Tapping positioning tool, tapping suit and using method of tapping suit

A technology for positioning tooling and kits, applied in the field of thread repair, can solve the problems of reducing the service life of lithium batteries, increasing maintenance costs, and low maintenance efficiency, and achieving the effect of ensuring performance and service life, improving maintenance efficiency, and avoiding replacement of aluminum bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

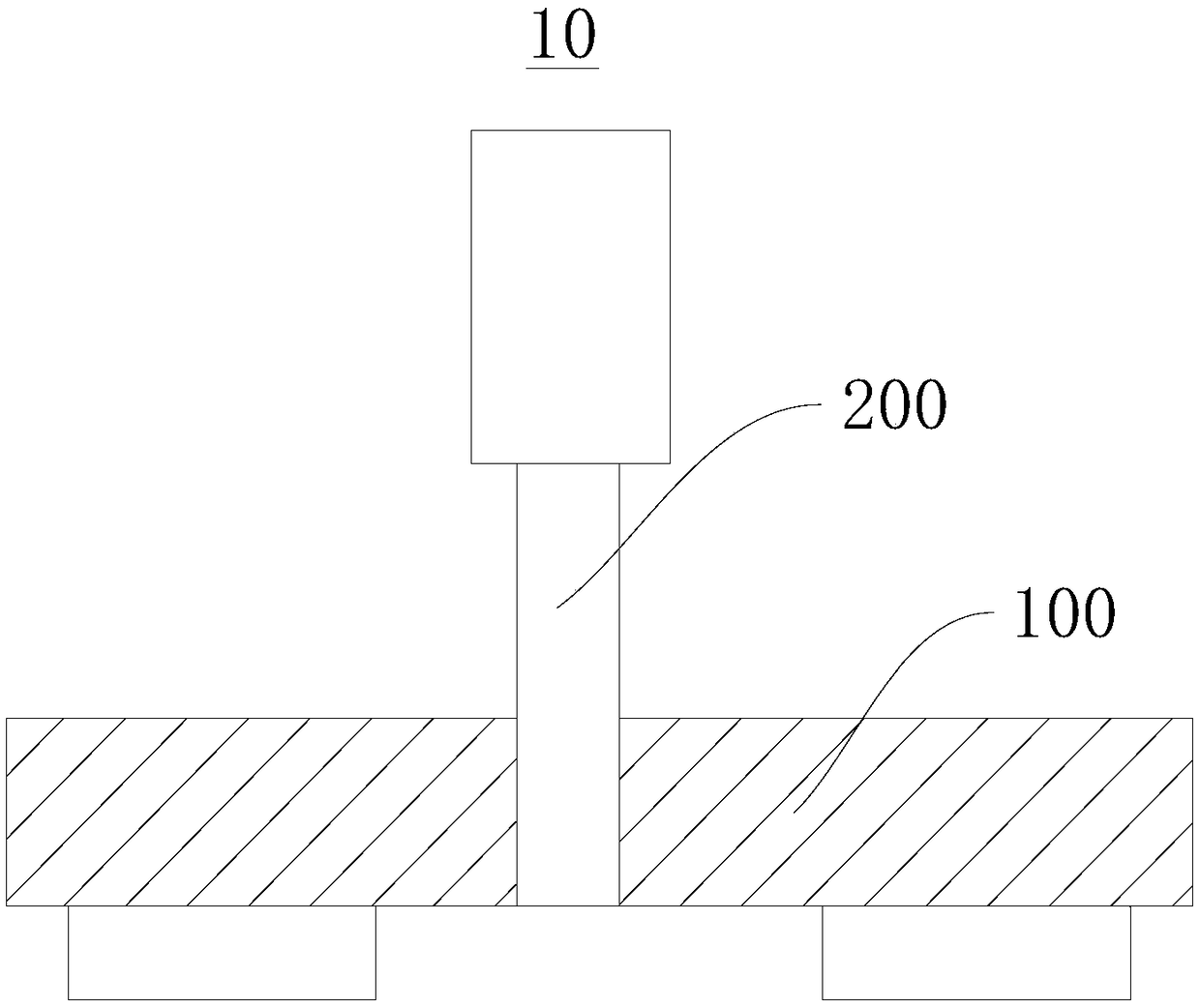

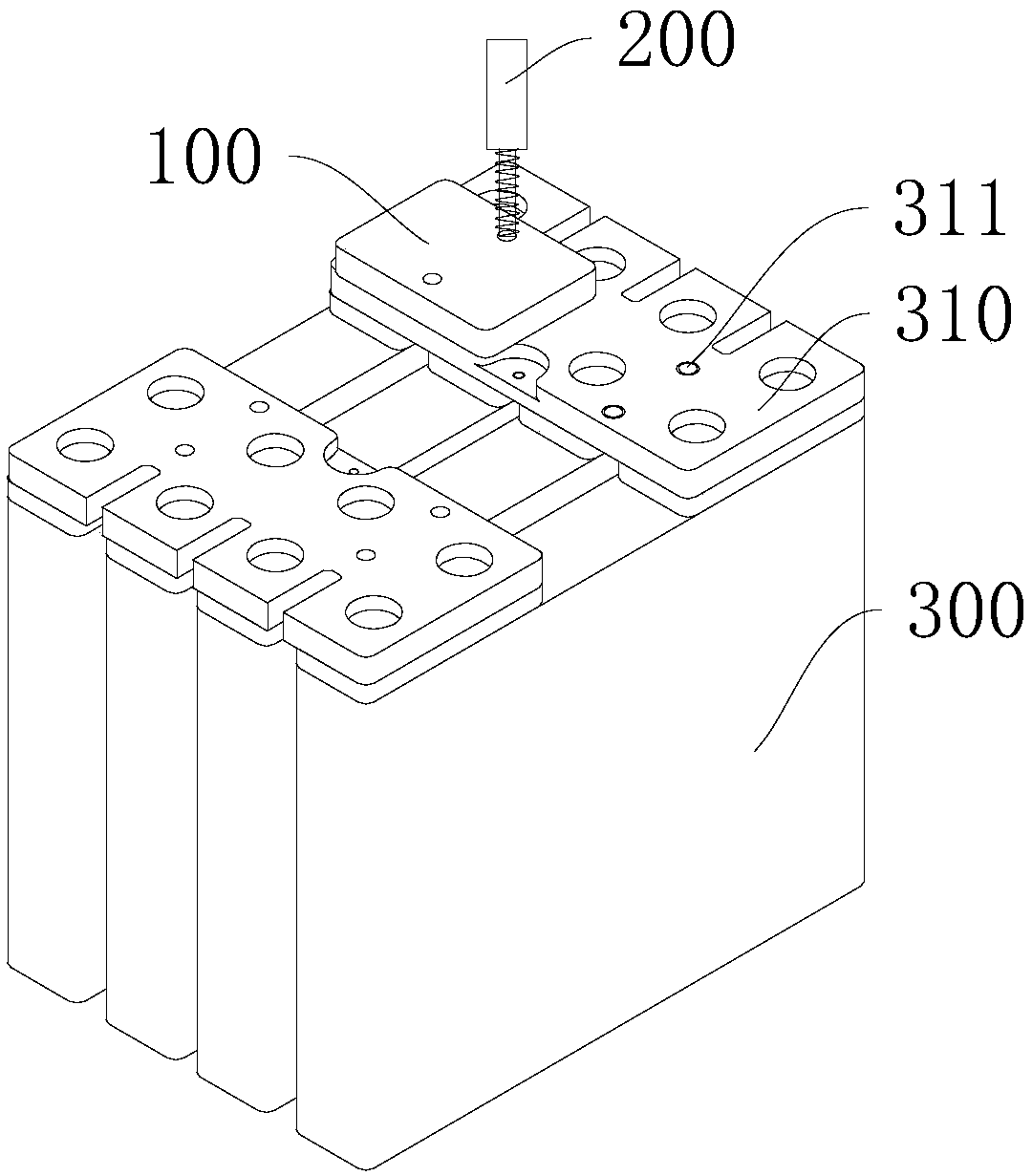

[0038] Please refer to figure 1 and figure 2 , the embodiment of the present invention provides a tapping set 10 for repairing the threaded hole 311 of the sliding wire on the aluminum bar 310 of the battery module 300 . Its structure is simple, the position of the threaded hole 311 can be positioned, and the threaded hole 311 can be re-tapped to avoid replacing the aluminum row 310, improve maintenance efficiency, ensure the performance and service life of the battery module 300, and is practical and efficient.

[0039] The tapping set 10 includes a tap 200 and a tapping positioning tool 100 . The tapping positioning tool 100 is used to be installed on the aluminum row 310 of the battery module 300, and is detachably connected with the aluminum row 310, so as to fix the relative position of the tapping positioning tool 100 and the aluminum row 310, and prevent the tapping positioning tool 100 from detaching Aluminum row 310. The tap 200 is used to cooperate with the tappi...

