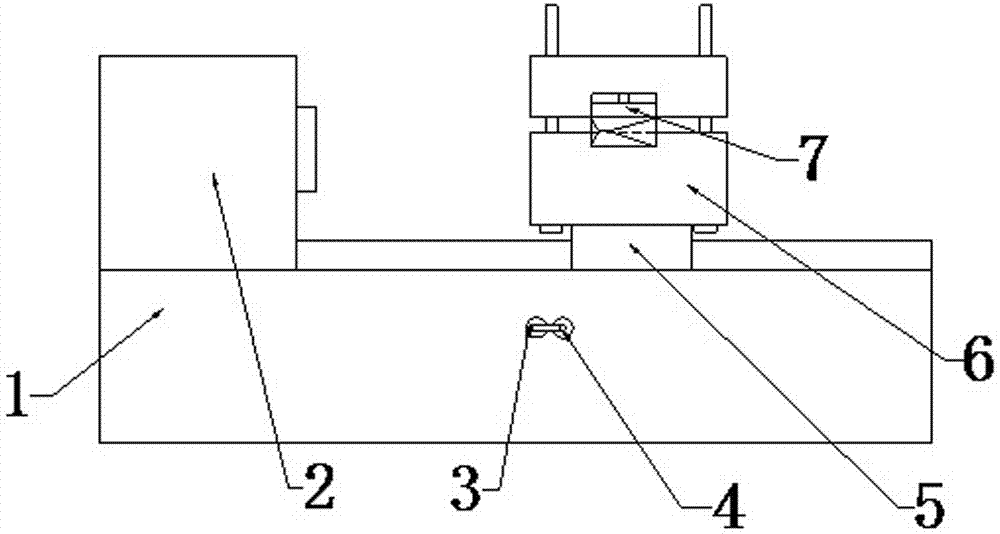

Intelligent machine tool provided with mechanical clamping-fixing type turning tool

An intelligent machine tool and clamping technology, which is applied to metal processing machinery parts, manufacturing tools, large fixed members, etc., can solve the problems of unstable clamping, tool interruption, high labor intensity, etc., and achieve good protection effect and convenient Good operation and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

