Assembly line conveyor sorting device

A sorting device and conveyor technology, used in sorting, manipulators, manufacturing tools, etc., can solve the problems of reduced efficiency, difficult manufacturing, and no control method, and achieve a reasonable control method, high work efficiency, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

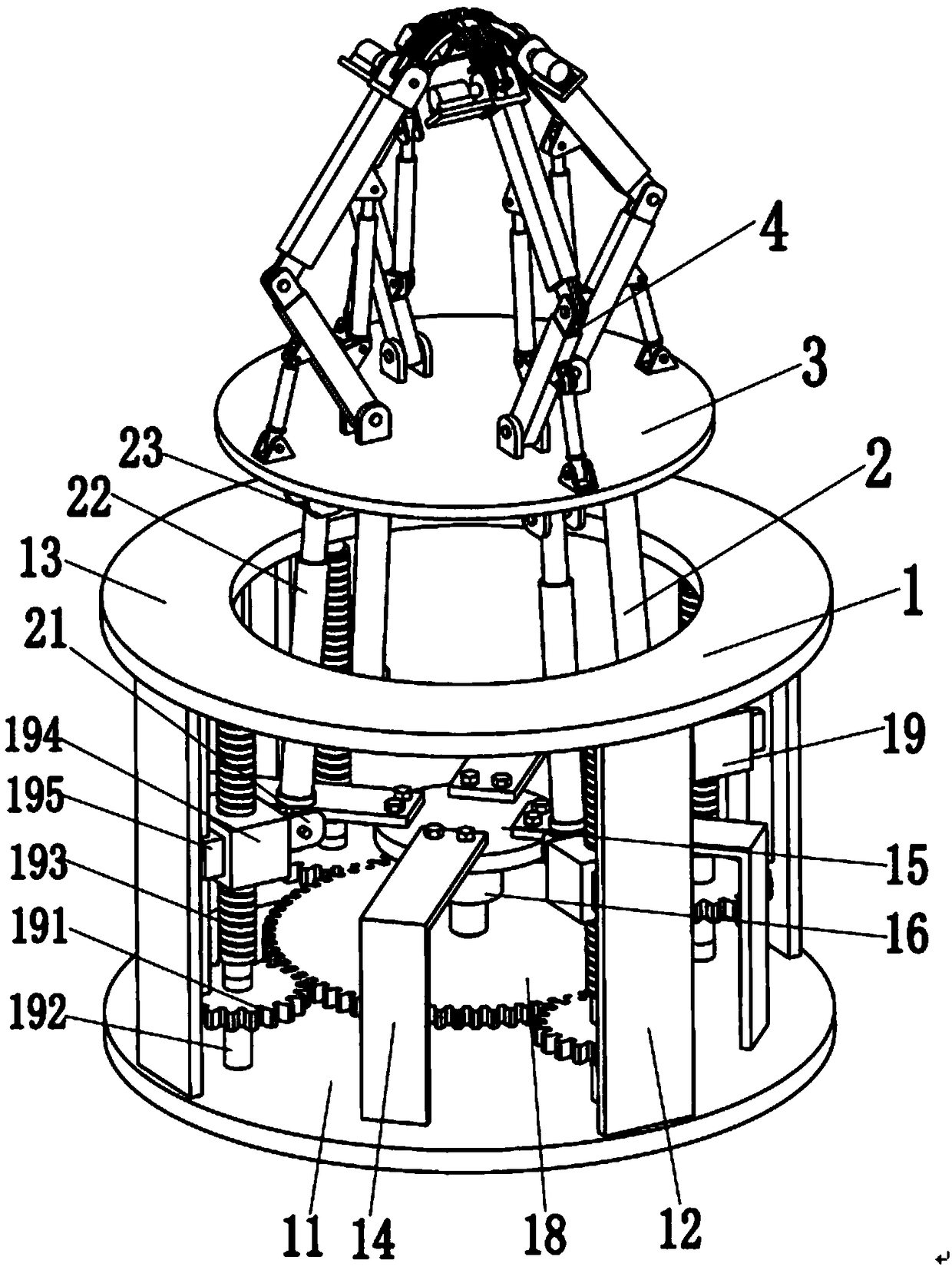

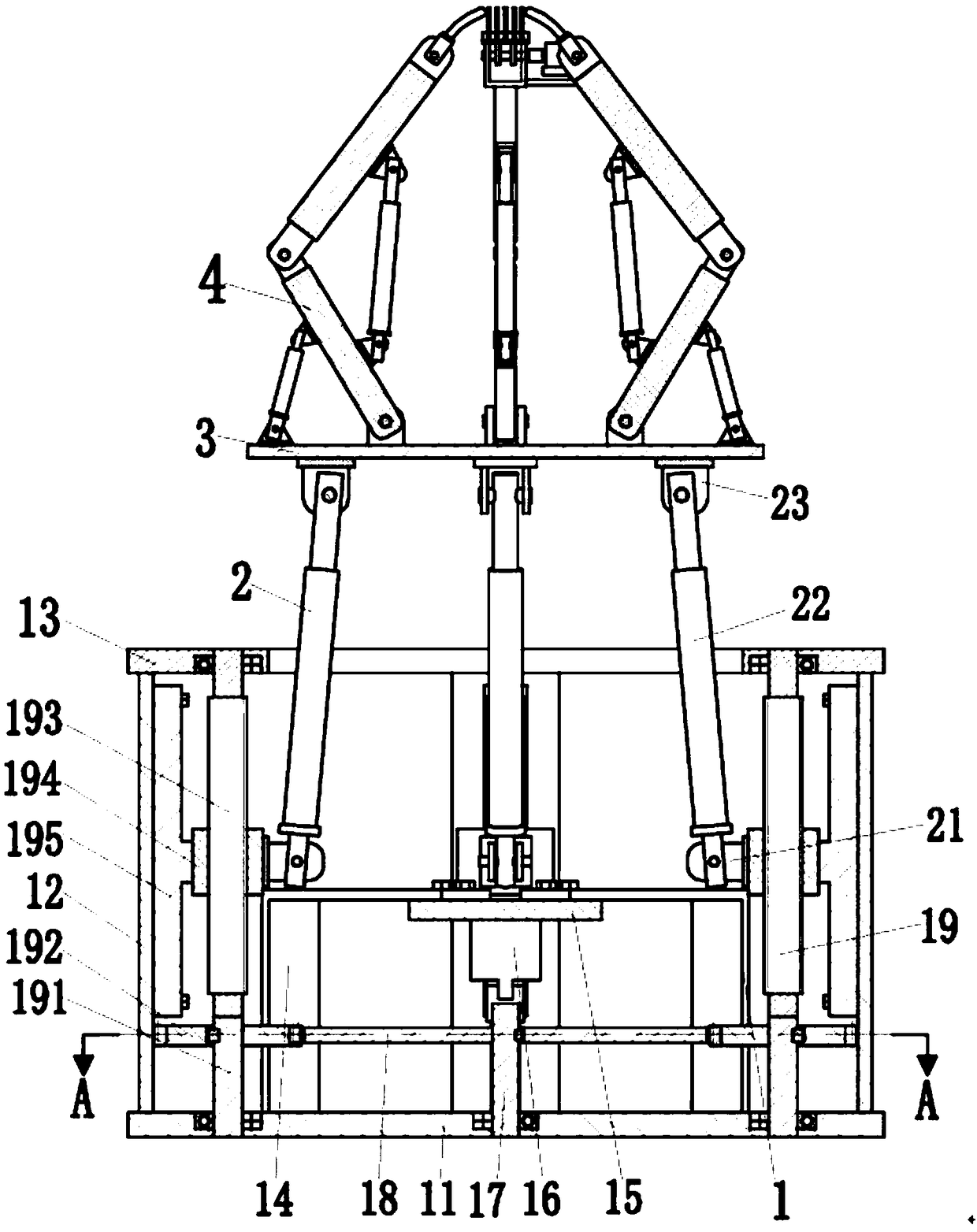

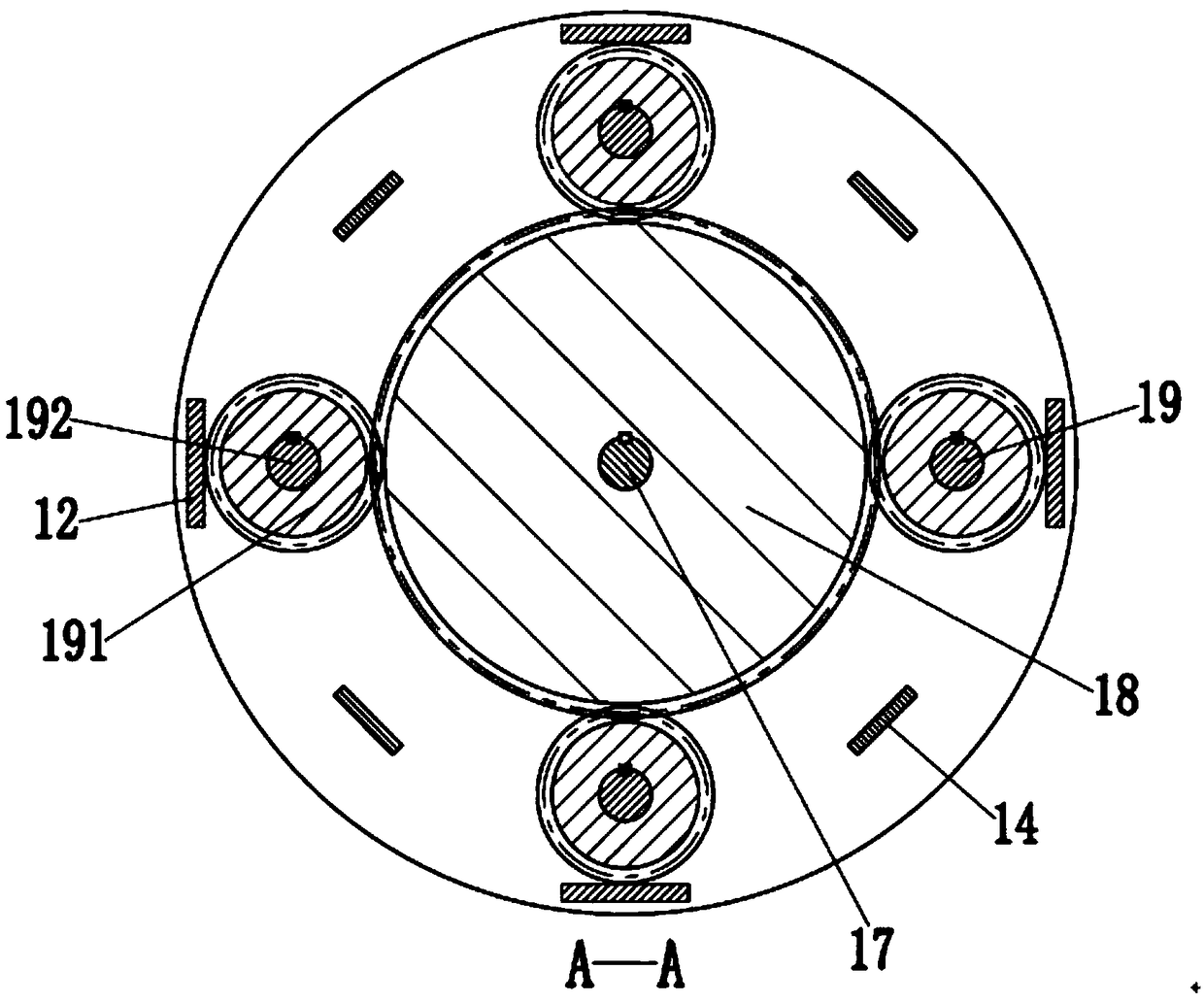

[0015] Such as Figure 1 to Figure 4 As shown, an assembly line conveyor sorting device includes a base body 1, and the base body 1 includes a base 11, four load-bearing frames 12 are evenly fixed on the upper part of the base 11, and a ring seat 13 is fixedly arranged on the top of the four load-bearing frames 12 , the load-bearing frame 12 supports the ring seat 13, and the middle of the ring seat 13 is provided with an annular mouth; the top of the base 11 is symmetrically provided with four right-angle frames 14, and the upper ends of the four right-angle frames 14 are equipped with a support seat 15 with bolts, Four right-angle frames 14 fix the supporting base 15, the following of the supporting base 15 is equipped with a rotating motor 16 through the motor base, the rotating motor 16 is connected with the output shaft 17 through a shaft coupling, and the following of the output shaft 17 is installed on the base 11 with a bearing ; Output shaft 17 is provided with drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com