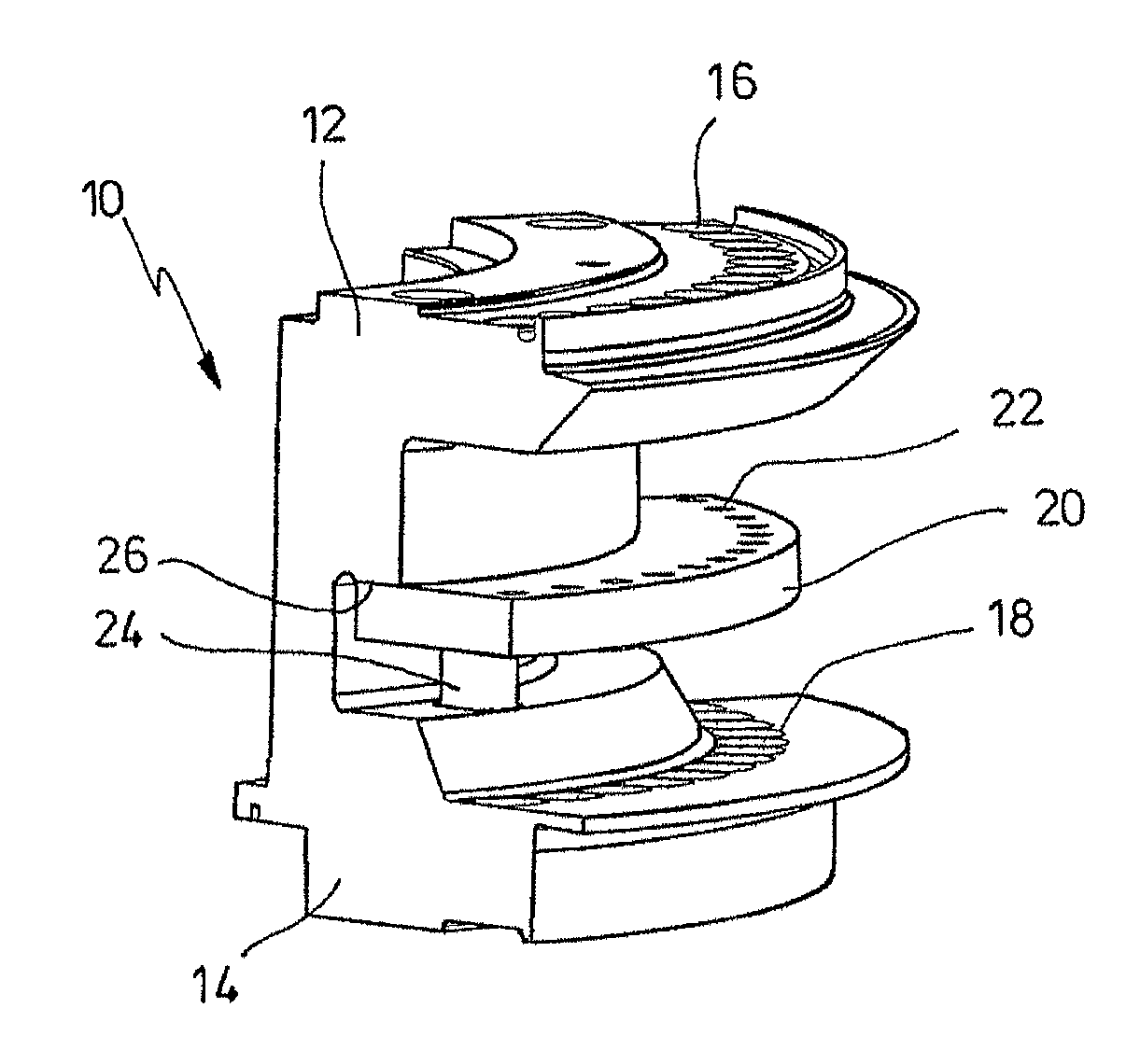

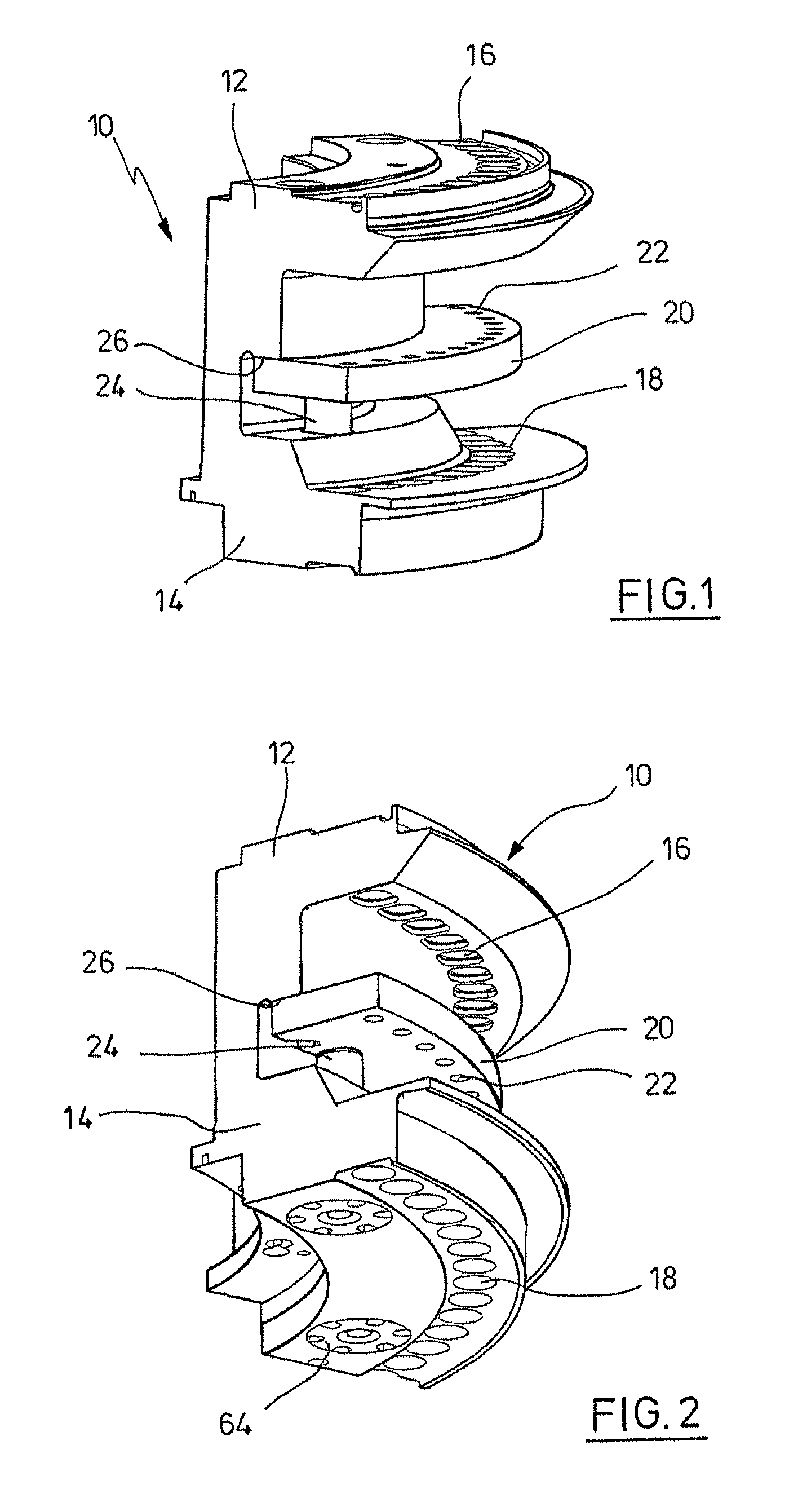

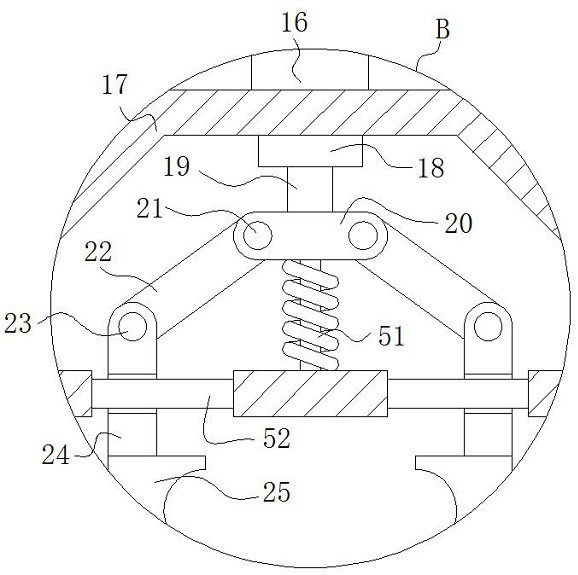

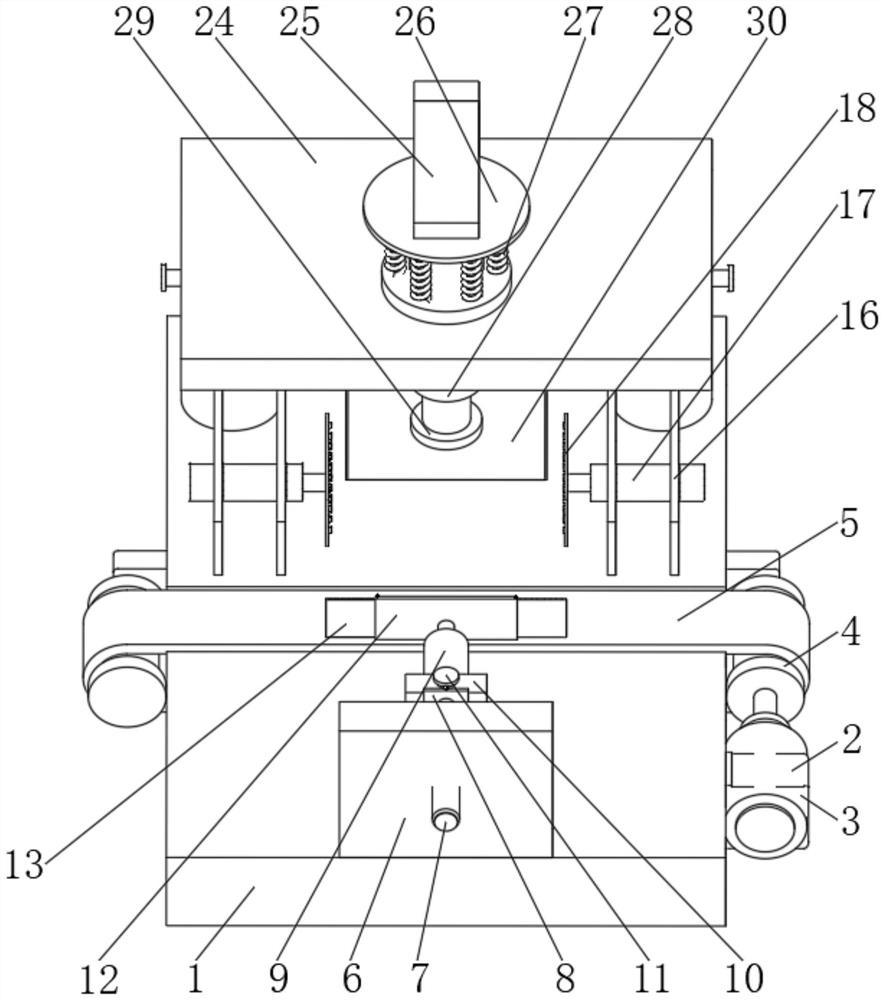

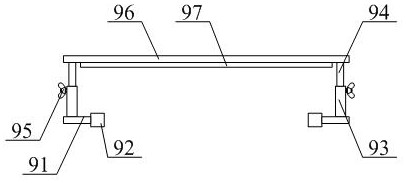

Parallelogram linkage automatic clamping holder

ActiveUS10207652B2Easy clampingFor automatic clampingPassenger spacePicture framesEngineeringMechanical engineering

A parallelogram linkage automatic clamping holder includes a rear base, a bottom support arm, a left clamping arm, a right clamping arm, and a return elastic member. When in use, the bottom support arm is moved downward by the weight of a mobile phone. By the deformation principle of the parallelogram, clamping parts move inward obliquely upward to clamp the mobile phone automatically. The clamping surfaces of the clamping parts don't have an angle change to ensure that the mobile phone has a larger contact surface with the clamping surfaces, providing a better clamping effect.

Owner:BENZHI (SHENZHEN) INFORMATION TECH CO LTD

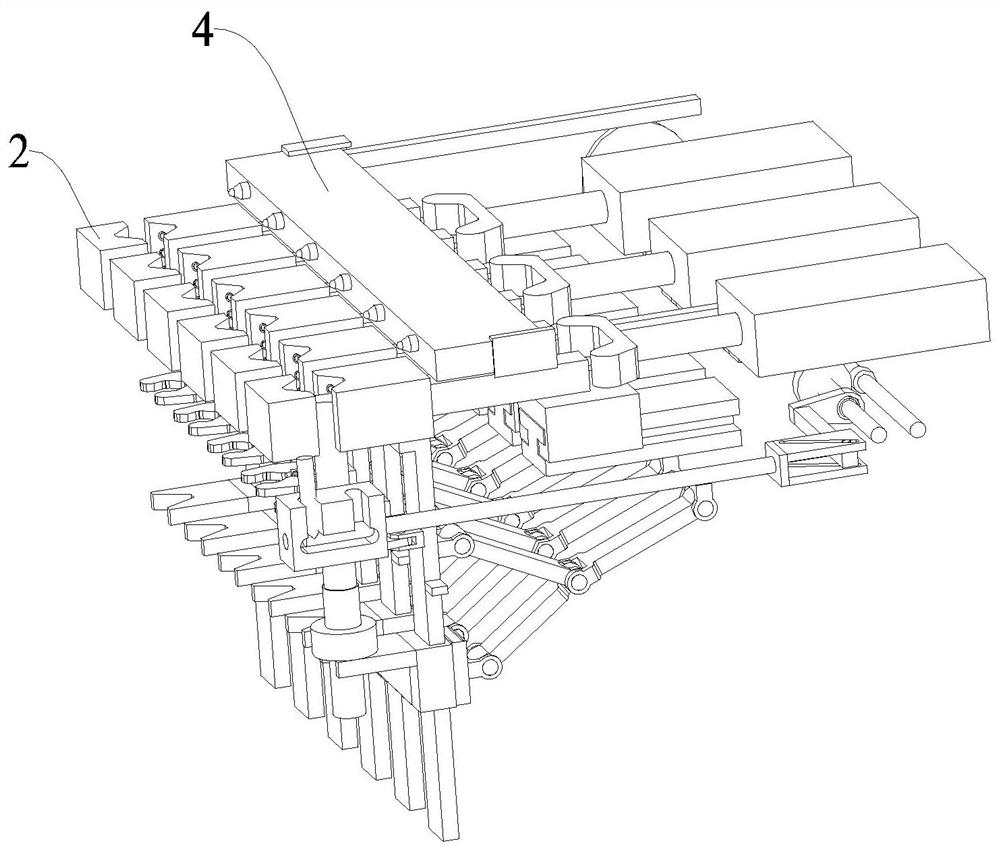

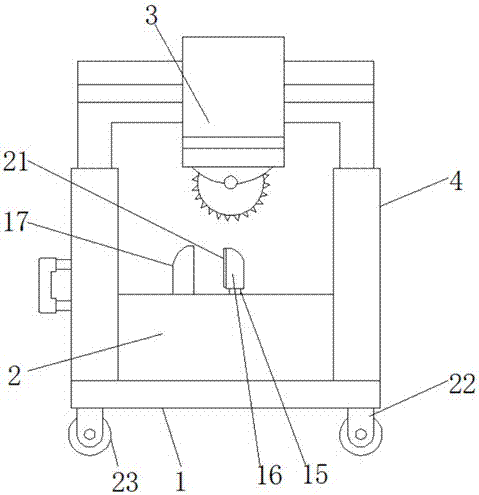

Grinding wheel cutter capable of automatically clamping and blocking

ActiveCN108081097AFor automatic clampingEnsure safetyGrinding machinesGrinding work supportsEngineeringGrinding wheel

The invention discloses a grinding wheel cutter capable of automatically clamping and blocking. The grinding wheel cutter comprises a base and a machine body, wherein the lower end of the base is equipped with a travelling mechanism; a brake mechanism is mounted on the travelling mechanism; a machine body is welded on the base; the upper end of the machine body is welded with a bracket; a motor and a tension device are mounted on the bracket; the left side of the top end of the bracket is rotatably connected with a pressure rod; the lower end of the pressure rod is rotatably connected with a plurality of first connecting rods at equal distance; one end, away from the pressure rod, of each first connecting rod is rotatably connected with a fixed plate; a plurality of strong springs are welded between the bracket and the fixed plates; and one end, away from each first connecting rod, of each fixed plate is welded with the grinding wheel cutter. The grinding wheel cutter is stable in structure, is simple to operate, is scientific and reasonable in design, is short in production period, is low in manufacturing cost, is good in anti-seismic property, is convenient to move, automaticallyclamps a cut object conveniently, blocks spark to guarantee safety of an operator, and is worthy of being popularized.

Owner:MINNAN INST OF SCI & TECH

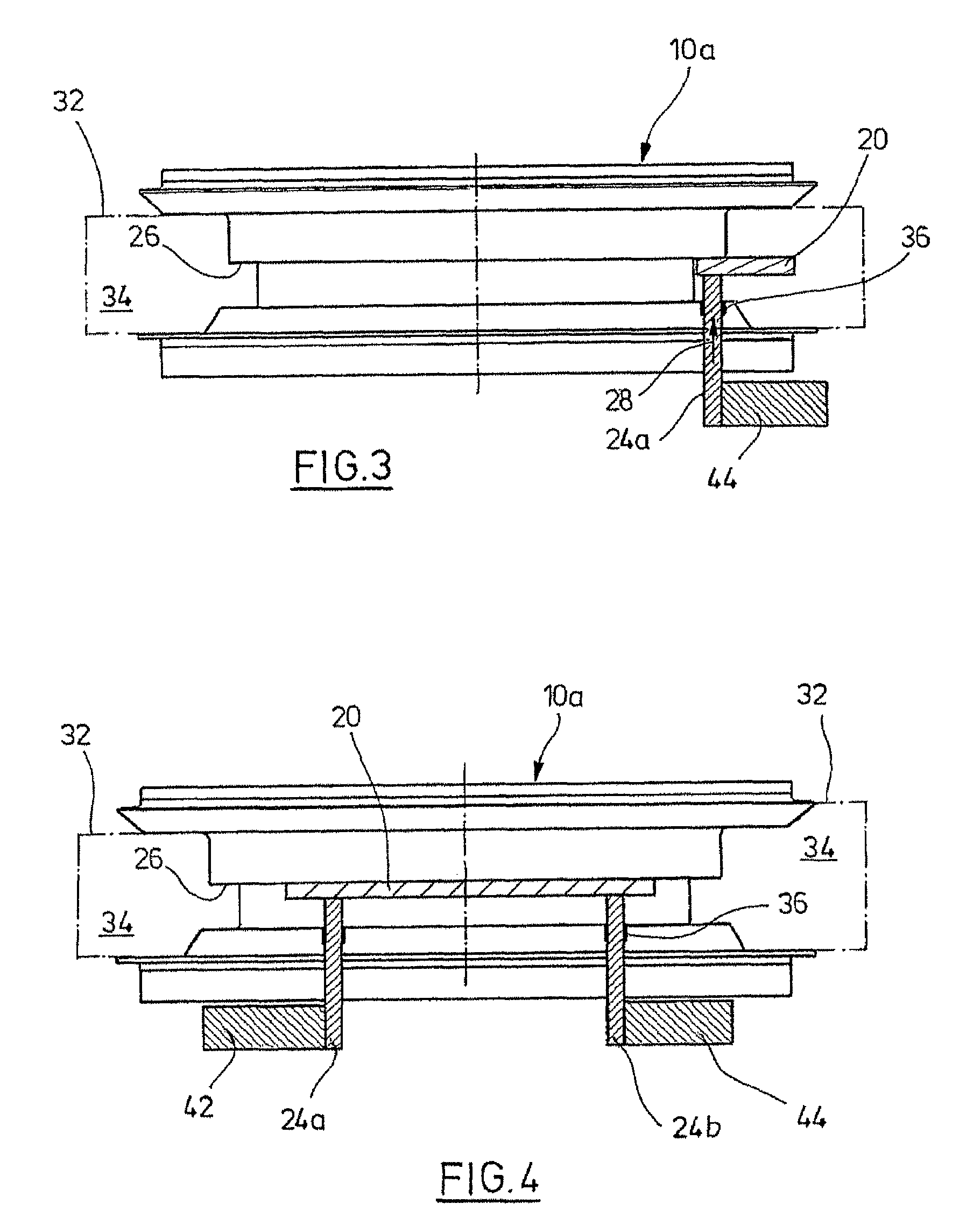

Tablet press

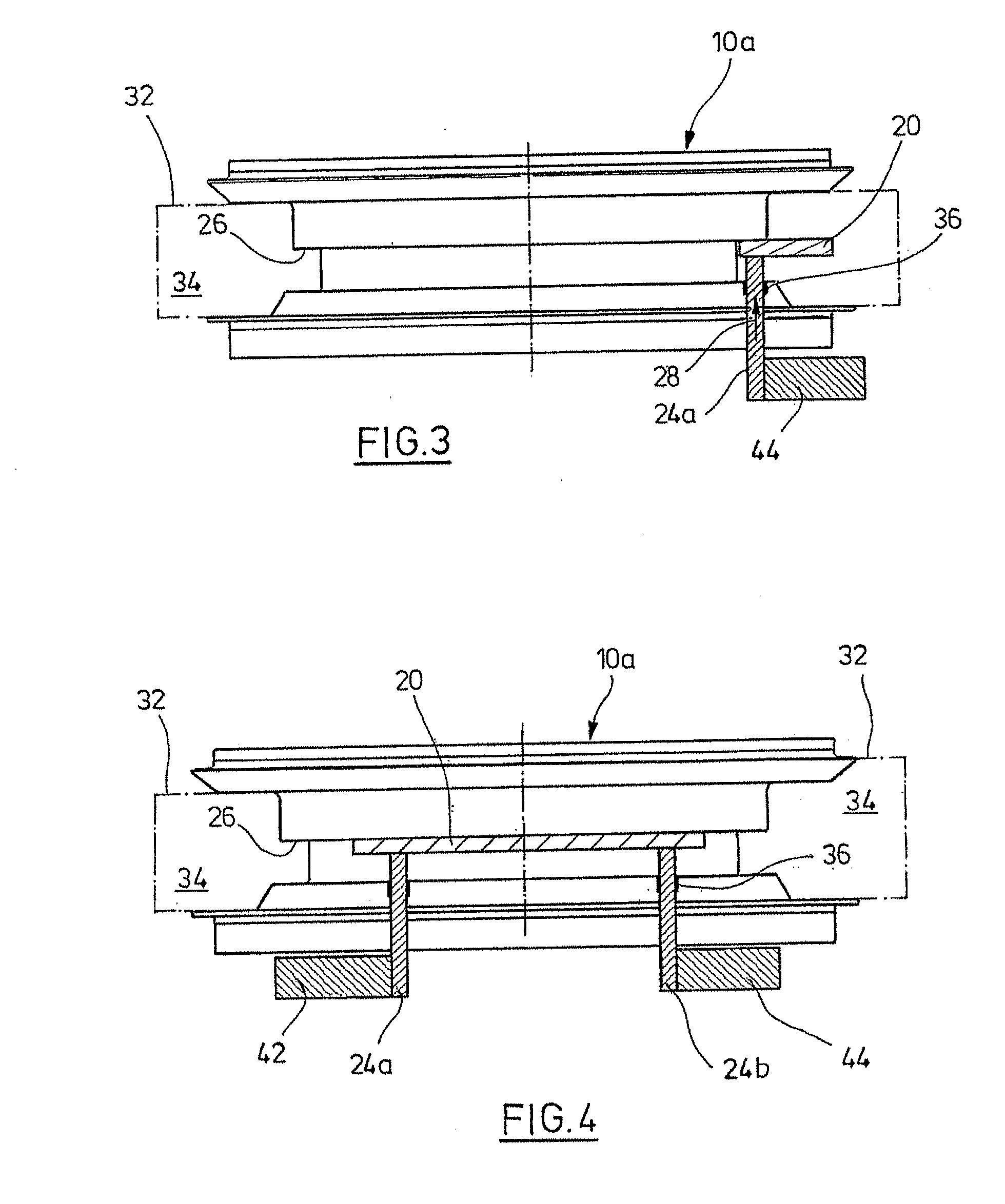

ActiveUS20090191297A1For automatic clampingNot to be disassembledConfectioneryCeramic shaping apparatusEngineeringMechanical engineering

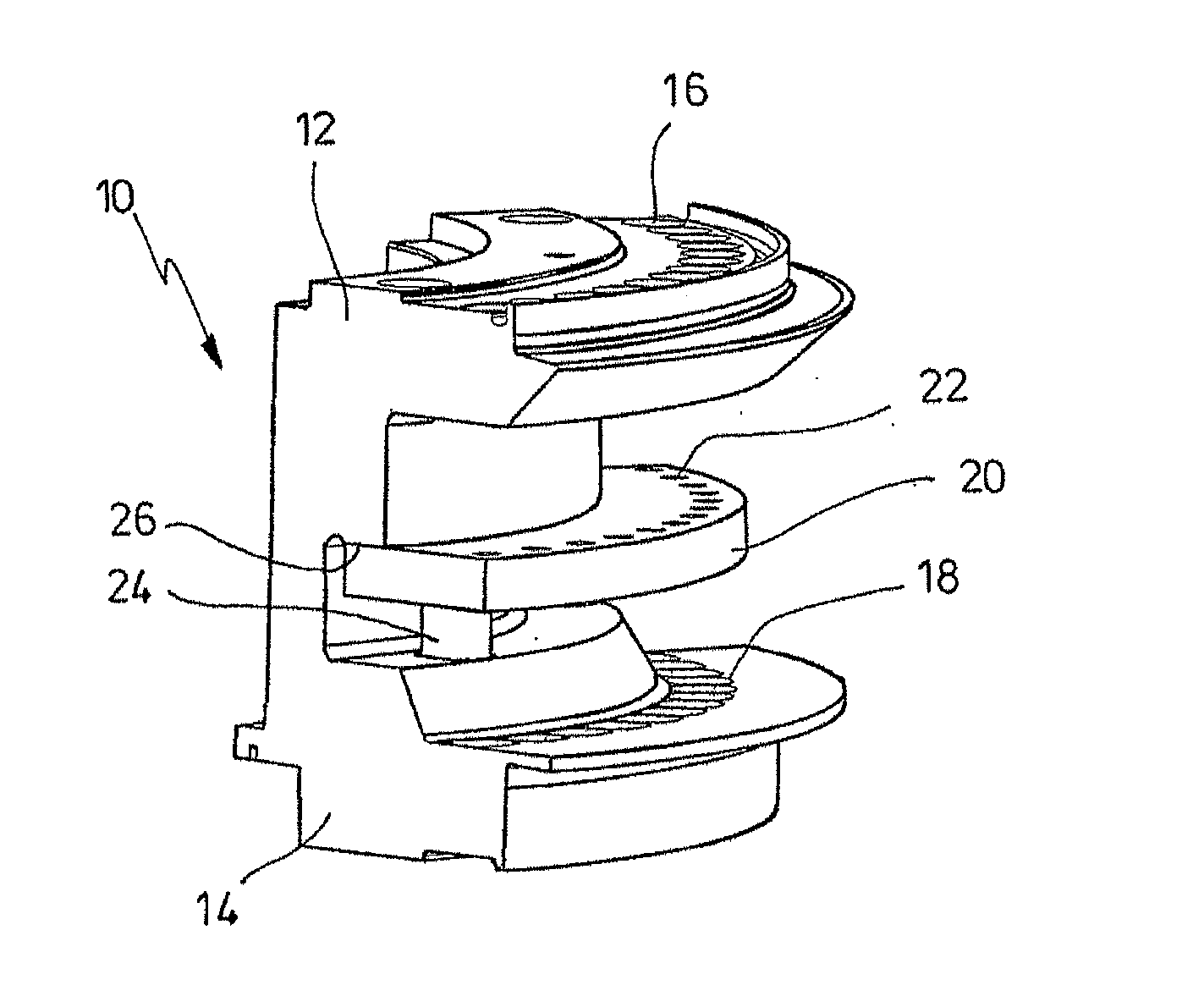

A tablet press with a rotor, which is rotatably mounted in a stand of the tablet press and which has an upper punch accommodation for the upper punches and a lower punch accommodation for the lower punches of the tablet press, as well as a die plate with a series of die bores which are aligned with the upper and the lower punches, wherein the die plate consists of at least two ring segments which can be attached on the rotor by means of a fastening device, wherein clamping elements are arranged in axis parallel passages of the rotor spaced apart in the perimeter distance, which act against the ring segments from the bottom side and clamp against an abutment surface of the rotor, characterised in that at least one drive device for the clamping elements is arranged in the stand of the tablet press, with a coupling element adjustable in the height, which can be selectively set into engagement with the lower end of the clamping element.

Owner:FETTE

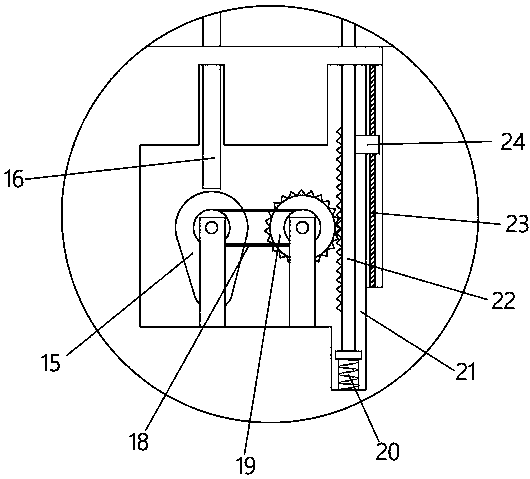

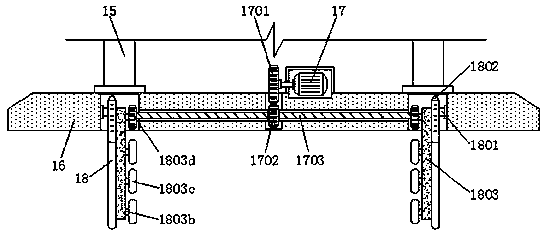

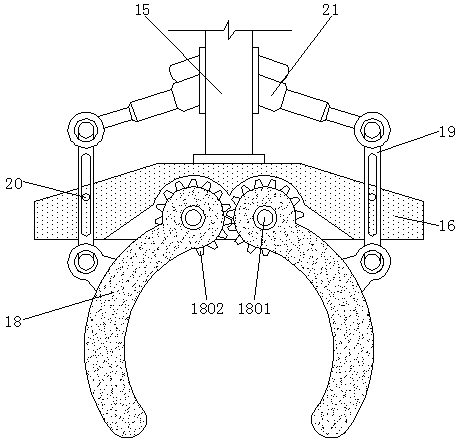

Support capable of fully-automatically performing rotary clamping by means of linkage between gear and rack

ActiveUS20190260865A1Simple structureEasy to produceStands/trestlesTelephone set constructionsMechanical engineeringLinkage concept

