A gravity sensing intelligent warehousing system

A gravity-sensing and intelligent technology, applied in the field of smart warehouses, can solve problems such as errors, affecting shipping efficiency, and troublesome quantity checking, reducing the possibility of errors, increasing shipping efficiency, and improving delivery accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

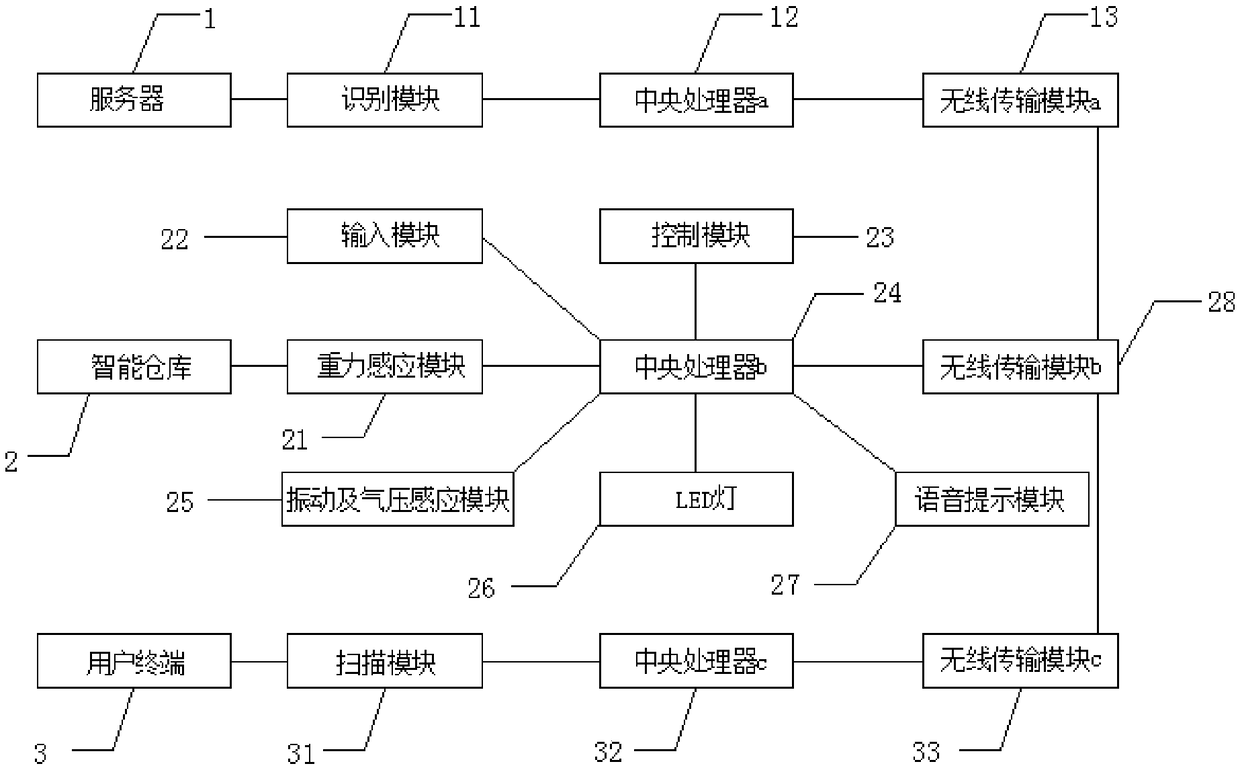

[0019] like figure 1 As shown, the present invention provides a gravity sensing intelligent outbound system, including a server 1, an intelligent warehouse 2 and a user terminal 3, and the intelligent warehouse 2 is provided with a central processing unit b24 and a control module 23 connected with the central processing unit b24 signal , input module 22, gravity sensing module 21, vibration and air pressure sensing module 25, LED lamp 26, voice prompt module 27, wireless transmission module b28; Server 1 comprises central processing unit a12 and the identification module 11 that is connected with central processing unit a12 , wireless transmission module a13; user terminal 3 comprises central processing unit c32 and scanning module 31, wireless transmission module c33 that are connected with central processing unit c32 signal; central processing unit c32 receives the scanning information of scanning module 31, and central processing unit c32 will scan The information is transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com