Coke particle biomembrane carrier and preparation method thereof

A technology of biofilm carrier and coke particles, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of high material cost, low porosity, complex processing technology, etc., and achieve the preparation method The effect of simplicity, good biocompatibility, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

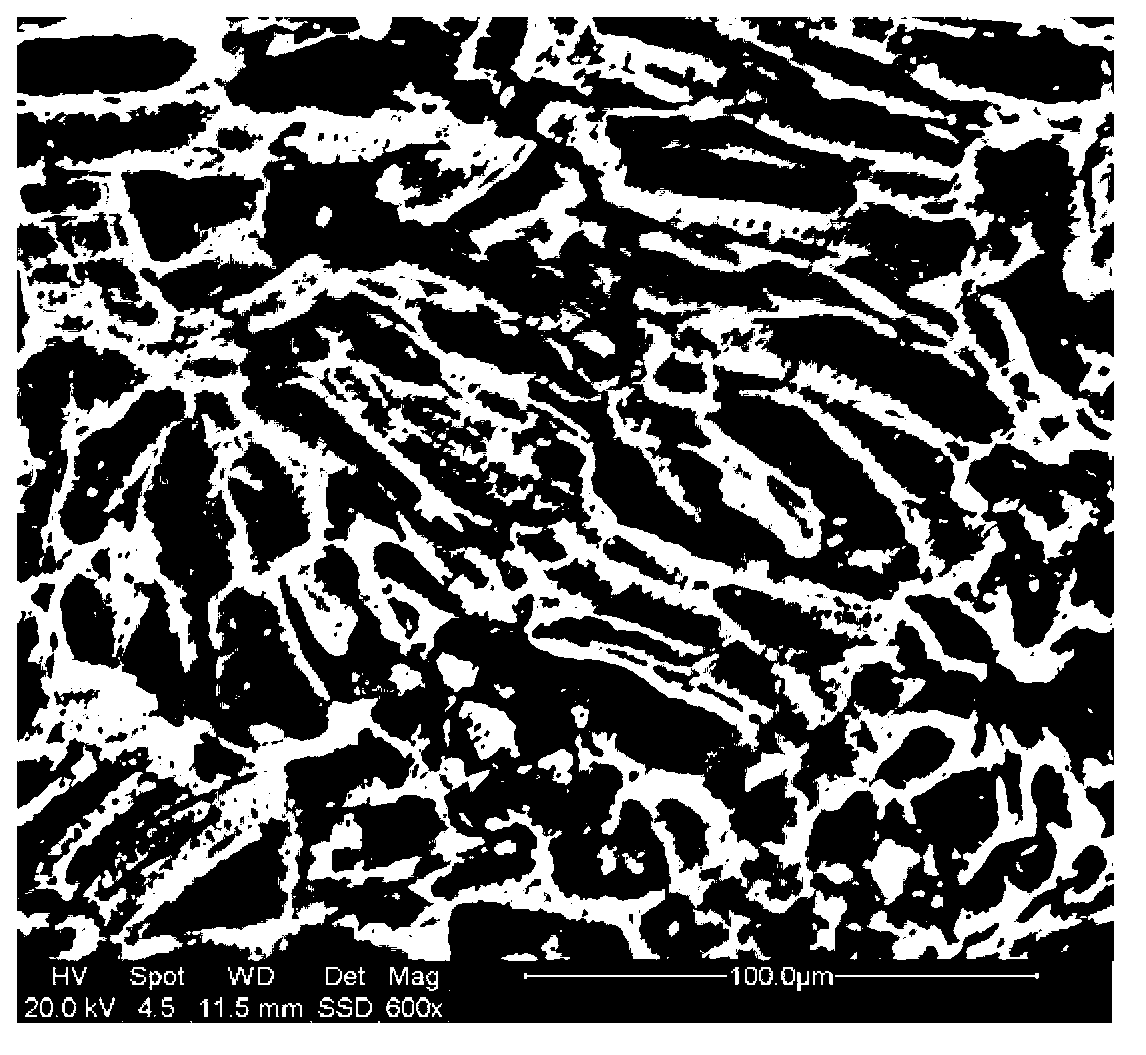

Image

Examples

Embodiment 1

[0034] 1) Weigh 50g of coke grains with a particle size of 200 mesh, put the coke grains into a closed carbonization chamber in CO 2 Under gas protection, heat up to 650°C for 3 hours, take out the carbonized coke particles and cool to room temperature.

[0035] 2) Add the carbonized coke particles in step 1) to the nitric acid solution with a mass concentration of 10% at 80°C, and the treatment time is 2 hours;

[0036] 3) The scorched grains treated in step 2) were soaked in a sodium hydroxide solution with a mass concentration of 31.7% at room temperature for 2 hours, washed until neutral, washed 1 or 2 times with tap water, and dried at 100°C for 2 hours Make char grain matrix;

[0037] 4) Dissolve 3g of polyvinyl alcohol (polymerization degree greater than 1750) in 97mL of boiling water at 100°C and stir for 8 hours to obtain a 3% polyvinyl alcohol solution;

[0038] 5) Measure 3.2mL of glyoxal solution with a mass concentration of 2.5%;

[0039] 6) Cross-link the poly...

Embodiment 2

[0045] 1) Weigh 10g of coke grains with a particle size of 300 mesh, put the coke grains into a closed carbonization chamber in CO 2 Under gas protection, heat up to 750°C for 1 hour, take out the carbonized coke particles and cool to room temperature.

[0046] 2) Put it in the nitric acid solution with a mass concentration of 50% at 100°C in step 1), and treat it for 2 hours;

[0047] 3) Wash the scorched granules treated in step 2) with 20% sodium hydroxide solution at room temperature for 0.5h until neutral, then wash with tap water for 1-2 times, and dry for 1 hour to make the scorched granule matrix ;

[0048]4) Dissolve 6g of polyvinyl alcohol (polymerization degree greater than 1750) in 94mL of boiling water at 100°C and stir for 8 hours to obtain a 6% polyvinyl alcohol solution;

[0049] 5) Measure 2mL of glyoxal solution with a mass concentration of 0.5%;

[0050] 6) Cross-link the polyvinyl alcohol solution and the cross-linking agent solution for 10 hours;

[00...

Embodiment 3

[0056] 1) Weigh 20g of coke grains with a particle size of 15 mesh, put the coke grains into a closed carbonization chamber in CO 2 Under gas protection, heat up to 700°C for 2 hours, take out the carbonized coke particles and cool to room temperature.

[0057] 2) Add the carbonized coke particles in step 1) into the nitric acid solution with a mass concentration of 20% at 100°C, and the treatment time is 1~3h;

[0058] 3) The scorched granules treated in step 2) were soaked in calcium hydroxide solution with a mass concentration of 6.4% at room temperature for 2 hours, washed until neutral, then washed with tap water for 1-2 times, and dried for 1 hour to make a scorched granule matrix ;

[0059] 4) Dissolve 8g of polyvinyl alcohol (polymerization degree greater than 1750) in 92mL of boiling water at 100°C and stir for 8 hours to obtain 8% polyvinyl alcohol solution;

[0060] 5) Measure 2mL of glutaraldehyde solution with a mass concentration of 1.5%

[0061] 6) Cross-link...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com