Button switch with socket and control method

A control method and button technology, applied in the direction of electric switches, contact parts, electrical components, etc., can solve the problems of troublesome use process, low product reliability, and control of high-load circuits, etc., to achieve expanded use range, convenient structure assembly, The effect of increasing the load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

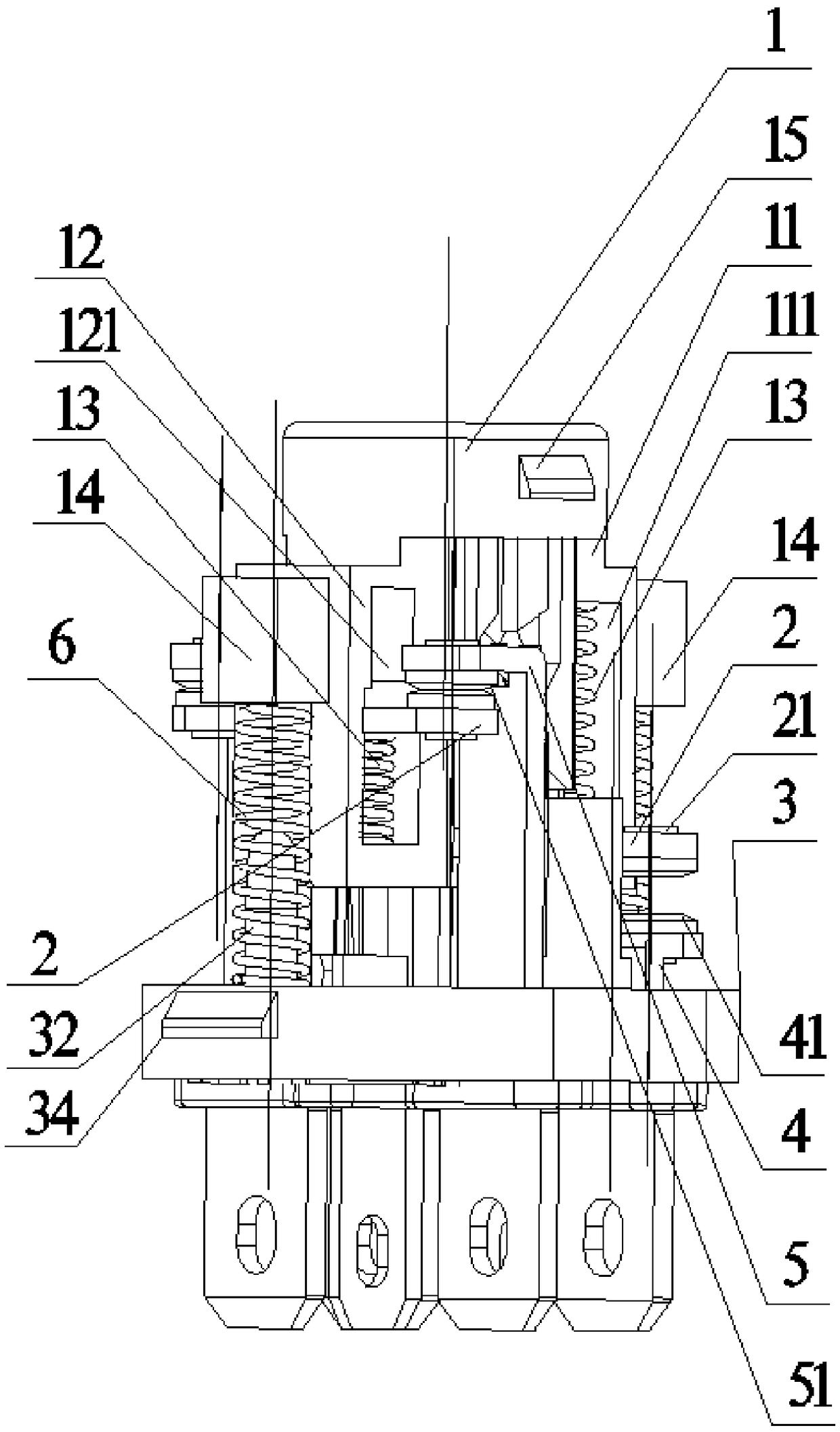

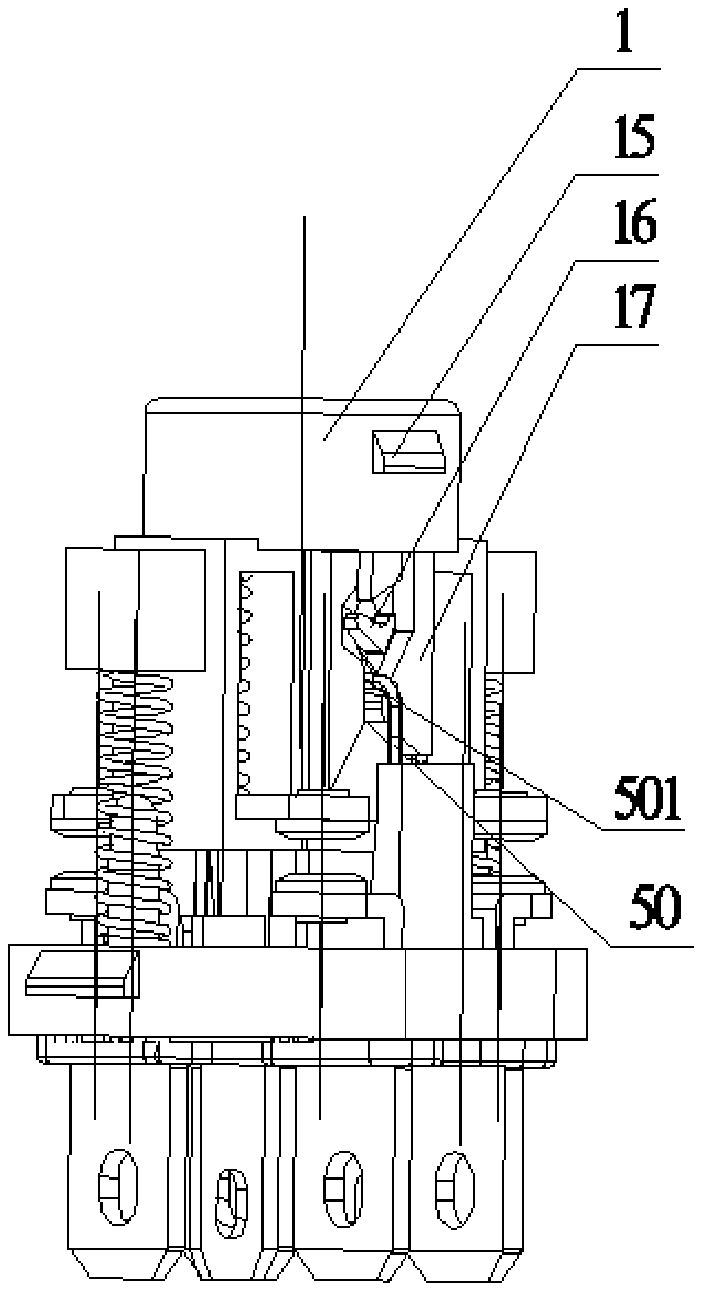

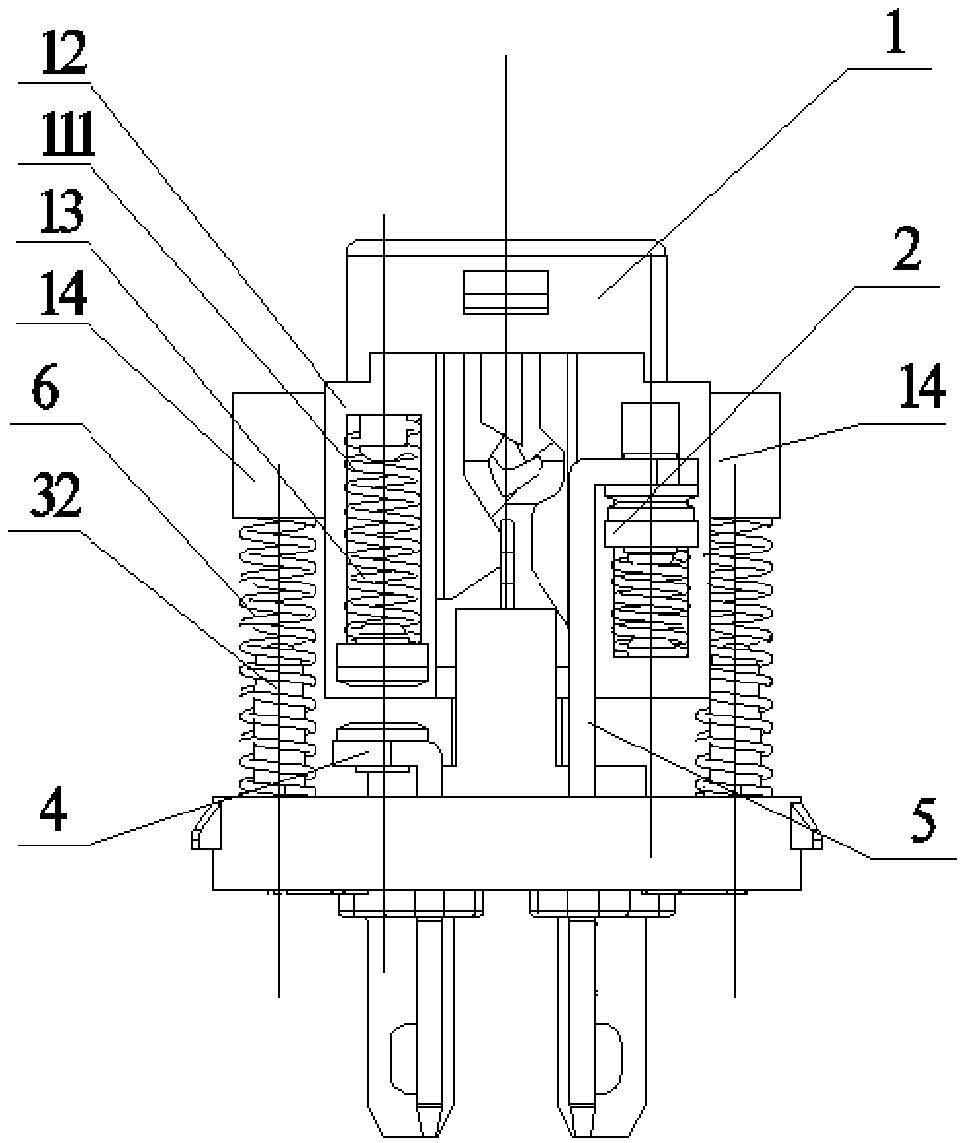

[0058] Such as figure 1 , Figure 5As shown, the push button switch with socket of the present invention includes: a push rod 1, a first push rod connection part 11 and a second push rod connection part 12 are protruded from one end thereof, and the first push rod connection part 11 and the second push rod