Processing technology of 25g optical module

A processing technology, optical module technology, applied in the coupling of optical waveguides, optics, light guides, etc., can solve the problems of reduced chip performance, complex processing, increased volume heat density, etc., to optimize processing steps, increase heat dissipation area, The effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

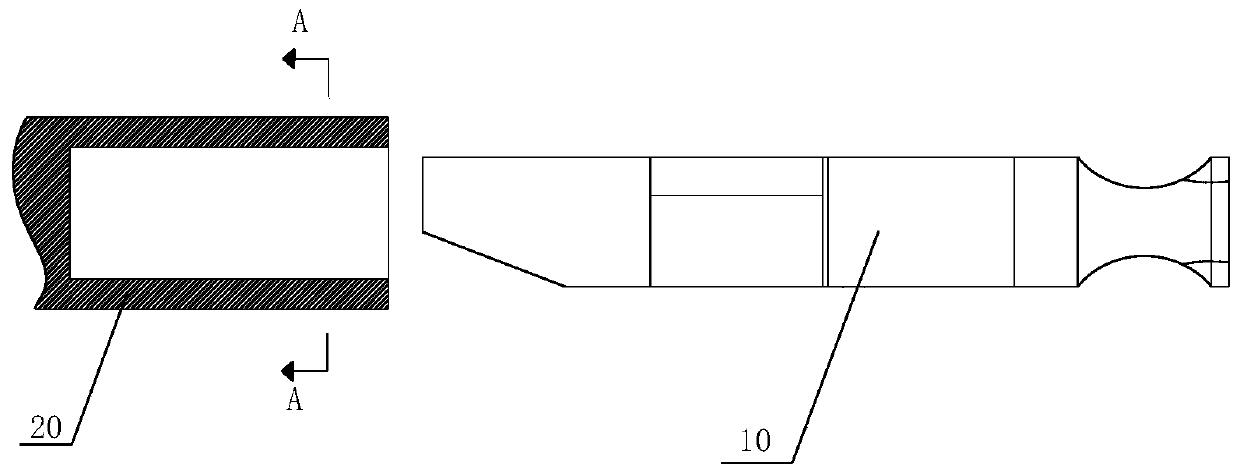

[0046] In each drawing, the optical module main body 10 is inserted into the housing 20 as the working state, and the optical module main body 10 is not inserted into the housing 20 as the non-operating state.

[0047] Such as figure 1 As shown, a 25G optical module includes an optical module main body 10 and an opening at one end, and a housing 20 for inserting the optical module main body 10. The optical module main body 10 can be socketed inside the housing 20 or not. , placed alone.