Owner:SHENZHEN ANNAIJIA ELECTRONICS CO LTD

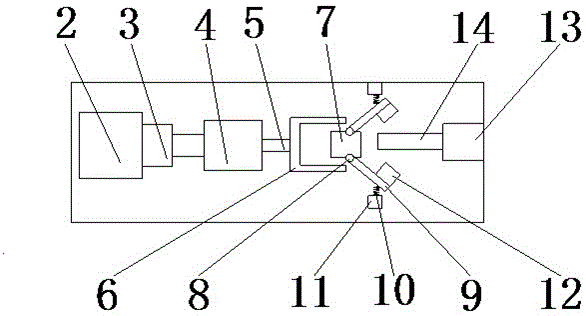

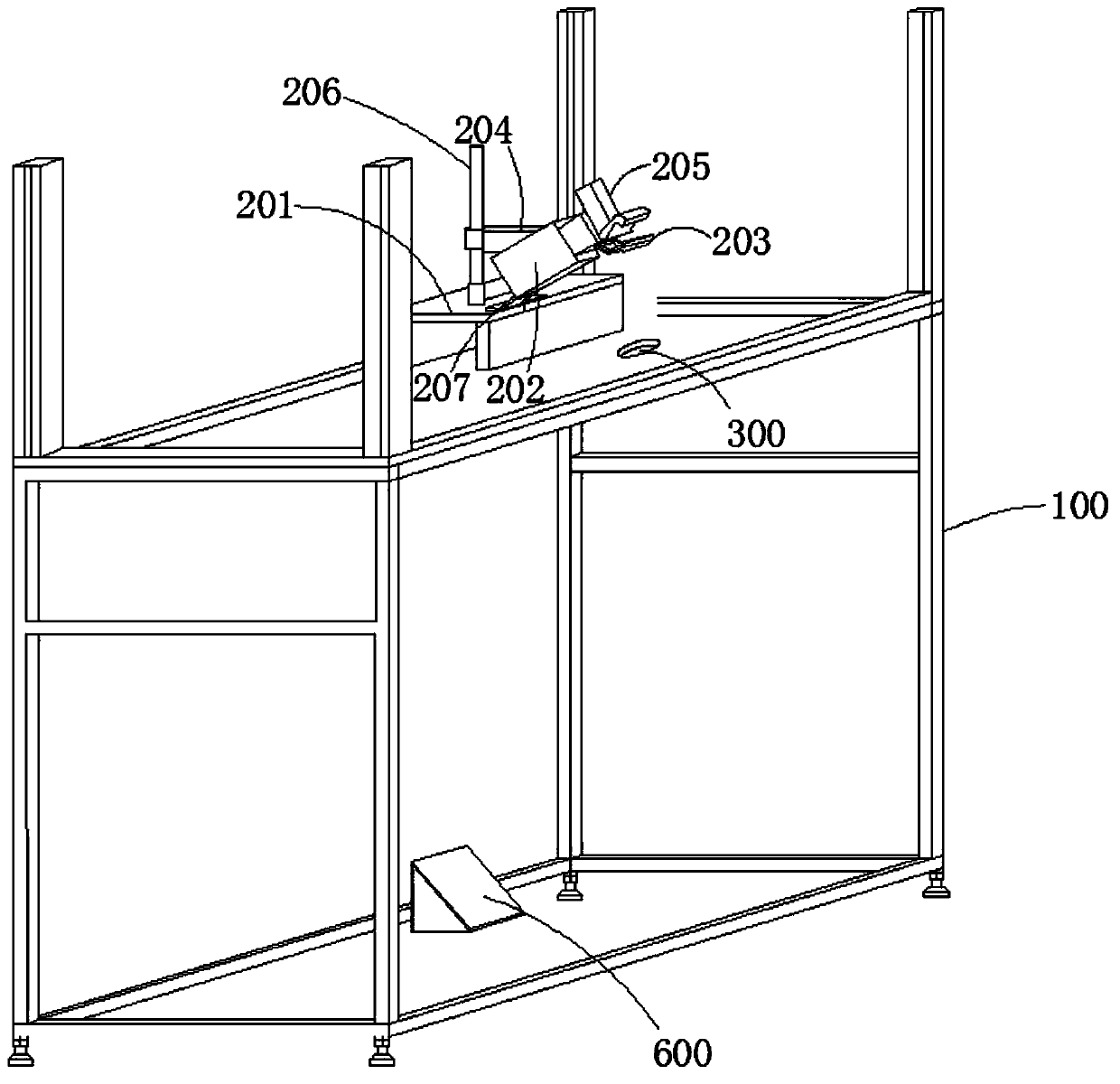

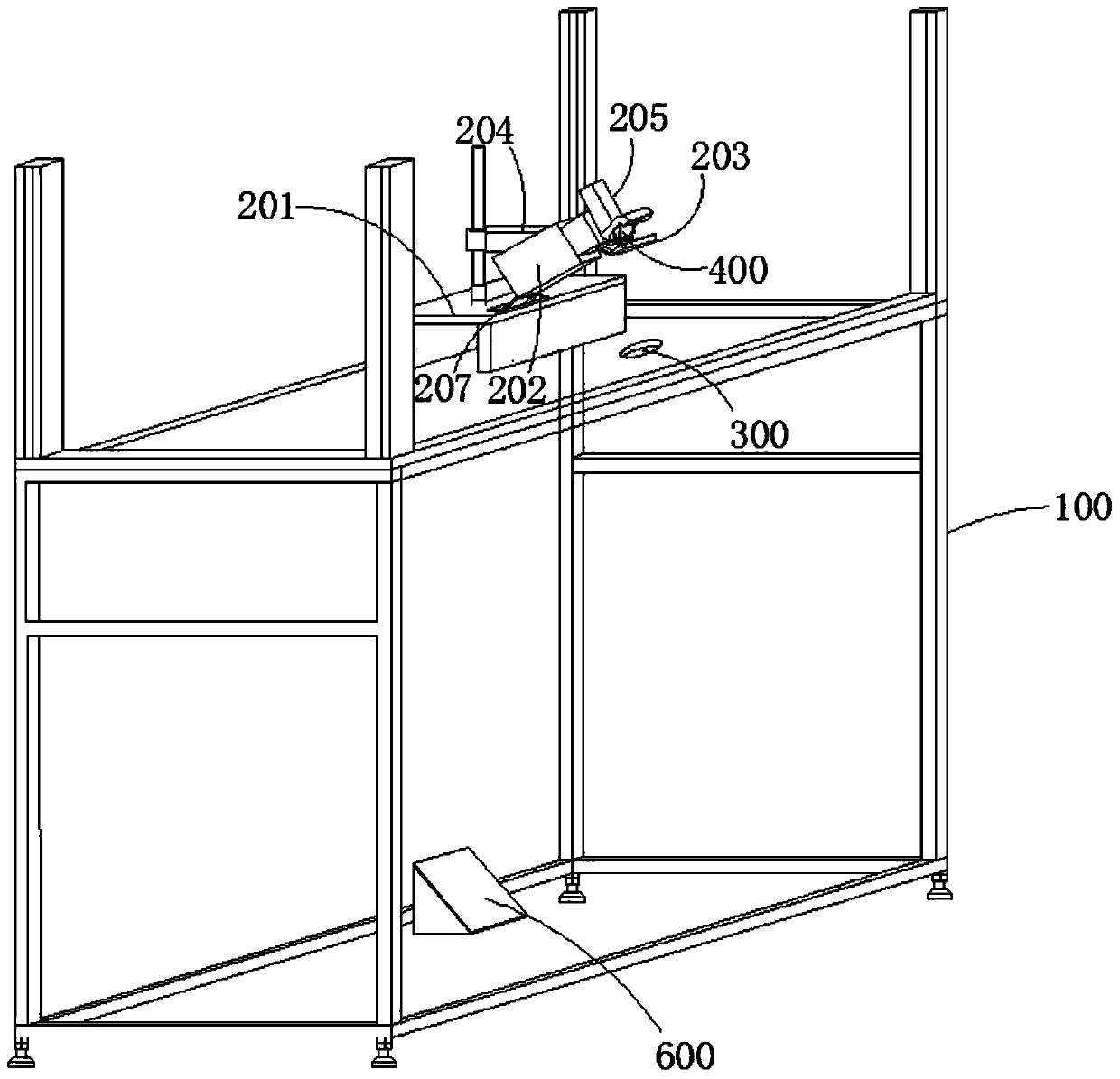

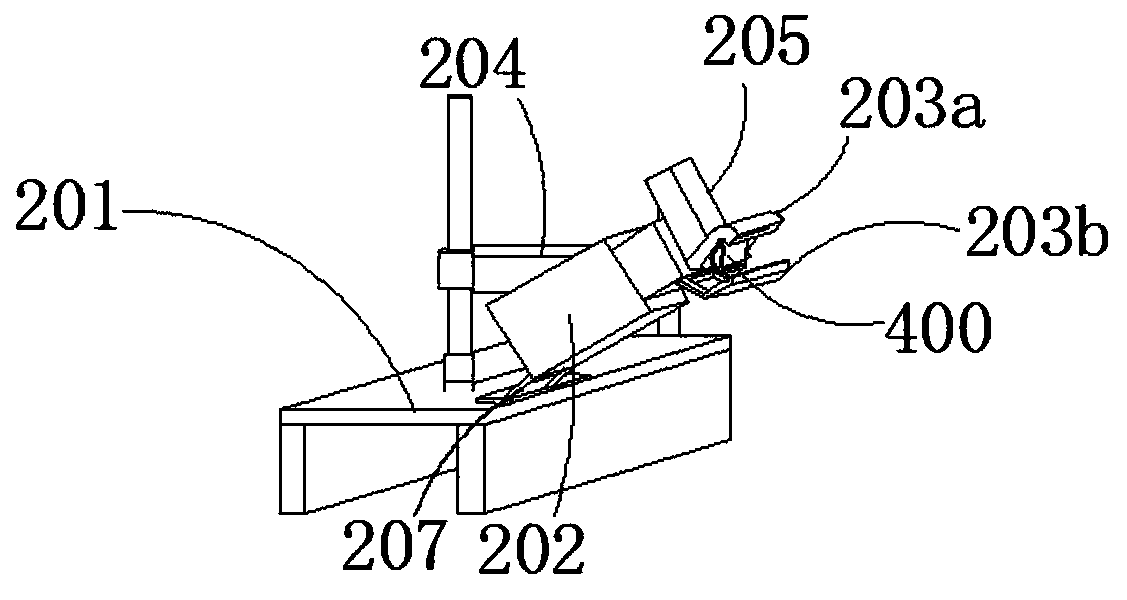

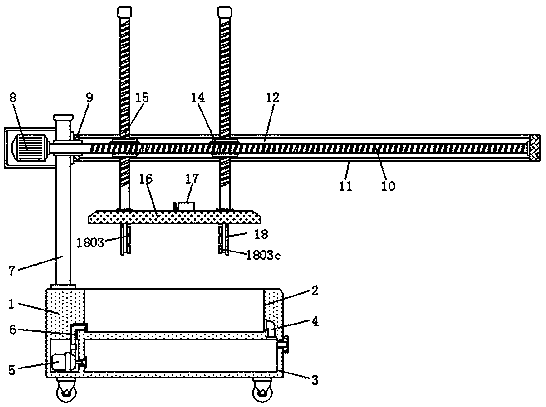

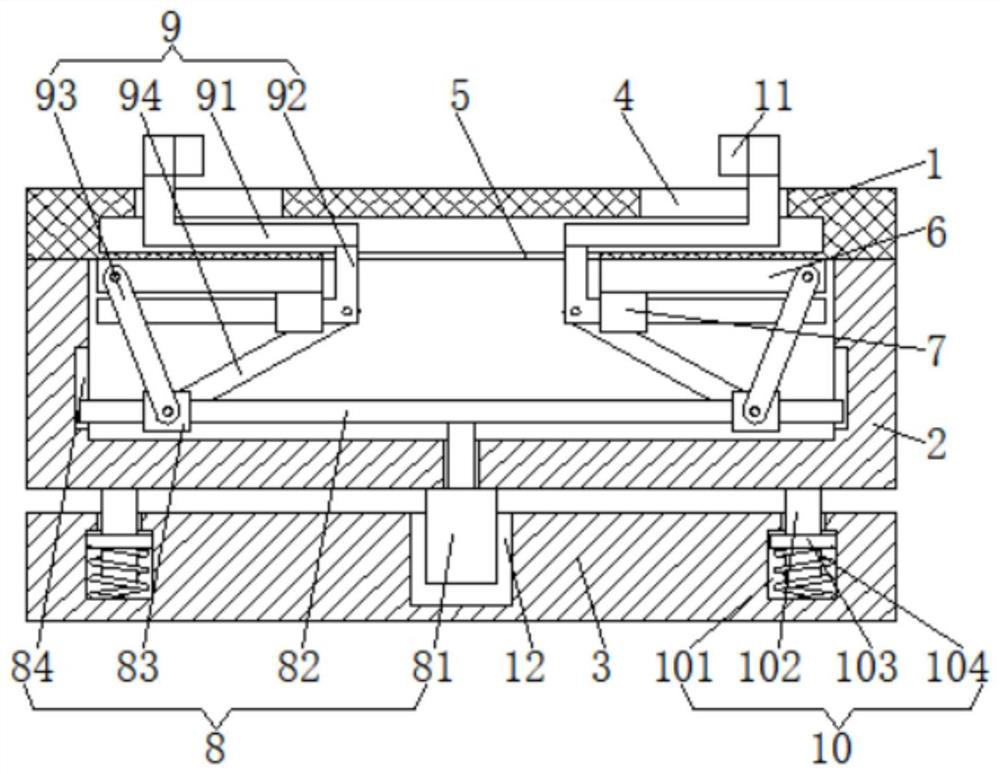

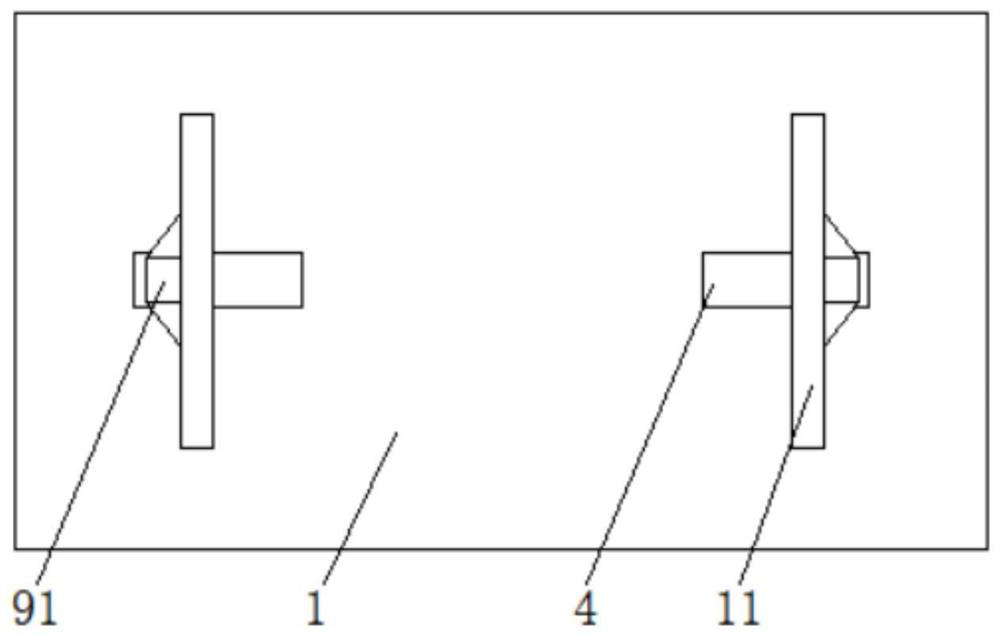

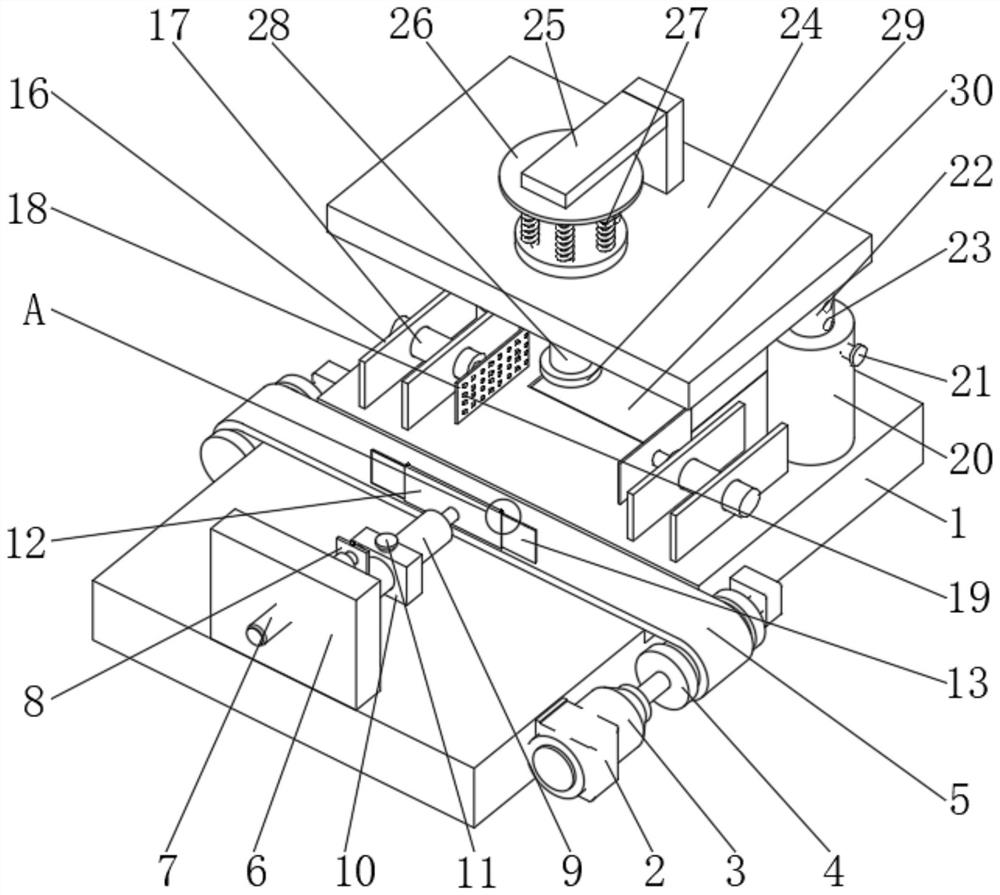

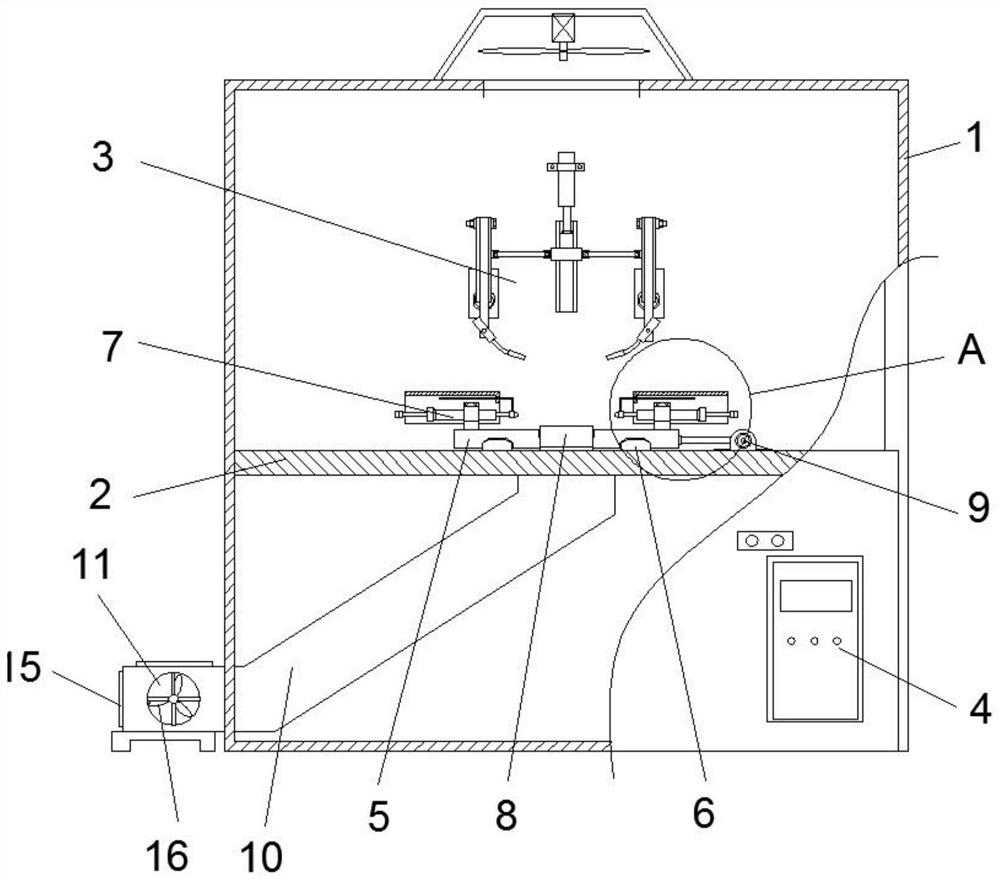

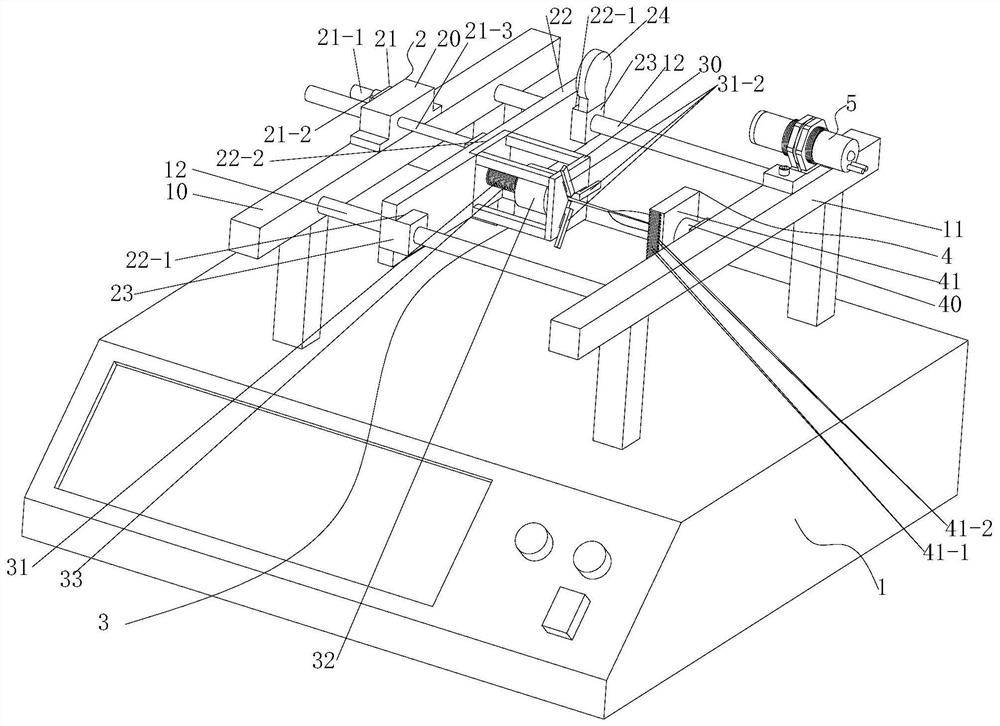

Detection table and detection method for perspective AR glasses optical module

PendingCN110967169AEasy to observeEasy to adjust and useTesting optical propertiesOptical elementsEngineeringOptical Module

The invention discloses a detection table and a detection method of a perspective AR glasses optical module. According to the detection table of the perspective AR glasses optical module, the opticalmodule at least comprises a lens. The detection table comprises: a rack; a profiling clamp assembly, wherein the shape of the profiling clamp assembly is matched with that of the optical module, and the profiling clamp assembly is installed on the rack and used for clamping the optical module; and a light source module which is a point light source, wherein the light source module is mounted on the rack, so that the light source module is imaged in the center of the view field of the optical module. The profiling clamp assembly is arranged on the rack, a light-emitting part is installed belowthe rack so that the light-emitting part can be imaged in the view center of the AR glasses optical module to be detected, the image output module outputs video or picture information, and if imagingof the light-emitting part in the view center of the optical module coincides with the video or picture output by the image output module, installation of the optical module is qualified.

Owner:TAPUYIHAI SHANGHAI INTELLIGENT TECH CO LTD

Tablet press

ActiveUS7641466B2For automatic clampingNot to be disassembledConfectionerySweetmeatsEngineeringMechanical engineering

A tablet press with a rotor, which is rotatably mounted in a stand of the tablet press and which has an upper punch accommodation for the upper punches and a lower punch accommodation for the lower punches of the tablet press, as well as a die plate with a series of die bores which are aligned with the upper and the lower punches, wherein the die plate consists of at least two ring segments which can be attached on the rotor by means of a fastening device, wherein clamping elements are arranged in axis parallel passages of the rotor spaced apart in the perimeter distance, which act against the ring segments from the bottom side and clamp against an abutment surface of the rotor, characterized in that at least one drive device for the clamping elements is arranged in the stand of the tablet press, with a coupling element adjustable in the height, which can be selectively set into engagement with the lower end of the clamping element.

Owner:FETTE

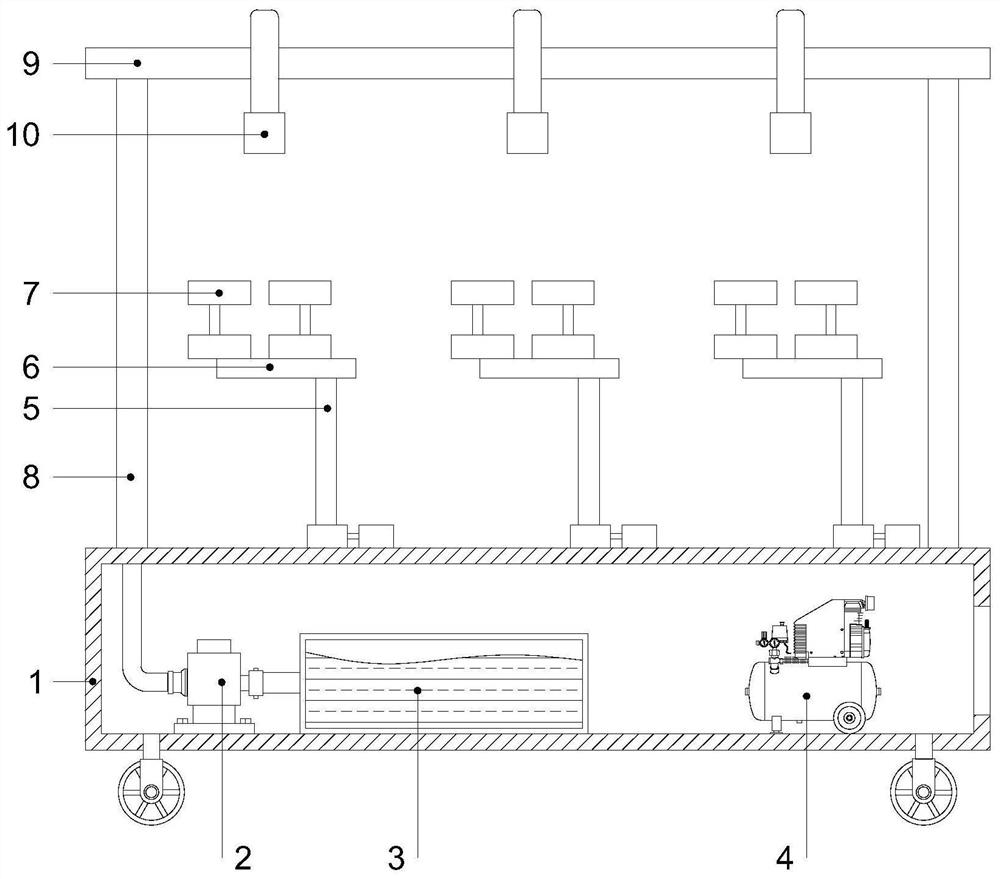

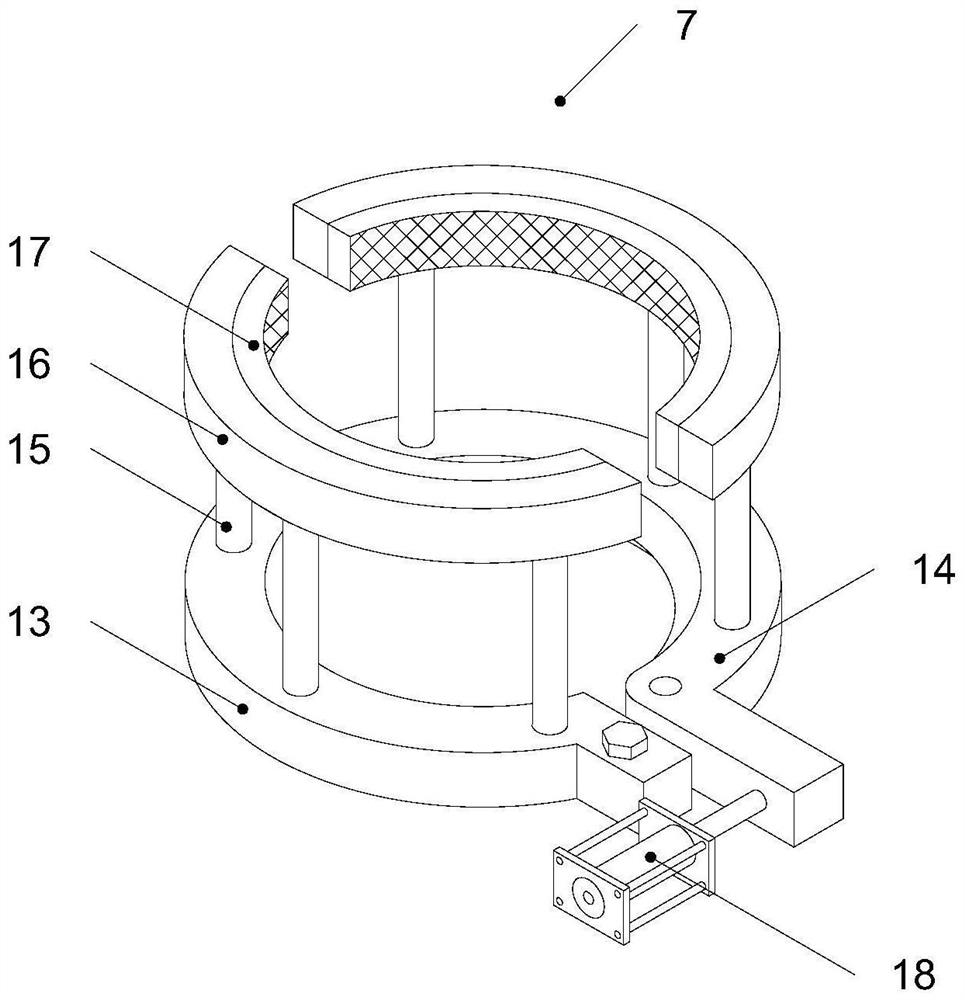

Quenching device capable of facilitating clamping and quenching of hardware materials

ActiveCN109112272AConvenient clamping and quenchingEasy to rotate and scrollFurnace typesHeat treatment furnacesLiquid storage tankQuenching

The invention discloses a quenching device capable of facilitating clamping and quenching of hardware materials. The device comprises a quenching box, a micro water pump, a mounting plate, a servo motor, a linkage rod and a driving cylinder, wherein the quenching box is provided with a quenching bath, a connecting pipe is arranged at the right side of the quenching bath, and the quenching bath isconnected with a liquid storage tank by means of the connecting pipe; the micro water pump is connected with the left side of the liquid storage tank, and the liquid storage tank and the micro water pump are both positioned inside the quenching box; the linkage rod is positioned at the outer side a clamping device, and is connected with a mounting cover by means of a connecting rod; the linkage rod is connected with the driving cylinder, and the driving cylinder is positioned at the outer side of an adjusting rod. The quenching device capable of facilitating clamping and quenching of hardwarematerials facilitates the automatic clamping of the cylindrical hardware materials by using the clamping device, thus avoiding the high temperature damage to workers; a pushing device conveniently drives the hardware materials to rotate and roll in cooling liquid, so that the uniform quenching of the hardware materials is facilitated.

Owner:YANCHENG NUOWEITE ELECTROMECHANICAL TECH

Automatic positioning and welding integrated production equipment for machining of diodes

InactiveCN112077492ARealize automatic pinch operationFor automatic homingWelding/cutting auxillary devicesAuxillary welding devicesKinematic pairVisual inspection

The invention discloses automatic positioning and welding integrated production equipment for machining of diodes. The automatic positioning and welding integrated production equipment comprises a main body frame, a conveying belt is installed on the lower portion of the interior of the main body frame, pins are installed on the upper portion of a support, a first servo motor is installed on the left side of the upper portion of the interior of the main body frame, and a first kinematic pair is connected to the right side of a first connecting rod in a screwed mode. Compared with existing common visual inspection equipment, the automatic positioning and welding integrated production equipment for machining of the diodes is provided with a groove, the first servo motor rotates to drive thefirst connecting rod, the first connecting rod rotates through the first kinematic pair, the first kinematic pair drives a second kinematic pair to move through a second connecting rod, the second kinematic pair drives a third kinematic pair to move through a first moving plate, a transverse limiting plate drives the first moving plate to slide through the third kinematic pair, a longitudinal limiting plate drives a lifting rod to stretch out and draw back through the third kinematic pair, and automatic clamping and conveying operation of a clamping frame is achieved.

Owner:广州市金点子机电科技发展有限公司

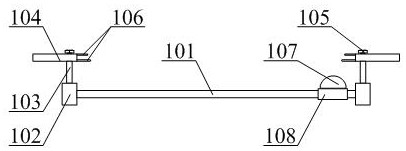

Automatic clamping holder for mobile device

ActiveUS10948001B2Placed in or taken out from the holder more quickly and flexiblyOperation is quick and flexibleCasings/cabinets/drawers detailsFriction grip releasable fasteningsPinch gripMobile device

An automatic clamping holder for a mobile device includes a base, a bottom support arm, left and right clamping arms, left and right pressing arms, and a trigger mechanism. The base is provided with left and right slide grooves. A first elastic member is disposed in each of the left and right slide grooves. The holder is provided with the trigger mechanism and the left and right pressing arms for controlling the opening and closing of the holder. The mobile device can be placed in or taken out from the holder more quickly and flexibly, thereby providing convenience for the user.

