Semi-coke microbial carrier and preparation method thereof

A microbial carrier, blue carbon technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Poor, complex processing technology and other problems, to achieve the effect of high content of volatile components, convenient material acquisition, high chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

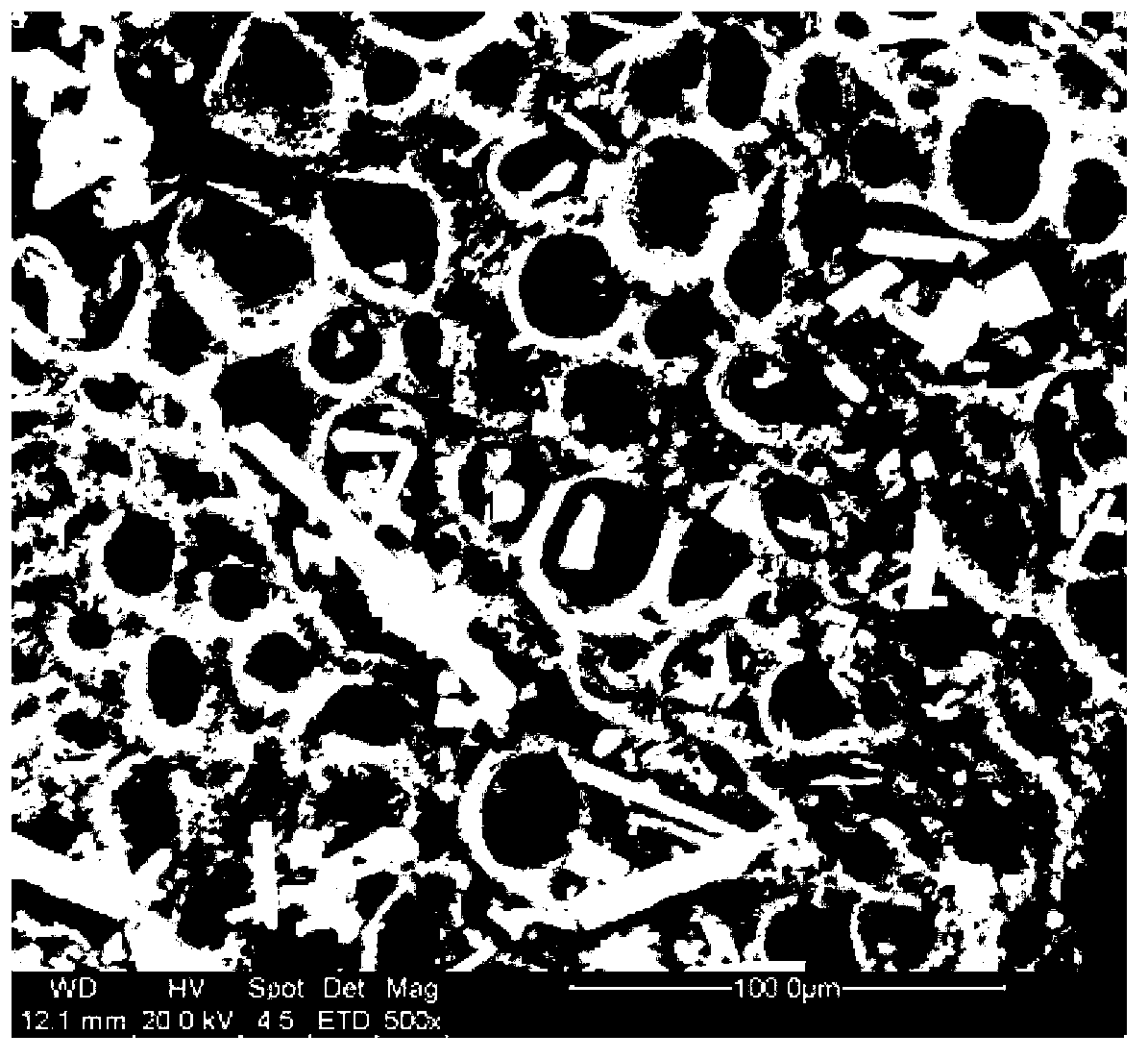

Image

Examples

Embodiment 1

[0033] 1) Weigh 50g of semi-coke with a particle size of 200 mesh, add the semi-coke to a nitric acid solution with a mass concentration of 10% at 80°C, and process for 4 hours;

[0034] 2) Immerse the treated blue carbon in a sodium hydroxide solution with a mass concentration of 31.7% at room temperature for 1 hour, wash until neutral, then wash it with tap water for 1 to 3 times, and dry it at 100°C for 2 hours to make a blue carbon matrix ;

[0035] 3) Dissolve 3g of polyvinyl alcohol (polymerization degree greater than 1750) in 97mL of boiling water at 100°C and stir for 8 hours to obtain a 3% polyvinyl alcohol solution;

[0036] 4) Measure 3.2mL of glyoxal solution with a mass concentration of 2.5%;

[0037] 5) Cross-link the polyvinyl alcohol solution and the cross-linking agent solution for 20 hours;

[0038] 6) Add the blue carbon matrix in step 2) into the crosslinked polyvinyl alcohol solution and stir for 3 hours, so that the polyvinyl alcohol gel can be evenly c...

Embodiment 2

[0043] 1) Weigh 10g of semi-coke with a particle size of 300 mesh, add the semi-coke to a nitric acid solution with a mass concentration of 50% at 100°C, and process for 2 hours;

[0044] 2) Immerse the treated blue charcoal in a sodium hydroxide solution with a mass concentration of 20% at room temperature for 0.5h, wash until neutral, wash with tap water for 1~3 times, and dry at 80°C for 1h to make blue charcoal matrix;

[0045] 3) Dissolve 6g of polyvinyl alcohol (polymerization degree greater than 1750) in 94mL of boiling water at 100°C and stir for 8 hours to obtain a 6% polyvinyl alcohol solution;

[0046] 4) Measure 2mL of glyoxal solution with a mass concentration of 0.5%;

[0047] 5) Cross-link the polyvinyl alcohol solution and the cross-linking agent solution for 10 hours;

[0048] 6) Add the medium blue carbon matrix in step 2) into the crosslinked polyvinyl alcohol solution and stir for 2 hours, so that the polyvinyl alcohol gel can be evenly coated on the blue...

Embodiment 3

[0053] 1) Weigh 20g of semi-coke with a particle size of 15 mesh, add the semi-coke to a nitric acid solution with a mass concentration of 20% at 100°C, and process for 5 hours;

[0054] 2) Immerse the treated blue carbon in a calcium hydroxide solution with a mass concentration of 6.4% at room temperature for 2 hours, wash until neutral, wash with tap water for 1 to 3 times, and dry at 90°C for 1 hour to make a blue carbon matrix ;

[0055] 3) Dissolve 8g of polyvinyl alcohol (polymerization degree greater than 1750) in 92mL of 100°C boiling water and reflux for 8 hours to obtain 8% polyvinyl alcohol solution;

[0056] 4) Measure 2mL of glutaraldehyde solution with a mass concentration of 1.5%;

[0057] 5) Cross-link the polyvinyl alcohol solution and the cross-linking agent solution for 24 hours;

[0058] 6) Add the blue carbon matrix in step 2) into the crosslinked polyvinyl alcohol solution and stir for 5 hours, so that the polyvinyl alcohol gel can be evenly coated on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com