Combined filter and filter combination method

A filter and filter tank technology, applied in gravity filters, chemical instruments and methods, fixed filter element filters, etc., can solve the problems of increasing product manufacturing costs, complicated procedures, expensive expenses, etc., and achieve cost savings, operation Convenience and avoid the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

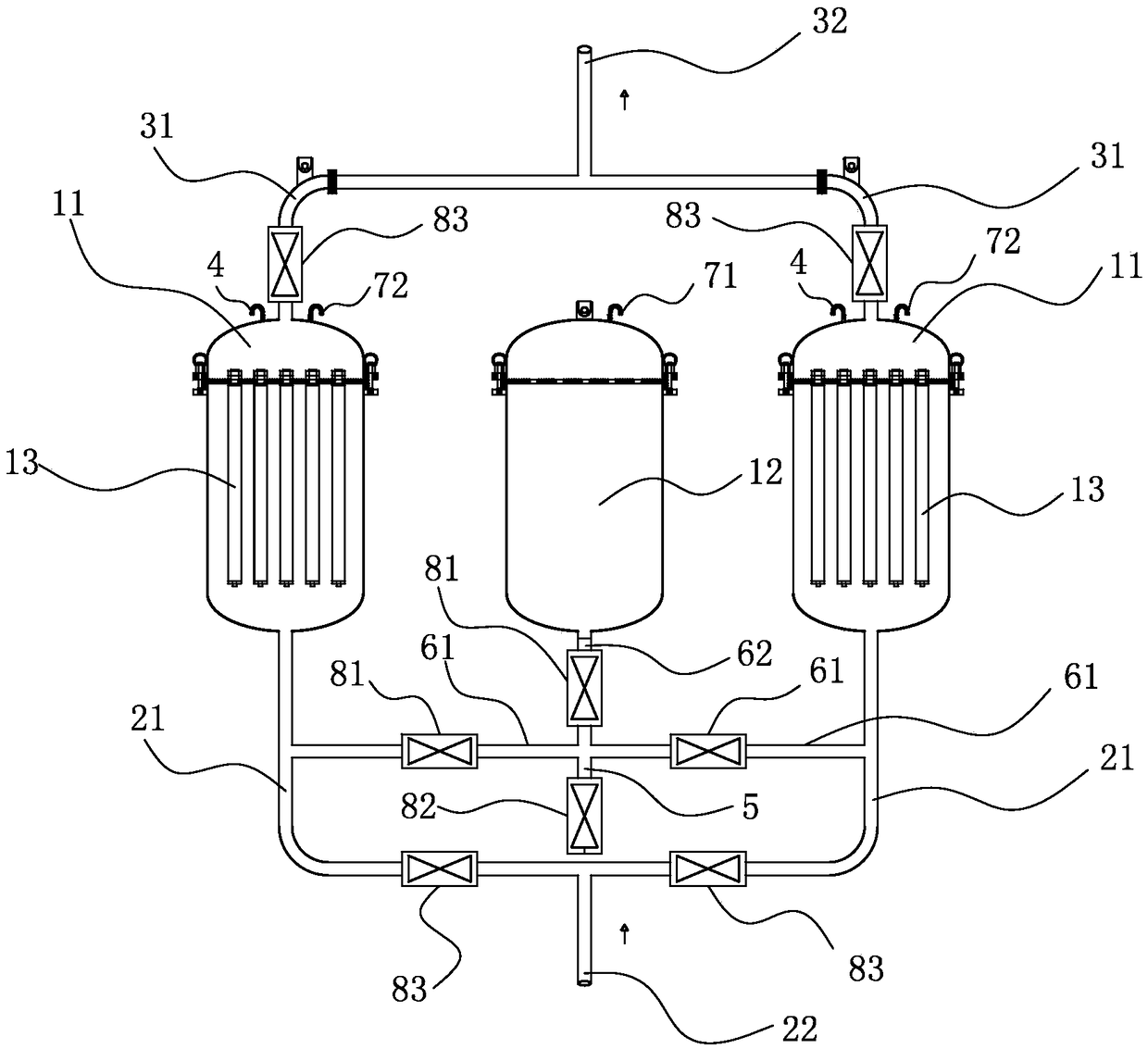

[0020] Such as figure 1 As shown, the combined filter includes two parallel filter tanks 11, an empty tank 12 which is arranged between the two filter tanks 11 and filled with nitrogen, two feed pipes 21, a confluence pipe 22, two discharge pipes 31, and an outlet pipe 22. Confluence pipe 32, two water inlet pipes 4, drain pipe 5, two transfer pipes, first air port 71, second air port 72, nitrogen source, first valve 81, second valve 82 and third valve 83. The feed pipe 21 and the discharge pipe 31 communicate with the lower end and the upper end of the filter tank 11 respectively, the two feed pipes 21 communicate with the inlet manifold 22 respectively, and the two outlet pipes 31 communicate with the outlet manifold 32 respectively, and the two feed pipes 21 and the two discharge pipes 31 are provided with a third valve 81 . The empty tank 12 and the two filter tanks 11 are provided with a first gas port 71 and a second gas port 72 respectively connected to the nitrogen so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com