Waste collecting device

A waste collection and collection frame technology, applied in the field of automobile stamping production, can solve problems such as affecting the normal production of the production line, increasing maintenance costs, and increasing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail in conjunction with the accompanying drawings.

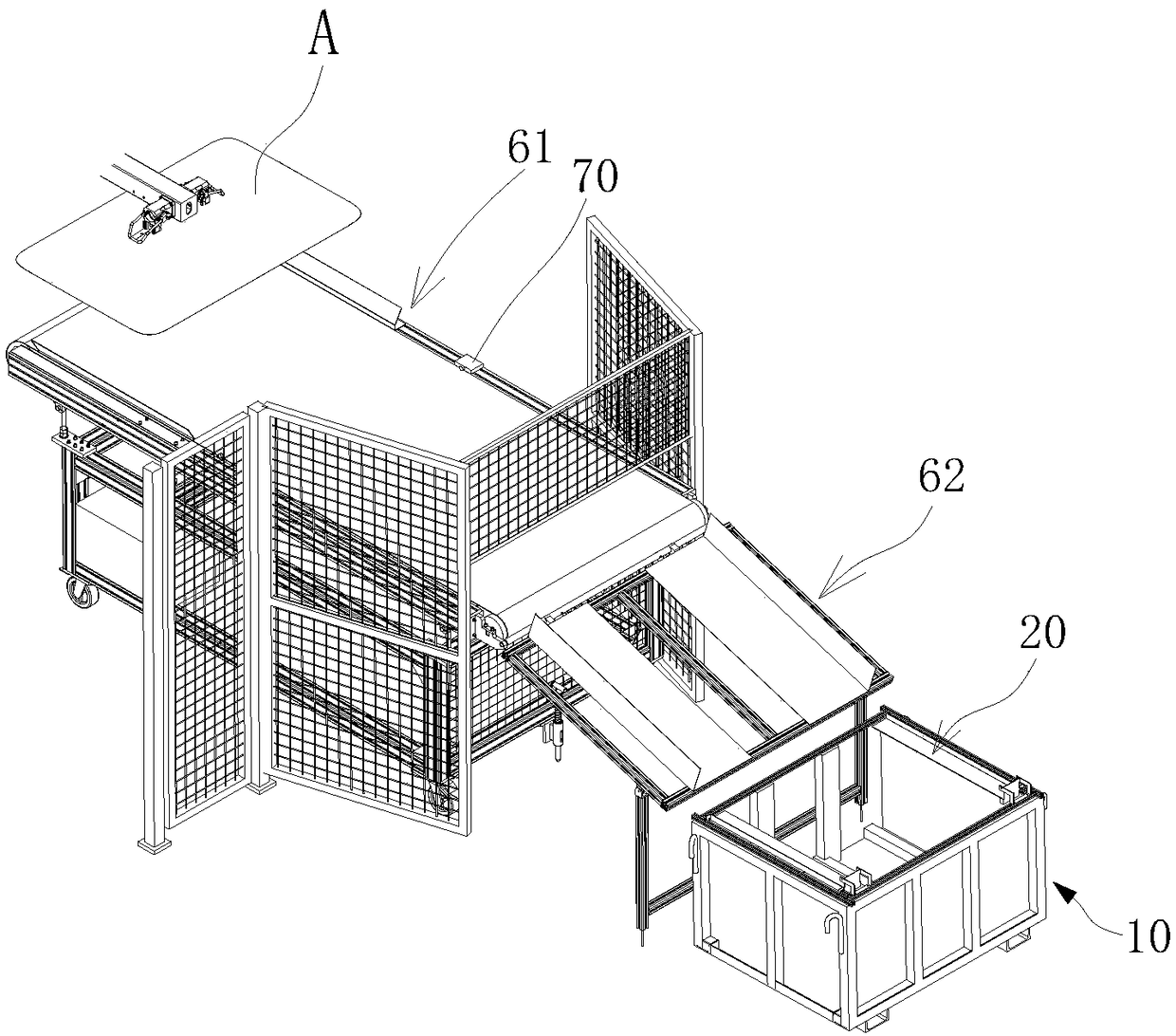

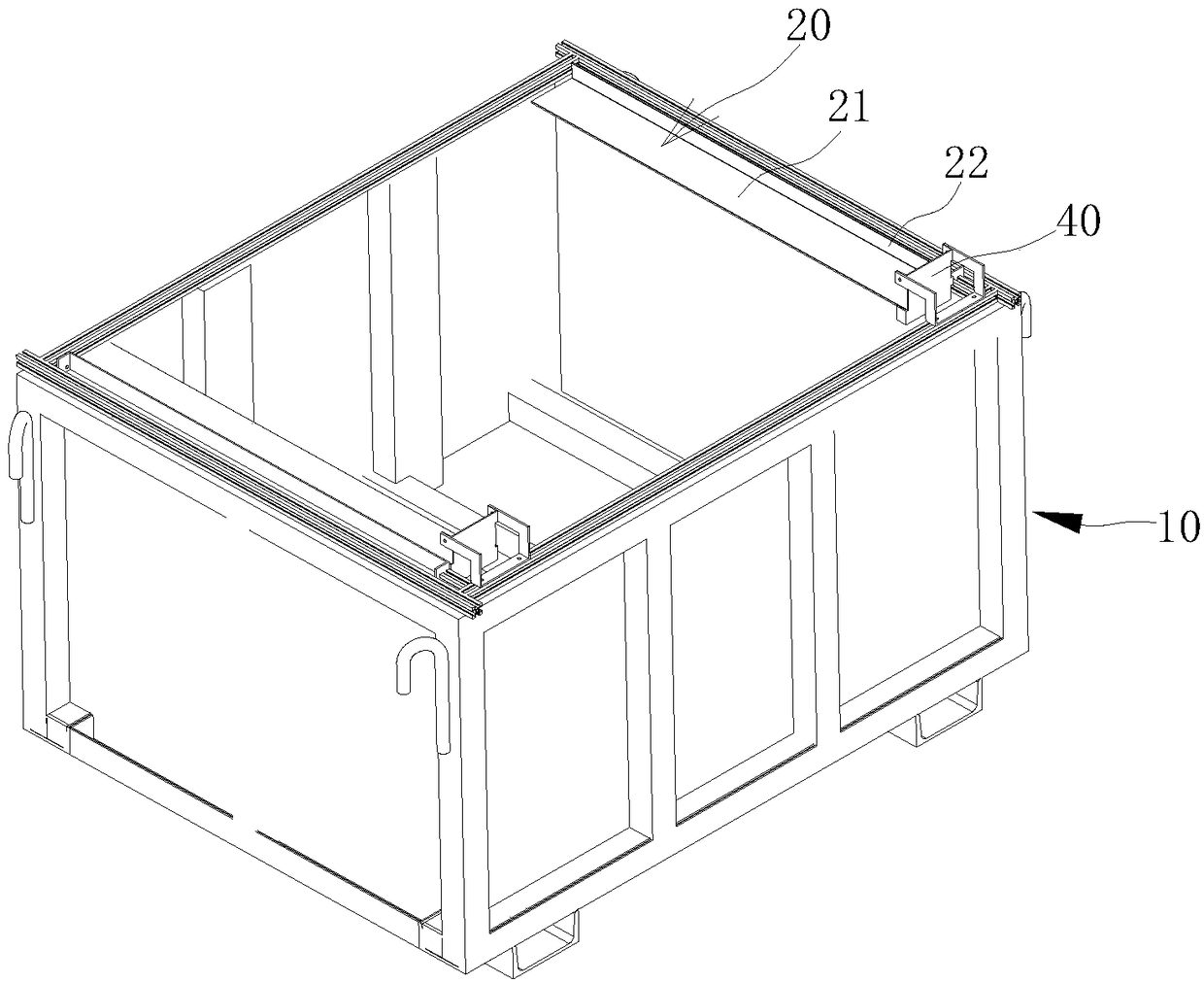

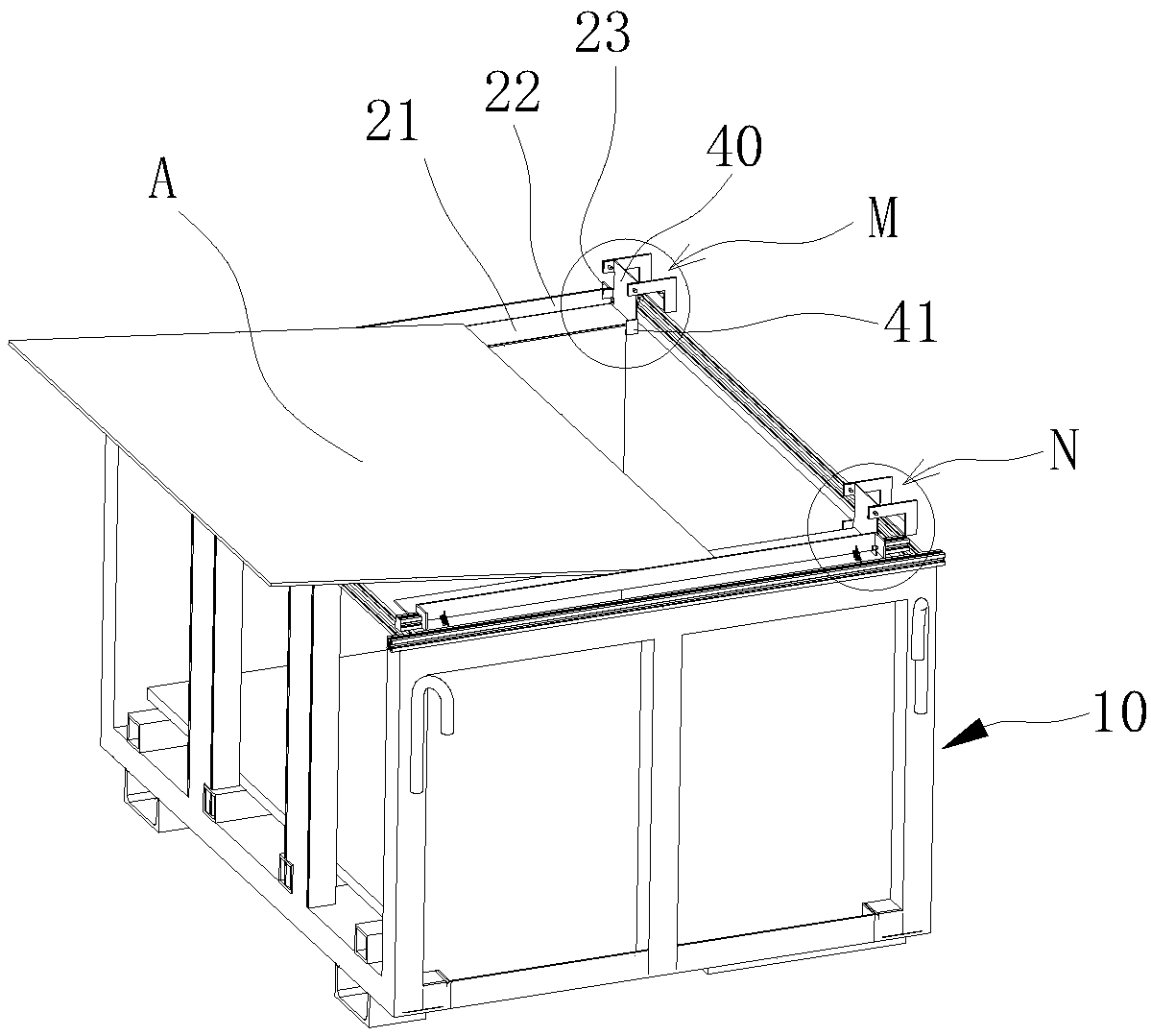

[0015] A waste material collection device, comprising a collection frame 10 of a waste board A, the opposite side of the upper end frame opening of the collection frame 10 is provided with a load strip 20, and the two ends of the load strip 20 and the collection frame 10 are connected by a first hinge shaft 30 Hinged, the first hinge shaft 30 is parallel to the length direction of the material slats 20, the same ends of the two material slats 20 are connected with the guide unit of the waste material board A and form the receiving end of the waste material board A, the two material slats The other end of the plate 20 is provided with a limit unit, which forms two cooperation states of contact and separation with the load strip 20. When the limit unit contacts and cooperates with the load strip 20, the load plate on the load strip 20 The plate surface of 21 is horizontal and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com