Calcaneal sustentaculum tali guide and using method thereof

A calcaneal load bearing and guider technology, applied in fixers, medical science, surgery, etc., can solve problems such as easy slippage of the positioning point of the calcaneus, less loading of talus screws, positioning errors, etc., and shorten the operation time time, improve safety, and reduce complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

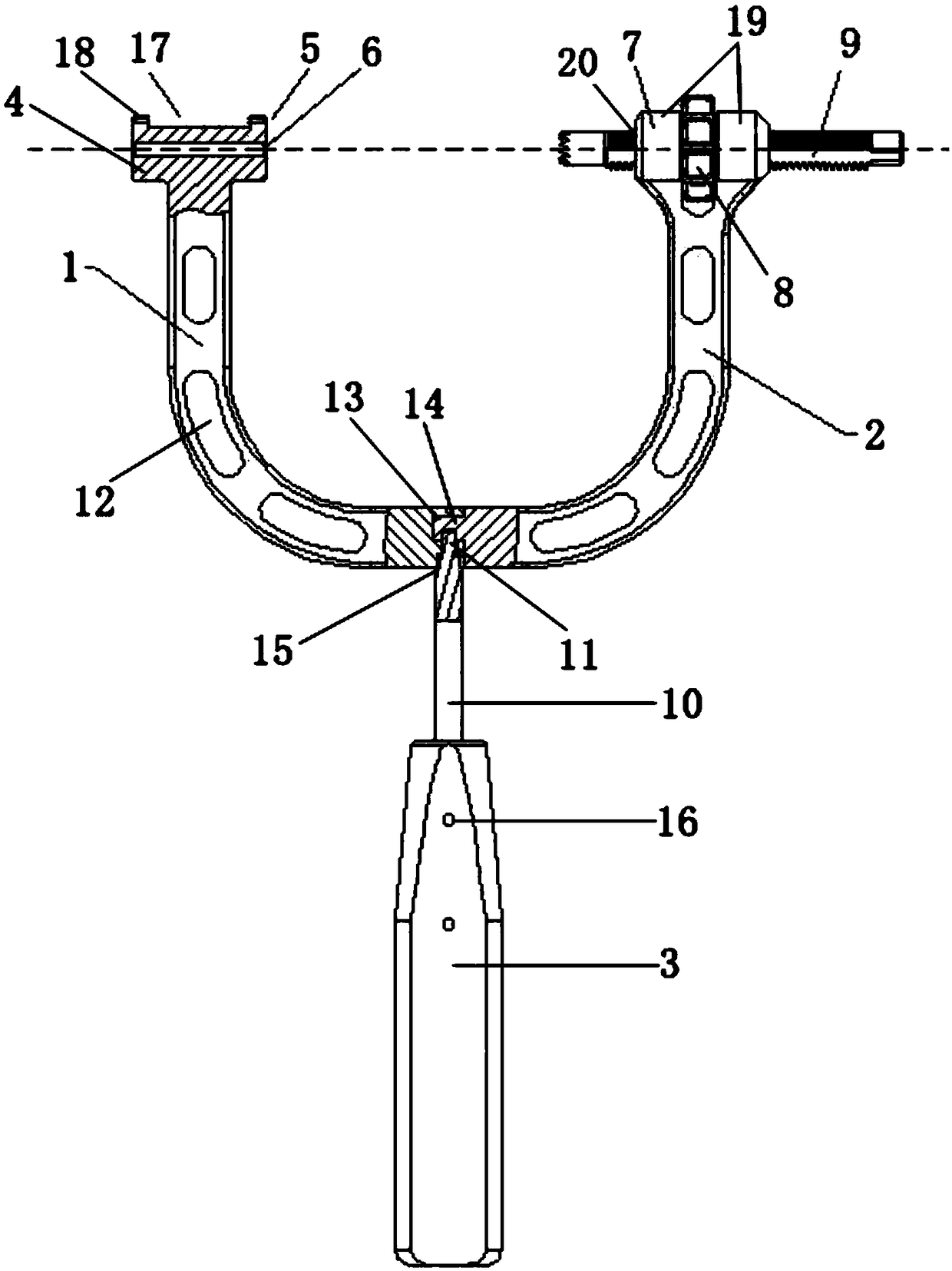

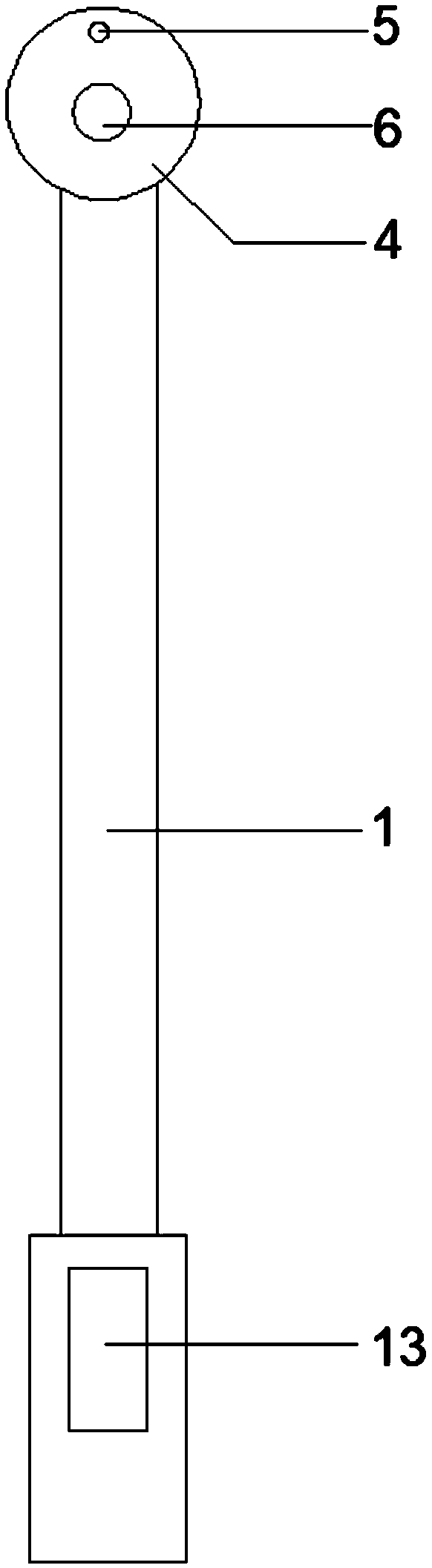

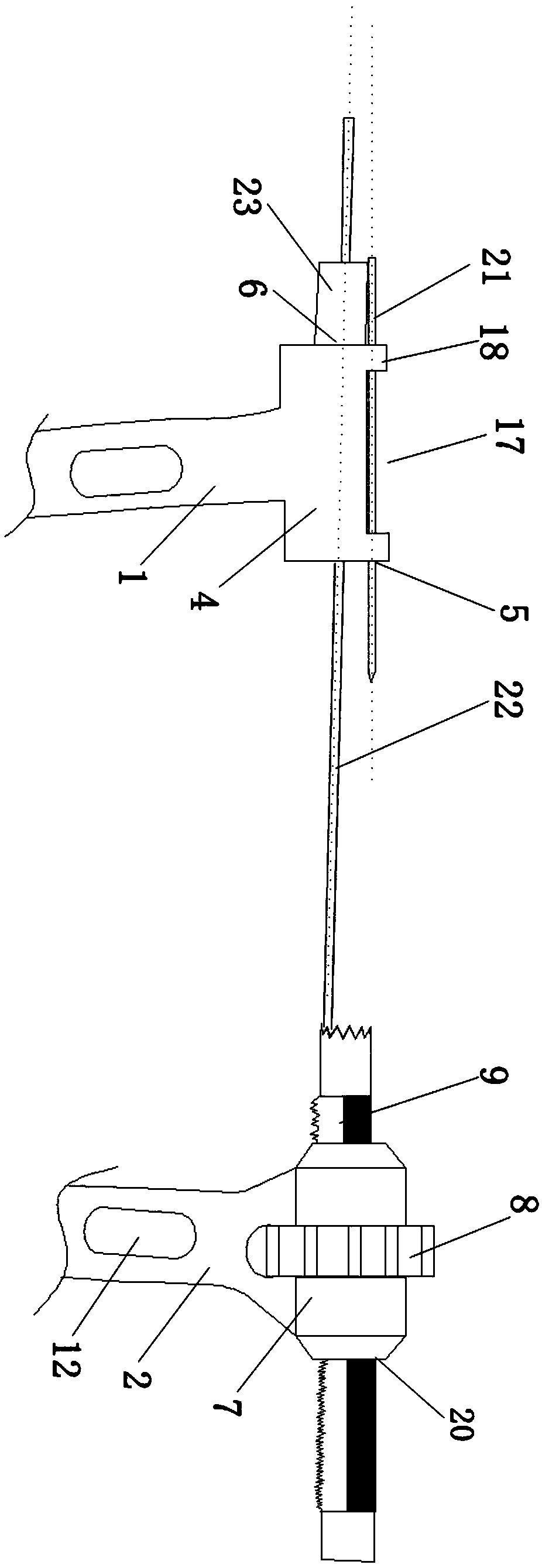

[0044] Such as Figure 1-3 As shown, a calcaneal load-carrying guider includes a handle 10, a U-shaped bracket with an opening away from the direction of the handle 10, and positioning pins 21, guide pins 22 and fixing pins (not shown in the figure) matched with the U-shaped bracket. . The U-shaped bracket is composed of an inner arm and an outer arm. The inner arm includes an inner support handle 1 and an inner guide sleeve 4 fixed on the top of the inner support handle 1. The outer arm includes an outer support handle 2 and an inner guide sleeve fixed on the outer support handle. 2. The outer guide sleeve 7 at the top, the bottom ends of the inner support handle 1 and the outer support handle 2 are all connected to the top end of the handle 10. The inner support handle 1 and the outer support handle 2 are symmetrically provided with a number of perforations 12 to facilitate the weight reduction of the calcaneus load-carrying guide.

[0045] The bottom end of the inner supp...

Embodiment 2

[0058] The difference from Embodiment 1 is that the fixed connection between the inner support handle 1 and the outer support handle 2 is reversed. The bottom end of the outer support handle 2 is provided with a fixing hole, the bottom end of the inner support handle 1 is provided with a boss that can be inserted into the fixing hole, and the lower side wall of the bottom end of the outer support handle 2 is provided with a Guide hole I, the lower side wall of the boss is provided with a guide hole II at the corresponding position; the inner wall of the guide hole I is provided with an internal thread, and the top of the handle is provided with a protruding rod coaxial with the handle , the diameter of the cross-sectional circle of the protruding rod is smaller than the diameter of the cross-sectional circle of the handle, and the outer wall of the protruding rod is provided with an external thread that matches the internal thread.

Embodiment 3

[0060] Different from Embodiment 1, the central axis of the positioning hole 5 is parallel to the central axis of the guide channel 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com