Integrated injector of liquid rocket engine

A liquid rocket and engine technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of complex fixing methods and poor flow uniformity of oxidant, and achieve the improvement of flow uniformity, performance improvement, and flow resistance reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

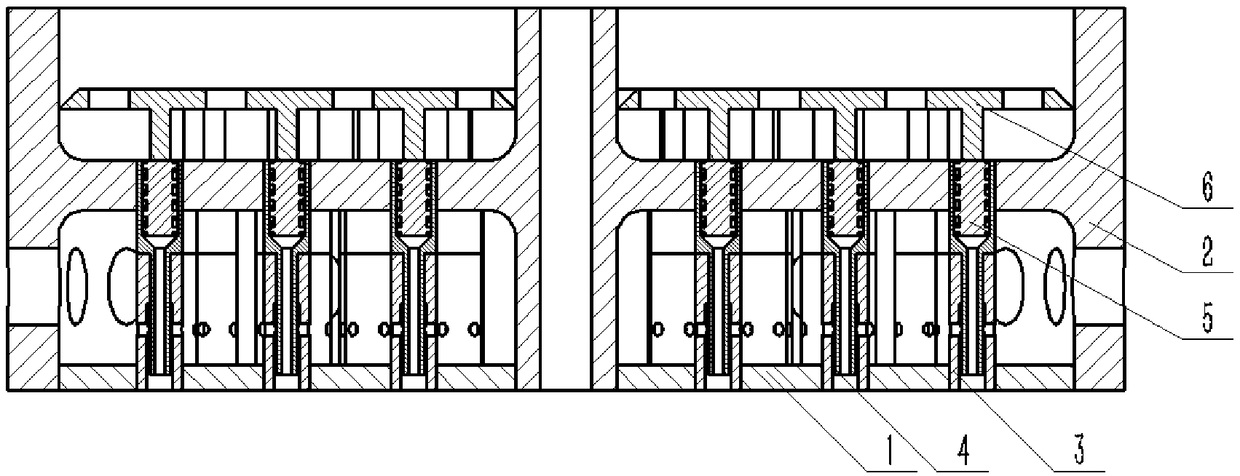

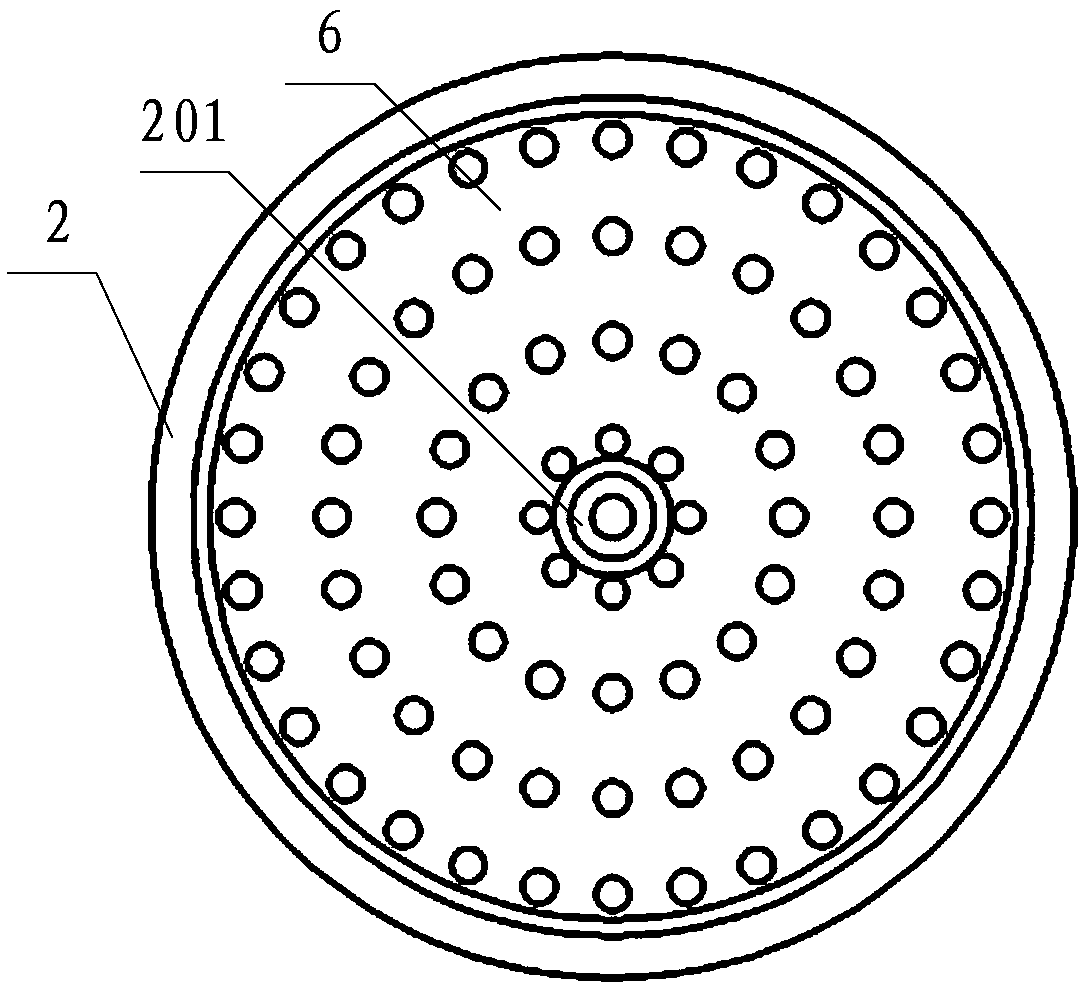

[0039] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention provides an integrated injector for a liquid rocket engine, combined with Figure 1 to Figure 6 As shown, it includes: a bottom plate 1, an outer cylinder 2, a fuel nozzle 3, an oxidant nozzle 4, a swirl device 5 and a flow equalizer 6. The space is connected by an annular horizontal plate 202, which divides the inner cavity of the outer cylinder 2 into an upper cavity and a lower cavity; a plurality of fuel through holes 203 are uniformly arranged on the side wall of the lower cavity, and the bottom of the lower cavity is connected to the bottom plate 1 ;

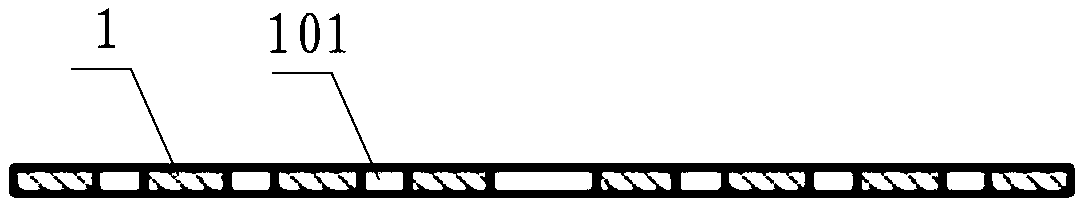

[0040] A plurality of fuel nozzle fixing holes 101 are evenly arranged on the bottom plate 1, and a plurality of oxidizer nozzle fixing holes 204 are evenly arranged on the annular horizontal plate 202, and the positions of the oxidizer nozzle fixing holes 204 correspond to the positions of the fuel nozzle fixing holes 101 one by one; the fuel n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com