Automatic collection device for production of steel balls

An automatic collection and steel shot technology, applied in the field of steel shot production and processing, can solve the problems of small size of steel shot, lower production efficiency, lower steel shot yield, etc., to achieve the effect of reducing production cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

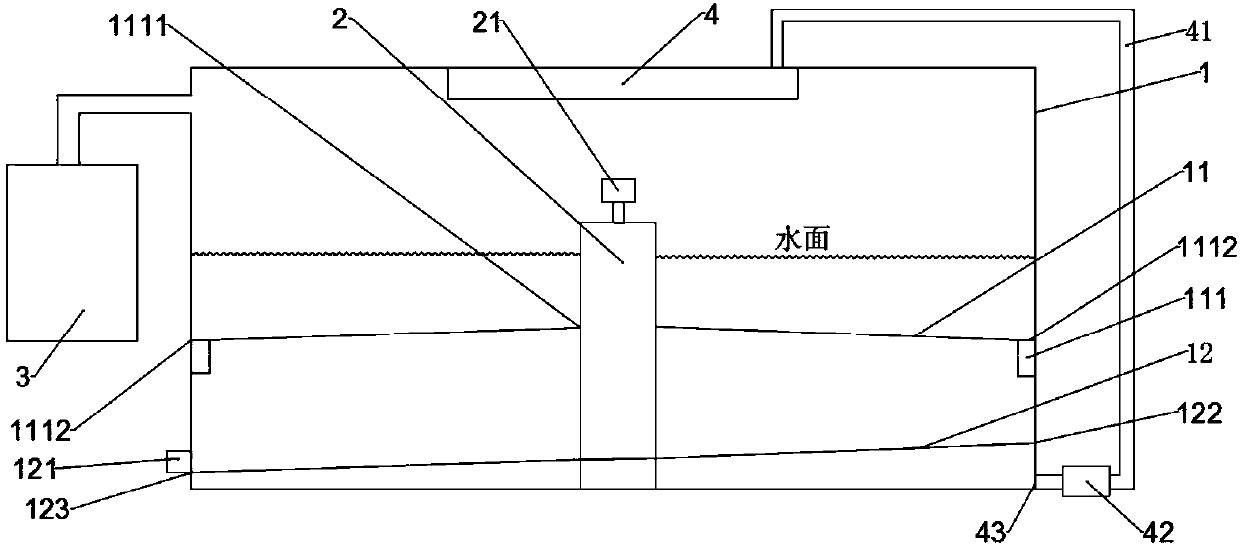

[0018] The present invention is further described below in conjunction with accompanying drawing:

[0019] Such as figure 1 , the present invention is composed of a cooling pool 1 connected to a nitrogen source 3, and the nitrogen source 3 provides nitrogen for the entire production process to ensure the production quality of the steel shot. The inner center of the cooling pool 1 top surface is also provided with a water curtain cooling device 4, which is circular and sprays cold water downwards. Cooling pool 1 is equipped with cold water inside, and the liquid level of cold water is lower than rotor 2. A centrifuge 2 is arranged in the center of the inner bottom surface of the cooling pool 1 . The centrifuge 2 is provided with a temperature insulation layer.

[0020] In the cooling pool 1, a water-repellent layer 11 and a screen 12 are sequentially arranged from top to bottom, and the height of both is lower than that of the nozzle 21; Also be provided with valve 111, wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com