Efficient thickener

A thickener and thickening technology, applied in the direction of chemical instruments and methods, separation methods, precipitation separation, etc., can solve the problems of increasing the production cost of the thickener, blockage of the discharge port, cumbersome operation, etc., to achieve convenient mineral processing and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

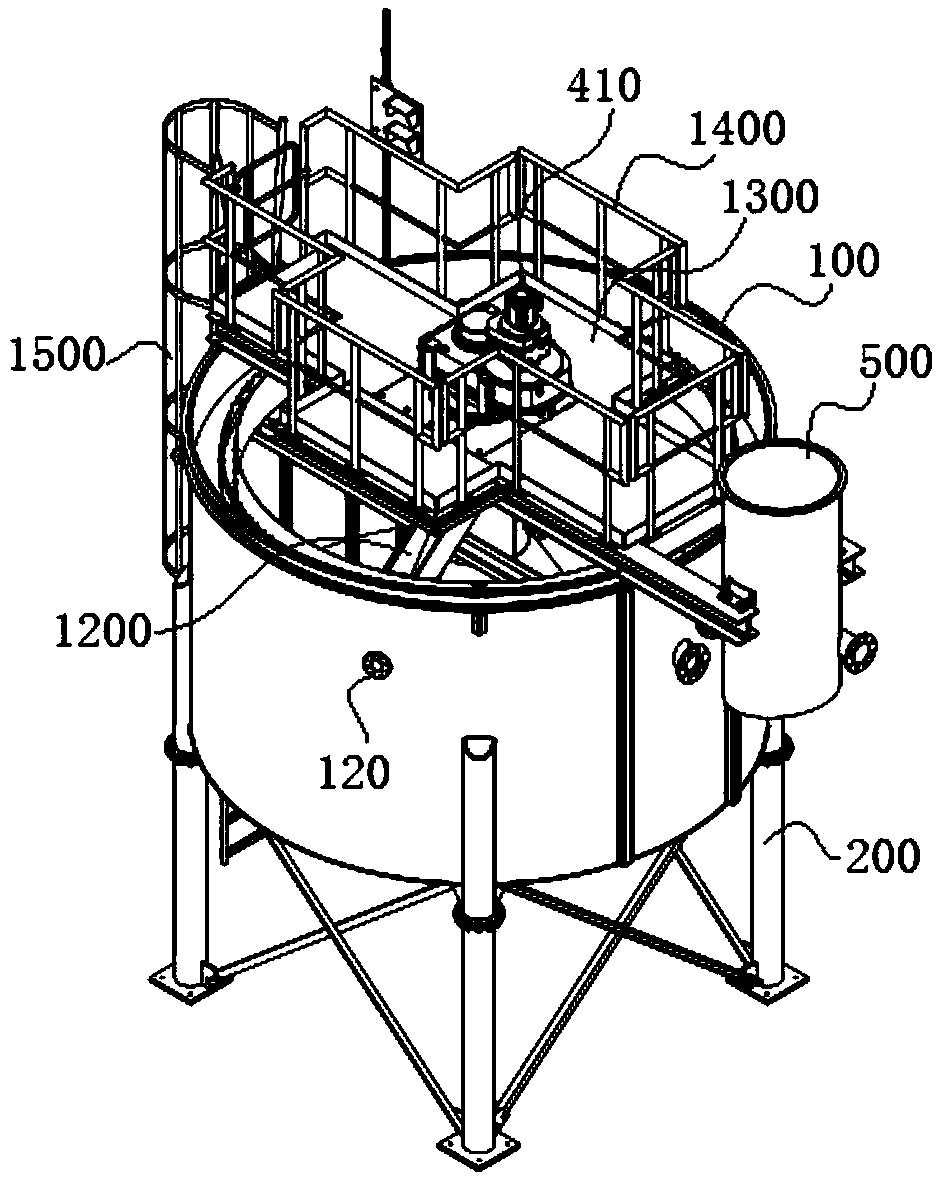

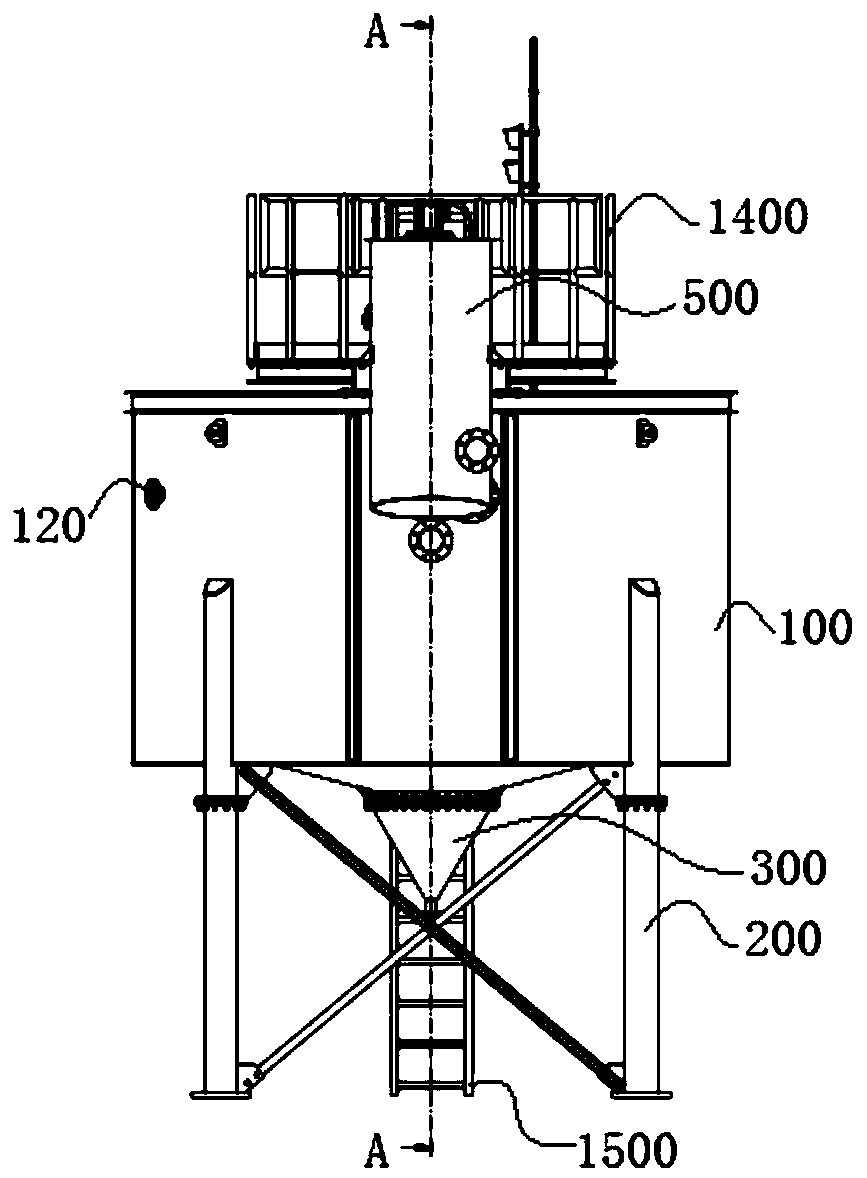

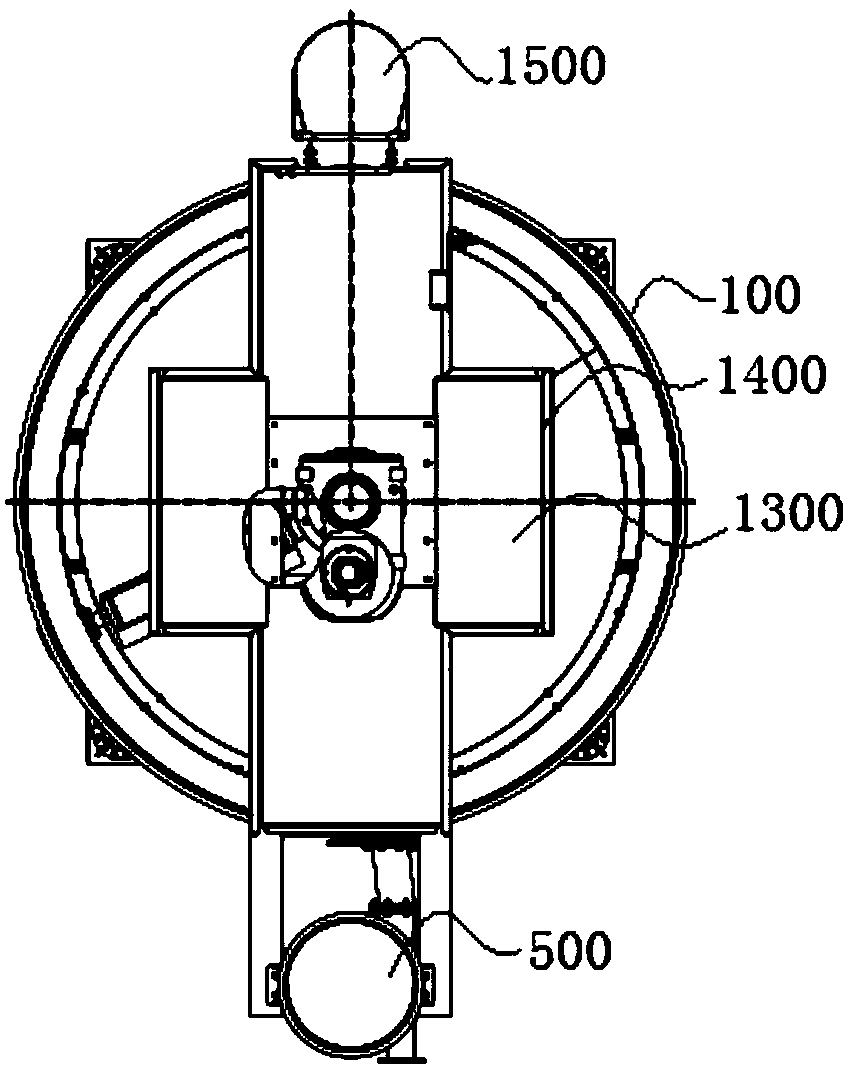

[0031] refer to Figure 1-Figure 6 Shown in the figure is a high-efficiency thickener, including a bracket 200, a thickening cylinder 100, an underflow cone 300, a stirring device 400, a defoaming box 500, a feeding cone 600, a scraper 1000, and a liquid level monitoring device 1700 , Overflow hole dirt removal device 1800 and PLC control system.

[0032] The dense cylinder 100 is cylindrical as a whole, and the dense cylinder 100 is set on the support 200. A cover plate 1300 is provided on the upper end of the dense cylinder 100, and an escalator 1500 is provided on one side of the dense cylinder 100, which is convenient for operators to pass through. The escalator 1500 moves up to the cover plate 1300 to observe the working state in the dense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com