Control method of thread trimming and presser foot lifting device on sewing machine

A control method and presser foot lifting technology are applied to the thread cutting mechanism, sewing machine components, sewing equipment and other directions in the sewing machine, which can solve the problems of poor structural adaptability, low efficiency, and the thread trimming mechanism is not suitable for long-distance transmission. Simple assembly, low noise, accurate and reliable driving stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

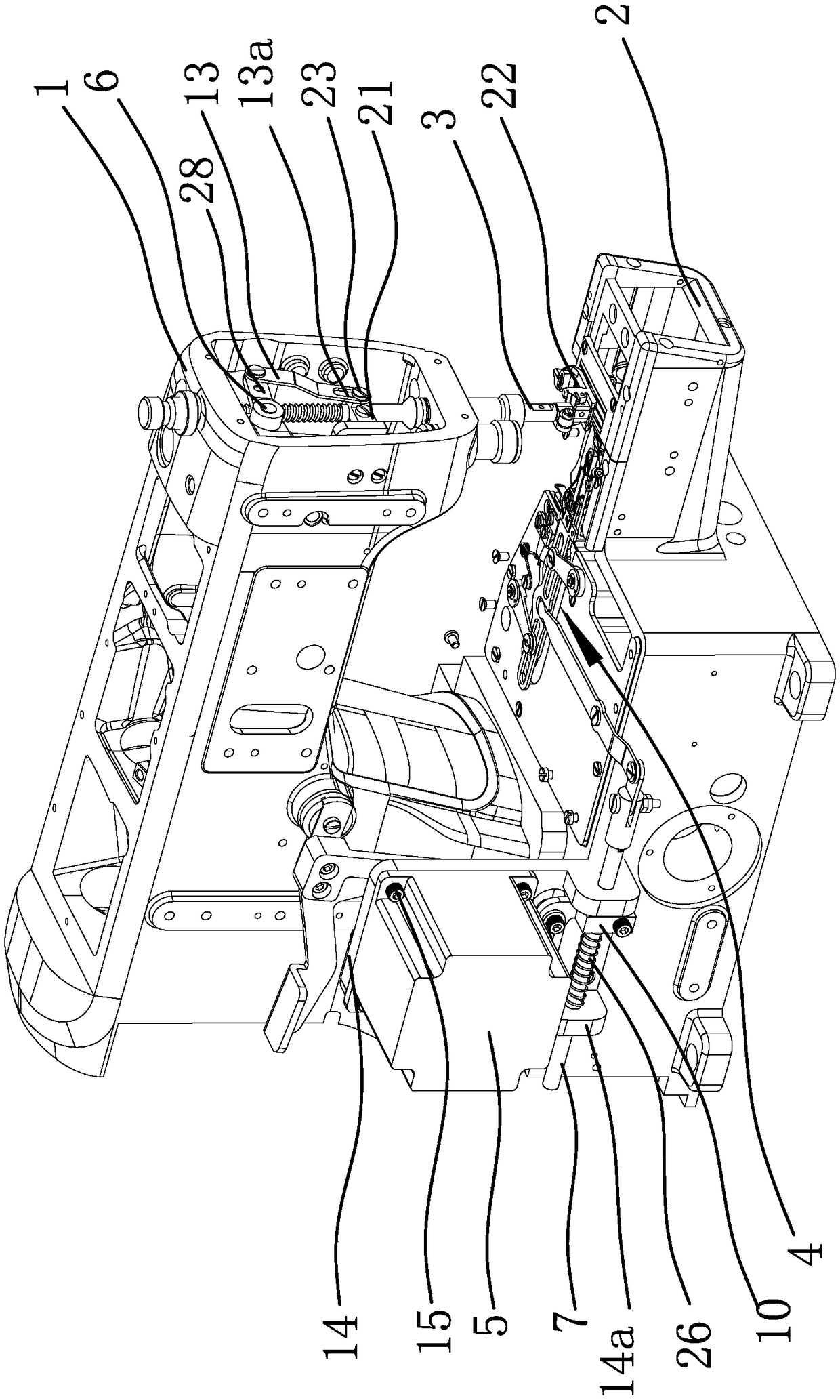

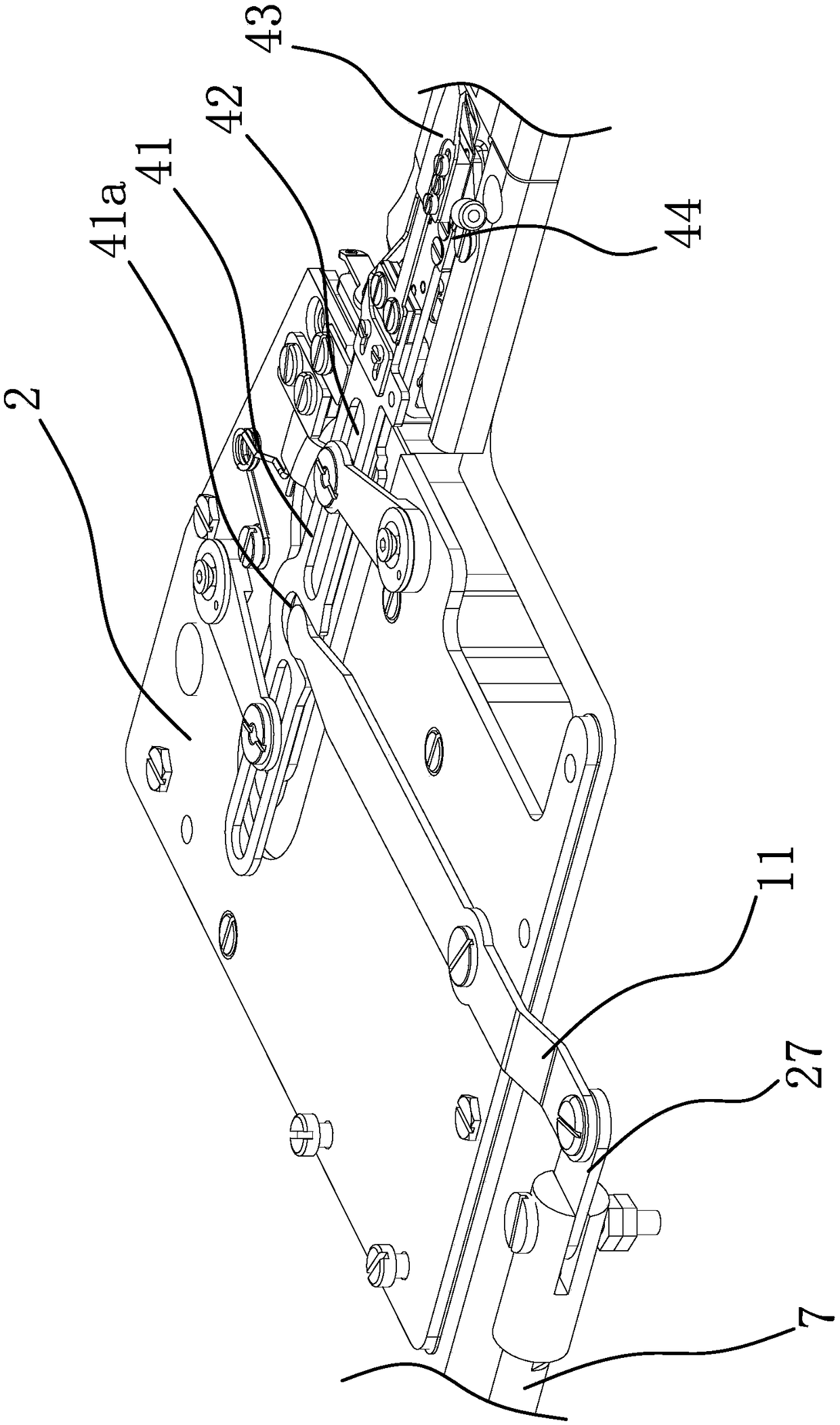

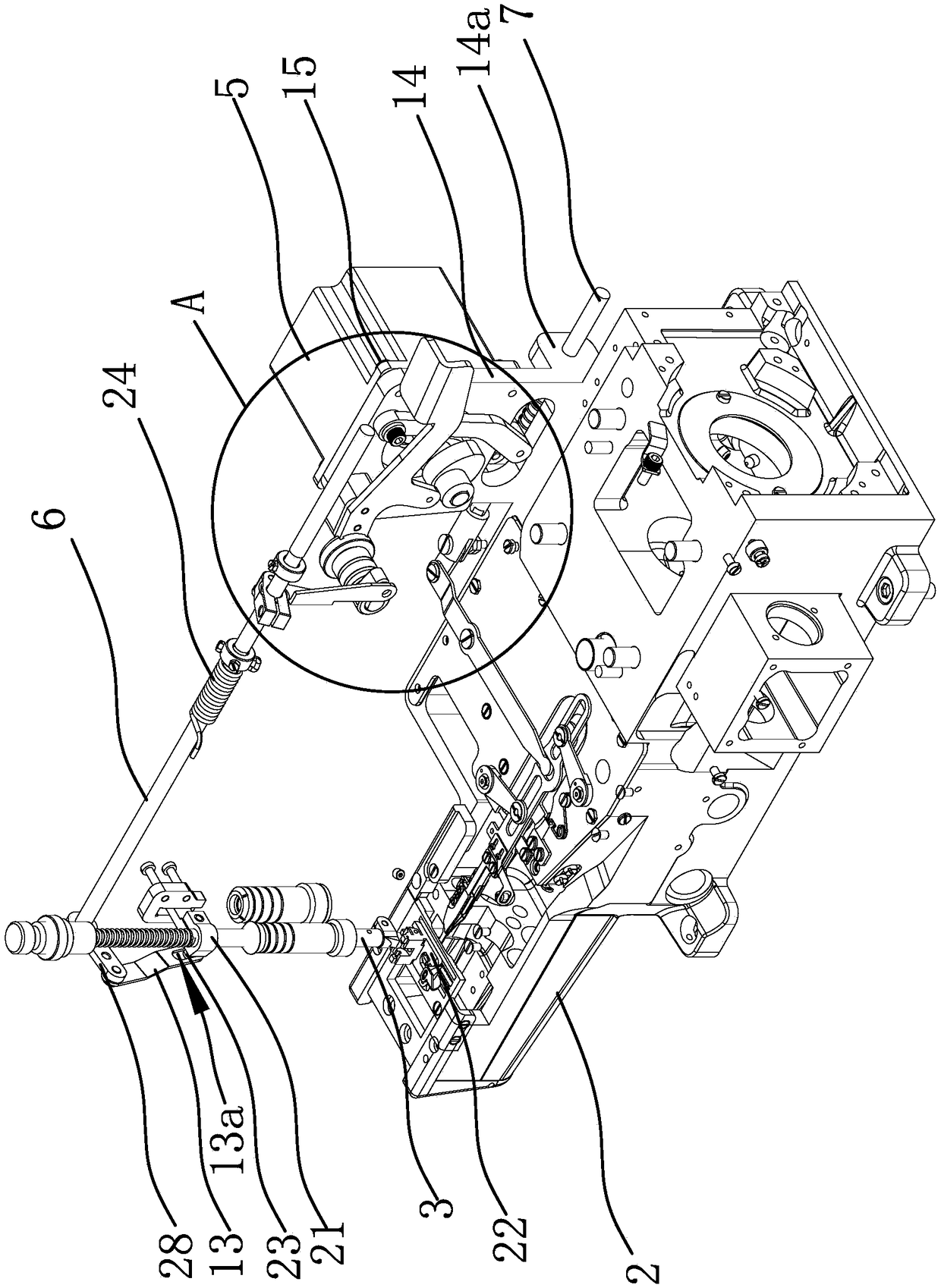

[0037] Such as Figure 1 to Figure 4 As shown, the sewing machine in this embodiment includes a casing 1, a machine base 2, a presser foot bar 3 arranged on the casing 1, and a presser foot 22 arranged at the lower end of the presser foot