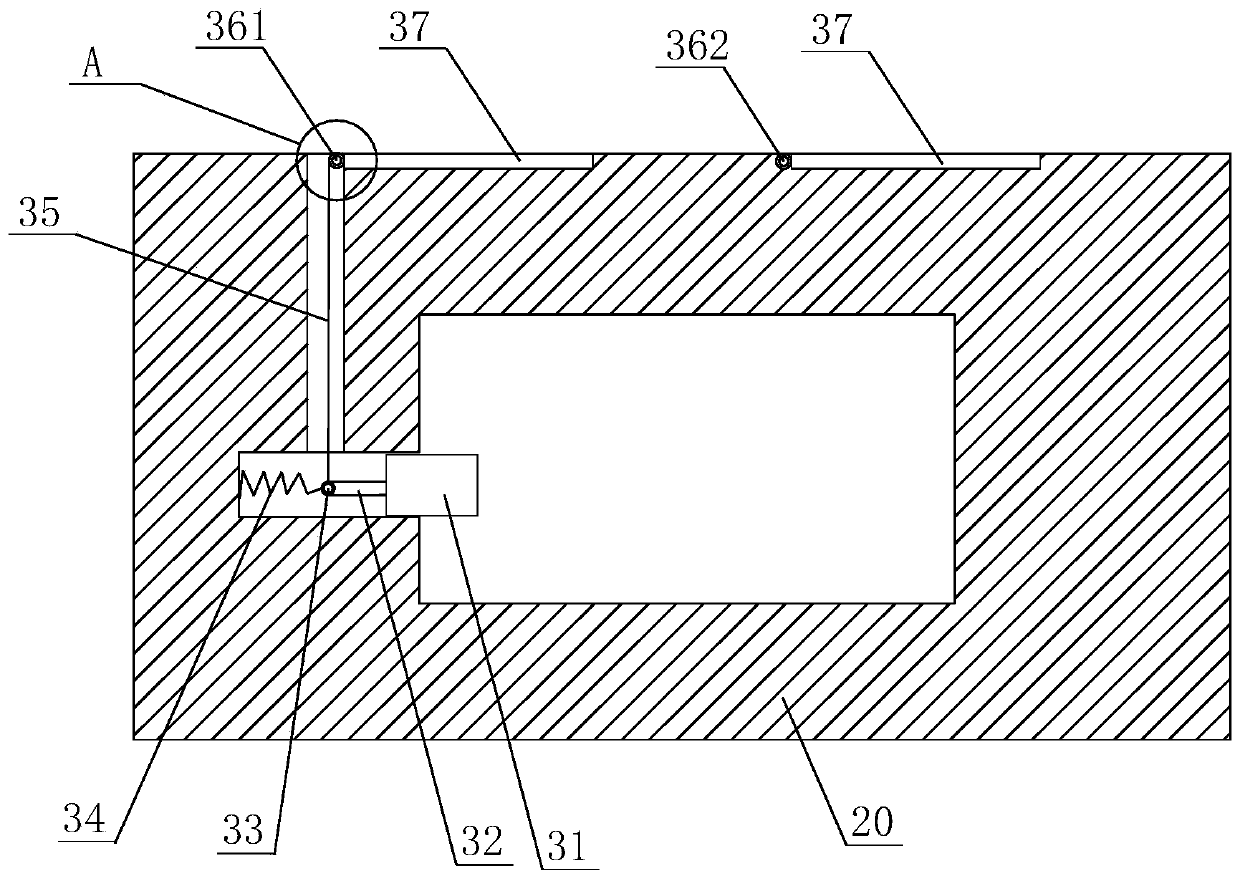

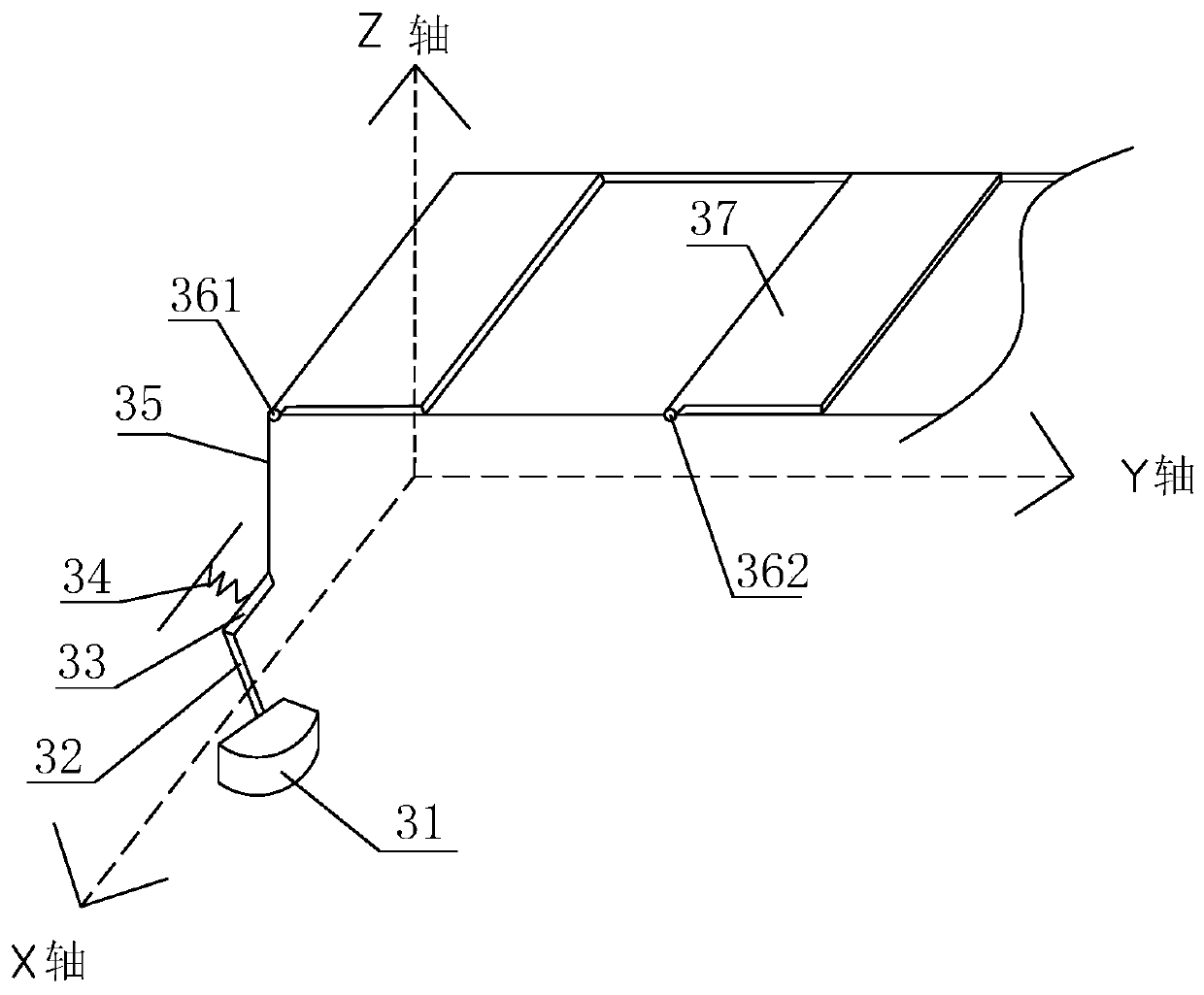

[0048] Such as Figure 2-5 As shown, the housing 20 includes a base 21 with a cavity inside, and the cavity allows the optical module main body 10 to enter and exit. A heat dissipation portion 22 is disposed above the base portion 21 . The base portion 21 and the heat dissipation portion 22 are actually a whole, and are divided into two parts for convenience of description.

[0049] An installation channel is provided on at least one side wall near the opening of the base 21 . A movable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com