Wrenching performance testing device for bolt screwing groove and testing method thereof

A test device and screw groove technology, applied in the field of detection and test, can solve the problems of sensor damage and troublesome operation, and achieve the effect of ensuring accuracy and simple operation.

Pending Publication Date: 2019-03-19

CHINA AERO POLYTECH ESTAB

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] For different screwdriver grooves, choose different bit types. The axial load can be realized by means of weights, force sensors, and push-pull force gauges. However, the operation in the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

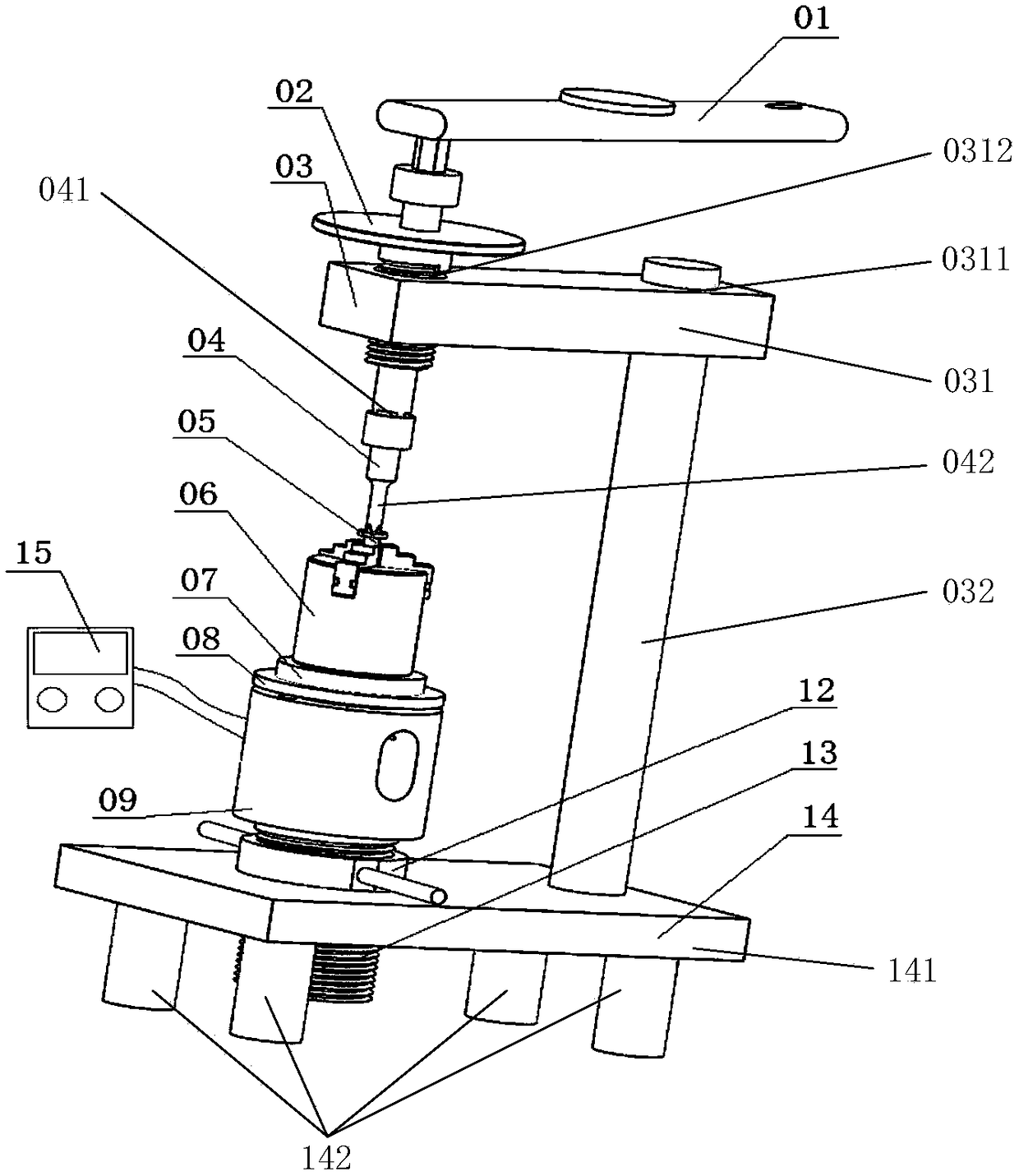

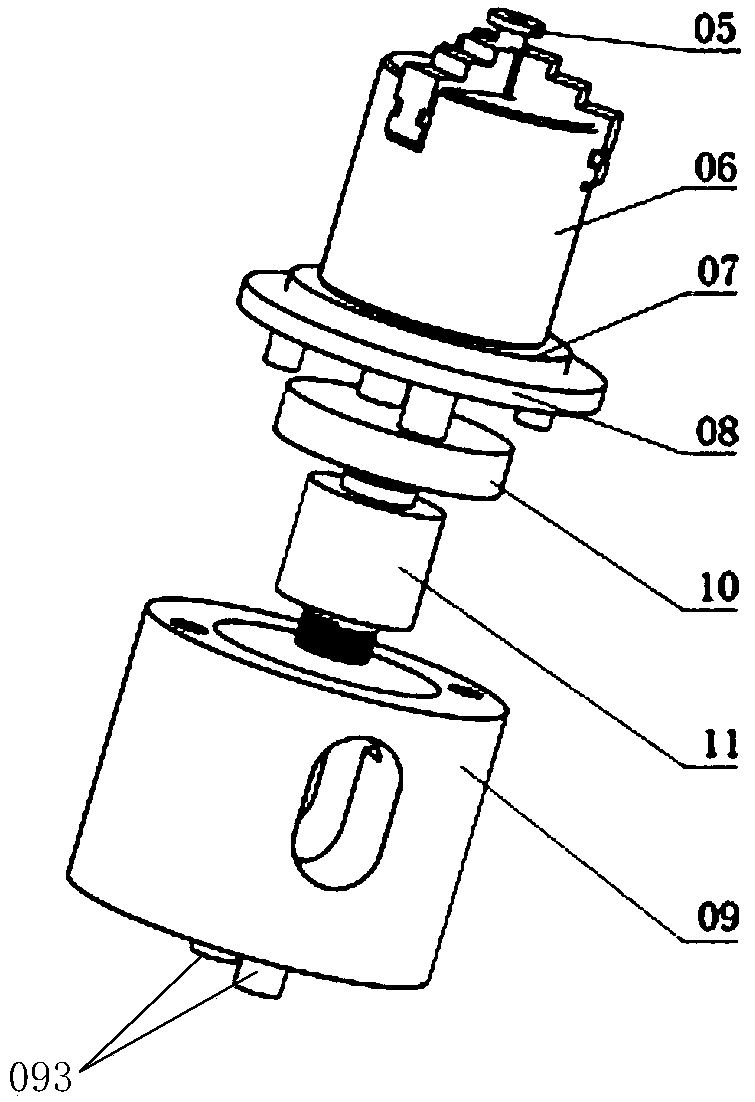

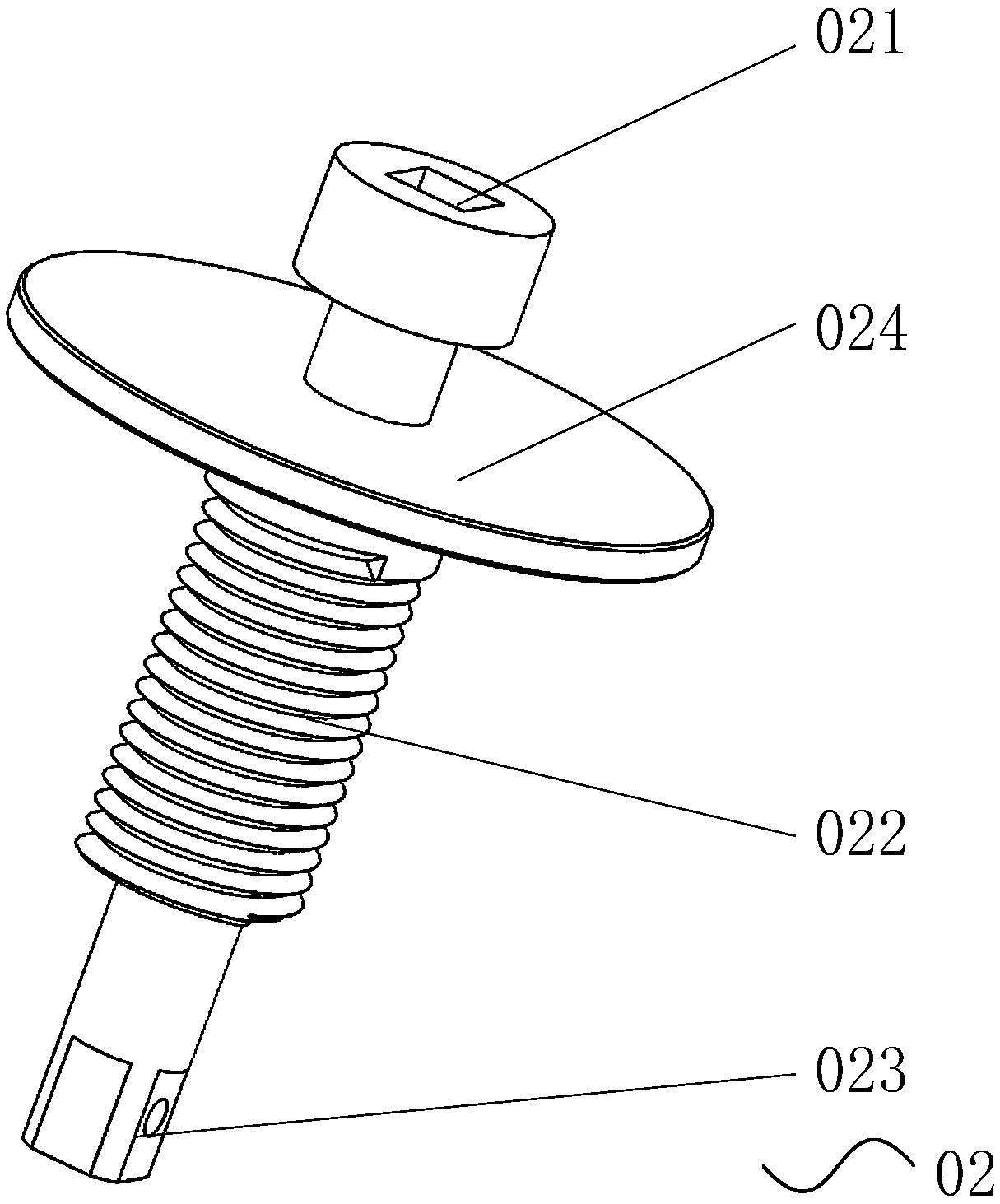

The invention discloses a wrenching performance testing device for a bolt screwing groove. The wrenching performance testing device comprises a torque wrench, a torque wrench fixing end, a bracket, ascrewing groove screwdriver set head, a three-jaw chuck, a three-jaw chuck fixing plate, a cover plate, an axis force sensor housing, an axis force