Owner:SHENZHEN ANNAIJIA ELECTRONICS CO LTD

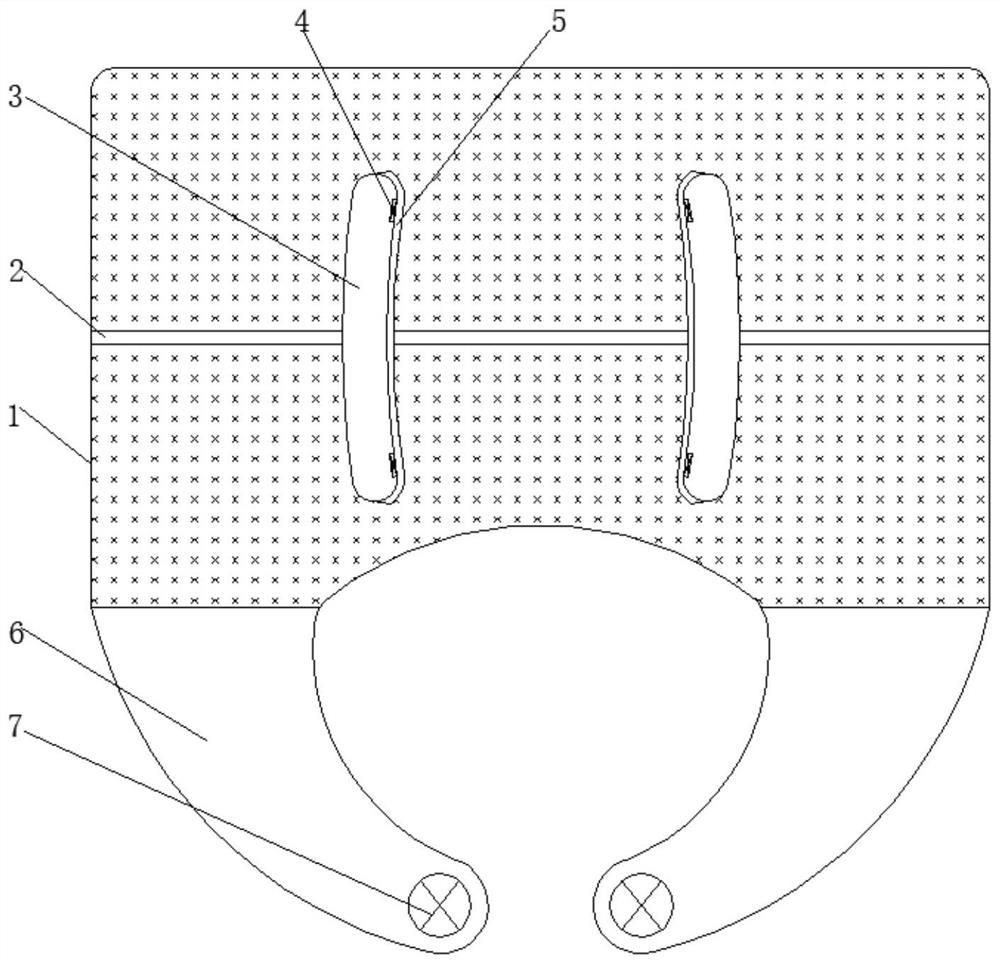

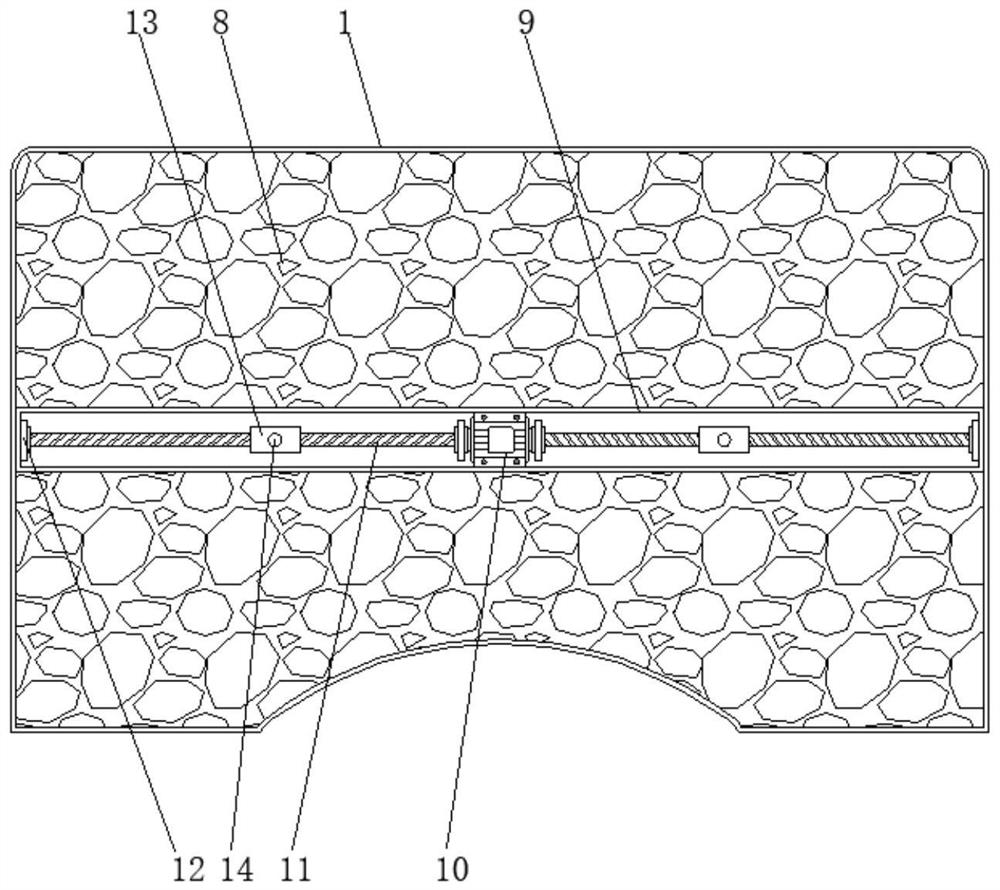

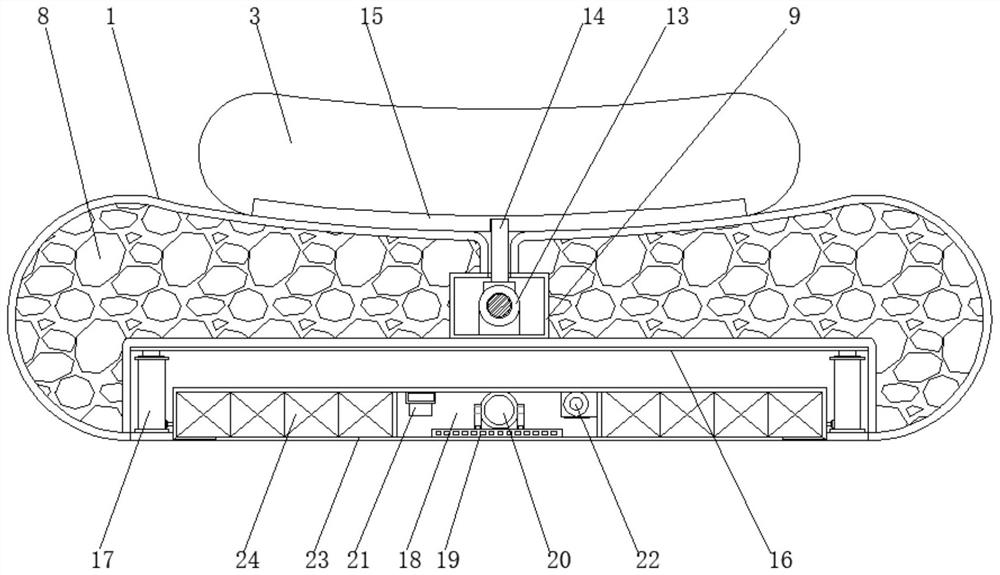

Decompression pillow for neurosurgery

PendingCN112336555AImprove comfortEasy to move aroundNursing bedsDiagnostic recording/measuringEngineeringNeurosurgery

The invention discloses a decompression pillow for neurosurgery. The decompression pillow comprises a head pillow, neck pillows and a control box, wherein a slit is formed in the middle of the head pillow, limiting pads are mounted on the left side and the right side of the outer side face of the head pillow correspondingly, pressure sensors are embedded in the front end and the rear end of the inner side of each limiting pad correspondingly, and the inner side face of each limiting pad is wrapped with a partition pad; the neck pillows are mounted on the left side and the right side of the front end of the head pillow, a monitoring box is mounted at the end, away from the head pillow, of each neck pillow, the head pillow is filled with a sponge filling layer, a driving box is mounted in the middle of the sponge filling layer, a double-head motor is mounted in the middle of the interior of the driving box, and lead screws are connected to the left end and the right end of the double-head motor; and the control box is mounted in the middle of the lower portion of a supporting plate, and a controller is arranged in the control box. According to the decompression pillow, the two neck pillows can wrap the neck of a patient, then heating physiotherapy is performed on the neck of the patient, the body temperature and the heart rate of the patient can be monitored, and the functionality of the whole decompression pillow is greatly expanded.

Owner:安徽医科大学附属阜阳医院

Support capable of fully-automatically performing rotary clamping by means of linkage between gear and rack

ActiveUS10673999B2Simple structureEasy to produceStands/trestlesTelephone set constructionsGear wheelIndustrial engineering

Owner:SHENZHEN ANNAIJIA ELECTRONICS CO LTD

Power battery pack transportation clamping device

InactiveCN112173386AReduce impactFor automatic clampingContainers to prevent mechanical damageInternal fittingsPower batteryStructural engineering

The invention discloses a power battery pack transportation clamping device. The power battery pack transportation clamping device comprises a hollow plate, wherein the bottom of the hollow plate is fixedly connected with a box body; a base is arranged at the bottom of the box body; movable grooves I are formed in two sides of the top of the hollow plate; a movable groove II is formed in the bottom of the hollow plate; connecting blocks are transversely and fixedly connected with two sides of the bottom of the hollow plate; one side, close to the movable groove II, of the bottom of each connecting block is fixedly connected with a sliding sleeve I; a hoisting mechanism is arranged in the box body; and a clamping mechanism is arranged in the hollow plate. The power battery pack transportation clamping device disclosed by the invention has the advantage of conveniently and automatically clamping a battery pack; and the problems that the battery pack is usually manually clamped in a battery pack clamping process, the workload is increased, excessive physical power is consumed and physical fatigue is easily caused are solved.

