Feeding mechanism of automatic ribber

A technology of feeding mechanism and rib machine, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc. It can solve the problems of high operating proficiency requirements for employees and large manpower demand, and achieve the effect of improving sewing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

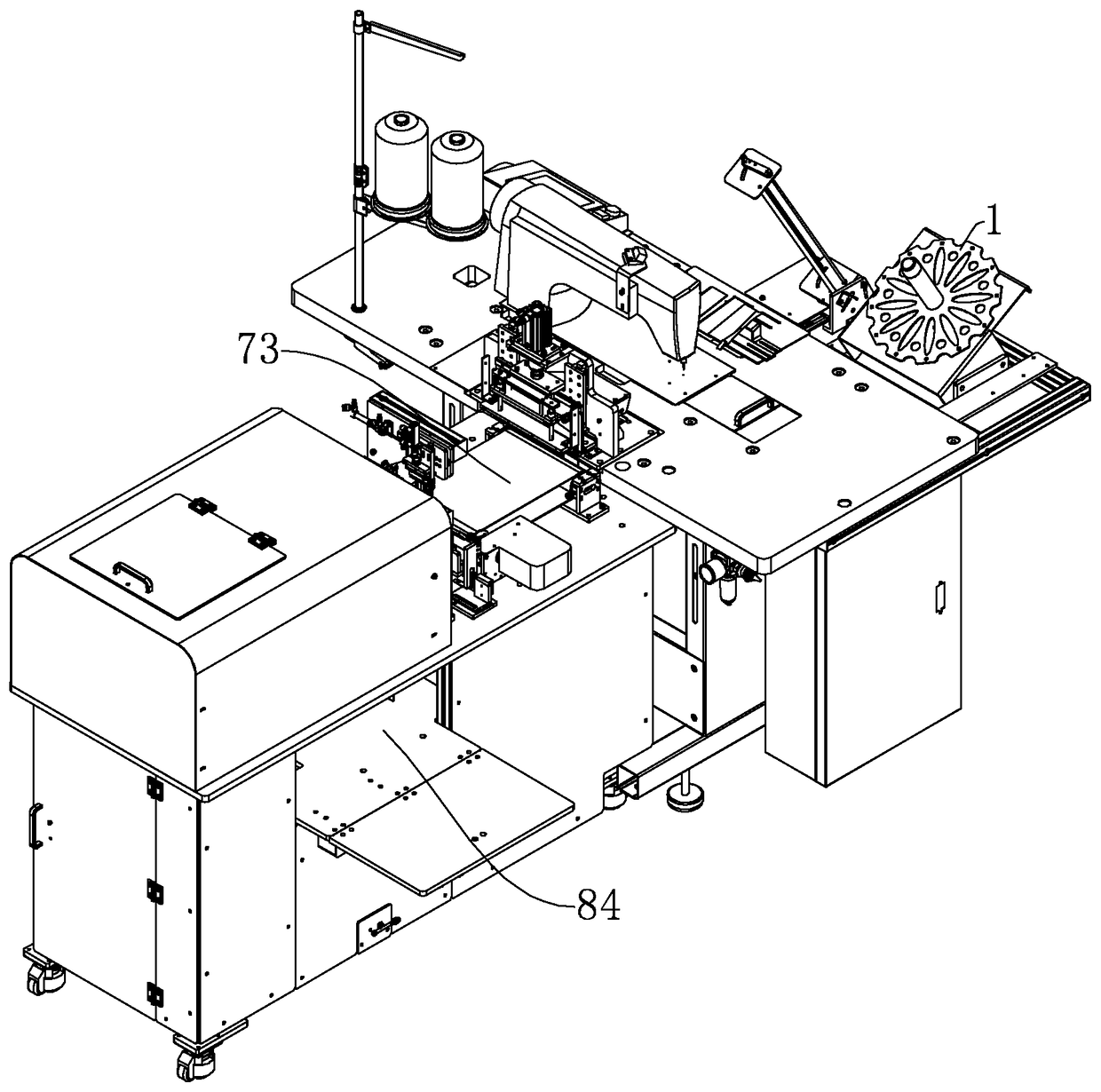

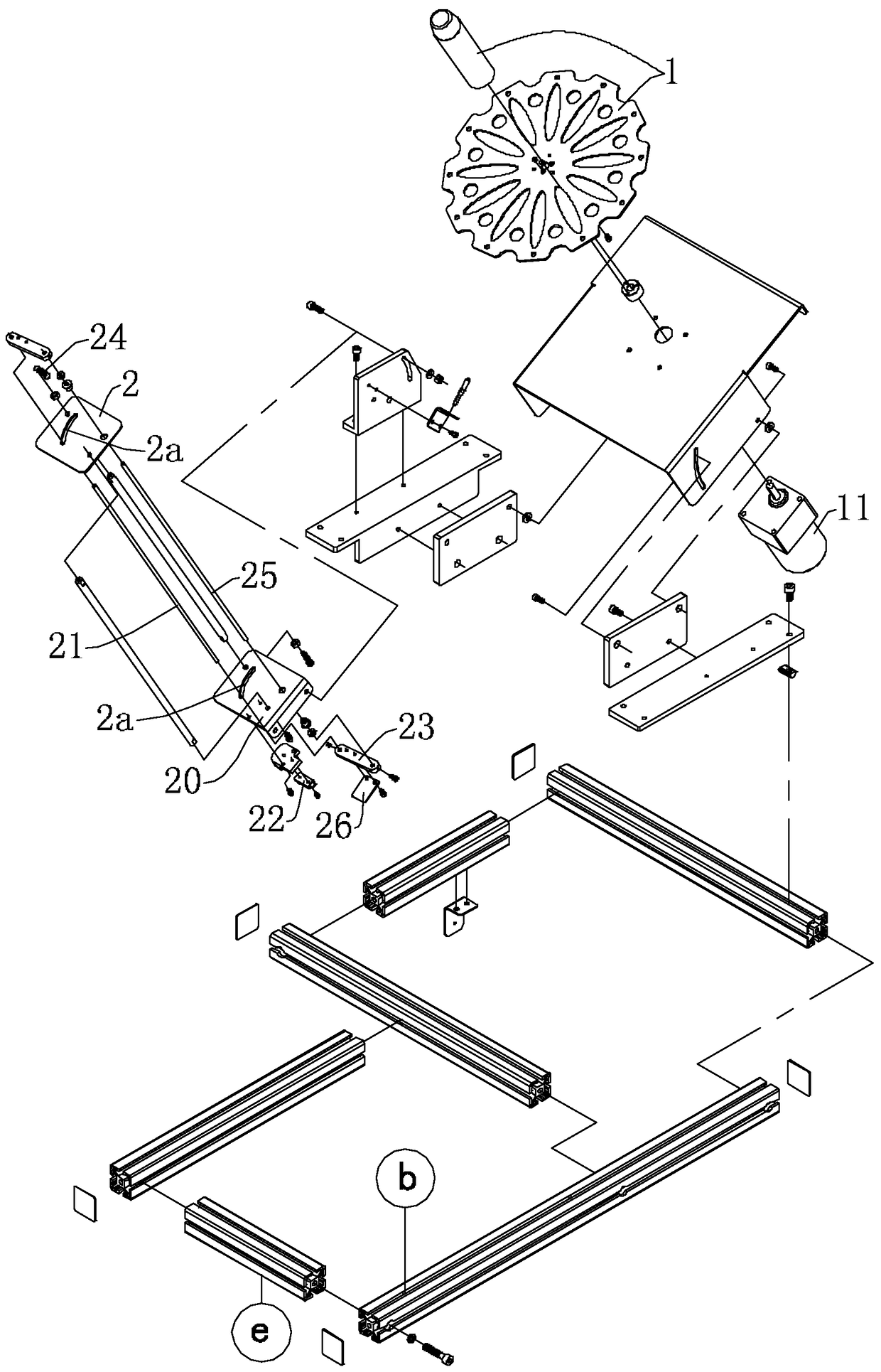

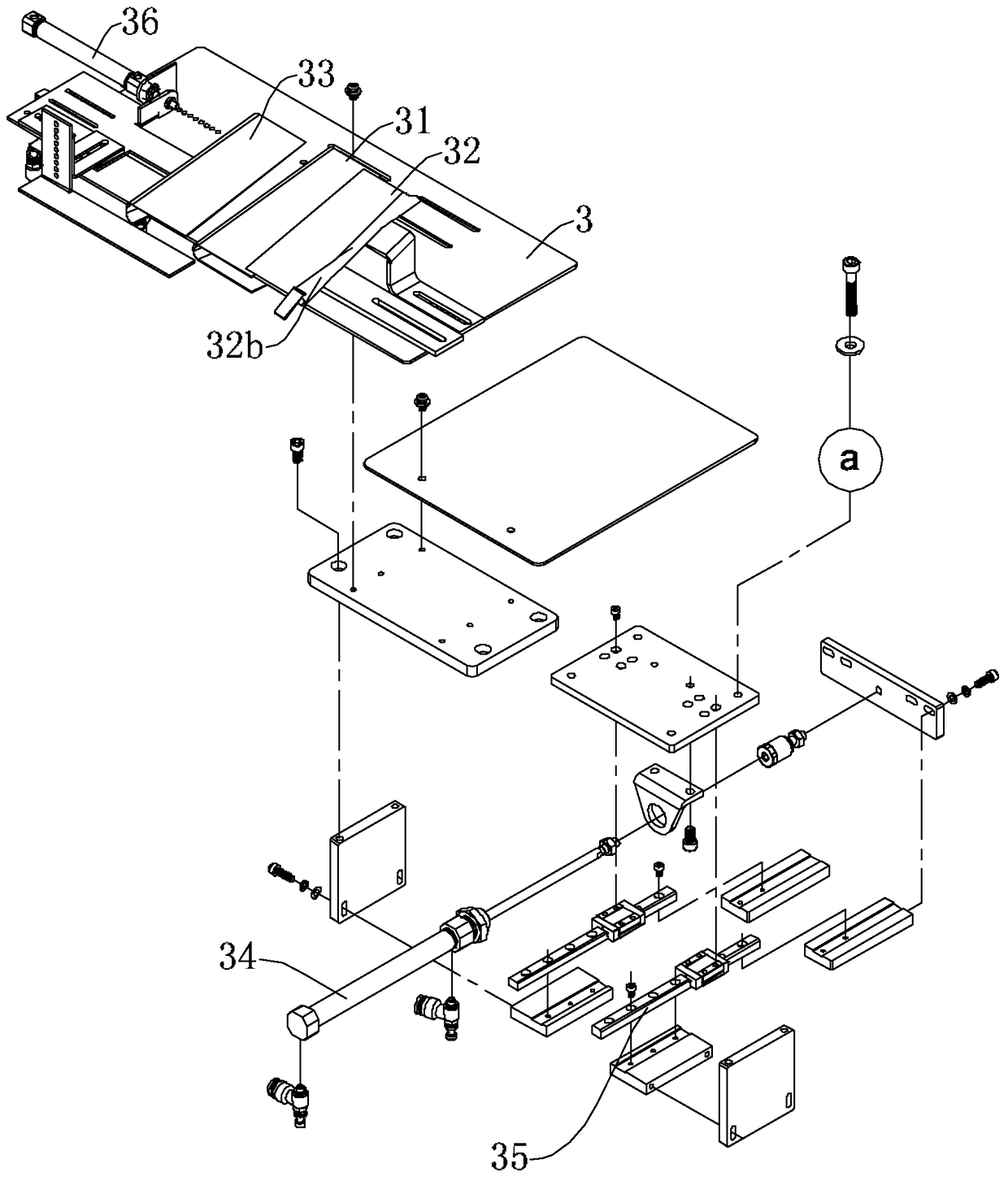

[0024] Figure 1 to Figure 8 Shown is a schematic diagram of the structure of the present invention.

[0025] The reference signs are: turntable 1, feeding motor 11, upper induction mounting seat 2, lower induction mounting seat 20, arc chute 2a, support rod 21, inductor 22, connecting plate 23, return spring 24, fixed The rod 25, the induction piece 26, the folding base 3, the first half-folding guide piece 31, the lower guide piece 31a, the second half-folding guide piece 32, the upper guide part 32a, the bending part 32b, the third half-folding guide piece 33, Upper half piece 33a, side half piece 33b, maintenance cylinder 34, maintenance moving guide 35, limit cylinder 36, material lifting chuck 4, material lifting mounting seat 42, translation cylinder 43, lifting mounting seat 44, lifting cylinder 45, clamp Material air claw 46, lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com