sensor force bearing plate, an axis force sensor, anut with a handle, a lifting screw lead, a base and an axis force sensor display terminal. The torque wrench fixing end is fixedly connected to the bracket and the torque wrench and the screwing groove screwdriver set head are separately mounted at two ends of the torque wrench fixing end; the three-jaw chuck is fixedly connected to the three-jaw chuck fixing plate, a chuck pin roll of the three jaw chuck fixing plate is inserted into a chuck pin roll hole of the cover plate, a cover plate pin roll of the cover plate is inserted into a cover plate pin roll hole of the axis force sensor housing, the axis force sensor is mounted in the axis force sensor housing, and a housing pin roll at the bottom is inserted into a housing pin roll hole in the top of the top of the lifting lead screw; andthe numerical value of the axis force sensor is displayed through the axis force sensor display terminal. The device and method can detect the wrenching performance of the bolt screwing groove and control application of an axial load precisely.

Description

technical field [0001] The invention belongs to the technical field of detection and testing, and in particular relates to a device for testing the screwing performance of a screwdriver groove of a bolt and a testing method thereof. Background technique [0002] In the fields of civil and aviation, there are many kinds of screwdriver grooves for bolts, including cross grooves, slotted grooves, hexagonal sockets and hexagonal sockets, etc. The twisting torque is an important test item for evaluating the anti-twisting performance of the screwdriver grooves. By selecting the bit that matches the groove number of the screwdriver, use a torque wrench to apply the torque required by the standard or document to the screwdriver groove, and at the same time apply an axial load of 49N or 98N in the axial direction of the bolt, and check the screwdriver of the bolt after the test Whether the groove is deformed or damaged. [0003] For different screwdriver grooves, choose different bi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/22G01N3/02

CPCG01N3/02G01N3/22Y02E30/30

Inventor 尹振波张志强阚奇王涛吴博

Owner CHINA AERO POLYTECH ESTAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com