Automatic part processing precision detecting method utilizing three-dimensional point cloud

A technology for parts processing and automatic detection, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of not considering the overall registration results and deviations, and achieve automatic detection of parts accuracy, strong sensitivity, and wide adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

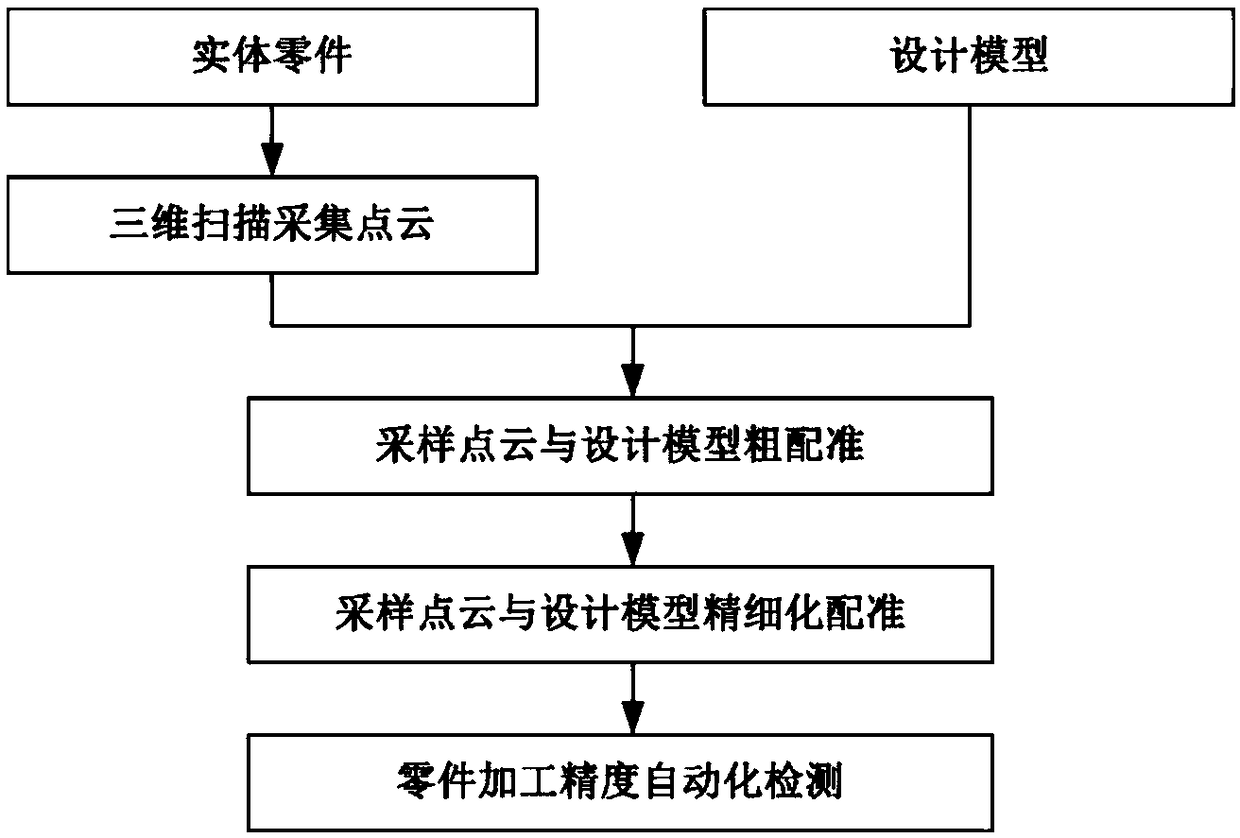

[0046] Such as figure 1As shown, the automatic detection method of parts processing accuracy using three-dimensional point cloud of the present invention, given a pair of parts and part design models, the detection method includes the following steps:

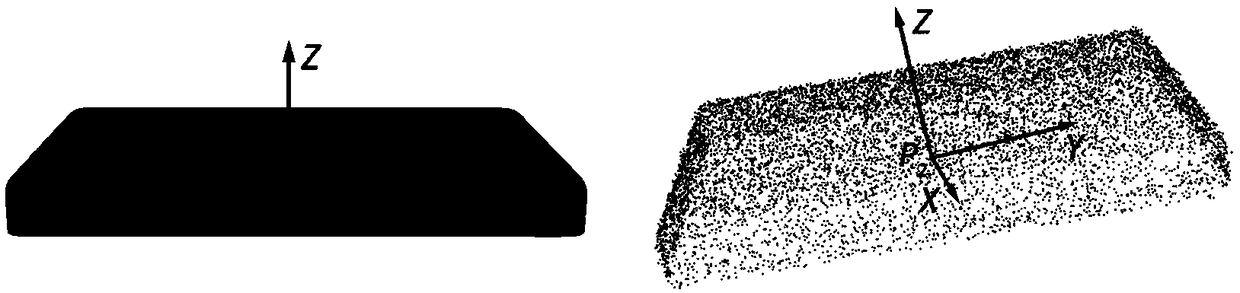

[0047] (1) For the part entity, use 3D laser scanning technology to sample the point cloud of the part, and collect the 3D point cloud P of the part;

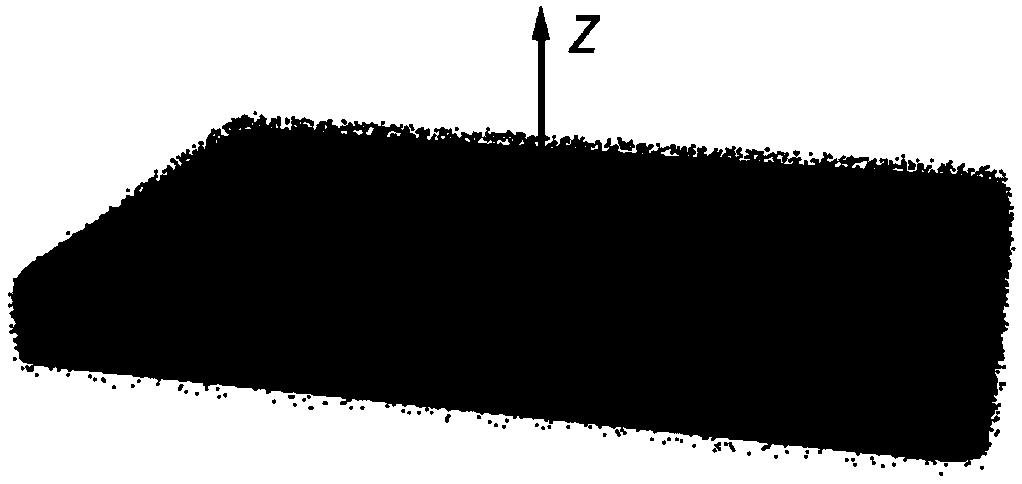

[0048] (2) Coarsely register the sampling point cloud and the part design model through the principal component analysis method, assign weights to the points according to the residual value of the point during the registration process of the sampling point cloud, and perform registration by iterating the nearest neighbor point by selecting the weight Quasi-fine adjustment, the specific content is:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com