Owner:星火智慧(杭州)信息科技有限公司

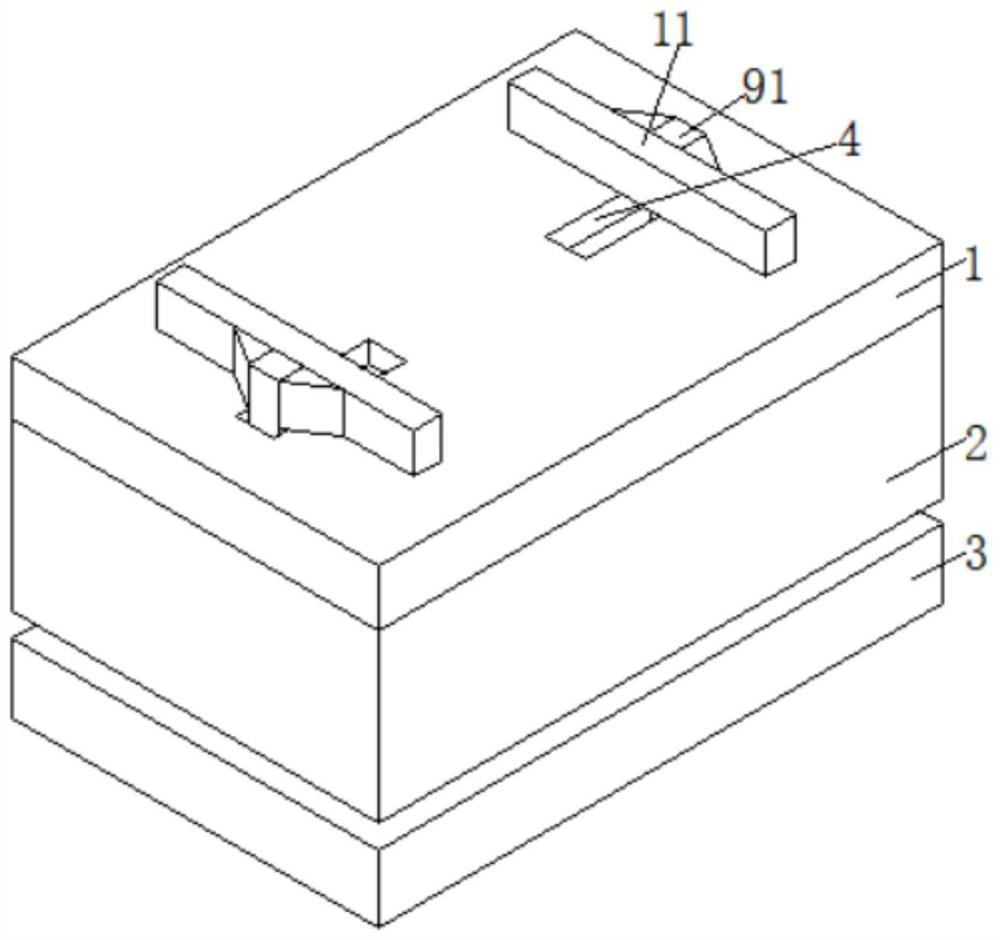

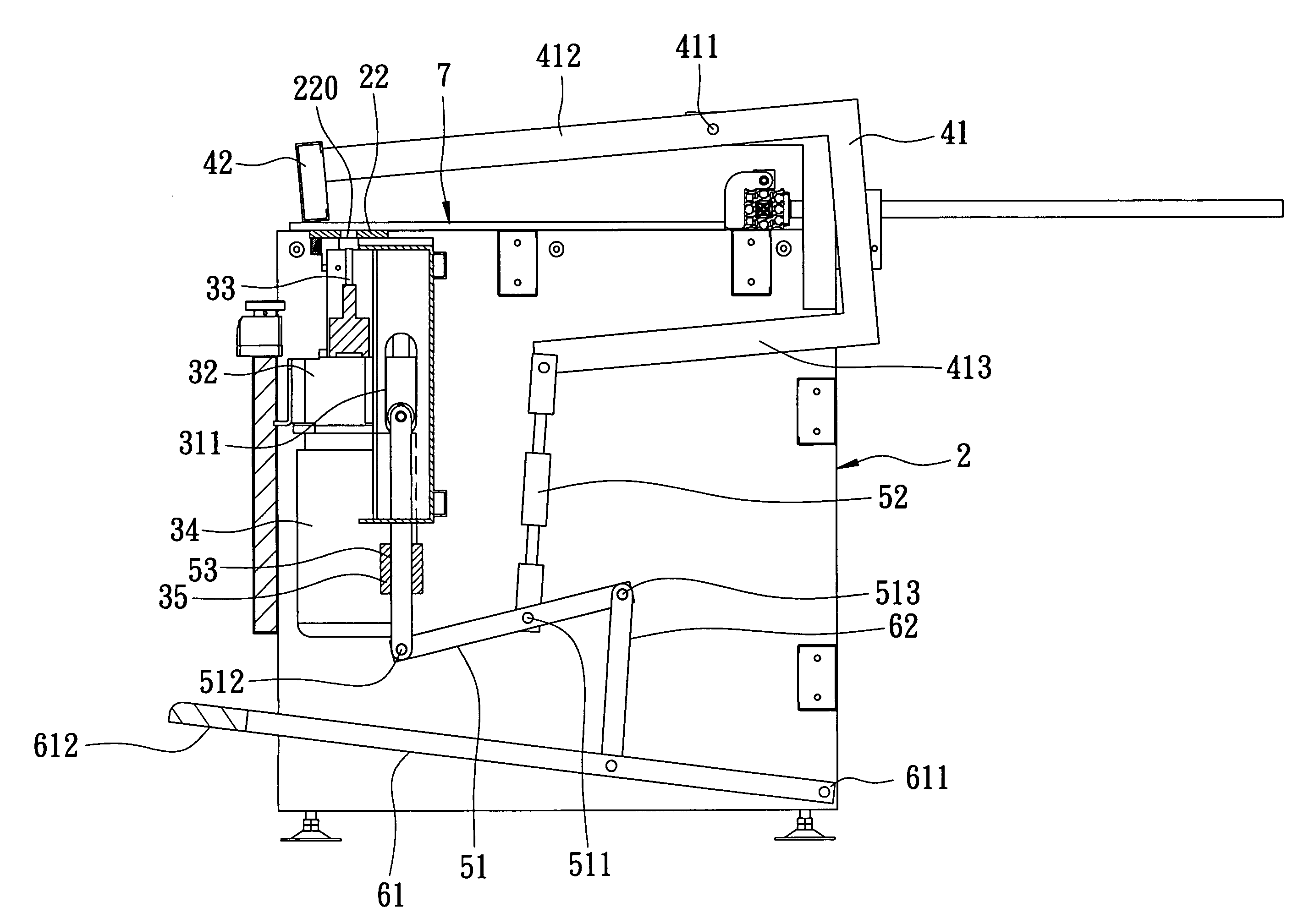

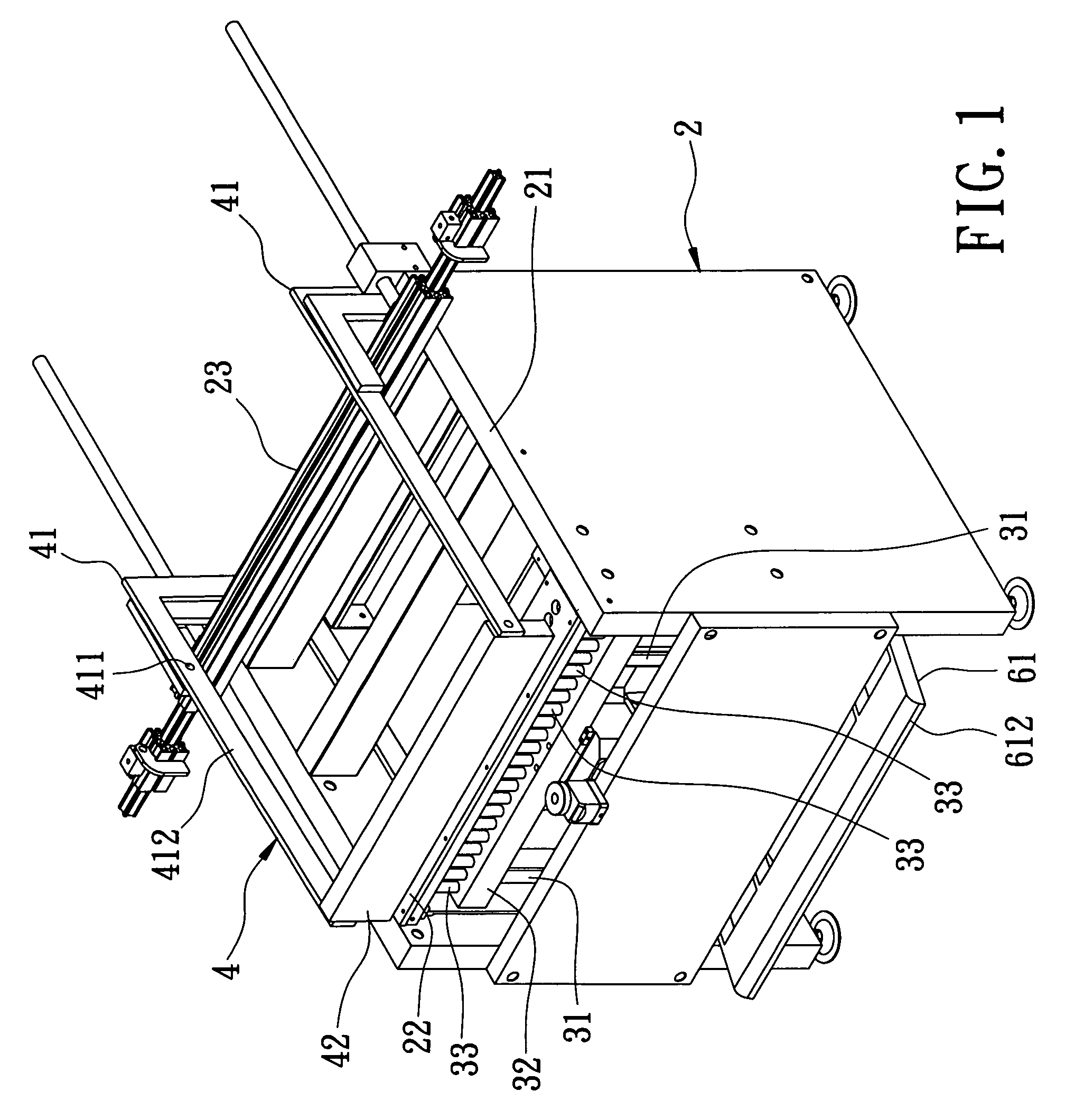

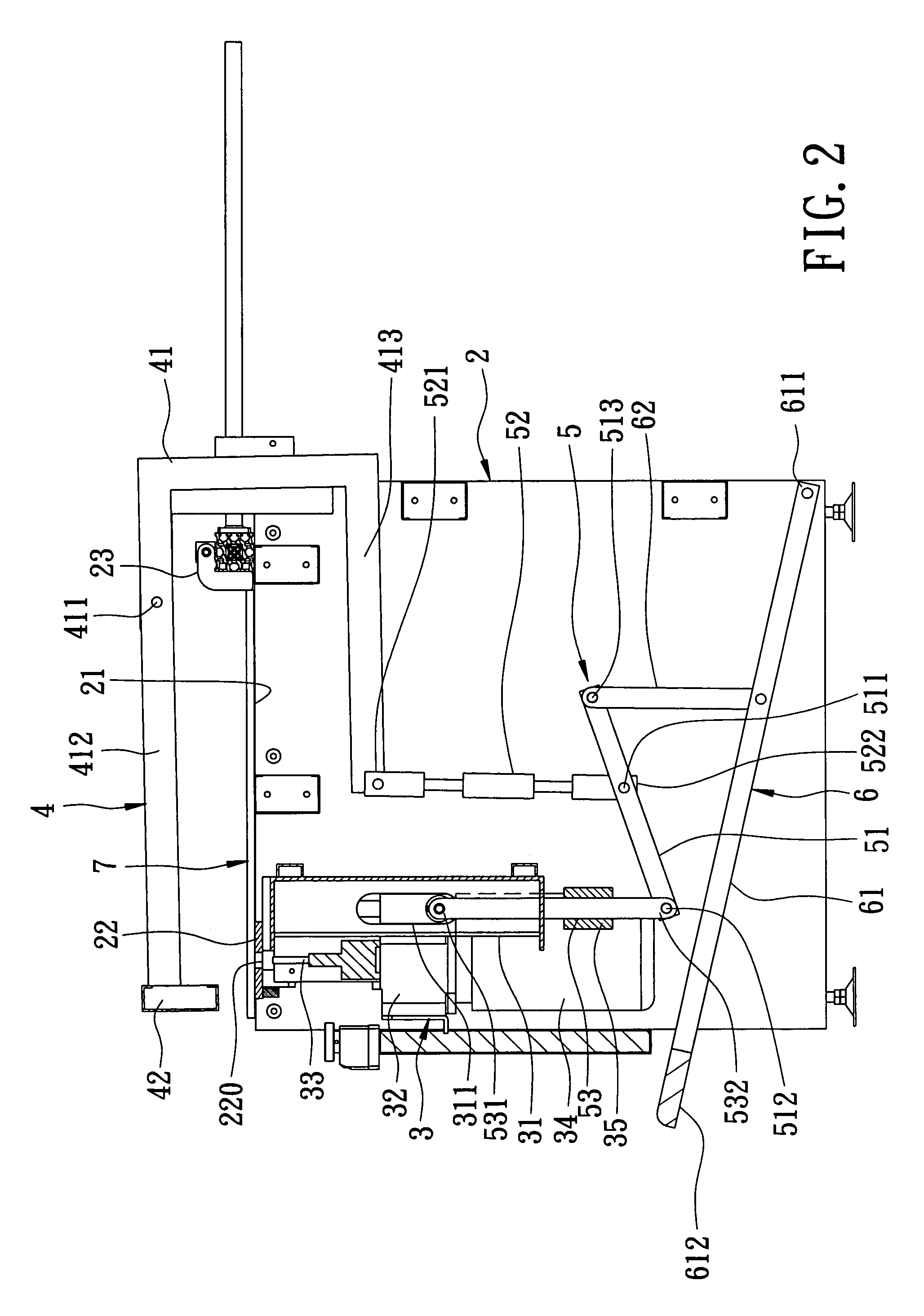

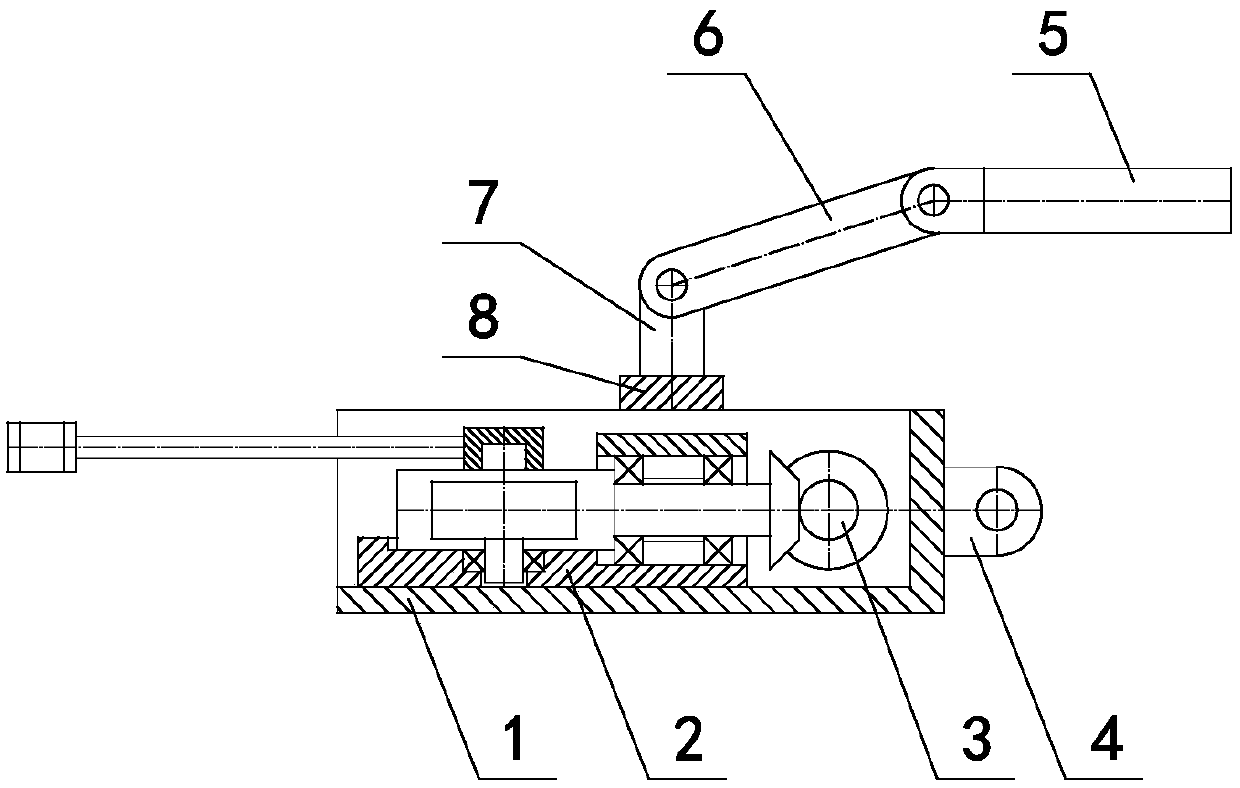

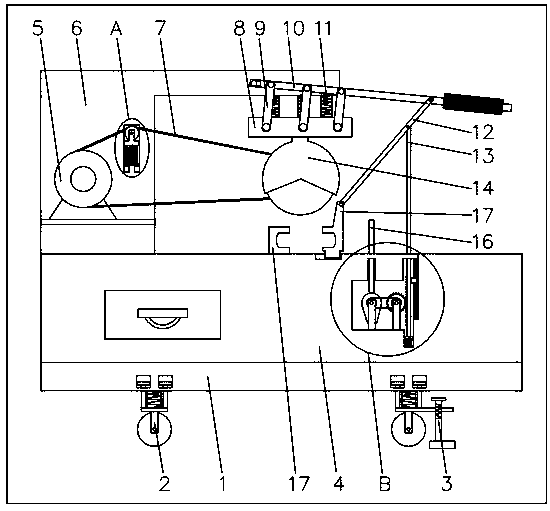

Working machine that can clamp a workpiece automatically

InactiveUS7537420B2For automatic clampingEasy to operateDrilling/boring measurement devicesThread cutting machinesEngineeringMechanical engineering

A working machine includes a base for placing a workpiece, a working mechanism movable relative to a first face of the workpiece, a clamping unit movable relative to a second face of the workpiece, a linkage connected to the working mechanism and the clamping unit to drive the working mechanism and the clamping unit to move relative to the workpiece simultaneously, and a drive unit connected to the linkage. Thus, the working machine is operated by a user's one foot, so that the working machine is operated easily and conveniently. In addition, the workpiece is clamped automatically without having to hold the workpiece by a user's one hand, thereby protecting the user's safety.

Owner:CHANG PIN FENG

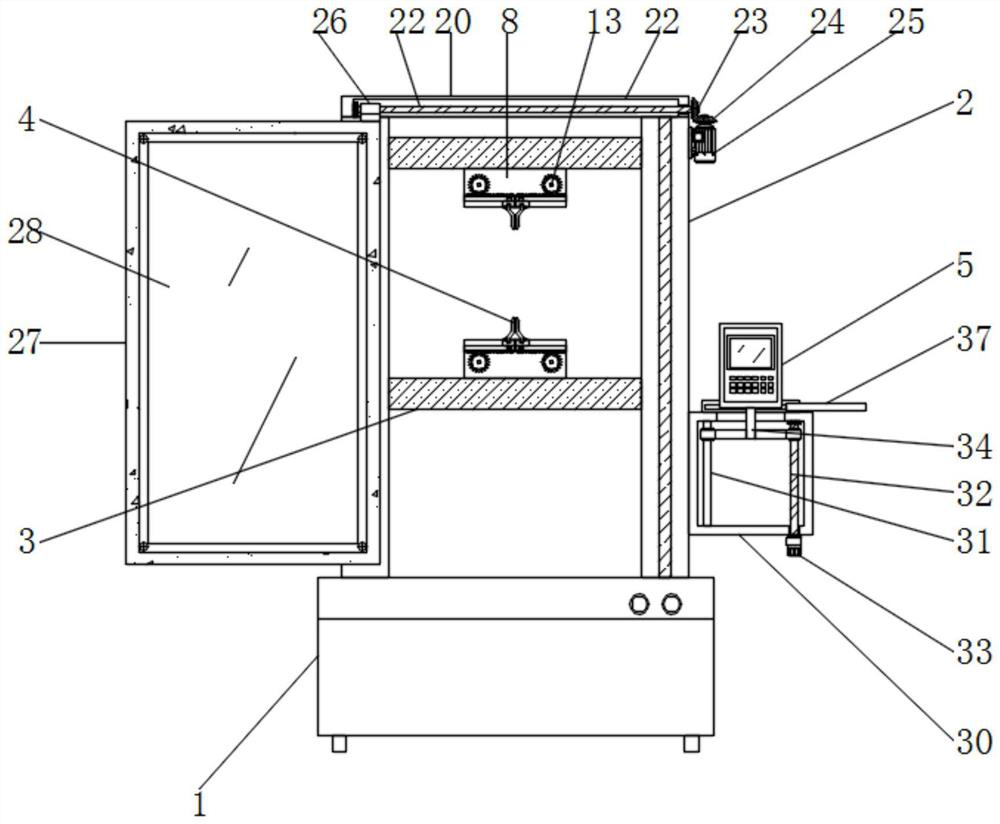

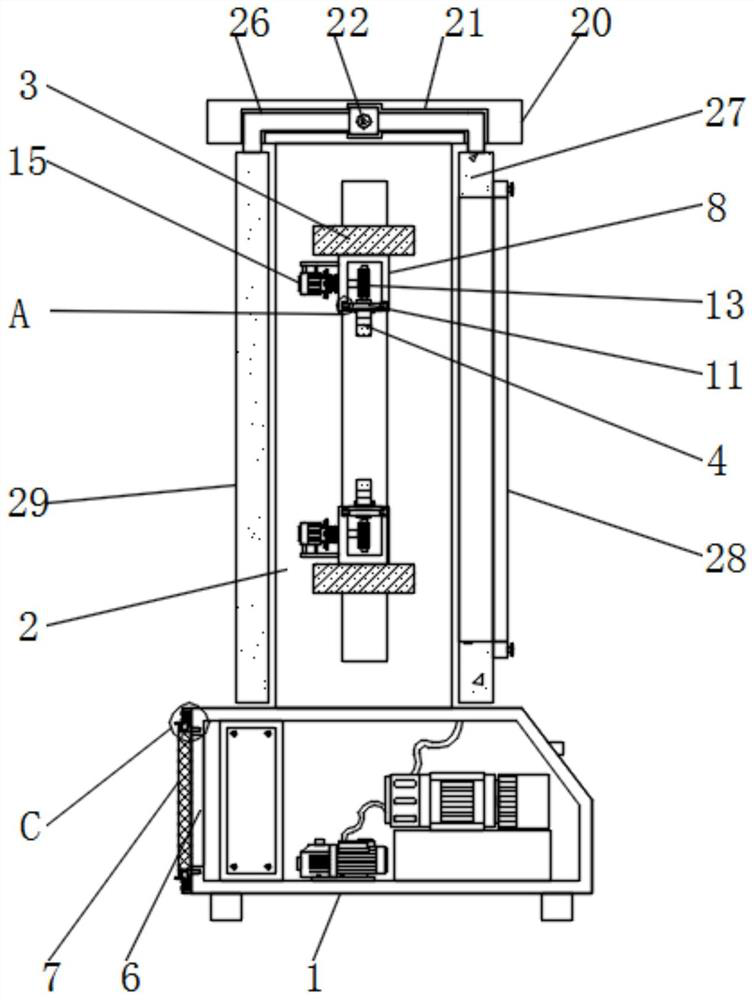

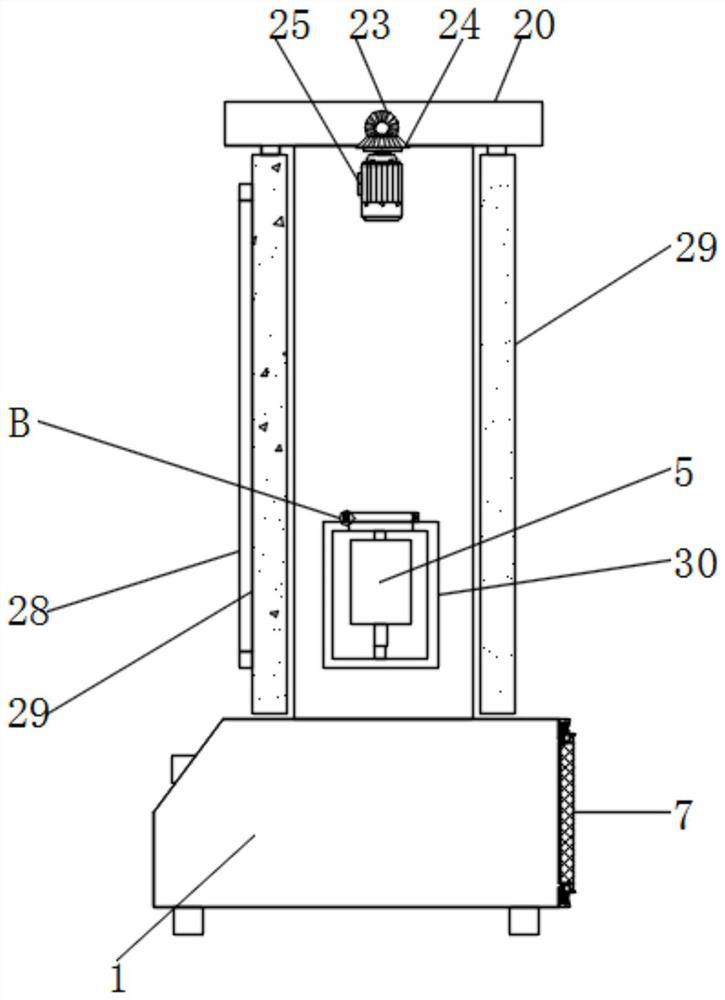

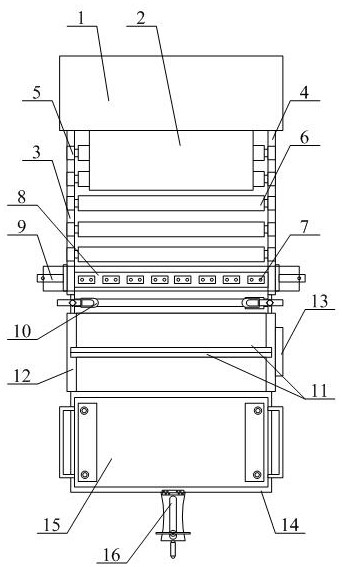

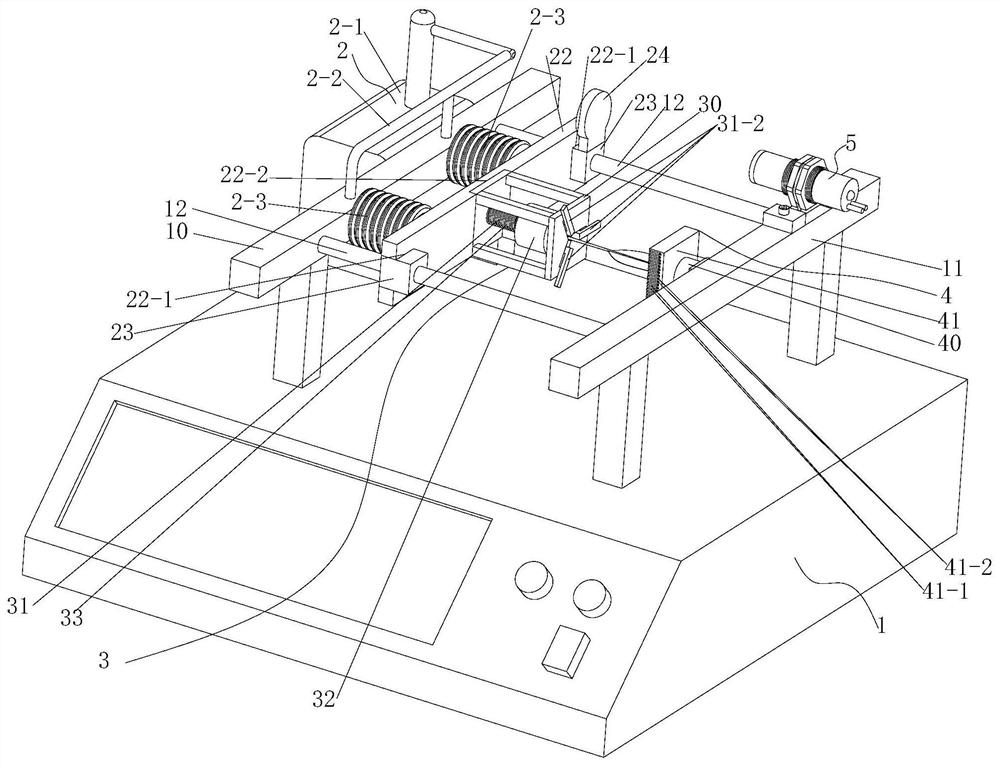

Tension testing machine with automatic clamping function for FPC (Flexible Printed Circuit) production

PendingCN114235583AFacilitates automatic workpiece clampingPrevent splashMaterial strength using tensile/compressive forcesProcess engineeringMechanical engineering

The invention discloses a tensile testing machine with an automatic clamping function for FPC (Flexible Printed Circuit) production. The tensile testing machine comprises a driving base; a moving mechanism is mounted at the top of the driving base, and the driving base acts on the driving moving mechanism to work. According to the tensile testing machine with the automatic clamping function for FPC soft board production, firstly, a fixing plate pulls clamping blocks to be close to each other, when the clamping blocks are close to an adaptive position, a workpiece is clamped through a protective pad, then, when explosion-proof transparent glass and a protective plate move to the adaptive position, a clamping mechanism is covered, and the clamping mechanism is clamped through a clamping mechanism; the method comprises the steps that firstly, a controller is stretched, so that fragments can be prevented from splashing out in the stretching process, then the controller completely slides into a storage box, the storage box is covered through a sealing plate, protection and dust prevention can be conducted on the controller, secondly, when one end of a positioning block slides out of a positioning groove, a dustproof net is pulled, the positioning block can be detached to be cleaned, and finally, the controller is prevented from being damaged. And the clamping blocks are pulled to slide out along the interiors of the connecting grooves, so that the clamping blocks can be detached for replacement.

