Gear ring type auxiliary fixing device for cable terminal manufacturing

A technology of fixing device and terminal head, which is applied to the equipment, circuit, electrical components, etc. for connecting/terminating cables, which can solve the problems of cable sinking and easy sinking of cables, so as to facilitate construction operations and avoid cable sinking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

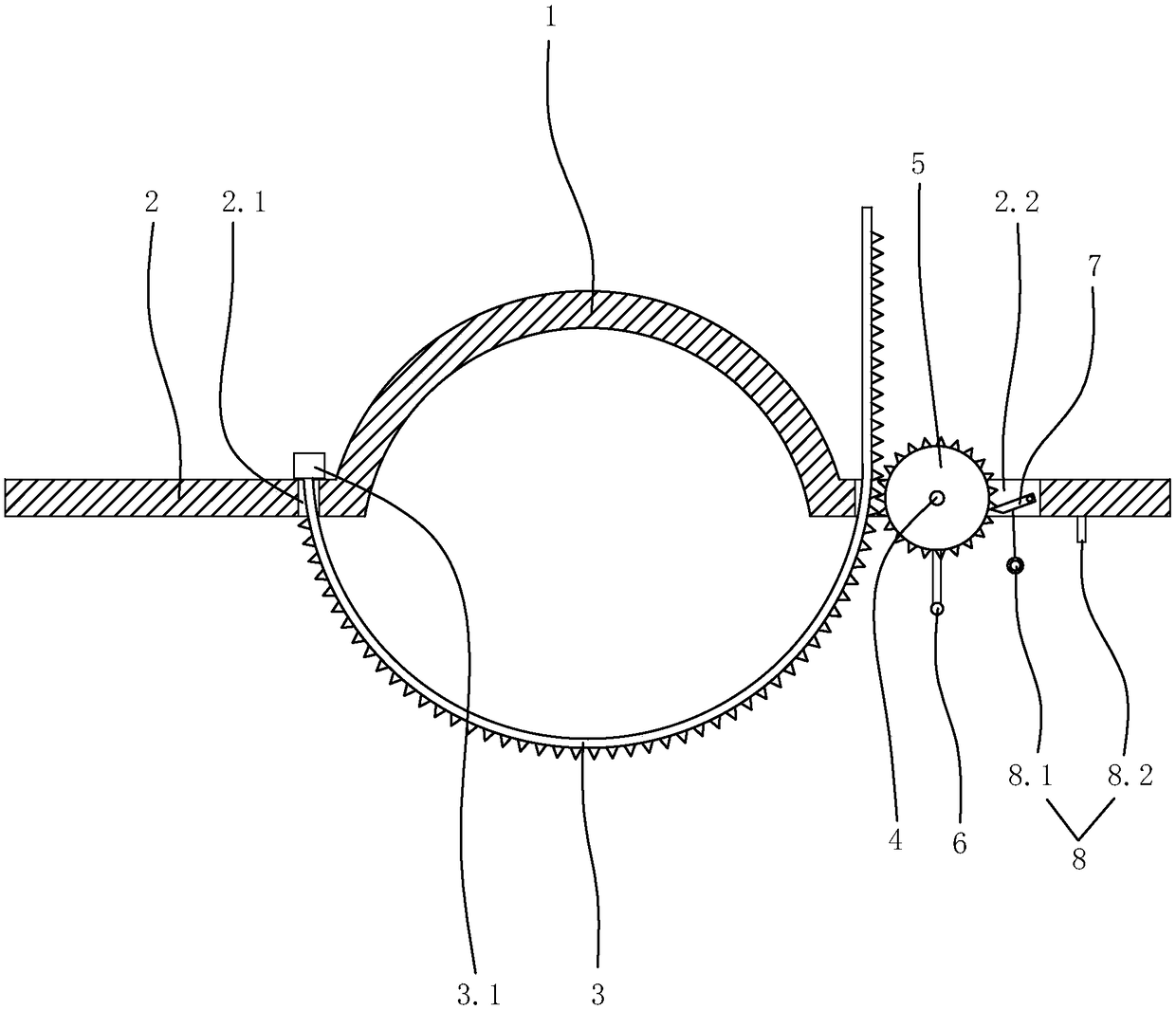

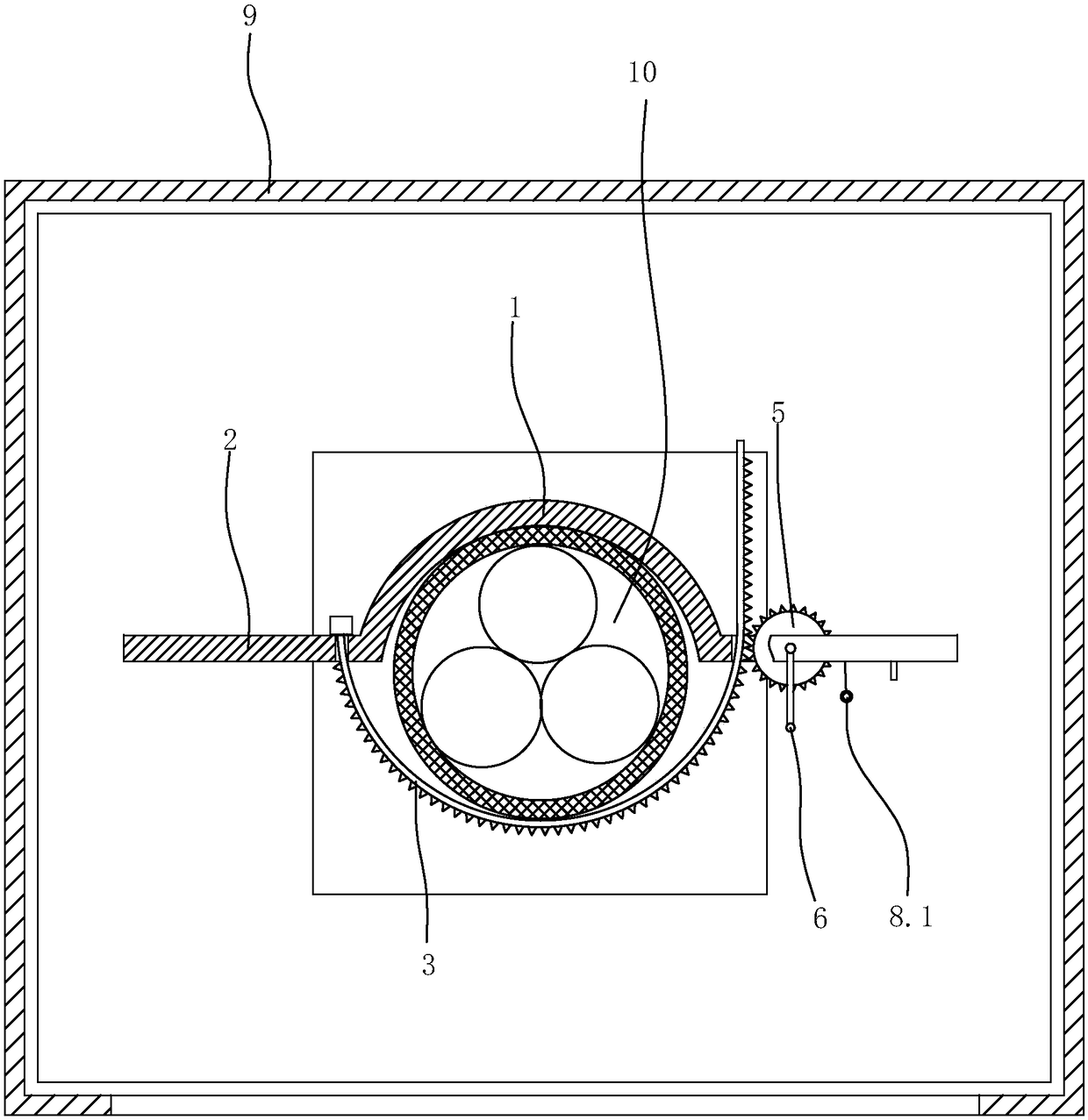

[0031] Such as figure 1 As shown, a gear ring auxiliary fixing device for cable terminal production includes a support hoop plate 1 , a flexible rack 3 , a driving gear 5 , a non-return pawl 7 , a release auxiliary device 8 and an operating rod 6 .

[0032] The supporting hoop is in the shape of a semicircle. The two ends of the support hoop are bent outwards to form a support plate 2 at both ends of the support hoop. One of the support plates is provided with a connection via hole 2.1, and the other support plate is provided with an installation through hole 2.2. The support hoop plate and the support plate are integrally bent and formed. The support plate is parallel to the axis of the support hoop plate.

[0033] One end of the flexible rack is provided with a limit block 3.1, and the other end of the flexible rack passes through the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com