bar 3, and the thread trimming and presser foot lifting devices include lifting Presser foot shaft 6, thread trimming shaft 7, drive motor 5 capable of forward and reverse rotation, foot pedal capable of controlling forward and reverse rotation of drive motor 5, thread trimmer mechanism 4 that is positioned at the position directly below presser foot 22 on the support 2, The casing 1 is fixed with a mounting seat 14, and the driving motor 5 is fixed on the mounting seat 14 through connecting bolts 15; , the output shaft of the driving motor 5 is respectively fixed with a thread trimming cam 8 and a presser foot lifting cam 9, and both the thread trimming cam 8 and the presser foot lifting cam 9 have a protruding portion 9b and an idle stroke ...

Embodiment 2

[0046] The specific structure of the thread trimming and presser foot lifting device in this embodiment is the same as that of Embodiment 1, the difference is that the control method in this embodiment includes the following steps:

[0047] a. Unloading: After turning on the sewing machine, step on the pedal to the bottom to make the drive motor 5 rotate clockwise, the presser foot lever 3 and the presser foot 22 rise to the preset height position driven by the drive motor 5, and the operator will prepare Good fabric to be sewn is placed below the presser foot 22;

[0048] b. Sewing: loosen the pedal, make the driving motor 5 rotate counterclockwise to the initial position, the presser foot lever 3 and the presser foot 22 reset, the presser foot 22 presses the fabric, the operator controls the sewing pedal of the sewing machine, and the sewing machine sews normally until the Wheel sewing process ends;

[0049] c. Thread trimming and material retrieving: the operator steps on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com