Slidable smoke absorption trapping and blowing device

A blowing device, smoke hood technology, applied in the direction of dust removal, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problem of endangering the health of workers and the workshop environment, affecting the health of cutting operators, and failing to achieve better smoke and dust collection Collection effects and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

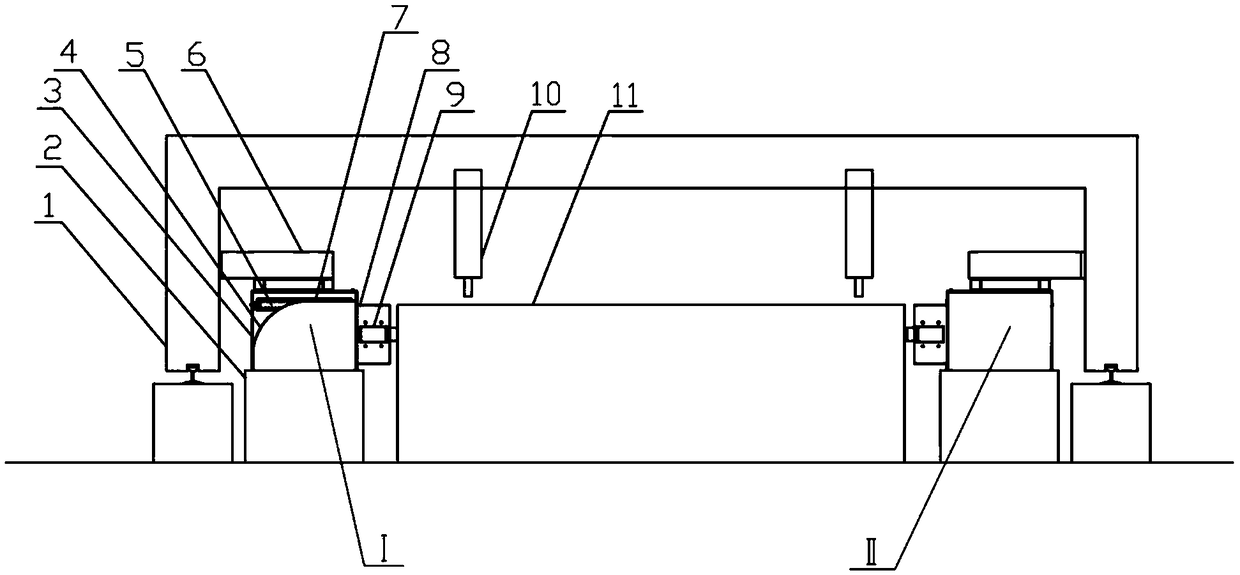

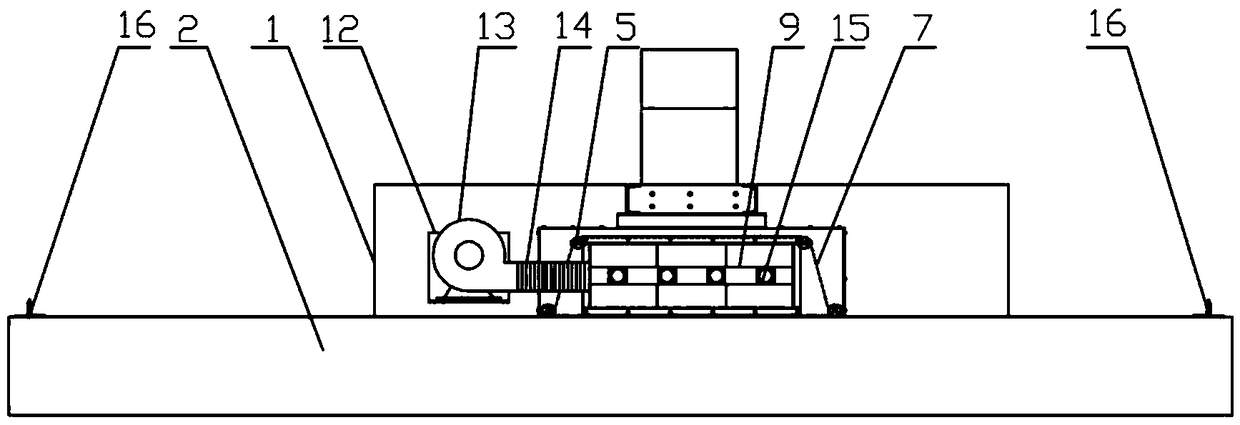

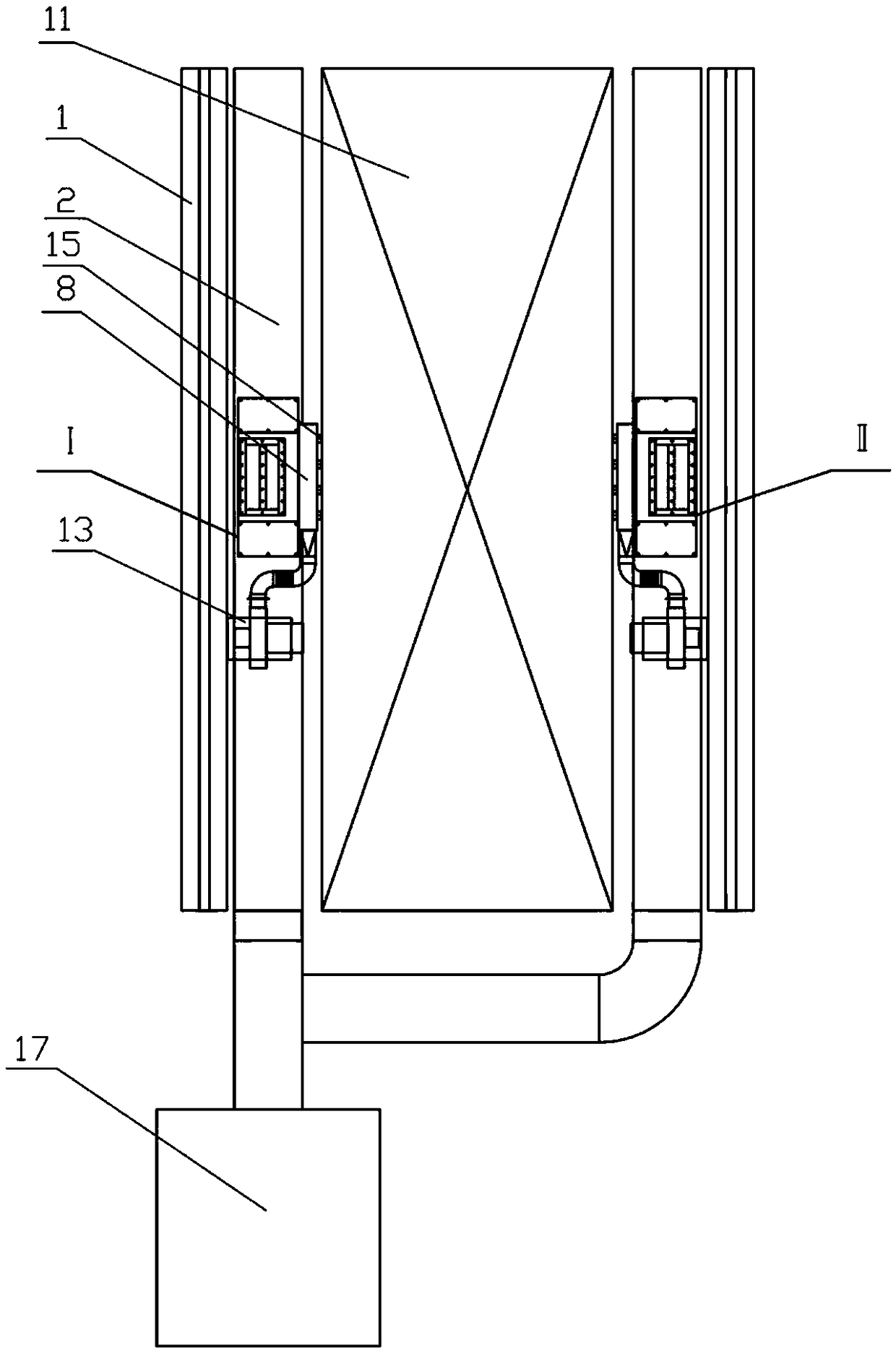

[0023] Such as Figure 1 to Figure 3 As shown, a slidable smoke trapping and blowing device includes two smoke trapping and blowing mechanisms AI and smoke trapping blowing mechanisms BII with the same structure and oppositely arranged, each smoke trapping and blowing mechanism includes a housing 3, a blower 13 , blowing pipe 9, smoking hood 8 and blowing port 15, the housing 3 is installed on the side beam 1 of the CNC cutting machine through the support frame 6 and can be driven to slide synchronously through the side beam 1 of the cutting machine, and the blower 13 is installed on the CNC cutting machine through the support 12. The side beam 1 of the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com