Wall thickness detection device of water-cooled wall

A detection device, water-cooled wall technology, applied in the direction of measuring devices, instruments, chemical instruments and methods, etc., to achieve the effects of accuracy, novel concept and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

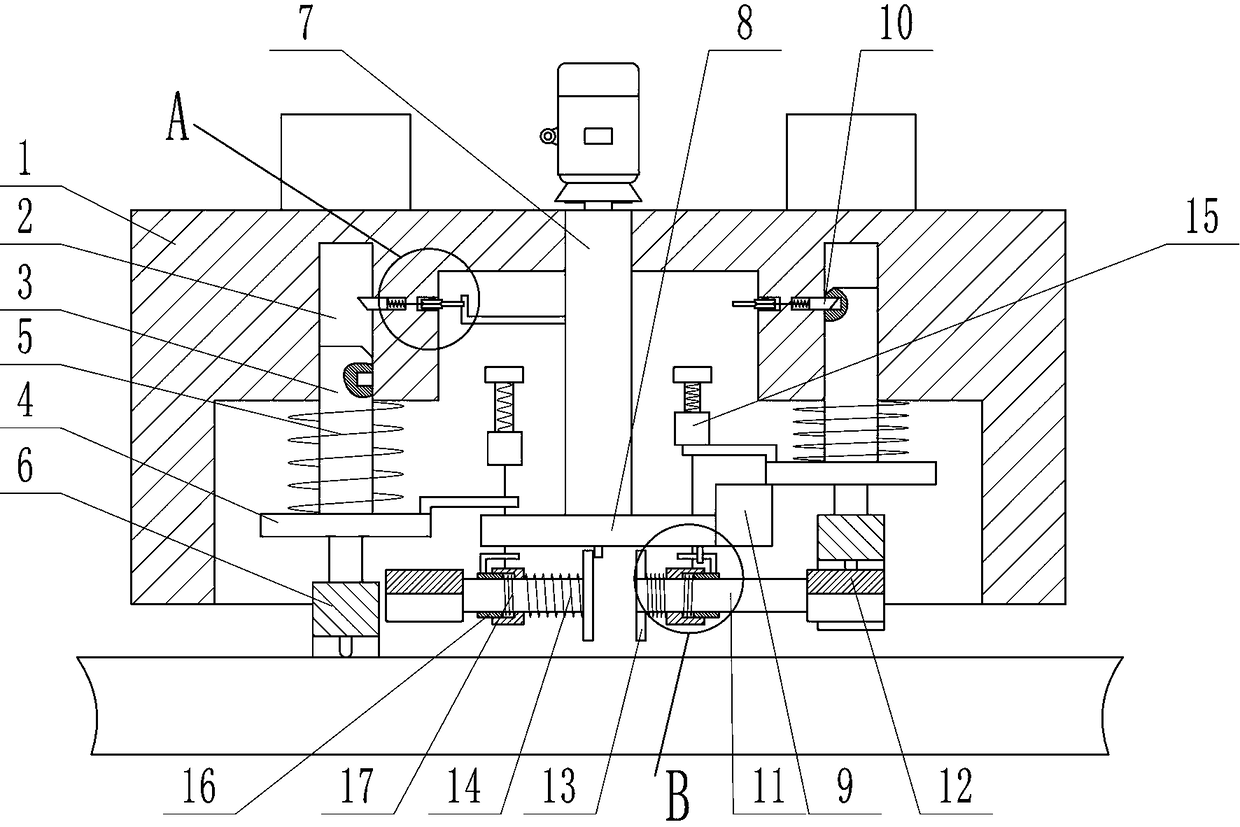

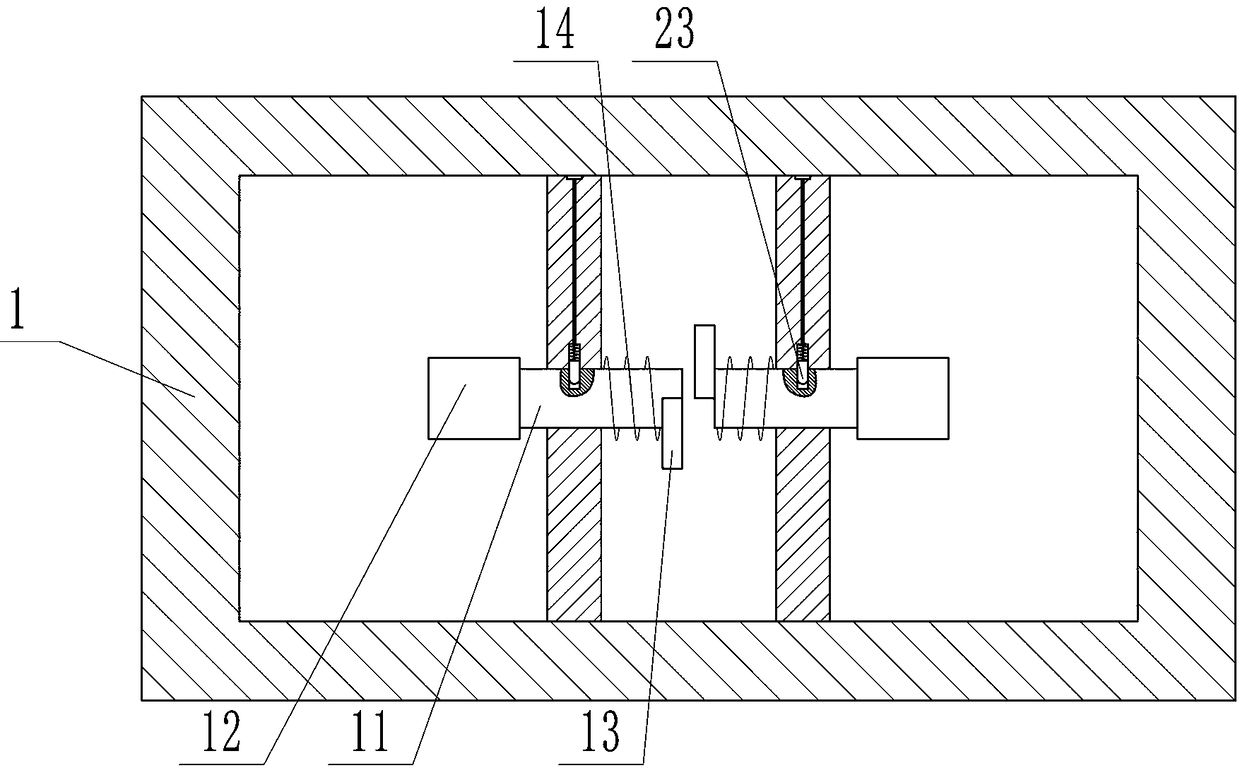

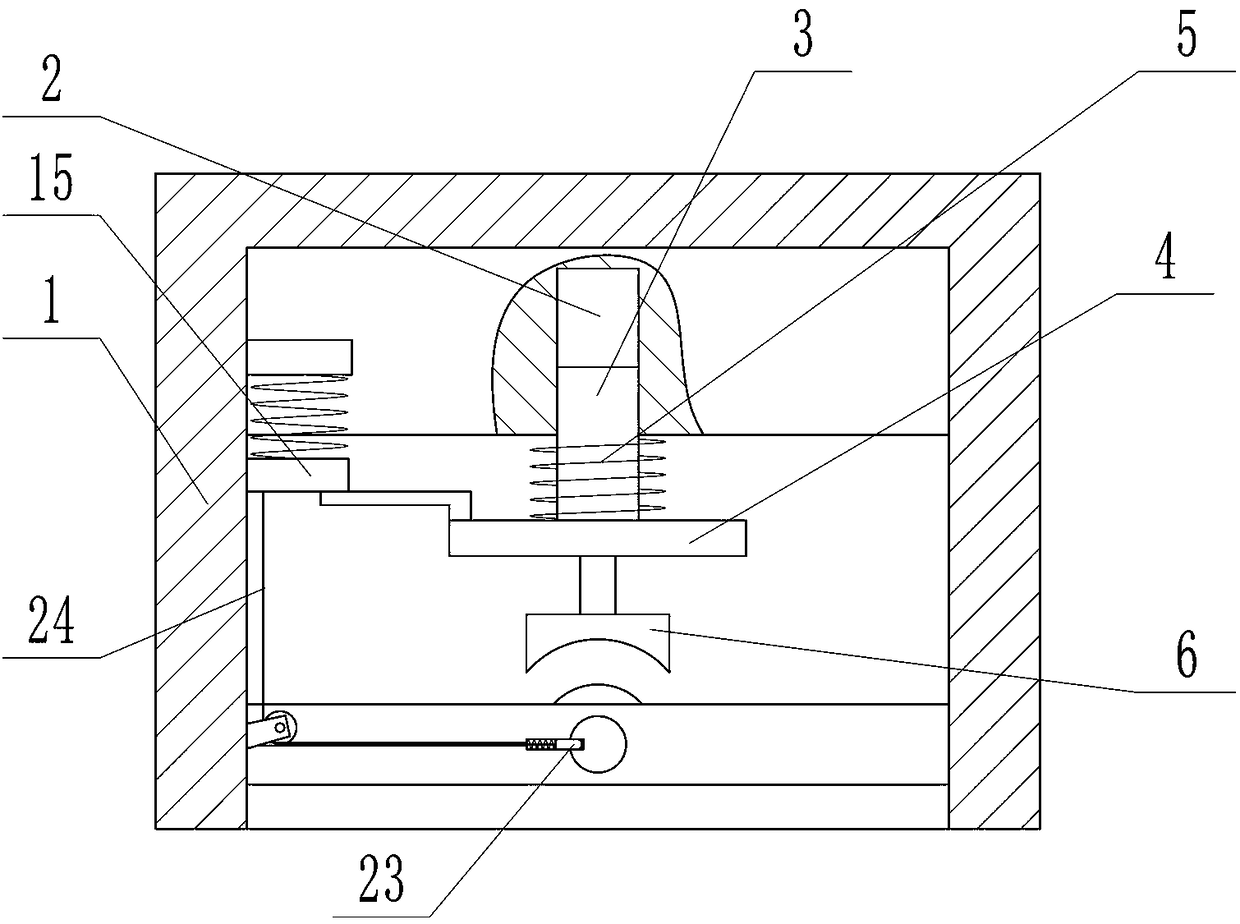

[0019] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Depend on Figure 1-10 It can be seen that the present invention includes a bracket 1, the bracket 1 is a shell structure with an open lower end, and the left and right sides of the top wall in the opening are respectively provided with a blind hole 2 on the bracket 1, and a blind hole 2 is installed in each blind hole 2. The movable telescopic rod 3 is provided with a boss 4 on the outer edge of each telescopic rod 3, and the first spring 5 which is sleeved on the outer circle of the telescopic rod 3 is connected between the boss 4 and the top wall of the support 1. A probe 6 is installed on the lower ends of each telescopic rod 3, and a rotating shaft 7 placed between the two telescopic rods 3 is inserted on the top wall of the support 1, and a disc 8 is arranged on the outer circle of the lower end of the rotat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap