Hook correcting mechanism of groove type reversing device

A commutator and groove technology, which is applied in the field of commutator inspection, can solve problems such as insufficient accuracy, unevenness and deviation, and achieve the effects of high correction accuracy, improved efficiency and guaranteed correction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means of the present invention and the technical effects that can be achieved more clearly and more completely disclosed, an embodiment is provided hereby, and the following detailed description is given in conjunction with the accompanying drawings:

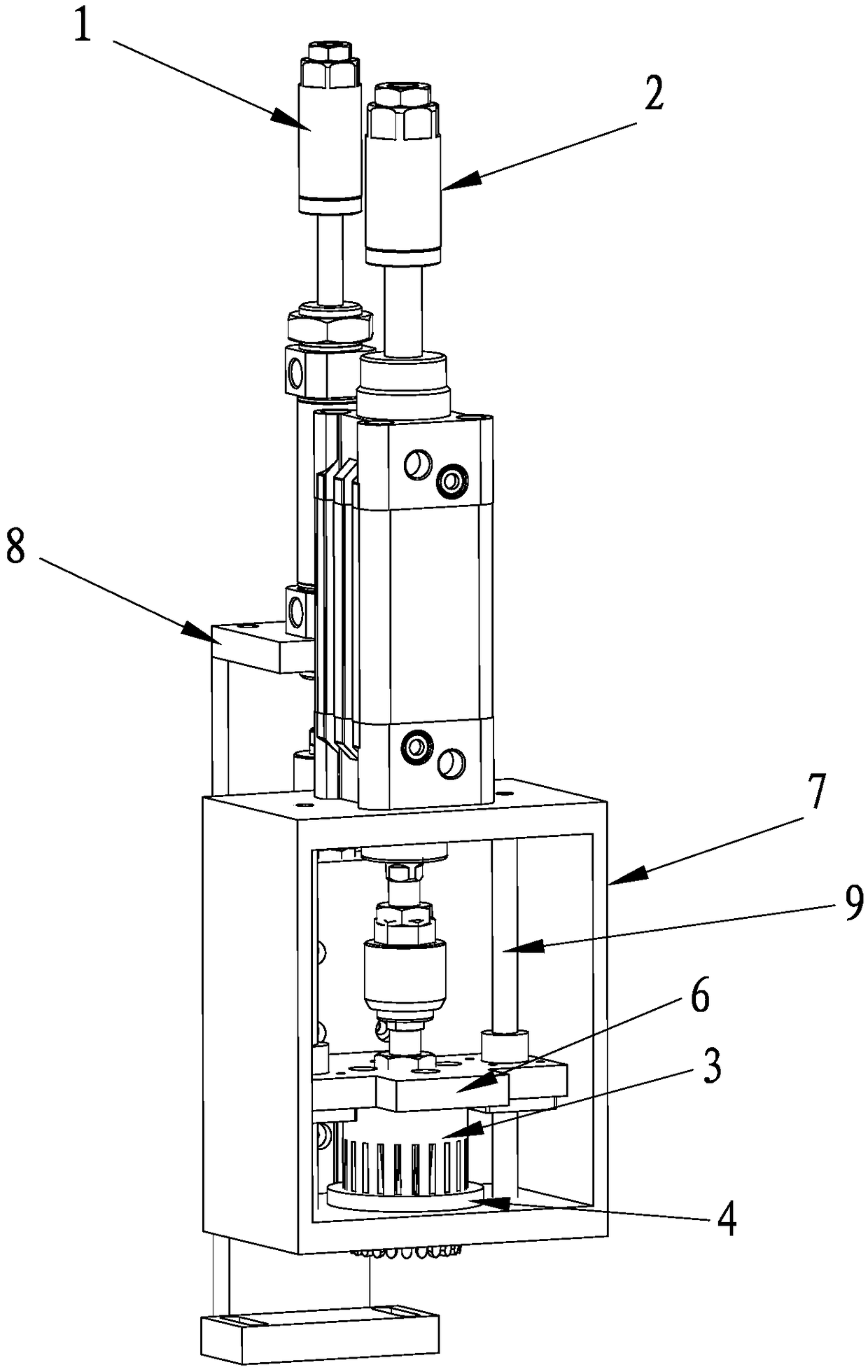

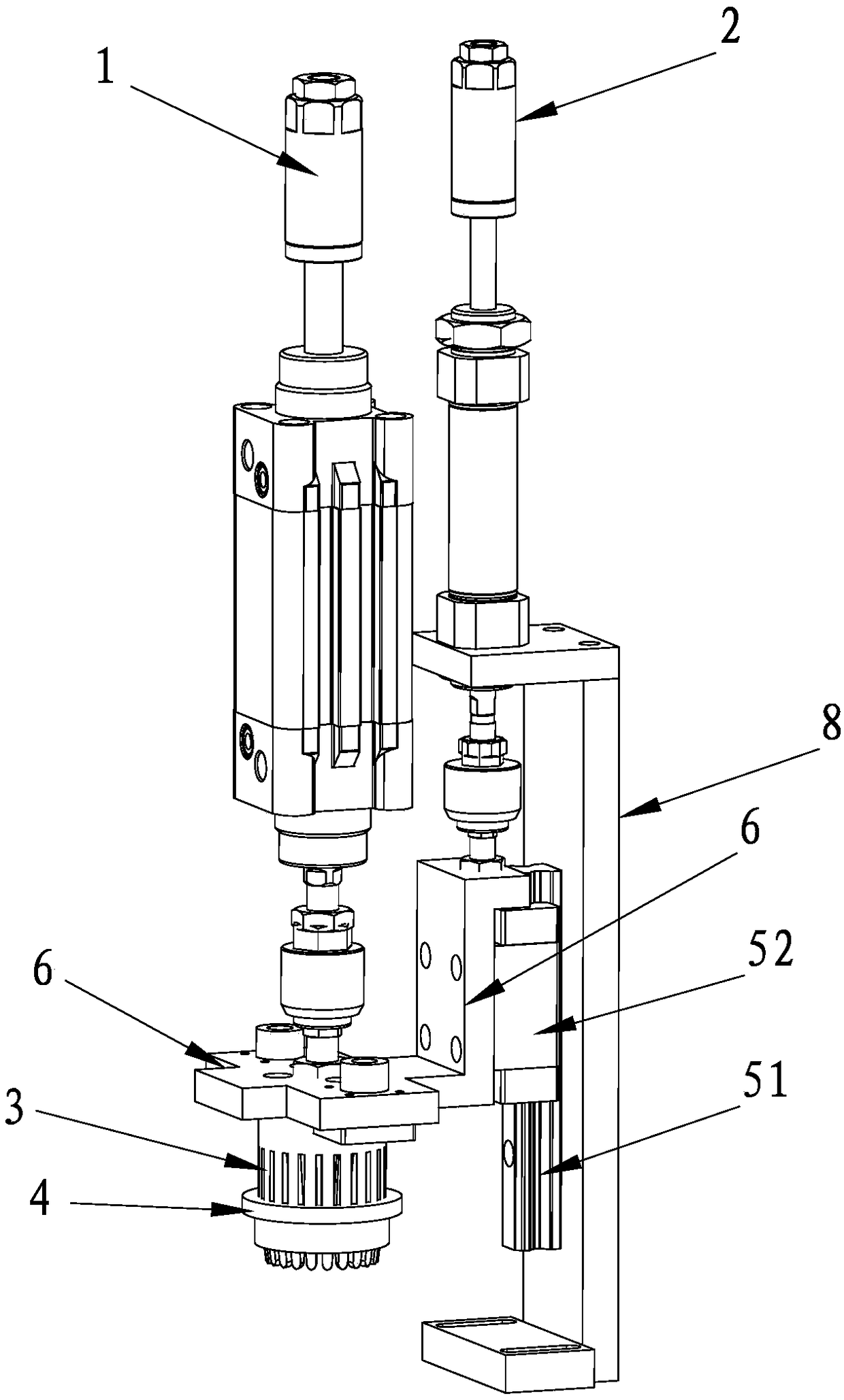

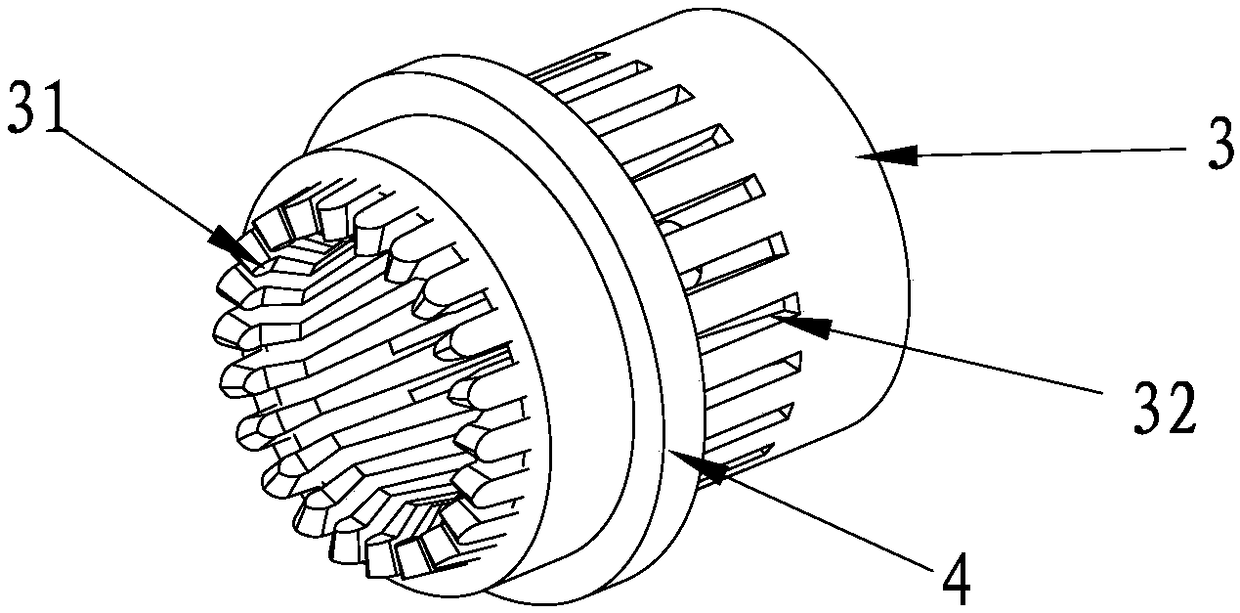

[0029] The groove-type commutator hook correction mechanism includes a bracket 8, a driving device installed on the bracket 8, a hook indexing correction head 3 linked with the driving device, and a tightening collar sleeved on the hook indexing correction head 3 4. The pressure of lifting cylinder two 2 is adjustable.

[0030] The driving device comprises a lifting cylinder one 1 and a lifting cylinder two 2 and includes a telescopic rod one and a telescopic rod two respectively, the lifting cylinder one 1 and the lifting cylinder two 2 are linked, and the lifting cylinder one 1 is fixedly installed on the support 8.

[0031] Guide rail 51 is installed on the support 8, slide block 52 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com