Method for diagnosing input signal fault of PLC system using counter

A technology of input signal and signal failure, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve problems such as reducing production efficiency, failing to alert operators to equipment failures, and taking long time to deal with failures. The effect of improving response speed and saving troubleshooting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

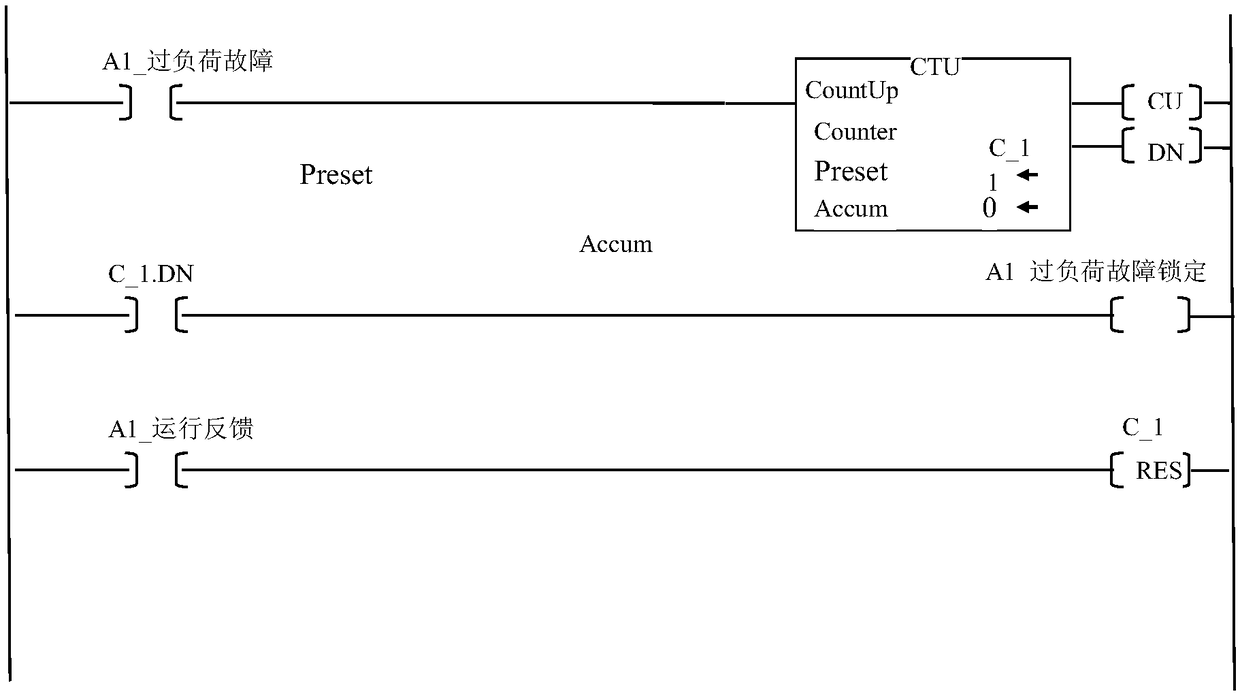

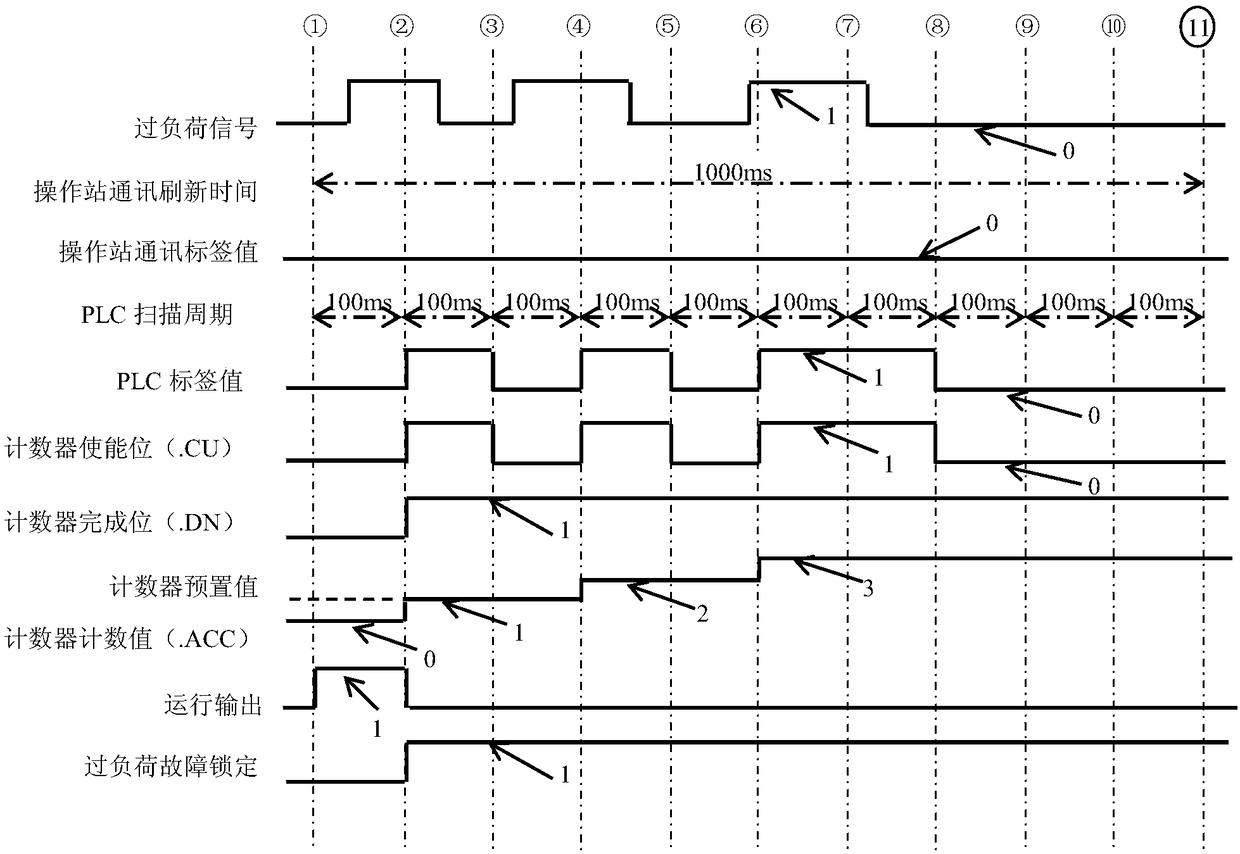

[0016] The present invention will be further described below by means of embodiments in conjunction with the accompanying drawings.

[0017] In an embodiment, a method for using a counter to diagnose a PLC system input signal fault, the steps are as follows:

[0018] Step 1: Counter instruction description. The counting instruction CTU is an output instruction, and the counter structure is shown in Table 1:

[0019] Table 1. Counter structure

[0020] mnemonic

type of data

illustrate

.CU

BOOL

Up counting enable bit --- indicates that the CTU instruction is enabled.

.DN

BOOL

Completion bit---Identifies accumulated value (.ACC)>=(preset value.PRE).

.OV

BOOL

Overflow bit --- indicates that the counter exceeds the upper limit value.

.PRE

DINT

preset value --- Specifies the value the accumulated value reaches before the instruction sets the done bit (.DN).

.ACC

DINT

Accumulated value --- I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com