Automatic control device for temperature of seedling-raising greenhouse by PLC control

An automatic control device and seedling-raising greenhouse technology, which is applied in greenhouse cultivation, temperature control using digital devices, temperature control using electric methods, etc., can solve problems such as temperature regulation, and achieve the effect of well-developed root system and good growth potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

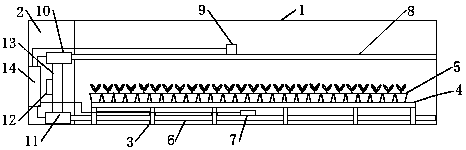

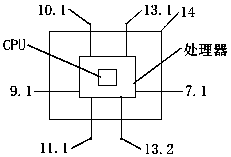

[0010] A control room 2 is arranged on one side of the nursery greenhouse 1;

[0011] A pillar 3 is arranged at the lower part of the seedling-growing greenhouse, a platform 4 is arranged at the upper part of the pillar, and seedling pots 5 are arranged on the platform;

[0012] A lower ventilation pipe 6 is arranged between the pillars, and a lower temperature sensor 7 is installed on the lower ventilation pipe. The lower ventilation pipe communicates with the air outlet of the lower fan 11. The lower fan is installed in the lower part of the control room, and the air suction port communicates with the electric heater 13;

[0013] An upper ventilation pipe 8 is installed in the upper space of the nursery greenhouse, and an upper temperature sensor 9 is installed on the upper ventilation pipe. One end of the upper ventilation pipe communicates with the upper fan 10 arranged in the control room, and the suction port of the upper fan communicates with the upper section of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com