Preparation method of vinegar fermented grains of Chishui

A technology of vinegar fermented grains and vinegar koji, which is applied in the field of preparation of Chishui vinegar fermented grains, can solve the problems of high energy consumption, influence on acetic acid, and large difference in acetic acid concentration, and achieve reasonable fermentation degree, stable product quality, and small difference in acetic acid concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of Chishui sun-dried vinegar fermented grains, comprising the following steps:

[0016] Step 1: Cook porridge: Before cooking porridge, wash the raw rice and glutinous rice, and soak the rice with a small amount of water for 4 hours. Add a certain volume of water into a jacketed pot using natural gas as fuel, heat to boil, then pour the soaked rice into the pot at a ratio of 2:1:16 for rice, glutinous rice, and water, and then pour in the glutinous rice after 10 minutes. Mix well, cook until the rice has no rice core, and the rice soup is in a thick slurry, then pour the porridge into a special clay fermentation tank for natural cooling;

[0017] Step 2: Alcohol fermentation: Cool the porridge to 40°C, add vinegar koji according to the ratio of raw materials and vinegar koji 7.5:1, soak for 1 hour, first crush the granules of vinegar koji and stir evenly, stir once a day in the morning and afternoon, After the production of carbon dioxide bubbles i...

Embodiment 2

[0024] A preparation method of Chishui sun-dried vinegar fermented grains, comprising the following steps:

[0025] Step 1: Cook porridge: Before cooking porridge, wash the raw rice and glutinous rice, and soak the rice with a small amount of water for 4 hours. Add a certain volume of water into a jacketed pot using natural gas as fuel, heat it to boil, then pour the soaked rice into the pot at a ratio of 3:1:18 among rice, glutinous rice, and water, and then pour in the glutinous rice after 10 minutes. Mix well, cook until the rice has no rice core, and the rice soup is in a thick slurry, then pour the porridge into a special clay fermentation tank for natural cooling;

[0026] Step 2: Alcohol fermentation: Cool the porridge to 40°C, add vinegar koji in a 7:1 ratio of raw materials and vinegar koji, soak for 1 hour, crush the granules of vinegar koji and stir evenly, stir once a day in the morning and afternoon, After the production of carbon dioxide bubbles in the alcohol f...

experiment example

[0033] Using Example 1 and Example 2 as a reference for the experiment, the following specific data were obtained.

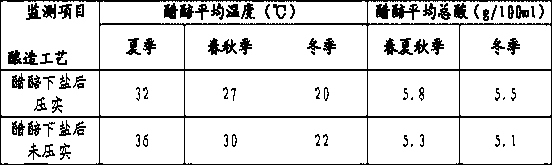

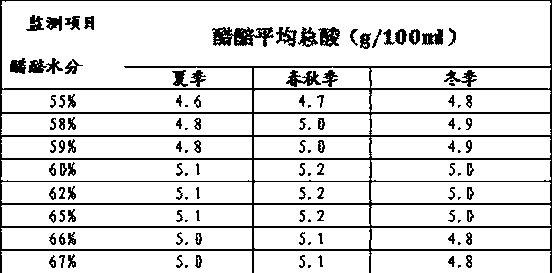

[0034] The relation of embodiment 1 and physical and chemical index is as shown in table 1:

[0035] Raw material ratio

Average alcohol content (%)

Average total acid (g / 100ml)

Average non-volatile acid (g / 100ml)

Average reducing sugar (g / 100ml)

Average soluble salt-free solids (g / 100ml)

Rice, glutinous rice, water 2:1:16

5.4

5.1

2.4

1.8

11.2

[0036] Table 1

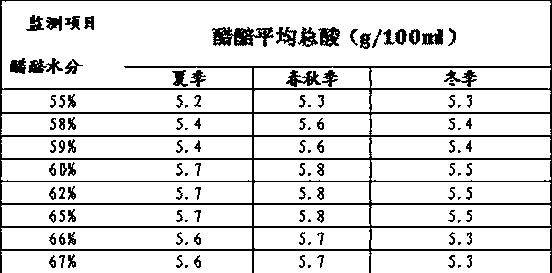

[0037] The relationship between brewing process and fermented grain temperature, total acid in embodiment 1 is as shown in table 2:

[0038]

[0039] Table 2

[0040] Combining Table 1 and Table 2, it can be seen from the relationship between brewing process, grain temperature and total acidity that the vinegar grains are flattened and compacted after salting, and the temperature of the vinegar grains is lowered quickly, and the temperature is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com