Owner:重庆宇隆光电科技股份有限公司

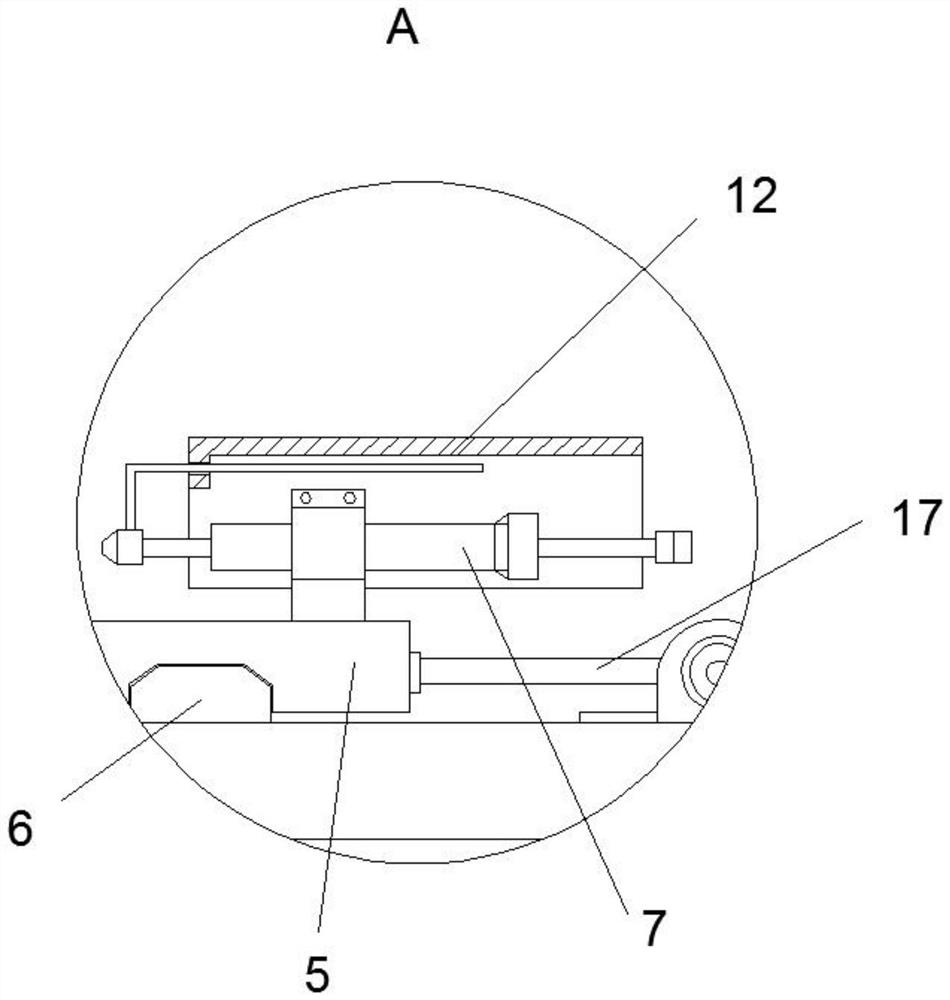

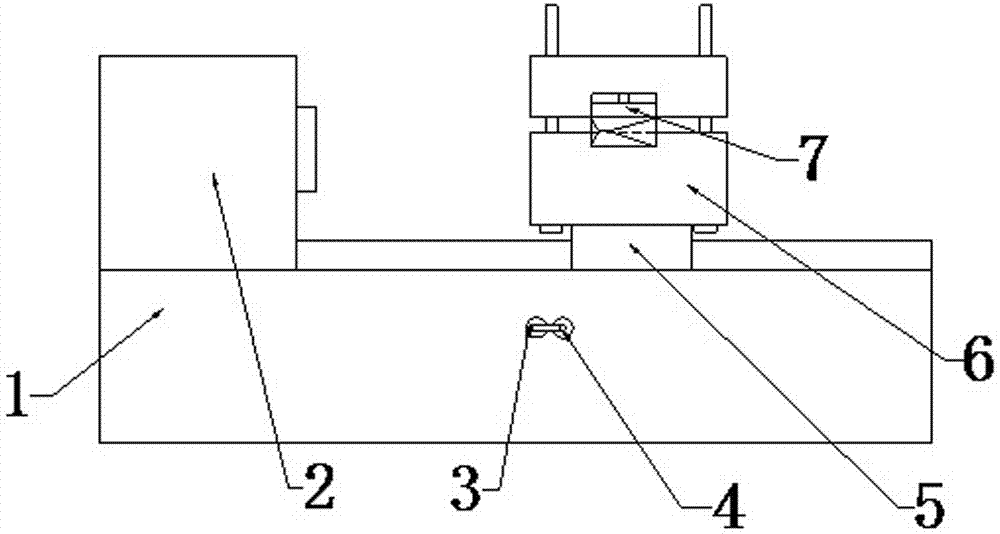

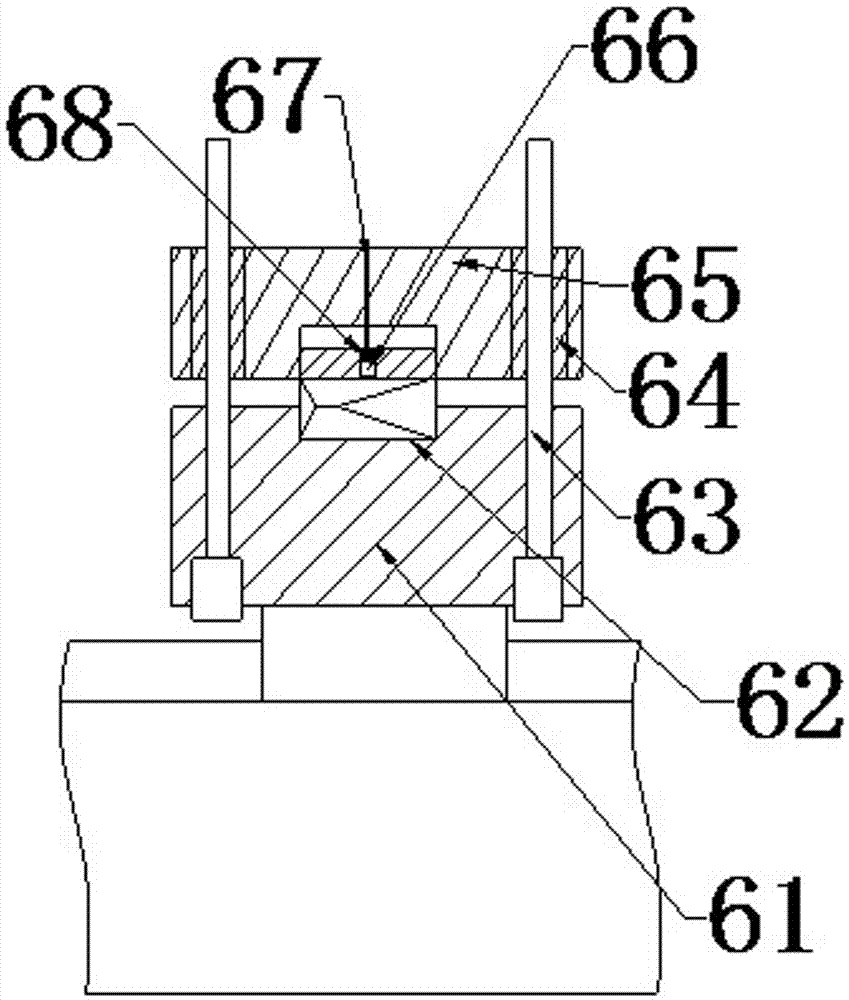

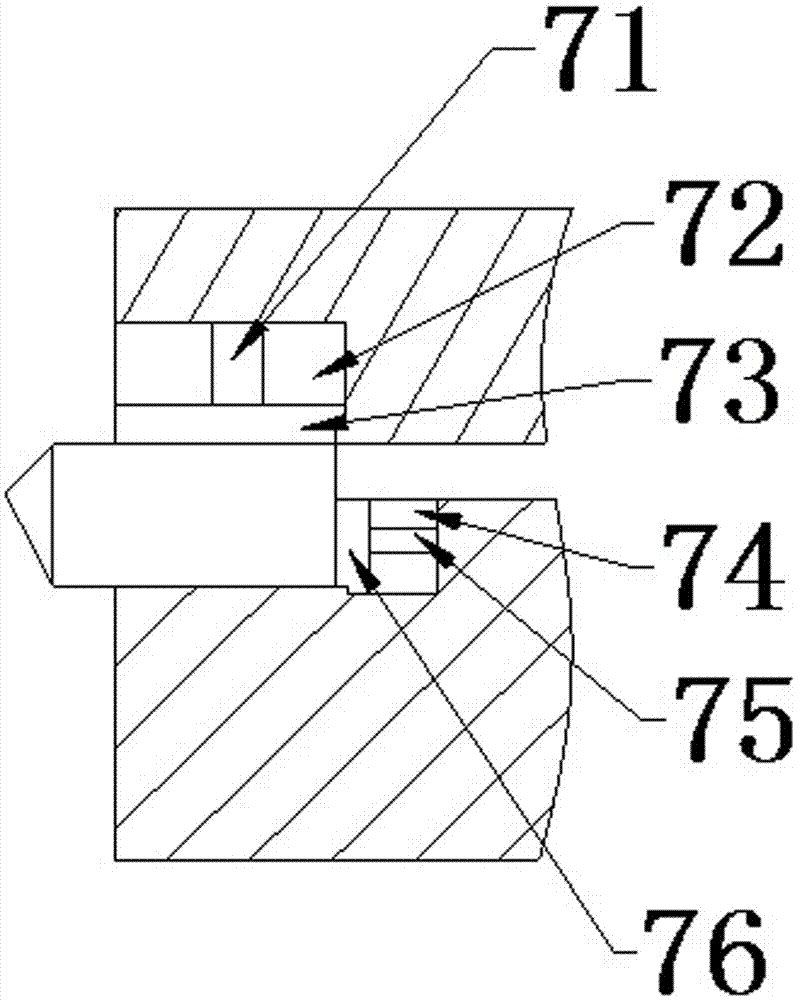

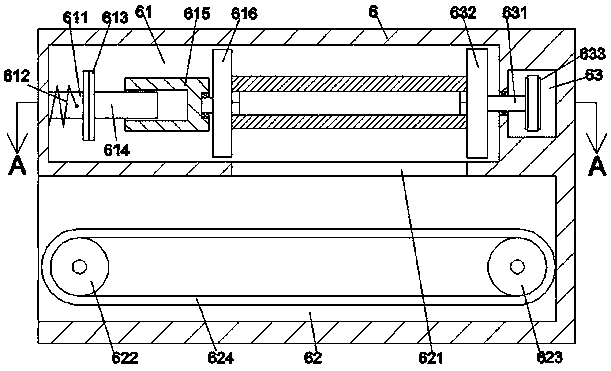

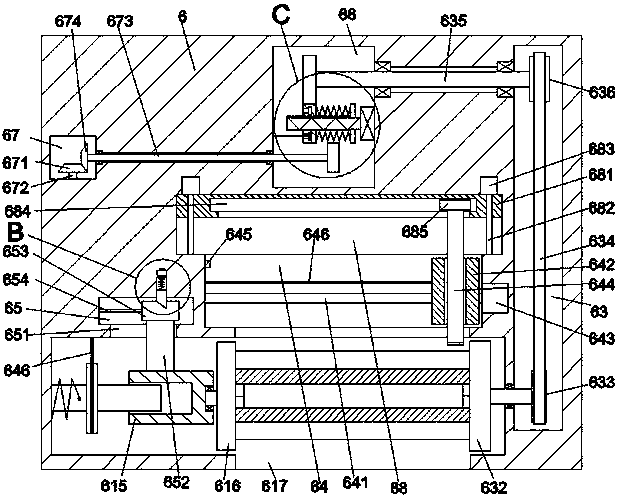

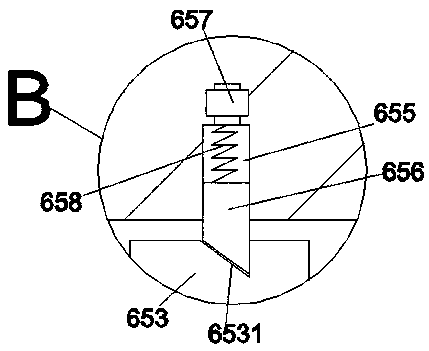

Paper tray grabbing mechanism

The invention relates to a paper tray grabbing mechanism comprising an installing box. An automatic clamping mechanism is horizontally installed in the installing box. A horizontal plate is horizontally arranged on the installing box. A vertical plate is vertically arranged on the horizontal plate. A push-pull rod is horizontally arranged above the installing box. A connecting plate is arranged between the vertical plate and the push-pull rod. The left end of the connecting plate is hinged to the vertical plate through a hinge pin. The right end of the connecting plate is hinged to the push-pull rod through a hinge pin. An ear handle is horizontally arranged on the right side of the installing box. A driving shaft is arranged in the position, on the right side of the automatic clamping mechanism, in the installing box. The driving shaft is arranged on the front and rear side faces of the installing box in a penetrating mode. A plurality of bevel gears are installed on the driving shaft. A worm is connected to the driving shaft through the bevel gears. Work efficiency is improved through the paper tray grabbing mechanism.

Owner:重庆莎姐食品科技有限公司

A grinding wheel cutting machine capable of automatically clamping and blocking

ActiveCN108081097BFor automatic clampingEnsure safetyGrinding machinesGrinding work supportsEngineeringGrinding wheel

The invention discloses a grinding wheel cutter capable of automatically clamping and blocking. The grinding wheel cutter comprises a base and a machine body, wherein the lower end of the base is equipped with a travelling mechanism; a brake mechanism is mounted on the travelling mechanism; a machine body is welded on the base; the upper end of the machine body is welded with a bracket; a motor and a tension device are mounted on the bracket; the left side of the top end of the bracket is rotatably connected with a pressure rod; the lower end of the pressure rod is rotatably connected with a plurality of first connecting rods at equal distance; one end, away from the pressure rod, of each first connecting rod is rotatably connected with a fixed plate; a plurality of strong springs are welded between the bracket and the fixed plates; and one end, away from each first connecting rod, of each fixed plate is welded with the grinding wheel cutter. The grinding wheel cutter is stable in structure, is simple to operate, is scientific and reasonable in design, is short in production period, is low in manufacturing cost, is good in anti-seismic property, is convenient to move, automaticallyclamps a cut object conveniently, blocks spark to guarantee safety of an operator, and is worthy of being popularized.

Owner:MINNAN INST OF SCI & TECH

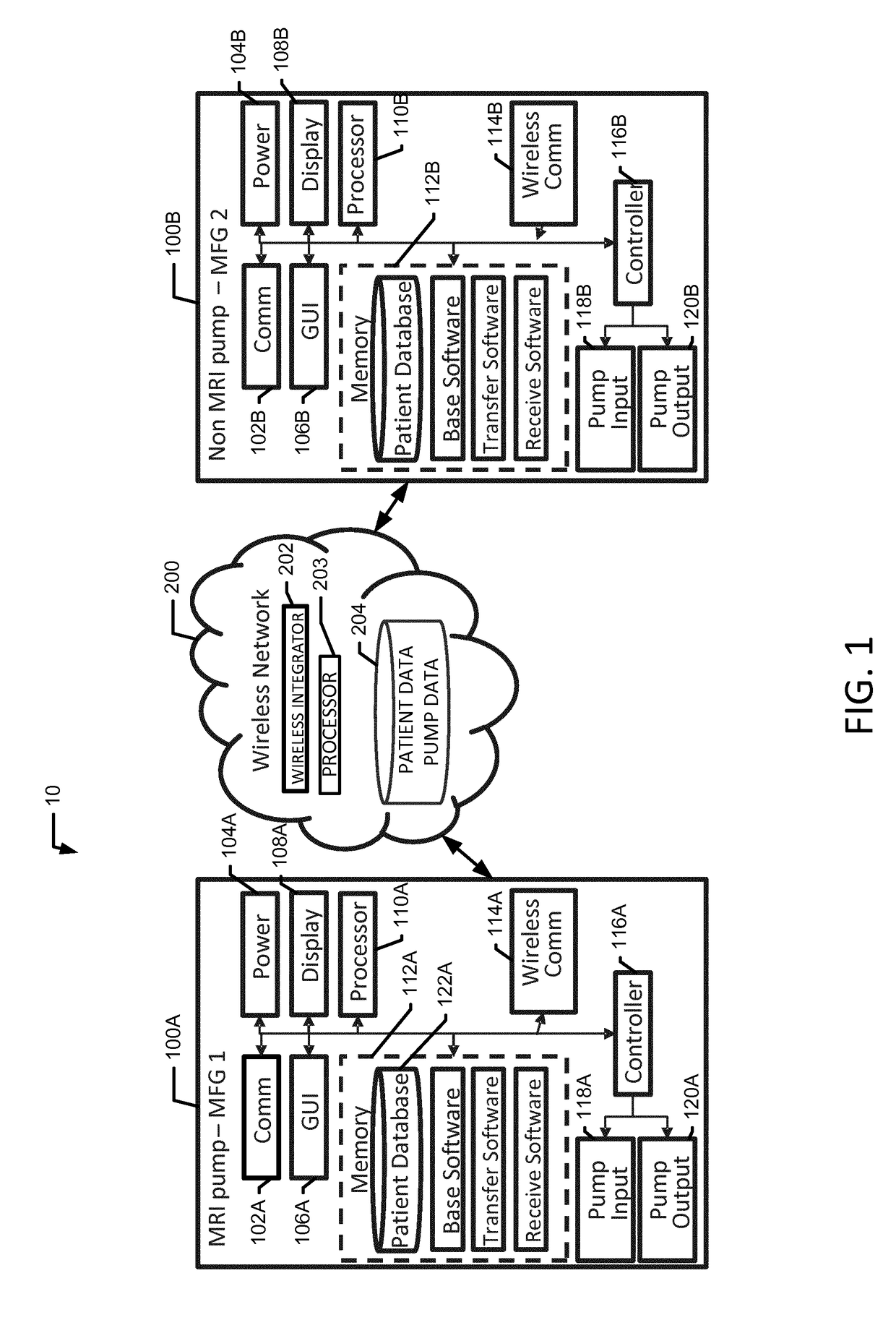

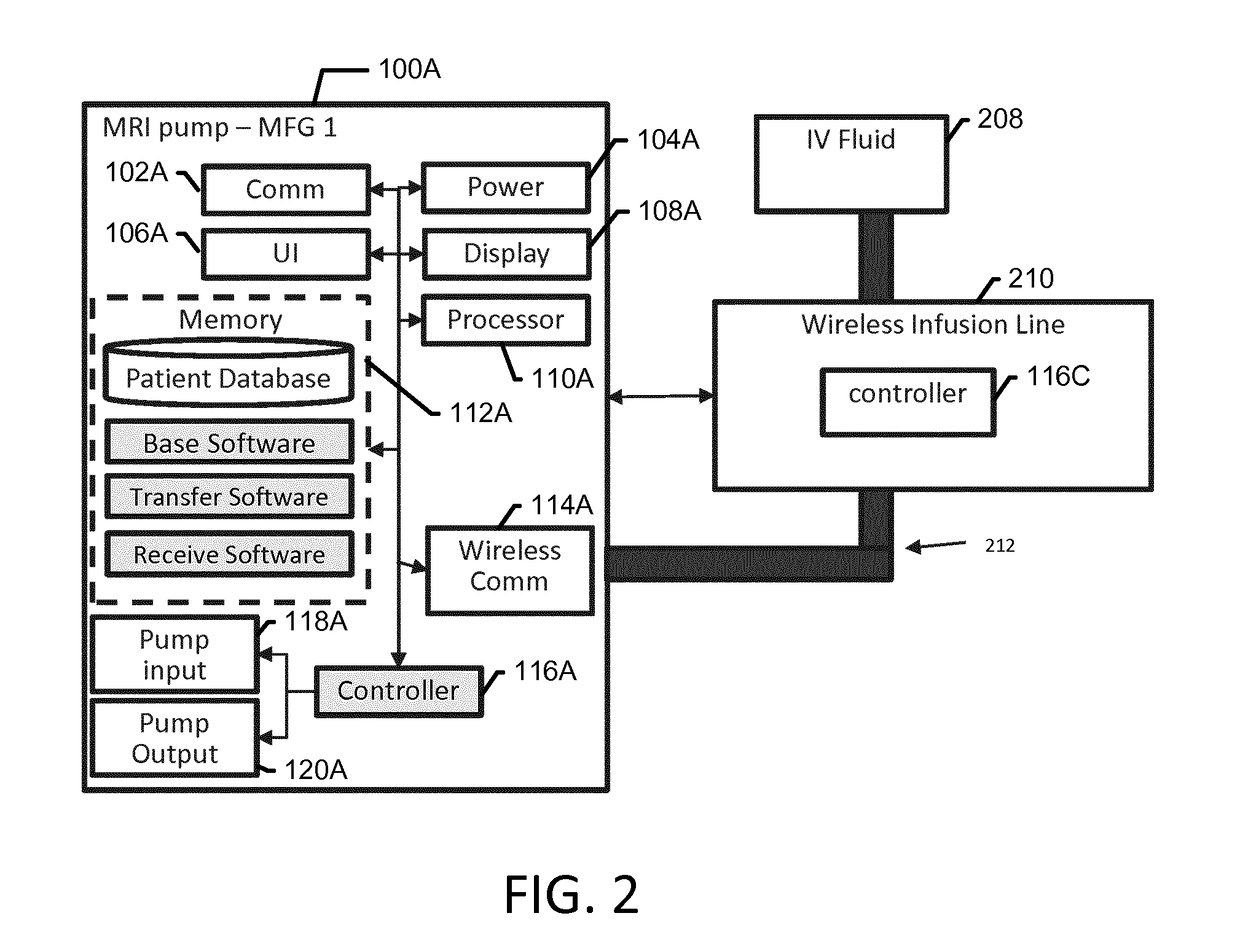

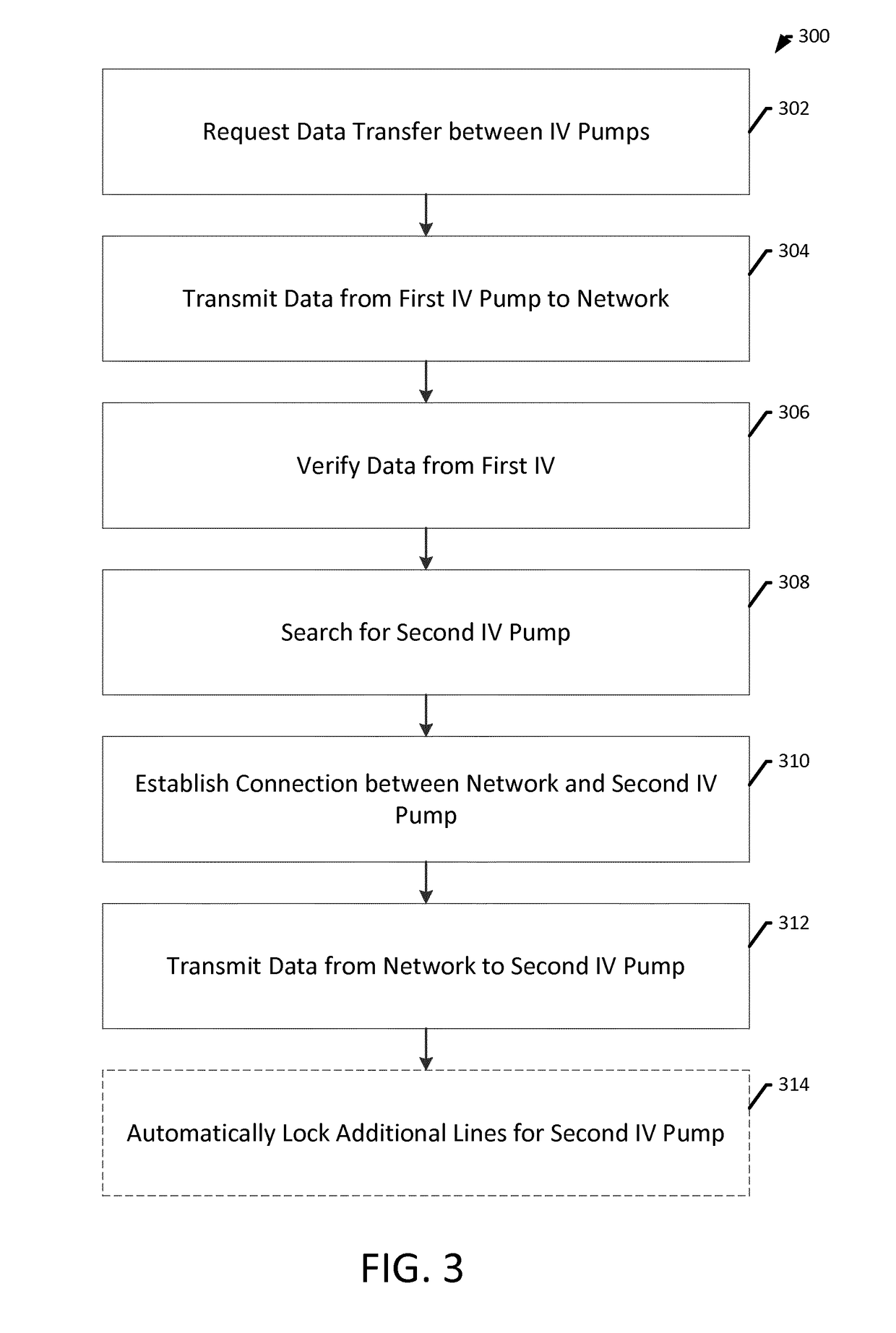

Automatically communicating between a non-MRI compatible iv pump and a MRI compatible iv pump

InactiveUS20190001051A1Easy transferFor automatic clampingDrug and medicationsMedical devicesUser inputEngineering

Methods and systems for automatically communicating information (e.g., patient information, flow rate, etc. . . . ) between a non-MRI compatible IV pump and a MRI compatible IV pump are described herein. Such methods and systems prevent human error from affecting the reprogramming of the IV pumps. Furthermore, automatically clamping infusion lines when a new line is added and locked in also reduces possible human error by removing the need for user input during this process.

Owner:KONINKLJIJKE PHILIPS NV

Automatic production device for cakes

InactiveCN109430325AFor automatic clampingEasy to loosenDough dividingDough processingPush pullEngineering

The invention relates to an automatic production device for cakes. The automatic production device comprises an operation table, wherein a conveyer belt is arranged on the operation table; a tray is arranged on the conveyer belt; a first bracket is arranged on the operation table; a mounting plate is arranged on the first bracket; a paper support frame is mounted on the mounting plate; a paper support is placed in the paper support frame; a paper support grabbing mechanism is arranged below the first bracket; a hydraulic cylinder is mounted on the first bracket; a hydraulic rod of the hydraulic cylinder is connected to a push-pull rod; an ear handle is horizontally arranged on the right side of a mounting box, and is hinged to the first bracket through a pin shaft; a driving shaft is arranged in the mounting box, on the right side of an automatic clamping mechanism, and is mounted on the front side surface and the rear side surface of the mounting box in a penetrating manner; a plurality of bevel gears are mounted on the driving shaft; a worm is connected to the driving shaft through the bevel gears; a second bracket is vertically arranged on the left side of the first bracket; anda material squeezing mechanism is vertically mounted on the second bracket. Through the adoption of the automatic production device disclosed by the invention, the working efficiency is improved.