connection part 11 The interior of the rod connecting portion 12 is respectively formed with a through first mounting portion 111 and a second mounting portion 121, and the first mounting portion 111 and the second mounting portion 121 are respectively embedded with a movable contact spring 13; the first push rod connecting portion 11 and the outer wall of the second push rod connecting portion 12 are respectively fixed with at least one stop block 14; two moving contacts 2, and the two moving contacts 2 are movably clamped on the first mounting portion 111 and the second mounting portion 111 respectively. In the part 121, the spring 13 of the movable contact is pressed aga...

Embodiment approach 2

[0072] The present invention also provides a method for controlling a button switch with a socket, wherein the method for controlling the button switch with a socket adopts the above-mentioned button switch with a socket, and the button switch with a socket in this embodiment is the same as that of Embodiment 1. The structures, working principles and beneficial effects are the same, and will not be repeated here. The control method of the button switch with socket comprises the following steps:

[0073] Step S1, press the push rod 1 downward, the movable contact 2 moves downward accordingly, and the stop spring 6 is in a compressed state under the force of pressing the push rod 1;

[0074] Step S2 , removing the active force applied to the push rod 1 , the push rod 1 moves upwards under the resilience of the stop spring 6 , and the movable contact 2 moves upward accordingly.

[0075]In a feasible embodiment, the button switch with the socket is set to a "one normally open and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com