An integrated equipment for corn harvesting and threshing quality inspection

A technology of corn kernels and corn, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of easy pollution of the environment, inability to adjust the wheel base, and lack of quality inspection functions for corn kernels, so as to reduce labor intensity, The effect of ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

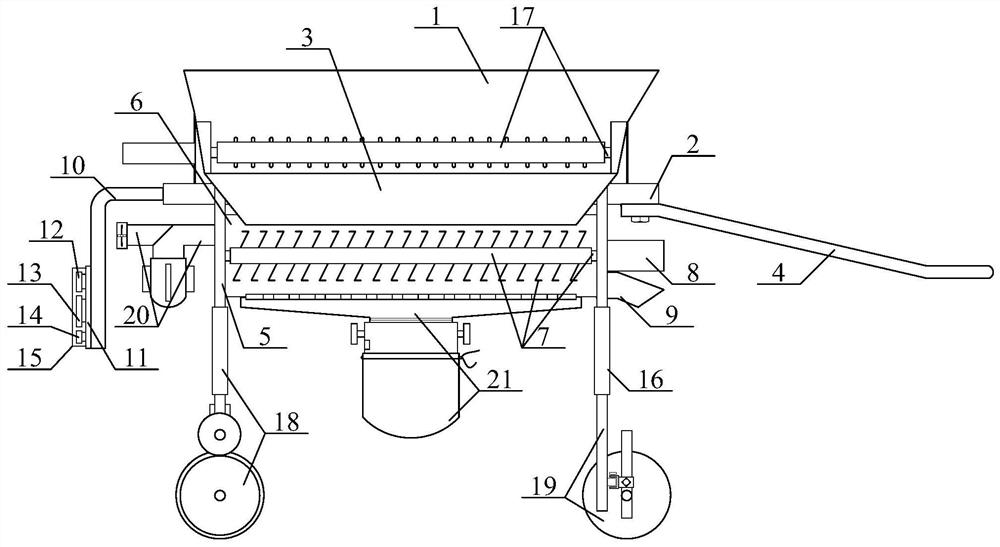

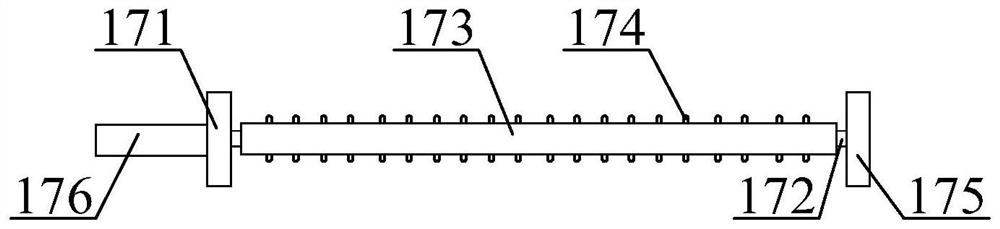

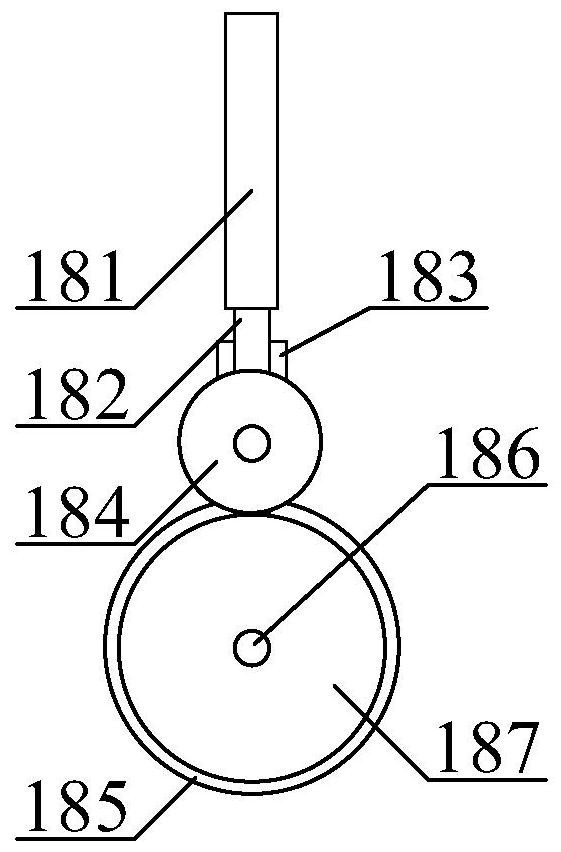

[0057] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, an integrated equipment for corn harvesting and threshing quality inspection includes an open-type corn cob collection bucket 1, an open machine base 2, a corn cob transfer bucket 3, a corn stalk harvesting rod 4, a machine rod 5, and a sealing threshing cylinder 6. Threshing roller 7, threshing motor 8, corncob discharge hopper 9, L-shaped handle 10, circuit board 11, controller 12, touch screen 13, master control switch 14, shield 15, connecting coil 16, corn cob extrusion Roll out guide wheel structure 17, self-moving push-free lifting wheel 18, corn field spacing adjustable mobile front wheel structure 19, corn dust auxiliary collection anti-fouling machine 20 and threshing quality inspection type corn grain collection rotary bag structure 21, all The bolts of the open-type corn cob collection bucket 1 are installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com