no. 2 example

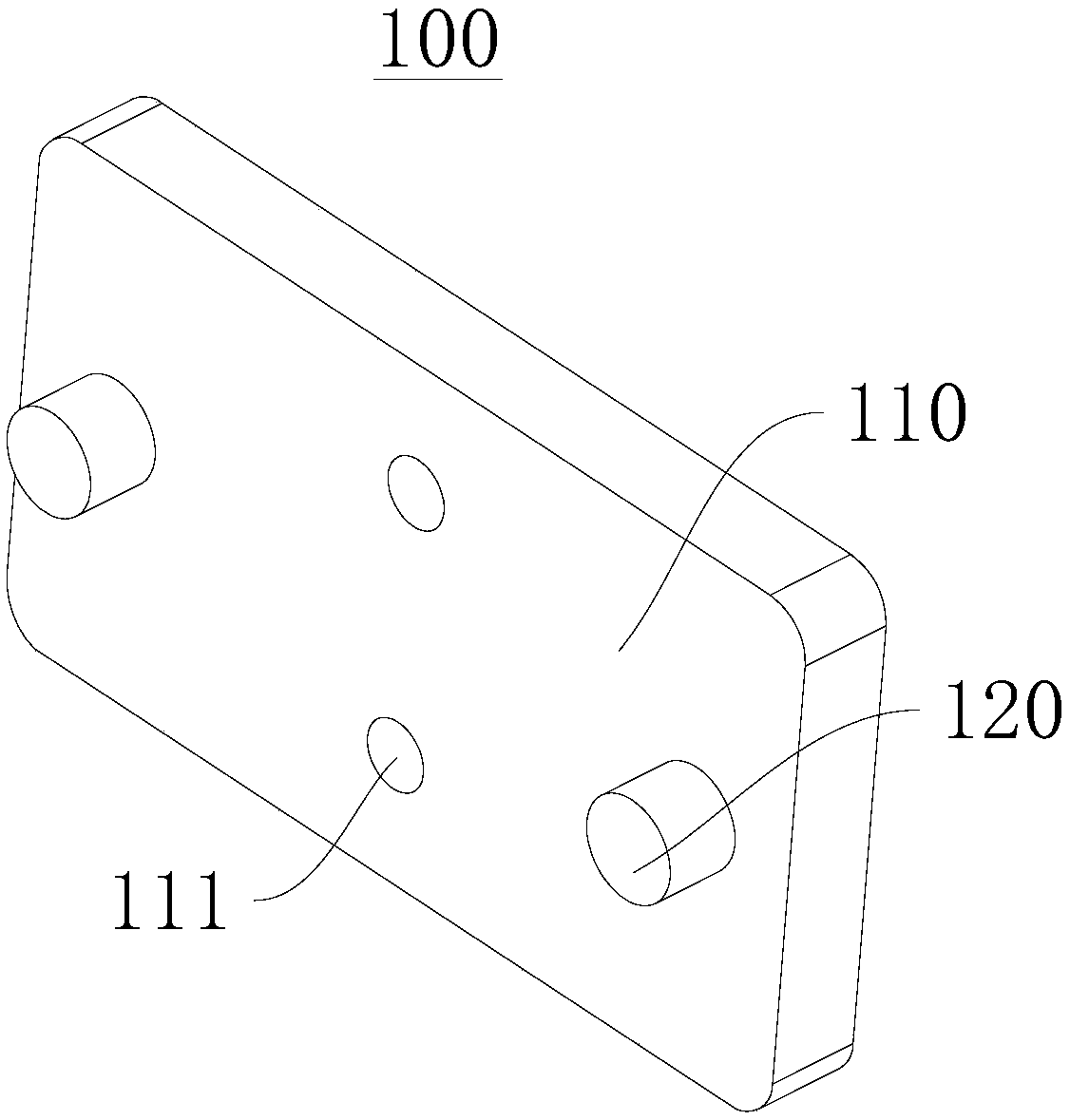

[0049] Please refer to Figure 5 and Figure 6 , the embodiment of the present invention provides a tapping positioning tool 100, compared with the first embodiment, the difference of this embodiment is that the shape and position of the limiting member 120 are different.

[0050] It is worth noting that the aluminum row 310 is a standard part, and the aluminum row 310 is also provided with a clearance hole 313 , and the distance between the clearance hole 313 and the threaded hole 311 is a fixed value, so as to improve the versatility of the aluminum row 310 . In this embodiment, the limiting member 120 is in the shape of a strip, and the limiting member 120 is used to extend into the gap hole 313 on the aluminum row 310 to limit the relative position of the positioning block 110 and the aluminum row 310 . Specifically, the limiting member 120 is loosely matched with the clearance hole 313 , so that the limiting member 120 is easily taken out from the clearance hole 313 or i...

no. 3 example

[0053] The embodiment of the present invention provides a method for using the tapping set 10 for repairing the threaded hole 311 of the sliding wire by using the tapping set 10 .

[0054] The using method of this tapping suit 10 comprises the following steps:

[0055] Step S101 : clamp the limiting member 120 on the aluminum row 310 , and press the positioning block 110 against the aluminum row 310 , so that the position of the tap hole 111 corresponds to the position of the threaded hole 311 .

[0056] It is worth noting that in step S101, the position of the threaded hole 311 of the sliding wire needs to be determined, and when the stopper 120 is clamped with the aluminum row 310, it is necessary to ensure that the positioning block 110 covers the threaded hole 311 of the sliding wire, so as to Make the position of the tap hole 111 correspond to the position of the threaded hole 311 .

[0057] Step S102 : screw the tap 200 into the tap hole 111 , and tap the threaded hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com