Signal-triggered startup low voltage rectifying and filtering type drive system for automatic clamping

A signal-triggered and automatic clamping technology, applied in output power conversion devices, conversion of AC power input to DC power output, electrical components, etc. Improves versatility and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

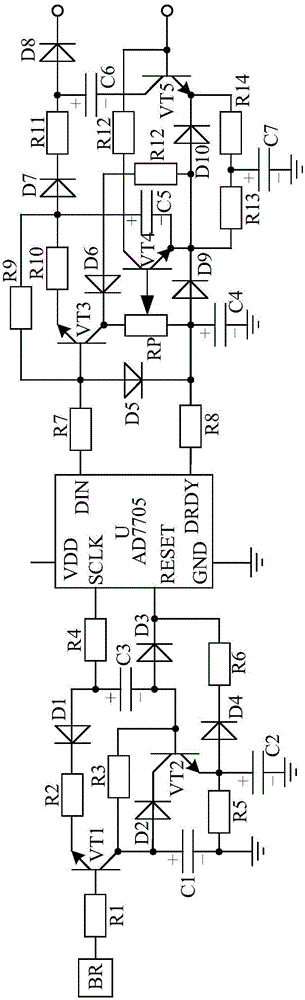

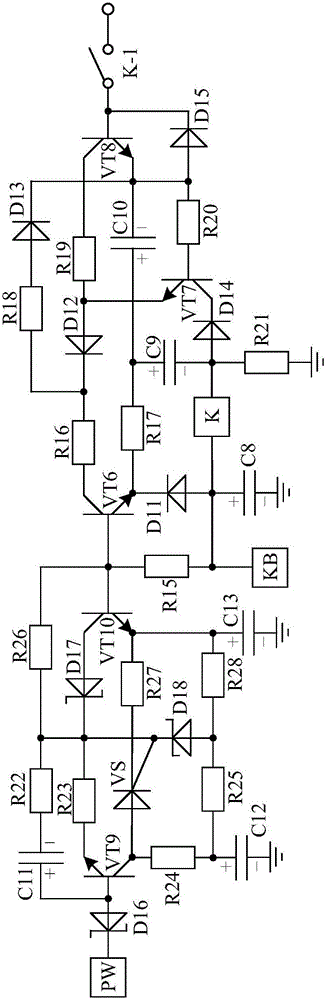

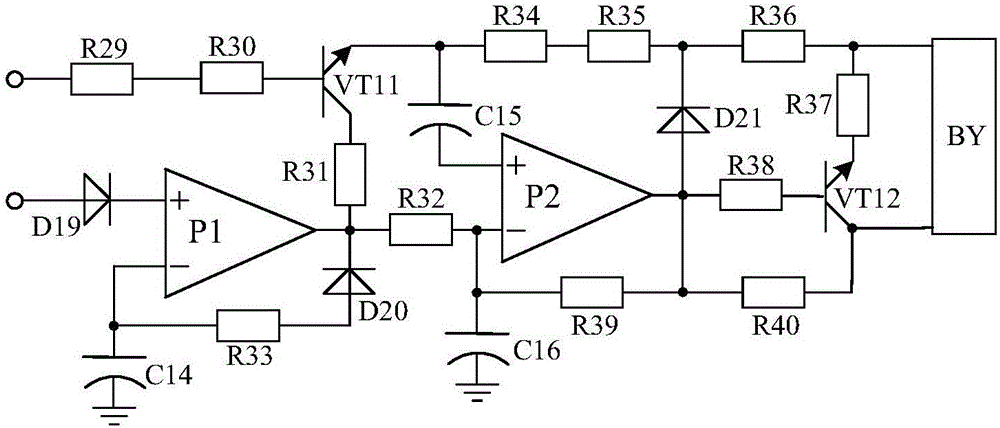

[0026] like Figure 1~3 As shown, the filtering and shaping general-purpose automatic clamping system of the present invention is mainly composed of a control chip U, a pressure sensor BR, a power source BY, a low-voltage rectifying circuit, a signal trigger circuit, a signal conversion circuit, a clamping control circuit and a filtering and shaping circuit. composition. The power source BY of the present invention is a motor, an air cylinder or a hydraulic cylinder, and the control chip U is an AD7705 integrated chip. The input terminal of the low-voltage rectification circuit is connected with the power supply PW, and the power supply PW of the present invention is a 220V low-voltage commercial power supply. The input end of the signal trigger circuit is connected to the output end of the low-voltage rectification circuit, and its output end is connected to the VDD pin of the control chip U. The input end of the signal conversion circuit is connected to the pressure sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com