Owner:重庆莎姐食品科技有限公司

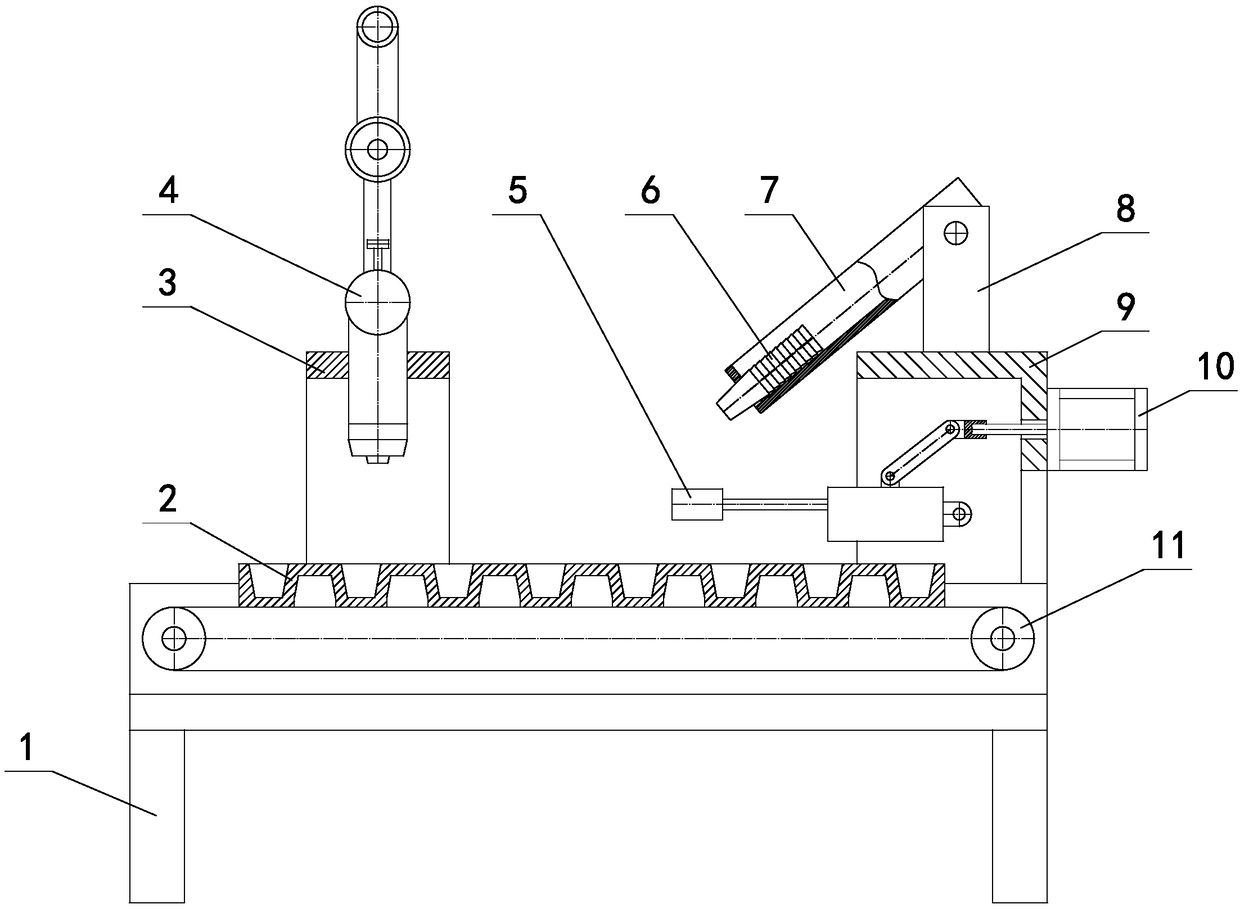

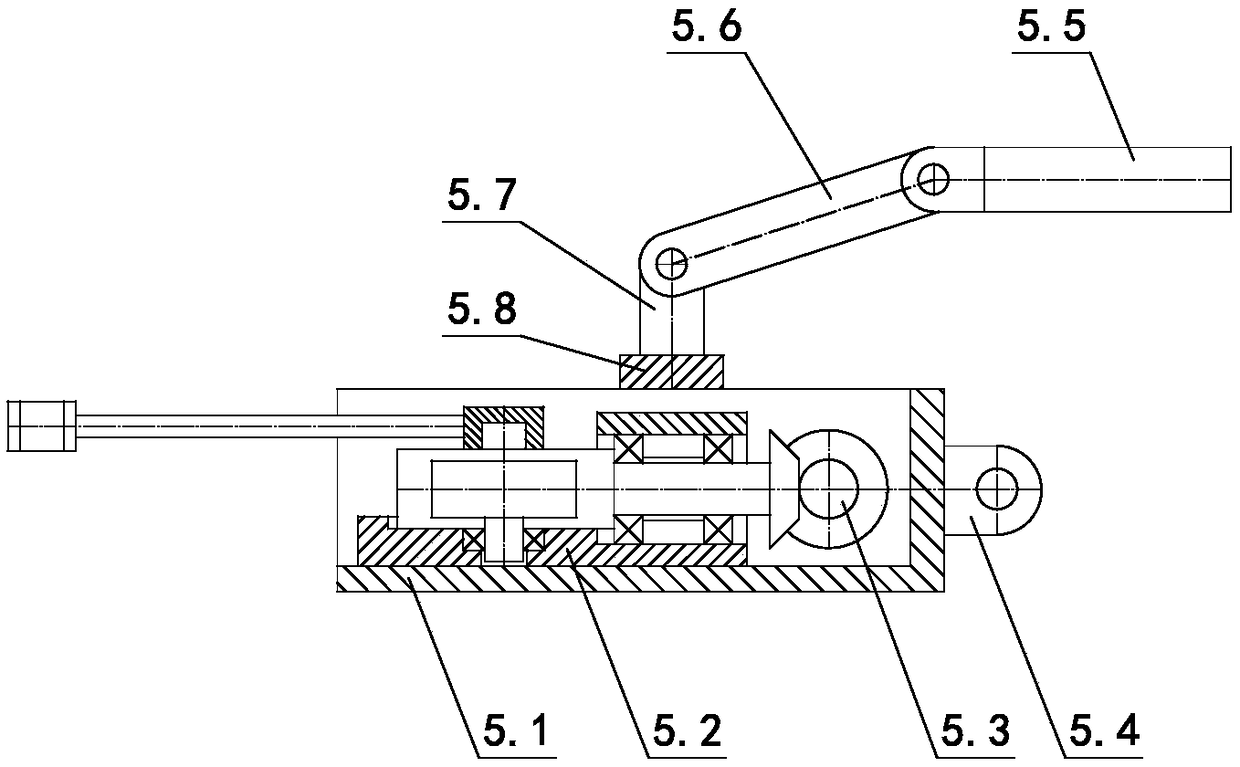

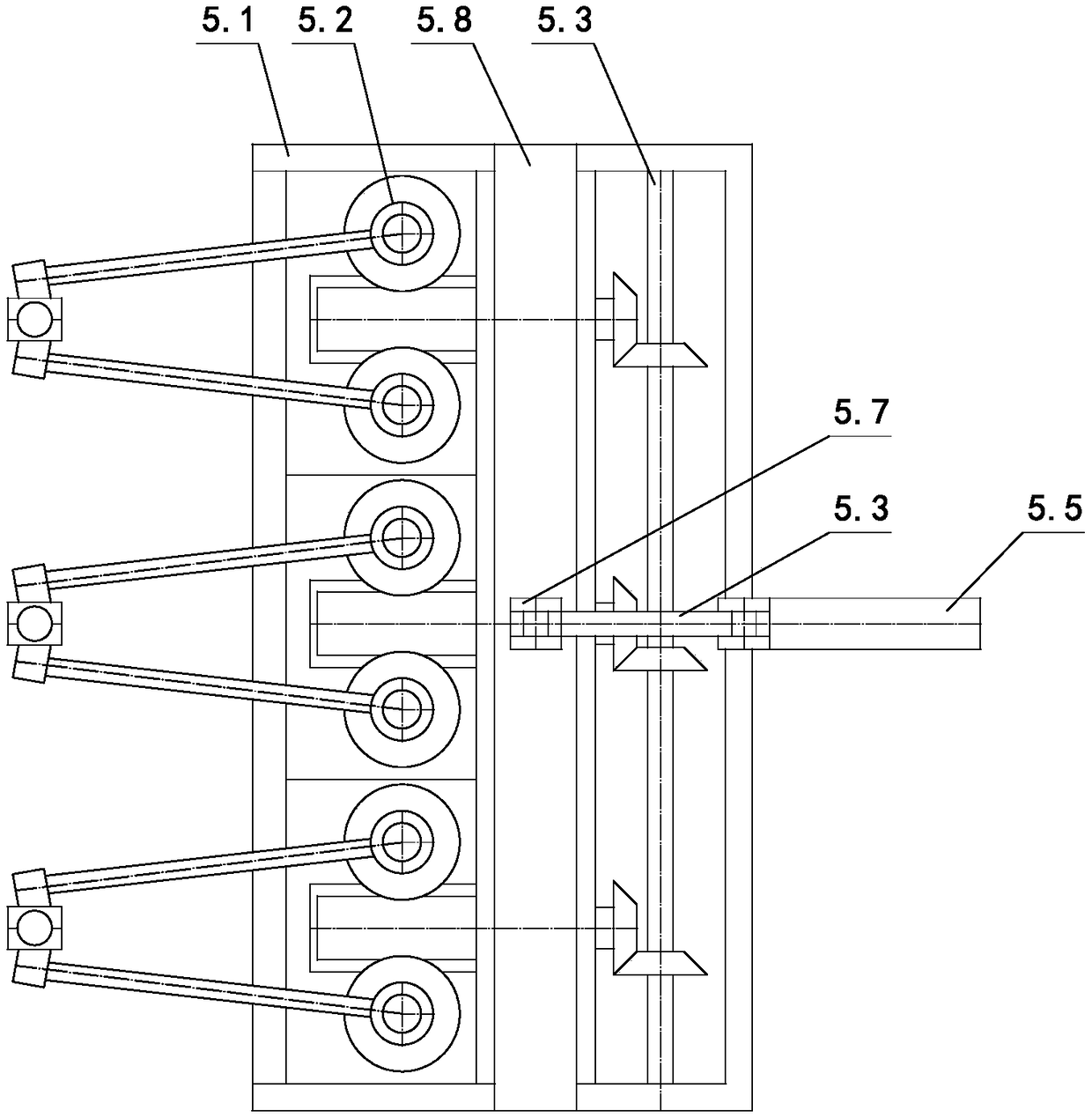

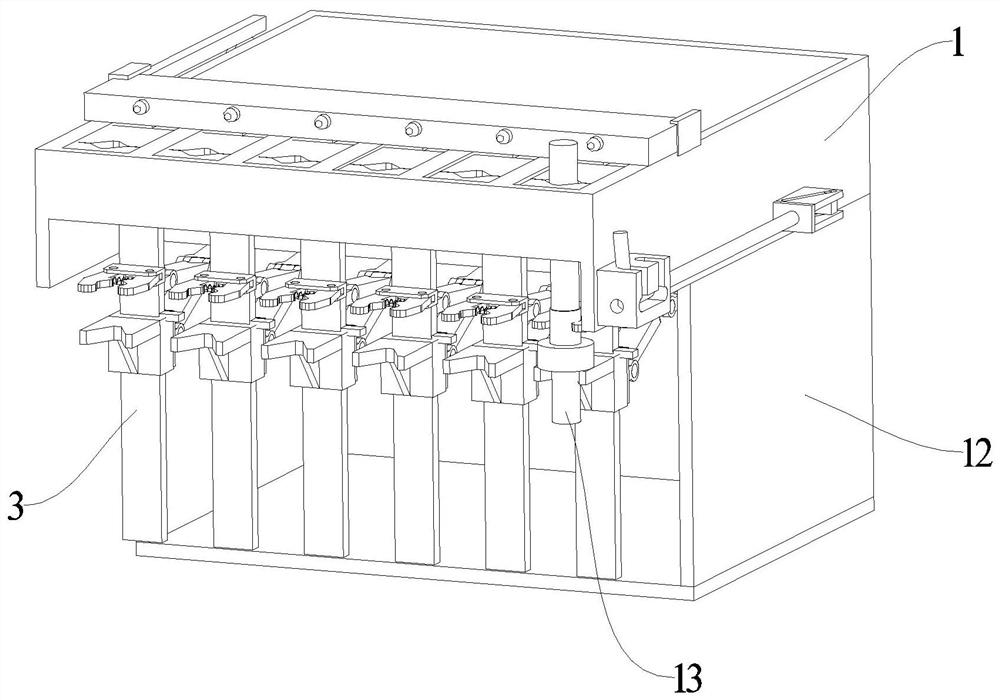

Vertical milling end face machining method for motor rotating shaft

ActiveCN113172264AReduce dependenceEasy loading and unloadingMilling equipment detailsMetal working apparatusElectric machineryEngineering

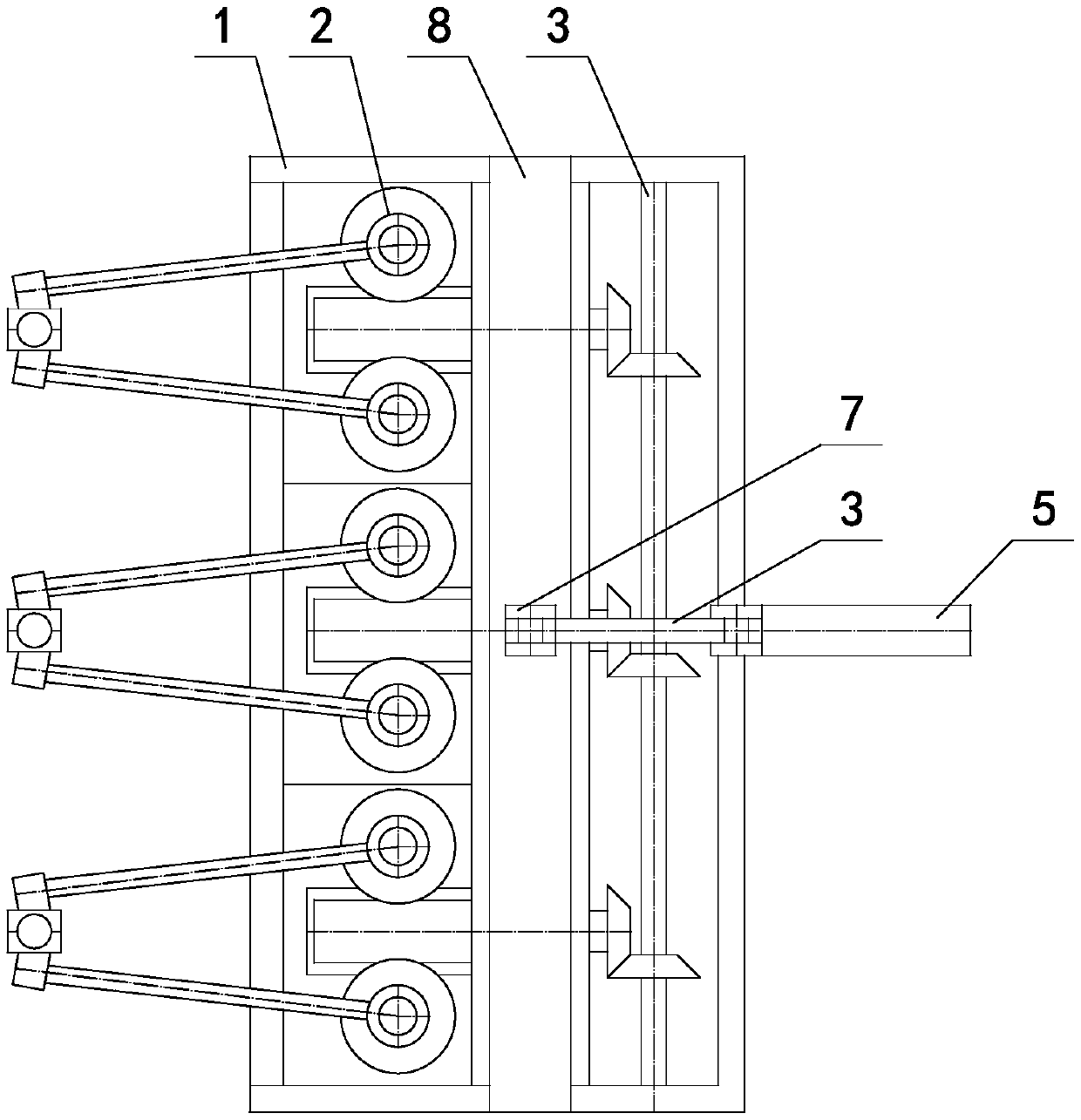

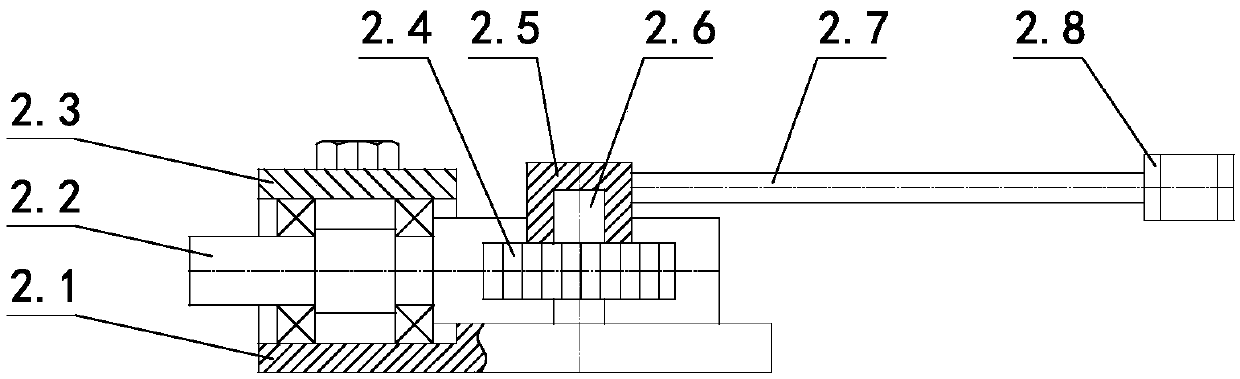

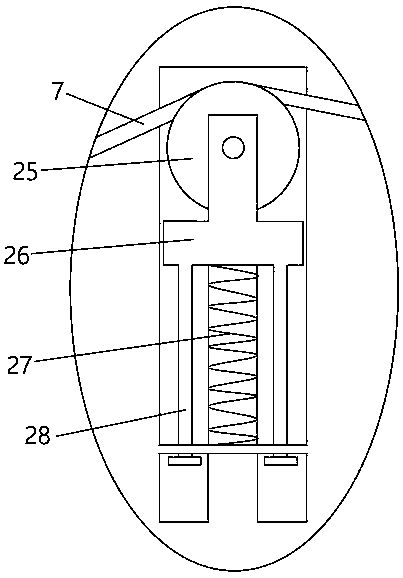

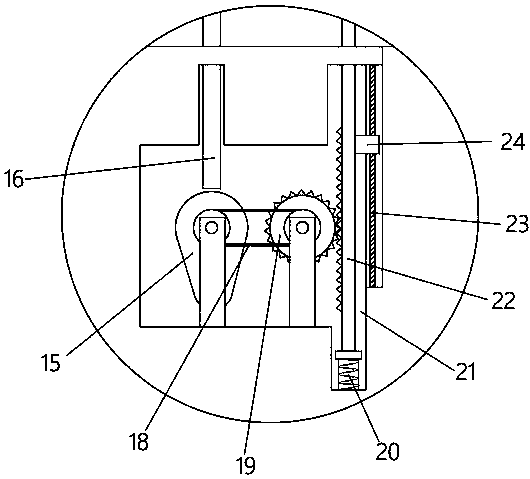

The invention relates to a vertical milling end face machining method for a motor rotating shaft. The vertical milling end face machining method for the motor rotating shaft adopts a vertical milling end face machining device for a motor shaft to machine the end face of the motor shaft. The vertical milling end face machining device for the motor shaft comprises a vertical milling end face clamp for the motor shaft, a vertical multi-station automatic clamping mechanism, an automatic positioning and feeding mechanism and a variable-speed spraying mechanism. The vertical milling end face machining method for the motor rotating shaft comprises the steps that 1, feeding is carried out; 2, automatic positioning and feeding are carried out; 3, automatic clamping is carried out; 4, the milling end face is automatically machined; 5, a workpiece is discharged; and 6, variable-speed cleaning is carried out. By means of the vertical multi-station machining clamp, horizontal single-station machining is changed into vertical multi-station machining, the dependence of a machining center on fourth shaft equipment is weakened, multi-station machining is achieved, vertical end face machining is facilitated, feeding and discharging clamping of workers or mechanical arms is facilitated, and the working efficiency of automatic production is improved.

