Phenolic molding compound feeding device

A technology of feeding device and bakelite powder, which is applied in the field of feeding and conveying, can solve the problems of low safety, low yield and low production efficiency, and achieve the effect of ensuring continuity, being practical and reasonable, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

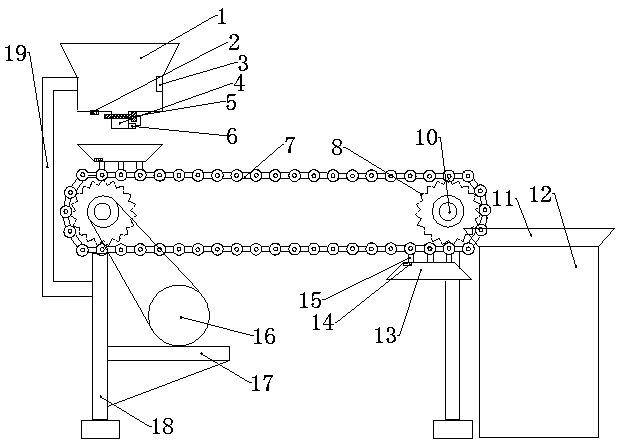

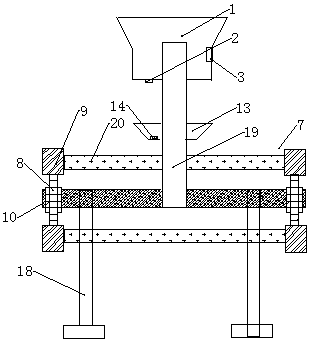

[0017] Such as Figure 1-2 Shown, a kind of bakelite powder feeding device, it comprises support 18, is characterized in that: described support 18 is provided with support plate 17, and described support plate 17 is provided with motor 16, and described motor 16 A sprocket 8 is connected by a belt, and the left and right sides above the bracket 18 are welded with connecting rods 10, and the sprockets 8 are respectively sleeved on the two ends of the connecting rod 10. A chain conveyor belt 7 is engaged, and the chain conveyor belt 7 is composed of a front chain 9, a fixed rod 20 and a rear chain 9. The fixed rod 20 is provided with a receiving plate 13, and the connection between the receiving plate 13 and the fixed rod 20 They are connected by a connection seat 15, the interior of the receiving plate 13 is embedded with a light emitter 14, the upper part of the chain conveyor belt 7 is provided with a feeding part 1, and the inside of the said feeding part 1 is provided with...

Embodiment 2

[0020] Such as Figure 1-2 Shown, a kind of bakelite powder feeding device, it comprises support 18, is characterized in that: described support 18 is provided with support plate 17, and described support plate 17 is provided with motor 16, and described motor 16 A sprocket 8 is connected by a belt, and the left and right sides above the bracket 18 are welded with connecting rods 10, and the sprockets 8 are respectively sleeved on the two ends of the connecting rod 10. A chain conveyor belt 7 is engaged, and the chain conveyor belt 7 is composed of a front chain 9, a fixed rod 20 and a rear chain 9. The fixed rod 20 is provided with a receiving plate 13, and the connection between the receiving plate 13 and the fixed rod 20 They are connected by a connection seat 15, the interior of the receiving plate 13 is embedded with a light emitter 14, the upper part of the chain conveyor belt 7 is provided with a feeding part 1, and the inside of the said feeding part 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com