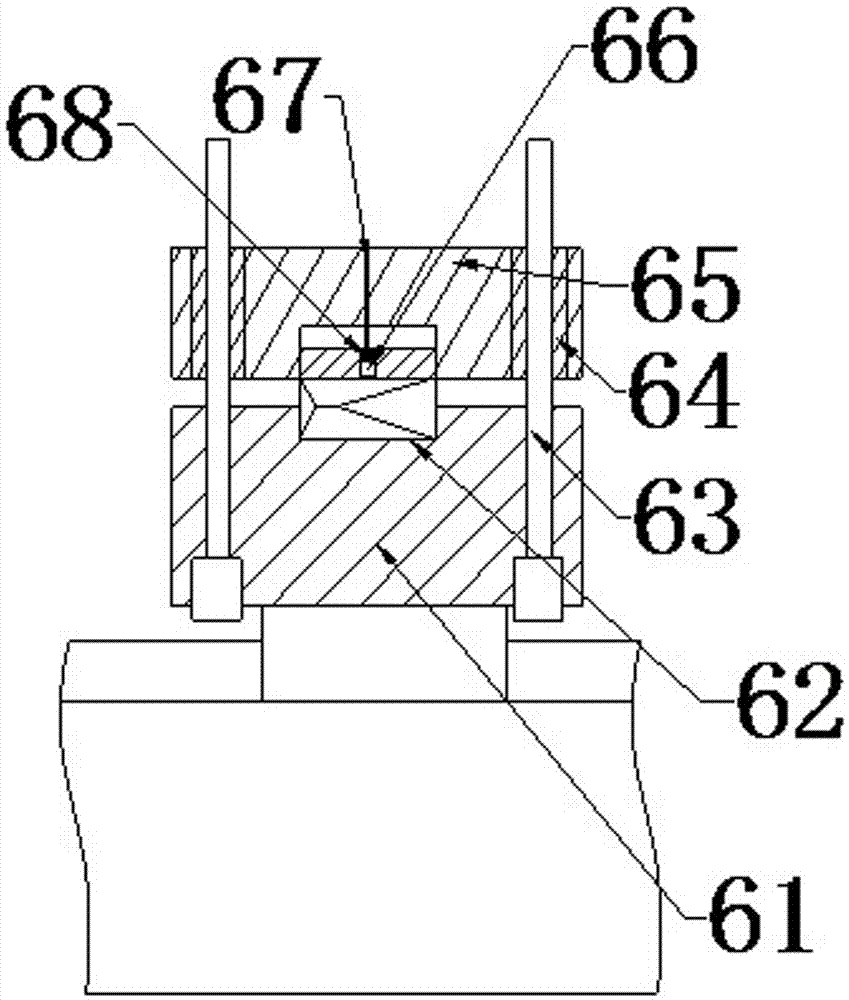

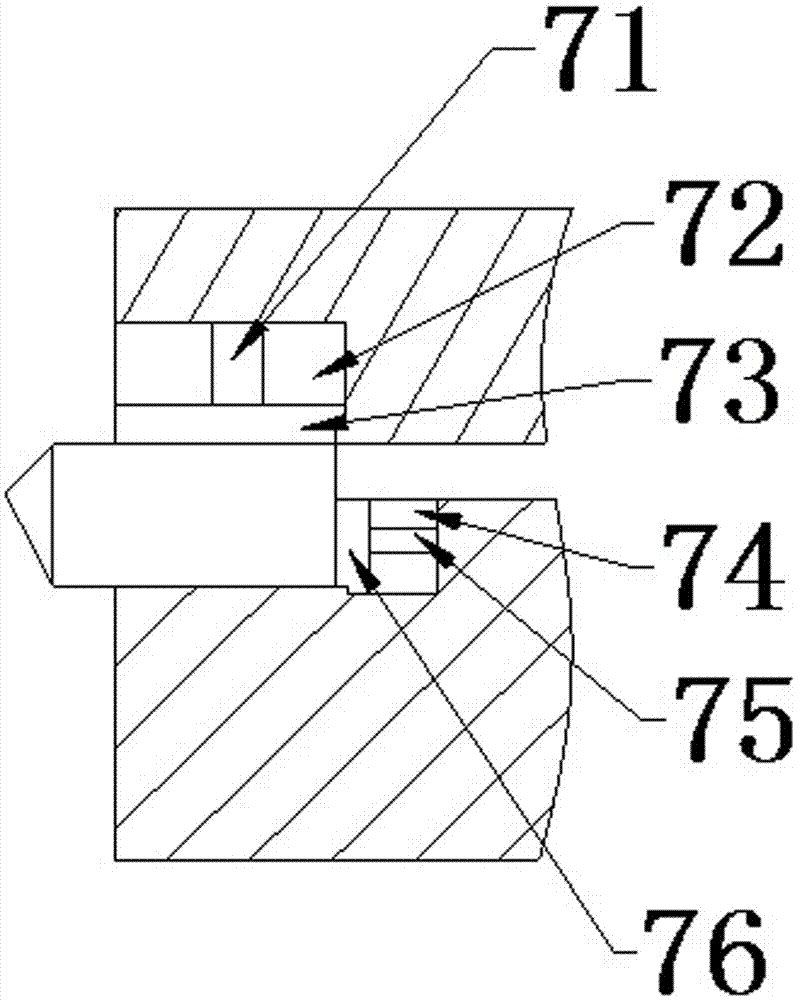

[0025] Specific implementation method: when the staff installs the cutter, the cutter is assembled inside the groove 62, and the motor connected to the screw rod 63 is operated, and the motor drives the screw rod 63 to rotate, and the ball nut pair converts the rotary motion of the screw rod 63 into a linear motion , so that the ball nut seat 64 drives the upper pressure table 65 to move, and the upper pressure table 65 moves to drive the cylinder 66 to move. When the lower end surface of the cylinder 66 fits the upper end surface of the tool, the cylinder 66 moves upward, compressing the spring 68 and driving the moving rod 67 moves inside the through hole. When the upper pressing table 65 is closely attached to the tool, the cylinder 66 is completely assembled into the blind hole, thereby driving the upper end of the moving rod 67 to move to the upper end surface of the upper pressing table 65. At this time, the staff makes the motor stop operation, the design facilitates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com