Owner:JIAMUSI ELECTRIC MACHINE

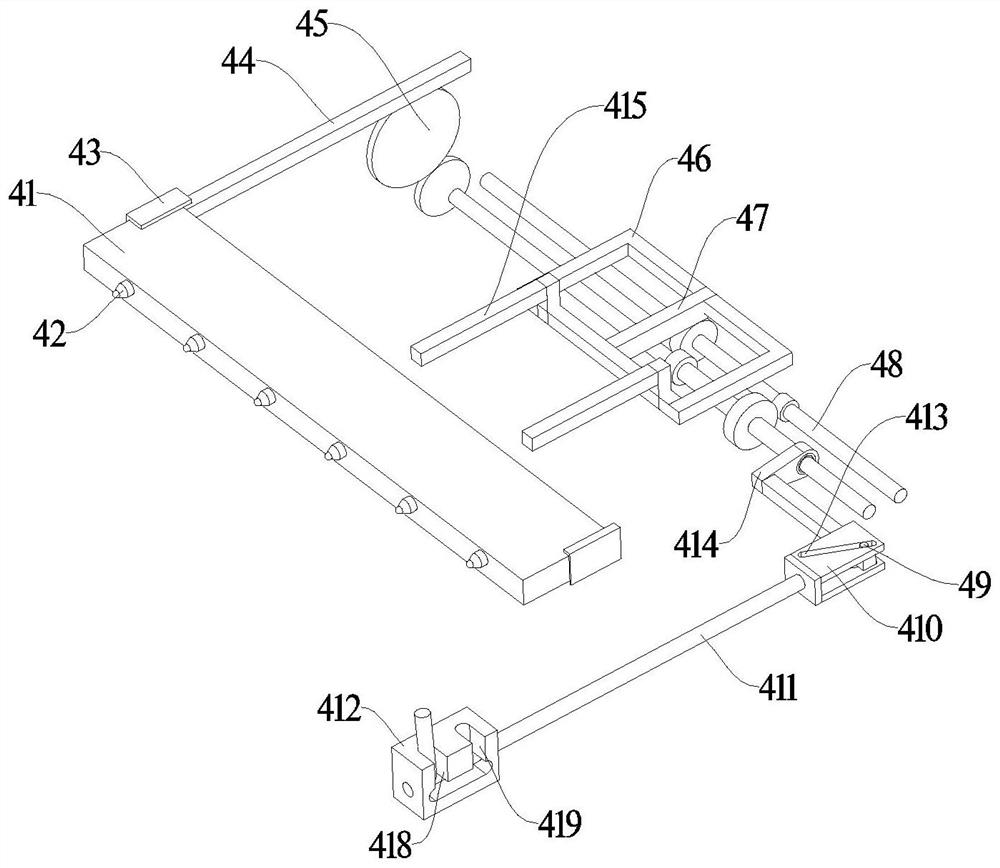

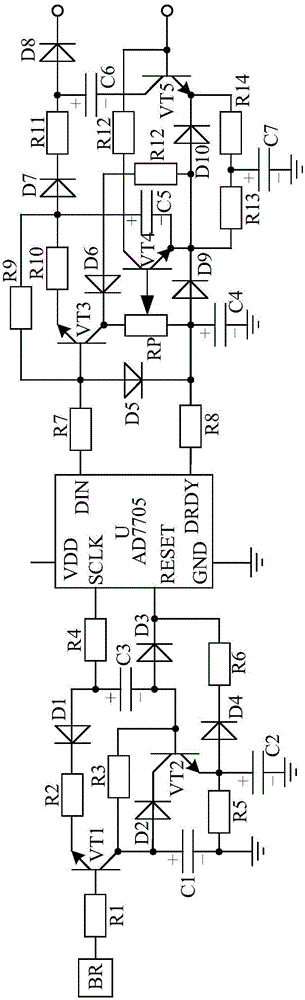

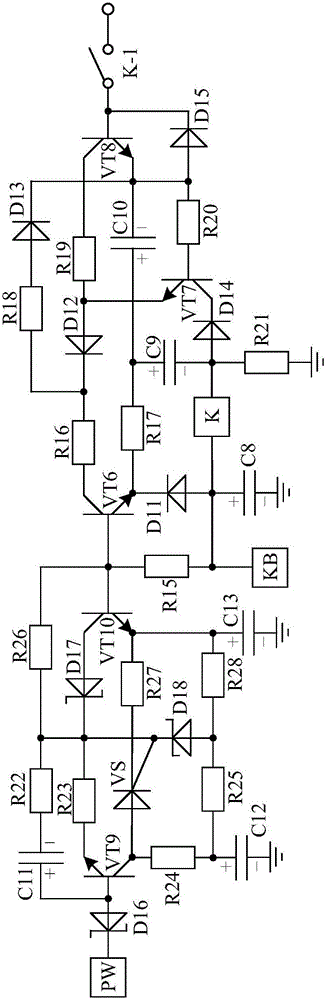

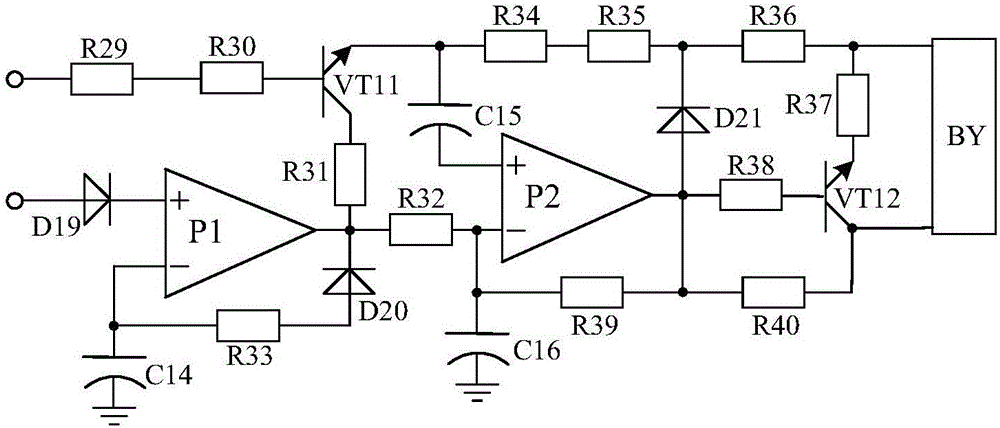

Signal-triggered startup low voltage rectifying and filtering type drive system for automatic clamping

InactiveCN105763080ASimple structureLow costAc-dc conversionElectrical resistance and conductanceLow voltage

The invention discloses a signal-triggered startup low voltage rectifying and filtering type drive system for automatic clamping. The drive system is characterized by mainly consisting of a control chip U, a pressure sensor BR, a power source BY, a low voltage rectifying circuit, a signal triggering circuit, a filtering and shaping circuit, a clamping control circuit and a signal conversion circuit, wherein an input end of the low voltage rectifying circuit is connected with a power source PW, an input end of the signal triggering circuit is connected with an output end of the low voltage rectifying circuit, an output end of the signal triggering circuit is connected with a VDD pin of the control chip U, an output end of the filtering and shaping circuit is connected with the power source BY, an input end of the clamping control circuit is connected with a DIN pin and a DRDY pin of the control chip U, an output end of the clamping control circuit is connected with an input end of the filtering and shaping circuit, an input end of the signal conversion circuit is connected with the pressure sensor BR via an electric resistor R1, and an output end of the signal conversion circuit is connected with an SCLK pin and an RESET pin of the control chip U. The drive system is simile in structure, low in cost and strong in generality. The drive system is convenient to use, applicable to all kinds of clamping objects and suitable for popularization and application.

Owner:CHENGDU CLAY STAR TECH CO LTD

Full-automatic stamping production line

PendingCN113210521ASimple and efficient connection transmission modeEasy connectionMetal-working feeding devicesShaping safety devicesServoStructural engineering

The invention belongs to the technical field of stamping production lines, and particularly discloses a full-automatic stamping production line. The full-automatic stamping production line comprises a ground foot and sliding rails, wherein a fixing frame is arranged at the side of a bottom plate; a servo motor is arranged at the inner side of the fixing frame; a transmission wheel is arranged at the end of the servo motor; a transmission band is arranged at the outer side of the transmission wheel; a vertical plate is arranged at the end of the bottom plate; a first electric telescopic rod is installed at the inner side of the vertical plate; a connecting plate is installed at the end of the first electric telescopic rod; a second electric telescopic rod is installed in the connecting plate; a fixing seat is arranged at the side of the second electric telescopic rod; a fixing nail penetrates through the top of the fixing seat; and a push plate is arranged at the end of the second electric telescopic rod. According to the full-automatic stamping production line, a user can conveniently and automatically convey and shift parts of the device, conveniently clamp and fix the parts of the device, conveniently adjust and set the stamping height and conveniently conduct damping on the structure of the device.

Owner:芮玲美

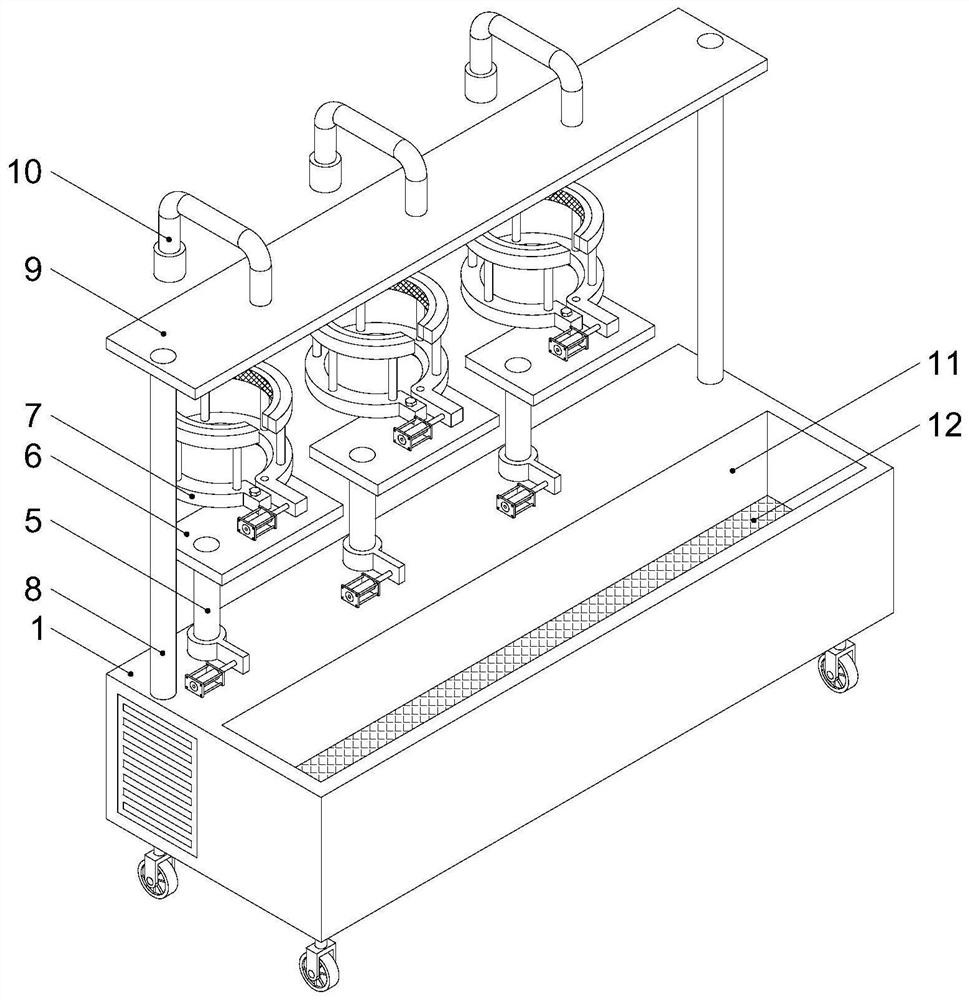

Automatic picking equipment for needle mushroom planting

PendingCN113273443AEasy to transportImprove picking efficiencyCultivating equipmentsMushroom cultivationAgricultural scienceAgricultural engineering

The invention discloses automatic picking equipment for needle mushroom planting. The automatic picking equipment comprises a main box body, a water pump is fixedly installed on one side in the main box body, a water tank is fixedly installed on the side, close to the water pump, in the main box body, the water tank communicates with the water pump through a pipeline, and an air pump is fixedly installed on the other side, close to the water tank, in the main box body; the top of the main box is fixedly provided with a plurality of rotating shafts, the tops of the rotating shafts are fixedly provided with fixing plates, the tops of the fixing plates are fixedly provided with picking devices, the two sides of the top of the main box are fixedly provided with fixing columns, the tops of the fixing columns are fixedly provided with a top plate, and the top of the top plate is fixedly provided with a plurality of water spraying pipes. The automatic picking equipment for needle mushroom planting is simple and compact in structure and convenient to use, the needle mushroom picking efficiency is effectively improved, and high practical value is achieved.

Owner:连云港如意情食用菌生物科技有限公司

An Intelligent Multifunctional Paper Machine Broken Paper Processing Classification System

ActiveCN108425266BFor automatic clampingGuarantee paper qualityPaper-making machinesIndustrial engineeringPaper sheet

The invention provides an intelligent multi-function broken paper processing and classification system for a paper machine, which includes a paper machine body, paper to be detected, a left bushing seat, a right bushing seat, a conventional bearing, a transmission roller, a damage detector, a fixed seat, and an adjustable Shading plate structure, automatic paper clamping claw structure, automatic opening and closing door, broken paper collection box, intelligent cabinet, placement table, paper transfer anti-falling plate structure and paper picker structure, the paper to be detected is set on the paper machine body At the exit of the lower middle position. The arrangement of the linear slide rail, connecting seat, supporting seat, clamping jaw adjusting seat, adjusting bolt, electric clamping jaw, paper cutter and electric slider in the present invention is beneficial to automatically clamp unqualified paper, and can pass through the paper cutter Cut the unqualified paper to ensure the quality of papermaking; the setting of the fixing screw, the main body of the transfer plate, the handle, the main body of the anti-drop plate, the compression spring and the fastening nut is beneficial to increase the quasi-transport function of qualified paper and prevent the occurrence of alignment wrinkle problem.

Owner:温州南冠机械有限公司

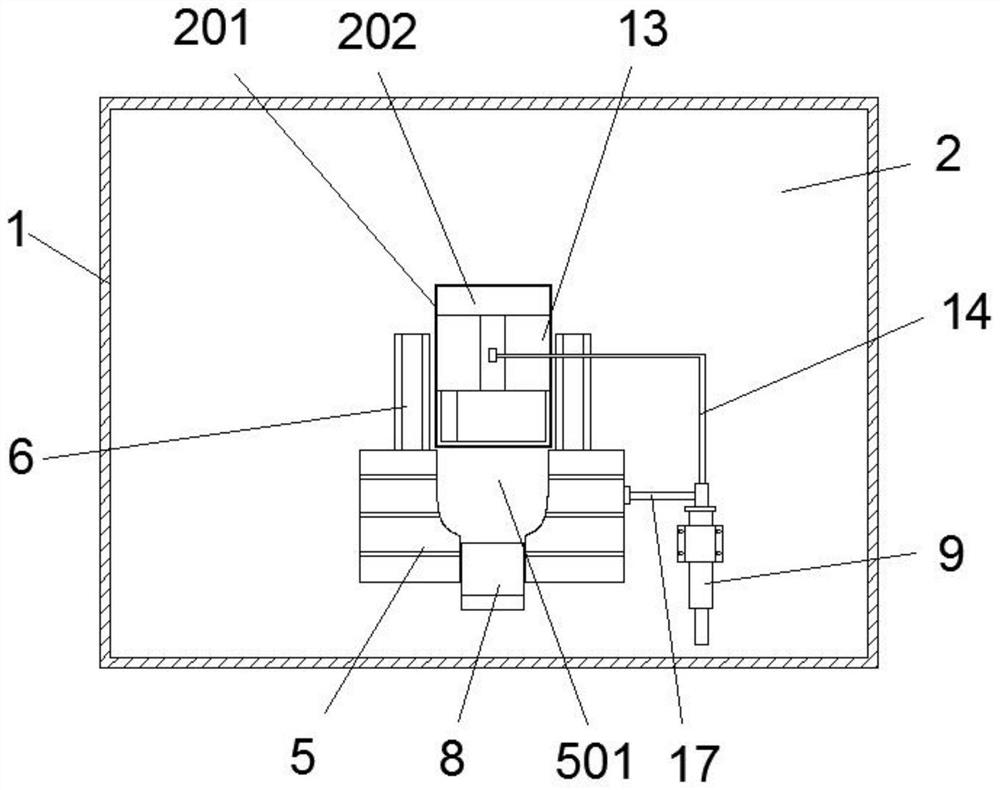

A spot welding machine with automatic blanking structure

ActiveCN109014532BEasy to installFor automatic clampingResistance welding apparatusEngineeringSpot welding

The invention relates to the technical field of spot welding machines, and provides a spot welding machine with an automatic blanking structure, including a protective shell, a mounting plate, an automatic welding machine and an electrical cabinet, and is characterized in that it also includes an automatic clamping structure and an automatic blanking structure. Structure, the automatic clamping structure includes a slide table and a slide rail, the slide rail is symmetrically fixed on the mounting plate, the slide table is slid and clamped on the slide rail, the top front side of the slide table is symmetrically installed with a clamping cylinder, and the top of the slide table is opened There is a U-shaped through groove, and an L-shaped placing plate is fixed between the slide rails, and the front end of the sliding table is clamped in the L-shaped placing plate; the automatic blanking structure includes a feeding cylinder, a slideway and a cooling chamber; the present invention solves the problem of existing The technical spot welding machine is inconvenient for loading and clamping and unloading, which affects work efficiency.

Owner:ANHUI HONGQIAO METAL MFG

Intelligent machine tool provided with mechanical clamping-fixing type turning tool

PendingCN107138746AFor automatic clampingSolve the problem that the degree of tool clamping cannot be determinedLarge fixed membersIntelligent machineEngineering

The invention provides an intelligent machine tool provided with a mechanical clamping-fixing type turning tool. The intelligent machine tool comprises a base, a lead screw, a rolling ball nut base, an upper pressure table, a cylinder, a spring, an electric lifting column I, a mounting slot I and a baffle plate I, wherein the base is fixedly arranged on the upper end surface of a movable base; the lower end of the lead screw is assembled inside the base; the upper end of the lead screw is connected with the upper pressure table through the rolling ball nut base; the cylinder is assembled on the lower end surface of the baffle plate I; and the spring is connected to the upper end surface of the cylinder; and the spring is mounted inside the baffle plate I. Automatic clamping of the tool is convenient through the design, the mounting slot is formed in the lower end surface of the upper pressure table, the upper end of the electric lifting column I is connected to the end surface at the upper side inside the mounting slot I, the lower end of the electric lifting column I is connected to the upper end surface of the baffle plate I, and the baffle plate I is assembled inside the mounting slot I; the design can protect the tool from being broken by a workpiece when a main shaft stops; and the intelligent machine tool is simple in structure, is convenient to operate, is good in stability and is good in protection effect on tool.

Owner:重庆卓成机电有限公司

Injection molding piece surface treatment equipment

InactiveCN111571364AFor automatic clampingConvenient automatic clamping installationEdge grinding machinesGrinding drivesEngineeringControl room

The invention discloses injection molding piece surface treatment equipment. The injection molding piece surface treatment equipment comprises a main shell; a polishing chamber is arranged in the mainshell; a discharging chamber, the left side of which communicates with the outside, is arranged on the lower side of the polishing chamber; a discharging conveying mechanism is arranged in the discharging chamber; a first sliding cavity is formed in the back side of the polishing chamber; a second sliding cavity is formed in the front side wall of the first sliding cavity in a communicating way;a driving control chamber is arranged on the back side of the first sliding cavity; a driving control mechanism is arranged in the driving control chamber; a limiting sliding cavity is formed in the left side of the second sliding cavity; a positioning groove communicating with the polishing chamber is formed in the front side of the limiting sliding cavity; an internal part of the limiting sliding cavity is connected to a limiting sliding block in a sliding fit way; an internal part of the positioning groove is connected to a positioning sliding block extending forwards and backwards in a sliding fit way; the tail end of the front side of the positioning sliding block is fixedly connected to the outer surface of an internal threaded sleeve; the back side of the positioning sliding block is fixedly connected to the front side of the limiting sliding block; and the injection molding piece surface treatment equipment is convenient to assemble and disassemble and improves the processing efficiency.

Owner:王涛

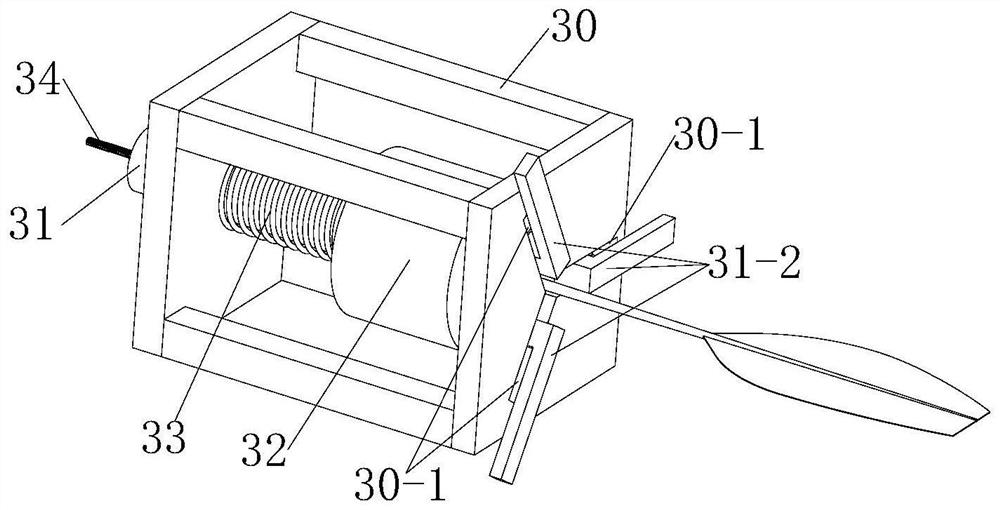

A Feather Elasticity Tester

ActiveCN109655352BImplement automatic detectionFor automatic clampingMaterial strength using steady bending forcesLaser rangingTester device

A feather elasticity tester of the present invention belongs to the technical field of detection equipment, and comprises a control box base, a mobile pressurization device, a tail clamping mechanism, a front-end limit mechanism and a laser range finder, and a bracket 1 and a laser range finder are arranged above the control box base Bracket 2, there is a cylindrical guide rod between bracket 1 and bracket 2, the mobile booster device is connected to the upper end of bracket 1, the tail clamping mechanism is composed of tailstock, clamping sleeve, tapered sleeve, pressure spring and adjusting screw rod, the tail There are three rectangular grooves on the end of the seat, and a threaded hole in the center of the clamping sleeve. There are three chucks on the clamping sleeve, and the tapered sleeve is set on the clamping sleeve. One end of the compression spring is connected with the end surface of the tapered sleeve Contact, the other end is in contact with the inner wall of the tailstock, the adjusting screw is connected with the screw pair of the threaded hole in the center of the clamping sleeve, the front limit mechanism is tightly connected with the inner wall of the second bracket, and the laser range finder is connected with the upper end of the second bracket to solve the existing background In technology, it is difficult to select feathers of the same quality through feather shape and human experience.

Owner:ANHUI POLYTECHNIC UNIV

Cutting device with high machining precision and used for machining manhole cover

PendingCN107398753ASolve the problem of not having automatic clamping functionAutomatic clamping withMetal sawing devicesPositioning apparatusEngineeringMachining

The invention discloses a cutting device with high machining precision and used for machining a manhole cover. The cutting device comprises a bottom board; the top of the bottom board is fixedly connected with a power supply box; a machine body is arranged on the top of the power supply box; fixed columns are fixedly connected with the two sides of the top of the bottom board; and the tops of the fixed columns are fixedly connected with the bottom of the machine body. Through arrangement and cooperation of the bottom board, the power supply box, the machine body, the fixed columns, a sliding board, a sliding groove, a first fixing block, a first transmission rod, a second fixing block, a second transmission rod, a third fixing block, a cylinder, a sleeve, a positioning pin, a sliding block, a movable clamping jaw, a fixing clamping board, a positioning block, a spring, an opening and a non-slip mat, the problem that an existing cutting device for machining the manhole cover does not have the automatic clamping function is solved, and the cutting device with high machining precision and used for machining the manhole cover has the advantage of automatic clamping, is convenient to use by users, shortens the time for the users, and improves the working efficiency.

Owner:长兴明强精密铸件厂(普通合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com