Plate and pier connecting method for precast bridge

A connection method and technology of prefabricated bridges, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as poor vibration isolation effect, and achieve the effect of good lateral movement resistance and not easy to be corroded and damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

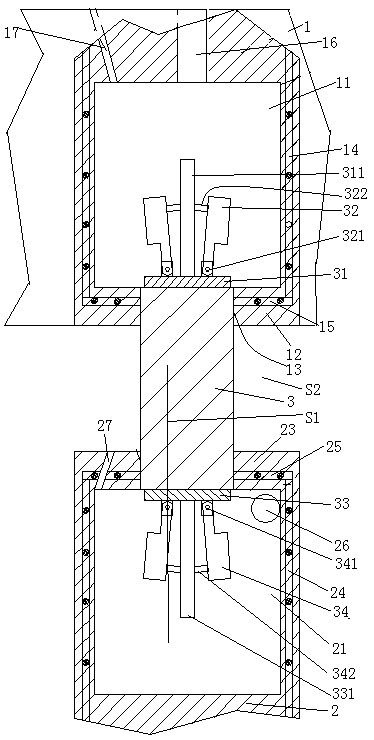

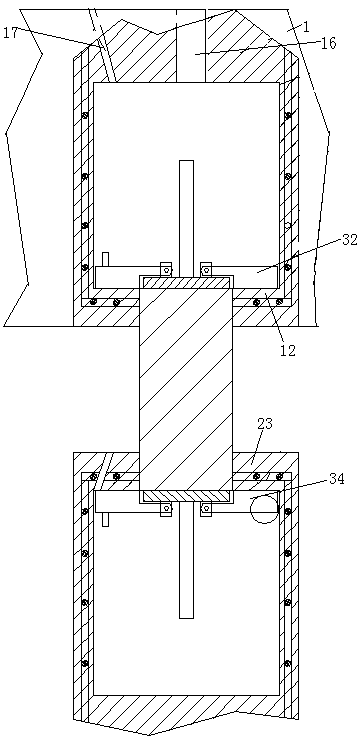

[0021] Embodiment one, see figure 1 , figure 2 and image 3 , a method for connecting bridge slabs and piers of a prefabricated bridge,

[0022] The first step is to set an upper assembly hole 11 on the lower end surface of the bridge plate 1, and an upper assembly hole annular cover 13 is integrally formed on the opening of the upper assembly hole, and a steel bar for the upper assembly hole side wall is provided in the hole wall of the upper assembly hole The frame 14 and the upper assembling hole annular cover are provided with an upper hole cover part reinforcement frame 15 to improve the structural strength of the upper assembling hole wall and the upper assembling hole annular cover. The upper assembly hole is provided with a pouring hole 16 for the bridge part and an exhaust hole 17 for the bridge part. Both the pouring holes of the bridge plate and the exhaust holes of the bridge plate pass through the upper surface of the bridge plate. A lower assembly hole 21 is...

Embodiment 2

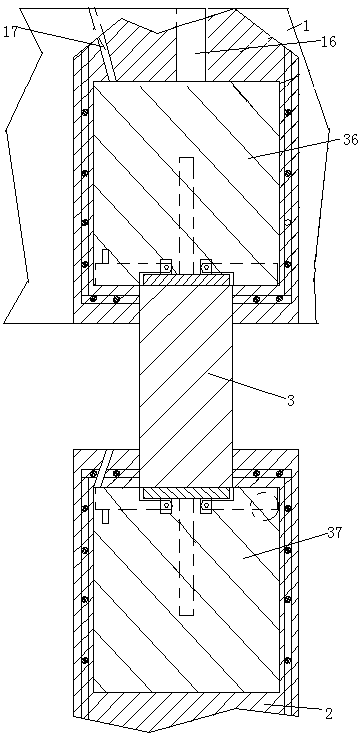

[0029] Embodiment two, the difference with embodiment one is:

[0030] see Figure 4 , the lower assembly hole annular cover is provided with permanent magnet 35. In the fifth step, the lower hooking rod is rotated under the adsorption of the ring-shaped permanent magnet so as to overlap the ring-shaped cover of the lower assembly hole. There is no need for artificial magnets to attract and turn over, which improves the convenience of construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com